Table of Contents

Advertisement

Quick Links

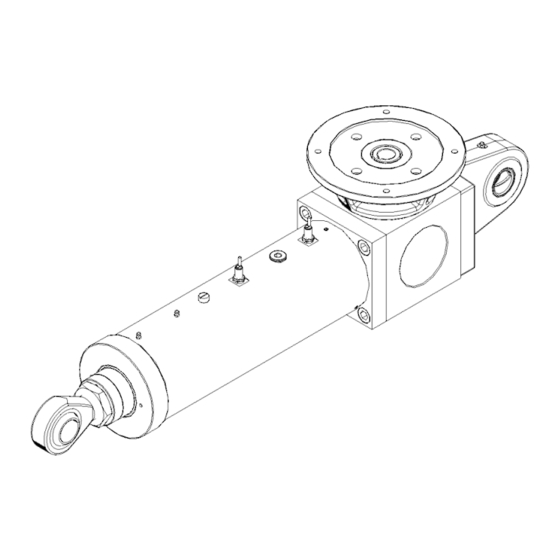

LINEAR ACTUATORS

HSA 10 – HSA 25 – HSA 50

HSA 100 – HSA 150 – HSA 200

Installation, operation and maintenance manual

Publication: 28.80-110-130-160-200-250.I - Rev. 00 Date (M/Y) 11/19

Servomech S.p.A. Via M. Calari, 1 - 40011 Anzola dell'Emilia (BO) - ITALY

Ph: + 39 051 6501711 Fax: + 39 051 734574

www.servomech.com info@servomech.com

Servomech S.p.A.

02.50-63-80.E - Rev. 02 Date (M/Y) 10/19

1

Advertisement

Table of Contents

Summary of Contents for Servomech HSA 10

- Page 1 HSA 100 – HSA 150 – HSA 200 Installation, operation and maintenance manual Publication: 28.80-110-130-160-200-250.I - Rev. 00 Date (M/Y) 11/19 Servomech S.p.A. Via M. Calari, 1 - 40011 Anzola dell’Emilia (BO) - ITALY Ph: + 39 051 6501711 Fax: + 39 051 734574 www.servomech.com info@servomech.com Servomech S.p.A.

- Page 2 The aforementioned conditions are therefore not contemplated and entail the immediate termination of the guarantee and the immediate decay of any responsibility on the part of Servomech S.p.A. Servomech S.p.A. reserves the right to make changes to the actuators and this manual without giving any notice. Servomech S.p.A.

-

Page 3: Table Of Contents

LINEAR ACTUATORS HSA 10 – 25 – 50 – 100 – 150 – 200 – 250 Installation, operation and maintenance manual Contents MODELS COVERED BY THIS DOCUMENT ....................4 IDENTIFICATION OF THE MANUFACTURER AND THE PRODUCT ..............4 Identification of the manufacturer ..................... 4 Description of the product ......................... -

Page 4: Models Covered By This Document

2.2 Description of the product For all the technical characteristics of the product (performance, features, dimensions) refer to the technical catalog. Componenti principali dell’attuatore: HSA 10 – 25 – 50 Push rod External tube HSA 100 – 150 – 200... -

Page 5: Identification Of The Product

2.3 Identification of the product Every SERVOMECH linear actuator is provided with a nameplate, as shown below, which allows the product identification and gives technical information about the product. Figure 2.2 – Identification nameplate 1) Product code: is an alphanumeric code stating the type, size, ratio, version and stroke end switches of the linear actuator;... -

Page 6: Trasport And Handling

1.8 kg 2.5 kg 3.2 kg 5.7 kg 9,2 kg 14,2 kg stroke length In case of doubt, consult SERVOMECH S.p.A. to get the appropriate information and prevent any kind of damage! Servomech S.p.A. 02.50-63-80.E - Rev. 02 Date (M/Y) 10/19... -

Page 7: Use Restriction

They must be subjected to the loading and speed conditions specified in the catalog. Modification of parts of the actuator or replacement of components with different and non-original parts is not permitted. The replacement of components with original spare parts is carried out only by Servomech S.p.A. -

Page 8: Standard Operating Conditions

4.1.2 Standard operating conditions The actuator must be used in an environment whose conditions comply with the provisions of Servomech S.p.A. The works necessary for obtaining and maintaining that conditions are in charge of the owner and, where applicable, are in charge of the end user. -

Page 9: Installation

MAKE SURE THE SAFETY PROTECTION OF THE MACHINE (MECHANICAL AND ELECTRICAL) ARE ACTIVE. DURING OPERATION, TEMPERATURE OF THE EXTERNAL SURFACE OF MOTORS CAN REACH HIGH TEMPERATURES. HOT SURFACES ON ACTUATOR CAN CAUSE BURNS AND SHOULD NOT BE TOUCHED. Servomech S.p.A. 02.50-63-80.E - Rev. 02 Date (M/Y) 10/19... -

Page 10: Fcp Inductive Proximity Stroke Limit Switches

The positions of the two limit switches are the extreme travel positions Lc and La (see Fig. 6.5). FC 1 – sensor for RETRACTED ACTUATOR Lc position FC 2 – sensor for EXTENDED ACTUATOR La position Actuator P [mm] HSA 10 HSA 25 HSA 50 HSA 100 10.5 HSA 150 20.5 HSA 200 Figure 6.1 –... -

Page 11: Electric Motor Wiring

K1, K2, K3 = contactor M = motor Br = brake Figure 6.2 – Electric wiring diagrams to power supply of AC 3-ph motor Servomech S.p.A. 02.50-63-80.E - Rev. 02 Date (M/Y) 10/19... - Page 12 Figure 6.3 – Electric wiring diagrams to motor terminal board of AC 3-ph motor IN CASE OF ELECTRIC MOTOR DIFFERENT FROM THE ABOVE MENTIONED, PLEASE REFER TO INSTALLATION INSTRUCTIONS SUPPLIED BY THE MANUFACTURER. Servomech S.p.A. 02.50-63-80.E - Rev. 02 Date (M/Y) 10/19...

-

Page 13: Linear Actuator Installation

“La” = EXTENDED ACTUATOR stroke Figure 6.5 – “Lc” and “La” dimensions Dimensions “Lc” and “La” are indicated in the technical catalogue of the product and on the check sheet supplied with the actuator. Servomech S.p.A. 02.50-63-80.E - Rev. 02 Date (M/Y) 10/19... -

Page 14: Installation Of Rod End Fitting Elements

To install a fitting element on the rod end threaded bore (BA), use a wrench on the rod end (for HSA 10-25) or fix the push rod with a clamp (for HSA 50-100-150-200) to counterhold the locking torque. The actuator is equipped with AR (anti-rotation) device: DO NOT TRANSFER ANY TORQUE TO THE PISTON ROD. -

Page 15: Commissioning And Use

7 COMMISSIONING AND USE SERVOMECH linear actuators are supplied lubricated and ready to be used. Before to start commissioning and activation, the following checks must be carried out: Shifting direction check Check if the push rod shifting direction is compatible to the indications on the control unit, by powering the electric motor on VERY BRIEFLY. -

Page 16: Lubrication

8 LUBRICATION SERVOMECH linear actuators HSA series are supplied lubricated, with lubricants indicated in the table below. PUSH ROD GUIDE ACTUATOR GEARBOX LINEAR DRIVE REAR HINGE HSA 10 Grasso (NLGI 00 DIN 51818): Grasso (NLGI 1 DIN 51818): LUBCON Thermoplex ALN 1001... -

Page 17: Maintenance

Every 2 months time interval: visual inspections of actuator conditions, cleaning of dirty parts of the actuator. In case of lubricant leakage, contact SERVOMECH. Note: for smaller sizes actuators, the rear hinge and push rod guide material is auto-lubricated, so it does not require additional lubrication. -

Page 18: Linear Drive Lubrication

Plug Ball nut grease nipple Figure 9.2 – Lubrication position ACTUATOR LUB dimension Ball nut grease nipple Greaser Pointed nozzle HSA 10 Flush-type grease nipple M6×1 Retracted actuator (Lc) (press-greaseing) (DIN 3405-A) HSA 25 Retracted actuator (Lc) HSA 50 Hydraulic-type grease nipple,... -

Page 19: Push Rod Guide Lubrication

Rear hinge grease nipples (2×) Figure 9.5 – Rear hinge grease nipples Apply the grease until the steel bush is filled. If necessary, remove excess of lubricant from the hinge pin. Servomech S.p.A. 02.50-63-80.E - Rev. 02 Date (M/Y) 10/19...

Need help?

Do you have a question about the HSA 10 and is the answer not in the manual?

Questions and answers