Table of Contents

Advertisement

Quick Links

ACDE

OM-06432-01

February 15, 2011

Rev. D 01‐09‐14

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

SUBMERSIBLE PUMP

MODEL

SF4A

THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO

www.grpumps.com

D

GORMAN‐RUPP OF CANADA LIMITED

ST. THOMAS, ONTARIO, CANADA

Printed in U.S.A.

e

2011 The Gorman‐Rupp Company

Advertisement

Table of Contents

Summary of Contents for GORMAN-RUPP PUMPS SF4A

- Page 1 February 15, 2011 Rev. D 01‐09‐14 INSTALLATION, OPERATION, AND MAINTENANCE MANUAL WITH PARTS LIST SUBMERSIBLE PUMP MODEL SF4A THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO www.grpumps.com GORMAN‐RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A. 2011 The Gorman‐Rupp Company...

- Page 2 Register your new Gorman‐Rupp pump online at www.grpumps.com Valid serial number and e‐mail address required. RECORD YOUR PUMP MODEL AND SERIAL NUMBER Please record your pump model and serial number in the spaces provided below. Your Gorman‐Rupp distributor needs this information when you require parts or service. Pump Model: Serial Number:...

-

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ..........PAGE I - 1 SAFETY ‐... - Page 4 TABLE OF CONTENTS (continued) PARTS LISTS: Pump Model Assembly ..........PAGE E - 3 Motor Assemblies .

-

Page 5: Introduction

SF SERIES OM-06432 INTRODUCTION Thank You for purchasing a Gorman‐Rupp SF Se Gorman‐Rupp of Canada Limited ries Pump. Read this manual carefully to learn 70 Burwell Road how to safely install and operate your pump. Fail St. Thomas, Ontario N5P 3R7 ure to do so could result in personal injury or dam... -

Page 6: Safety - Section A

SF SERIES OM-06432 SAFETY - SECTION A This information applies to the SF Se ries submersible pump indicated on the front cover of this manual. The electrical power used to operate In addition to this manual, see the sepa this pump is high enough to cause inju rate literature covering the control box, ry or death. - Page 7 OM-06432 SF SERIES to the incoming power lines. The pump motor is designed to operate through a Gorman‐Rupp approved control box which provides overload protection and power control; otherwise, the pump The electrical power used to operate warranty will be voided. Make certain this pump is high enough to cause inju...

- Page 8 SF SERIES OM-06432 Do not remove plates, covers, gauges, After the pump has been installed, make pipe plugs, or fittings from an over certain that the pump and all piping or heated pump. Vapor pressure within the pump can cause parts being disen hose connections are secure before op...

-

Page 9: Installation - Section B

SF SERIES OM-06432 INSTALLATION - SECTION B Review all SAFETY information in Section A. match the ratings on the control box and in coming power. Since pump installations are seldom identical, this e. Carefully read all tags, decals, and markings section is intended only to summarize general rec... -

Page 10: Lifting

SF SERIES See Table B-1 for motor specifications. TABLE B-1. PUMP MOTOR SPECIFICATIONS MODEL VOLTAGE/ SIZE H.P . MOTOR LOCKED PHASE LOAD ROTOR AMPS AMPS SF4A 208/3 4” 20.0 1750 63.4 416.0 SF4A 230‐460‐575/3 4” 24.0 1750 61.6/30.8/24.6 376.0/188.0/150.0 Lifting by mounting hardware, and that the guide shoe is fully seated in the baseplate. -

Page 11: Electrical Connections

SF SERIES OM-06432 Either hose or rigid pipe may be used to make dis TABLE B-2. MOTOR VOLTAGE LIMITS charge connections. The discharge line must be NOMINAL PHASE MINIMUM MAXIMUM independently supported to avoid vibration and VOLTAGE VOLTAGE VOLTAGE strain on the pump. For maximum pumping capac ity, keep the line as short and straight as possible. -

Page 12: Control Box Connections

OM-06432 SF SERIES lead (s). Connect the second test lead to an unin sulated point on the pump body. The test circuit should close. If the test circuit does not close, there is a defect in the cable or motor which must be corrected. Control Box Connections The pump warranty is void if the motor is not operated through a control box ap... -

Page 13: Liquid Level Devices

SF SERIES OM-06432 Liquid Level Devices phragm which flexes with changes in liquid level, thus activating an enclosed miniature switch. Optional controls available from Gorman‐Rupp may provide a means to automatically regulate the Bulb (Float) Type: a bulb raises or lowers liquid level. -

Page 14: Operation - Section C

SF SERIES OM-06432 OPERATION - SECTION C GENERAL INFORMATION pendent upon the quality and performance of the electrical controls, the pump warran Review all SAFETY information in Section A. ty is valid only when controls have been specified or provided by The Gorman‐ Rupp Company. - Page 15 OM-06432 SF SERIES SF4A 230/460/575V 3P PERFORMANCE CURVE PAGE C - 2 OPERATION...

- Page 16 SF SERIES OM-06432 SF4A 208V 3P PERFORMANCE CURVE OPERATION PAGE C - 3...

-

Page 17: Control Box

OM-06432 SF SERIES Control Box 2. Lock out the power to the control panel to ensure that the pump will Control boxes are available as optional equipment remain inoperative. from the factory. The control boxes contain con 3. Allow the pump to completely cool trols for starting and stopping the pump, and pro... -

Page 18: Impeller Rotation

SF SERIES OM-06432 burns and injuries. If overheating of the ry or death. Make certain that incoming pump occurs: power is off and locked out before inter changing motor leads. 1. Stop the pump immediately. 2. Ventilate the area. 3. Allow the pump to completely cool. 4. - Page 19 OM-06432 SF SERIES between starts, it will over‐heat, resulting in damage to the motor windings. Stopping To avoid serious damage to the pump, check for unusual noises or excessive vi bration while the pump is running. If noise Follow the instructions accompanying the control or vibration is excessive, stop operation box for stopping the pump.

-

Page 20: Cold Weather Preservation

SF SERIES OM-06432 Check the oil level(s) as indicated in the following On a new pump, check the oil level in the seal cav LUBRICATION section. ity before initial startup, and drain and replace the oil after the first 200 hours of operation. Following this, check the oil level in the seal cavity after the COLD WEATHER PRESERVATION first two weeks of operation, and every month... - Page 21 OM-06432 SF SERIES in Draining Oil. Add premium quality submersible pump oil through the fill plug hole until the oil is lev el with the bottom of the plug hole. Install and tighten the fill plug. PAGE C - 8 OPERATION...

-

Page 22: Troubleshooting - Section D

SF SERIES OM-06432 TROUBLESHOOTING - SECTION D Review all SAFETY information in Section A. NOTE Many of the probable remedies listed in the TROU BLESHOOTING CHART require use of electrical test instruments; for specific procedures, see ELECTRICAL TESTING at the end of the chart. TROUBLESHOOTING CHART TROUBLE POSSIBLE CAUSE... - Page 23 OM-06432 SF SERIES TROUBLESHOOTING CHART (cont'd) TROUBLE POSSIBLE CAUSE PROBABLE REMEDY Discharge head too high. Reduce discharge head or install MOTOR RUNS, BUT staging adaptor and additional PUMP FAILS TO DELIVER RATED pump. DISCHARGE. Low or incorrect voltage. Measure control box voltage, both when pump is running and when shut off.

- Page 24 SF SERIES OM-06432 ELECTRICAL TESTING 3. The pump submerged and running under full load. Make the electrical checks which follow to deter The voltage measured under each condition mine if pump malfunctions are being caused by must be the same. problems in the motor or in the motor cable.

- Page 25 OM-06432 SF SERIES motor cable green/yellow ground lead. Touch and 1 megohm, insulation is acceptable but the other test lead to each of the motor cable should be rechecked regularly. If resistance leads in turn. Note the readings. reads less than 1 megohm, insulation should be checked more closely and frequently.

-

Page 26: Pump Maintenance And Repair - Section E

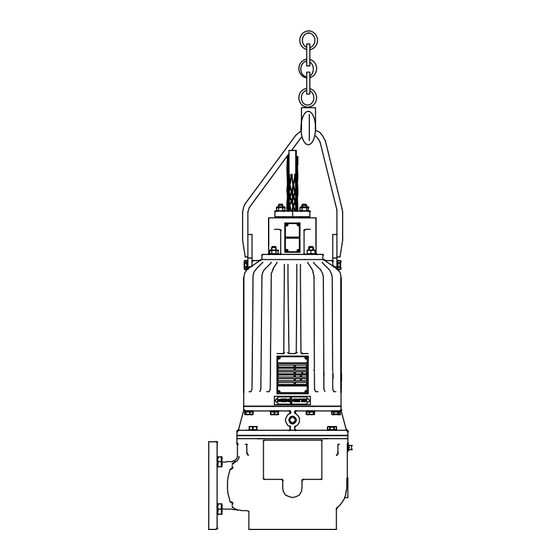

SF SERIES OM-06432 PUMP MAINTENANCE AND REPAIR - SECTION E GENERAL INFORMATION The maintenance and repair instructions in this manual are keyed to the illustrations, Figures E-1 and E-2, and the corresponding parts lists. Review all SAFETY information in Section A. Select a suitable location, preferably indoors, to perform required maintenance. - Page 27 OM-06432 SF SERIES ILLUSTRATION PARTS PAGE Figure E-1. SF4A Pump Model Assembly PAGE E - 2 MAINTENANCE AND REPAIR...

- Page 28 SF SERIES OM-06432 SF4A Pump Model Assembly Parts List (From S/N 1488019 Up) If your pump serial number is followed by an “N”, your pump is NOT a standard production model. Contact the Gorman‐Rupp Company to verify part numbers. ITEM...

- Page 29 OM-06432 SF SERIES ILLUSTRATION Figure E-2. 47111-821, -822 and -823 Motor Assemblies PAGE E - 4 MAINTENANCE AND REPAIR...

- Page 30 SF SERIES OM-06432 47111-821, -822 and -823 Motor Assemblies Parts List ITEM PART MAT'L PART NAME NUMBER CODE MOTOR SUBASSEMBLY -208‐230/3 47111-838 --MOTOR HOUSING 38311-214 10000 --STATOR 47113-095 --TERMINAL HOUSING STUD MC1042 17000 --VOLTAGE TAG 38816-094 --ROTATION DECAL 38815-027 -460/3 47111-837 --MOTOR HOUSING 38311-214...

- Page 31 OM-06432 SF SERIES Select a suitable location, preferably indoors, to PUMP AND SEAL DISASSEMBLY AND perform required maintenance. All work must be REASSEMBLY performed by qualified personnel. Review all SAFETY information in Section A. Check the chart in TROUBLESHOOTING, Section D of this manual, to determine the nature of the This pump requires little service due to its rugged, pump problem.

- Page 32 SF SERIES OM-06432 Pump Casing Removal (Figure E-1) Position the pump assembly on a flat surface and Do not attempt to lift the pump by the use the lifting bail and lifting device to support the motor power cable or the piping. Attach pump in a vertical position.

- Page 33 OM-06432 SF SERIES move the impeller screw (4). Remove the impeller If no further disassembly is required, proceed to washer (3). Remove the metal rod from between the appropriate areas in PUMP END REASSEMB the vanes of the impeller. NOTE Upper Seal Removal An alternate method of removing the impeller screw (Figures E-2 and E-3)

- Page 34 SF SERIES OM-06432 PUMP END REASSEMBLY precautions printed on solvent contain ers. NOTE Inspect the rotor shaft (3, Figure E-2) for dam Reuse of old O‐rings or shaft seal parts will result in aged threads, scoring, or nicks. Remove nicks and premature leakage or reduced pump performance.

- Page 35 OM-06432 SF SERIES ROTOR STATIONARY SHAFT SEAL SEAT ROTATING O‐RING ELEMENT SPRING BELLOWS AND RETAINER ASSY SPRING CENTERING WASHER SEAL RETAINING RING STATIONARY SEAL PLATE SEAL SEAT O‐RING ROTATING BELLOWS AND ELEMENT RETAINER ASSY SPRING SHIM SET SPRING RETAINER IMPELLER Figure E-3.

- Page 36 SF SERIES OM-06432 Position the intermediate so the holes for the against the shaft shoulder. Use caution not to nick mounting hardware in the intermediate align with or damage the O‐ring on the shaft keyway. those in the motor housing and press the inter Position the seal plate on a clean flat surface with mediate into the motor housing until fully seated.

- Page 37 OM-06432 SF SERIES Lubricate the I.D. of the bellows with water and the pump casing in order to set the impeller‐to‐ slide the rotating subassembly over the shaft wear ring clearance. sleeve (18) until the seal face is just flush with the If the wear ring was removed from the suction undercut end of the sleeve.

- Page 38 SF SERIES OM-06432 pump casing and suction head toward the impeller attempting to open or service the pump until the proper clearance is achieved. assembly. Tag electrical circuits to pre vent accidental start‐up. When the face clearance is properly set, secure the Carefully inspect any O‐rings before removal and adjusting screws (8) by tightening the jam nuts cleaning to determine if a proper seal and com...

- Page 39 OM-06432 SF SERIES Rotor Shaft and Bearing Removal precautions printed on solvent contain ers. (Figure E-2) Rotate the bearings by hand to check for rough See PUMP END DISASSEMBLY, and remove all ness or binding. If rotation is rough, replace the pump end and seal components.

- Page 40 SF SERIES OM-06432 Using two propane heat torches of the type de is recommended that these steps be performed by signed to melt ice or burn weeds from sidewalks at least two people to promote efficient installation and driveways, apply heat quickly and evenly to of the stator.

- Page 41 OM-06432 SF SERIES turns. Tape the stator leads together to protect bent or damaged, or if the laminations are sepa them during installation. rated, replace the shaft and rotor (a single assem bly). NOTE Stator installation involves heating the motor hous ing.

- Page 42 SF SERIES OM-06432 intermediate to the motor housing with the hard race, balls, or ball cage. Press only on the ware (11 and 12). Torque the capscrews to 47 ft. inner race. lbs. (6,5 m. kg.). After the bearings have been installed and allowed to cool, check to ensure that they have not moved Terminal Housing Assembly Installation out of position in shrinking.

- Page 43 OM-06432 SF SERIES housing over the opening in the top of the motor Hoisting Bail Installation housing. (Figure E-1) Check to ensure that the contacts on the ends of If the hoisting bail (19) was removed in order to re the motor stator leads are firmly installed in their re...

- Page 44 SF SERIES OM-06432 See Figure E-4 and connect the vacuum pump or Seal and Motor Cavity Testing compressor/venturi system directly to the pump at the hole for the seal cavity drain plug (7, Figure Connect the vacuum pump or compressor/venturi E-2).

- Page 45 OM-06432 SF SERIES Remove the plug, and screw a short 1/4 inch NPT LUBRICATION nipple into the hole. Plug the open end of the nipple with your finger. Tip the pump and drain off a small Seal Cavity amount of oil into a transparent cup, and stand the pump up again.

- Page 46 For U.S. and International Warranty Information, Please Visit www.grpumps.com/warranty or call: U.S.: 419-755-1280 International: +1-419-755-1352 For Canadian Warranty Information, Please Visit www.grcanada.com/warranty or call: 519-631-2870 THE GORMAN‐RUPP COMPANY D MANSFIELD, OHIO GORMAN‐RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA...

Need help?

Do you have a question about the SF4A and is the answer not in the manual?

Questions and answers