Advertisement

Operating Instructions and Parts Manual

SPECIFICATIONS

POWER SUPPLY REQUIREMENTS

MOTOR

HORSEPOWER

CUT IN PRESSURE

CUT OUT PRESSURE

PERFORMANCE

Model

HP

PSI

30

SWS50

1/2

40

50

30

SWS75

3/4

40

50

30

SWS100

1

40

50

© 2020, WAYNE/Scott Fetzer Company.

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

120 or 230 V, 60 Hz

Single Phase AC Induction

1/2 HP ...................(SWS50)

3/4 HP ...................(SWS75)

1 HP ....................(SWS100)

30 PSI

50 PSI

Discharge Head (Lift Distance)

0 ft

5 ft

10 ft

15 ft

711

674

638

601

543

506

470

433

375

338

302

265

779

750

721

691

644

615

586

557

510

481

451

422

1084

1022

960

899

799

737

675

613

513

451

389

328

Intended for Indoor Use Only

Shallow Well Jet Pump Water Systems

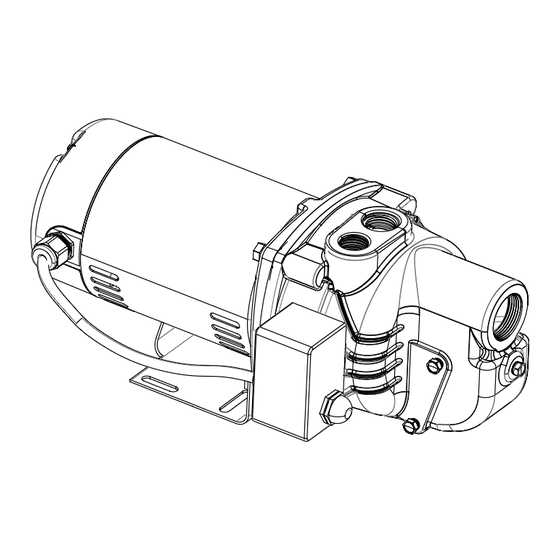

MOTOR HOUSE

SEAL PLATE

DIFFUSER

IMPELLER

SHAFT

PUMP SUCTION

PUMP DISCHARGE

20 ft

25 ft

565

529

397

361

229

193

662

633

528

499

393

364

837

775

551

490

266

204

www.waynepumps.com

CONSTRUCTION

Carbon Steel

Cast Iron

Thermoplastic

Thermoplastic

Stainless Steel

1-1/4 in. NPT

1 in. NPT

640002W-001 F 08/20

SWS

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Wayne SWS Series

- Page 1 1 in. NPT PERFORMANCE Discharge Head (Lift Distance) Model 0 ft 5 ft 10 ft 15 ft 20 ft 25 ft SWS50 SWS75 1084 1022 SWS100 Intended for Indoor Use Only 640002W-001 F 08/20 www.waynepumps.com © 2020, WAYNE/Scott Fetzer Company.

-

Page 2: General Safety Information

Operating Instructions and Parts Manual DESCRIPTION GENERAL SAFETY INFORMATION Shallow well jet pumps are single stage residential water pumps CALIFORNIA PROPOSITION 65 designed for pumping potable water in applications where the water is located less than 25 feet vertically from the pump. A pressure switch is a standard feature. -

Page 3: Pre-Installation

Operating Instructions and Parts Manual GENERAL SAFETY INFORMATION (CONT'D) Do NOT touch an operating motor. Modern motors are designed to operate at high temperatures. Disconnect power and release all pressure from the system before attempting to install, service, relocate or perform any Ne touchez PAS un monteur en fonctionnement. -

Page 4: Installation

Operating Instructions and Parts Manual PRE-INSTALLATION (CONT'D) Flexible pipe is prohibited on suction pipe (inlet pipe). TANKS - CONVENTIONAL STORAGE MISE EN GARDE The function of the tank is to store a quantity of water under Un tuyau flexible est interdit sur le tuyau pressure. - Page 5 Operating Instructions and Parts Manual DUG WELL, CISTERN, LAKE AND SPRING INSTALLATION (FIGURE 12 ON PAGE 11) The foot valve MUST be at least 18” from the 1. Install a foot valve on inlet pipe and lower into water. bottom of the well or sand or sediment WILL be drawn into the system. MISE EN GARDE Le clapet de pied DOIT au moins être The foot valve MUST be at least 18”...

-

Page 6: Operation

Operating Instructions and Parts Manual ELECTRICAL the system before attempting to install, service, relocate or perform any maintenance. Risk of electrical shock. This pump is designed for indoor installation unless housed and protected from the elements. Débrancher de la source d’alimentation puis dissiper toute la pression du système avant d’essayer d’installer, de Risque de choc électrique! Cette pompe est réparer, de déplacer ou de procéder à... -

Page 7: Maintenance

Operating Instructions and Parts Manual MAINTENANCE OUTLET AIR VOLUME Disconnect power and release all pressure from AIR VOLUME the system before attempting to install, service, relocate or perform any HOSE COUPLING maintenance. Lock the power disconnect in the open (OFF) position. Tag out the power disconnect to prevent unexpected application of power. - Page 8 Operating Instructions and Parts Manual KITS SECTION (CONT'D) SEAL PLATE IMPELLER 8. Remove the seal plate. ROTATING SHAFT 9. Pry the rotating shaft seal member (including stainless collar SEAL MEMBER and rubber seal) from the impeller (Figure 9). RUBBER SEAT RING 10.

- Page 9 Please provide following information: Address any correspondence to: - Model number WAYNE Pumps 101 Production Drive - Serial number (if any) Harrison, OH 45030 U.S.A. - Part description and number as shown in parts list 1, 2, 3 Ref.

-

Page 10: Troubleshooting Chart

Operating Instructions and Parts Manual TROUBLESHOOTING CHART Symptoms Possible Cause(s) Suggested Remedies Pump will not 1. Power off 1. Turn power on or call power company start or run 2. Blown fuse or tripped breaker 2. Replace fuse or reset circuit breaker 3. - Page 11 Operating Instructions and Parts Manual...

- Page 12 LIMITED WARRANTY For three years for SWS50, SWS75 and SWS100 models from the date of purchase, from an authorized dealer, WAYNE Pumps will repair or replace, at its option for the original purchaser, any part or parts of its Well Pumps or Water Pumps (“Product”) found upon examination by WAYNE Pumps to be defective in materials or workmanship.

Need help?

Do you have a question about the SWS Series and is the answer not in the manual?

Questions and answers