Table of Contents

Advertisement

Quick Links

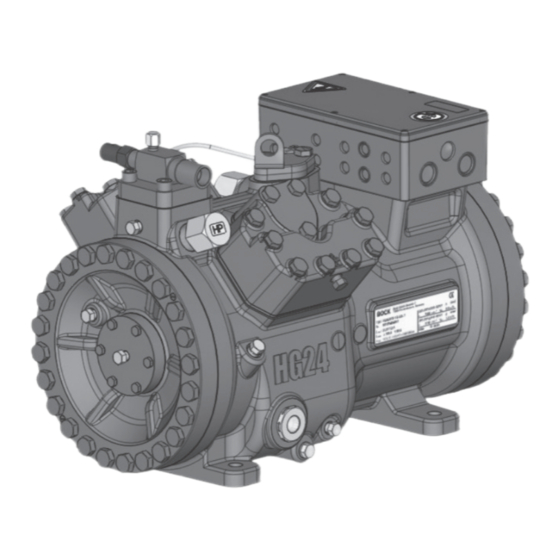

BOCK HGX

Assembly instructions

96523-05.2022-Gb

Translation of the original instructions

HGX24/55-4 ML CO

2

HGX24/70-4 ML CO

2

HGX24/90-4 ML CO

2

HGX24/110-4 ML CO

2

HGX24/55 MLP 6 CO

2

HGX24/70 MLP 7 CO

2

HGX24/90 MLP 8 CO

HGX24/110 MLP 10 CO

BOCK

®

2

4 CO

T

HGX24/55-4 S CO

T

HGX24/70-4 S CO

T

HGX24/90-4 S CO

T

HGX24/110-4 S CO

T

HGX24/55 SP 7 CO

T

HGX24/70 SP 9 CO

T

HGX24/90 SP 12 CO

2

T HGX24/110 SP 15 CO

2

T

2

T

HGX24/55-4 SH CO

2

T

HGX24/70-4 SH CO

2

T

HGX24/90-4 SH CO

2

T

HGX24/110-4 SH CO

2

T

HGX24/55 SHP 7 CO

2

T

HGX24/70 SHP 9 CO

2

T

HGX24/90 SHP 12 CO

2

T

HGX24/110 SHP 15 CO

2

T

2

T

2

T

2

T

2

T

2

T

2

T

2

T

2

colour the world

of tomorrow

D

GB

F

E

1

Advertisement

Table of Contents

Summary of Contents for BOCK HGX24/55 MLP 6 CO2 T

- Page 1 4 CO BOCK HGX Assembly instructions 96523-05.2022-Gb Translation of the original instructions HGX24/55-4 ML CO HGX24/55-4 S CO HGX24/55-4 SH CO HGX24/70-4 ML CO HGX24/70-4 S CO HGX24/70-4 SH CO HGX24/90-4 ML CO HGX24/90-4 S CO HGX24/90-4 SH CO HGX24/110-4 ML CO...

-

Page 2: Table Of Contents

Observe the safety instructions contained in these instructions. These instructions must be passed onto the end customer along with the unit in which the compres- sor is installed. Manufacturer Bock GmbH 72636 Frickenhausen Contact Bock GmbH Benzstraße 7... - Page 3 Contents Page Areas of application 3.1 Refrigerants 3.2 Oil charge 3.3 Limits of application Compressor assembly 4.1 Storage and transportation 4.2 Setting up 4.3 Connecting the pipelines - solder system 4.4 Connecting the pipelines - cutting ring system 4.5 Pipes 4.6 Flange shut-off valves (HP/LP) 4.7 Laying suction and pressure lines 4.8 Operating the shut-off valves...

-

Page 4: Safety

1 | Safety 1.1 Identification of safety instructions: DANGER Indicates a dangerous situation which, if not avoided, will cause immediate fatal or serious injury WARNING Indicates a dangerous situation which, if not avoided, may cause fatal or serious injury CAUTION Indicates a dangerous situation which, if not avoided, may imme- diately cause fairly severe or minor injury. -

Page 5: Safety Instructions

These assembly instructions describe the standard version of the compressors named in the ti- tle manufactured by Bock. Bock refrigerating compressors are intended for installing in a machine (within the EU according to the EU Directives 2006/42/EC Machinery Directive and 2014/68/EU Pressure Equipment Directive). -

Page 6: Product Description

2 | Product description 2.1 Short description • Semi-hermetic four-cylinder reciprocating compressor with suction gas cooled driving motor. • The flow of refrigerant sucked in from the evaporator is led over the engine and provides for a particularly intensive cooling. Thus the engine can be kept on a relatively low temperature level specially during high load. • Oil pump independent of direction of rotation for reliable and safe oil supply. •... -

Page 7: Type Key

2 | Product description 2.2 Name plate (example) BOCK Bock GmbH, Benzstr. 7 72636 Frickenhausen, Germany HGX24/70-4 S CO BC12345A001 31,0/17,9A 169A BOCK lub E85 100/150 bar IP66 Fig. 3 Voltage, circuit, frequency Type designation 50 Hz Nominal rotation speed Machine number... -

Page 8: Type Key Compressors With Lspm Motor (Line Start Permanent Magnet)

2 | Product description 2.4 Type key compressors with LSPM Motor (example) Transcritical version Motor power in HP LSPM Motor Compressor version ³ Swept volume Number of cylinders Size Oil charge ² Series ¹ ¹ HG - Hermetic Gas-Cooled (suction gas-cooled) ²... -

Page 9: Areas Of Application

3.3 Limits of application ATTENTION Compressor operation is possible within the operating limits. These can be found in Bock compressor selection tool (VAP) under vap.bock.de. Observe the information given there. - Permissible ambient temperature (-20 °C) - (+60 °C). -

Page 10: Compressor Assembly

4 | Compressor assembly INFO New compressors are factory-filled with inert gas. Leave this service charge in the compressor for as long as possible and prevent the ingress of air. Immediately after refrigeration technological connection of the compressor close the shut-off devices in suction-, dis- charge-, oil return line etc. -

Page 11: Connecting The Pipelines - Solder System

4 | Compressor assembly 4.3 Connecting the pipelines - solder system ATTENTION Damage possible. Superheating can damage the valve. Remove the pipe supports therefore from the valve for soldering and accordingly cool the valve body during and after soldering. Only solder using inert gas to inhibit oxidation products (scale). Material soldering / welding connection: S235 (JRG2C) The pipe connections have graduated inside diameters so that pipes with standard millimetre and inch dimensions can be used. -

Page 12: Pipes

4 | Compressor assembly 4.5 Pipes Pipes and system components must be clean and dry inside and free of scale, swarf and layers of rust and phosphate. Only use hermetically sealed parts. Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being cracked and broken by severe vibrations. -

Page 13: Laying Suction And Pressure Lines

4 | Compressor assembly 4.7 Laying suction and pressure lines ATTENTION Property damage possible. Improperly installed pipes can cause cracks and tears which can result in a loss of refrigerant. INFO Proper layout of the suction and pressure lines directly after the compressor is integral to the smooth running and vibration behaviour of the system. -

Page 14: Operating Mode Of The Lockable Service Connections

After activating the spindle, generally fit the spindle protection cap again and tighten with 40 - 50 Nm. This serves as a second sealing feature during operation. 4.10 Oil return To ensure the oil return function will work reliably no matter what kind of system configuration you are using, Bock recommends incorporating oil separators or oil level monitoring equipment. The "O" connection is already available from the factory for the purpose of installing the additional oil level monitoring component. Oil should be returned from the oil separator to the compressor via the "D1" connection provided for this purpose on the compressor. -

Page 15: Electrical Connection

5 | Electrical connection Electrical connection DANGER Risk of electric shock! High voltage! Only carry out work when the electrical system is disconnected from the power supply! ATTENTION When attaching accessories with an electrical cable, a minimum bending radius of 3 x the cable diameter must be maintained for laying the cable. - Page 16 5.3 Circuit diagramm for direct start 230 V ∆ / 400 V Y FC1.1 I> I> I> FC1.1 L3 N PE -EC1 Θ B1 B2 INT69G Compressor terminal box Anschlußkasten Verdichter Fig. 14 Cold conductor (PTC sensor) motor winding Thermal protection thermostat (PTC sensor) Load circuit safety switches Control power circuit fuse High pressure safety monitor...

- Page 17 L1.1 L2.1 L3.1 L1.2 P> Θ Θ Main switch Control voltage switch Compressor motor Compressor contactor INT69 G Electronic trigger unit INT69 G Oil sump heater...

-

Page 18: Electronic Trigger Unit Int69 G

5| Electrical connection 5.4 Electronic trigger unit INT69 G The compressor motor is fitted with cold conductor temperature sensors (PTC) connected to the electronic trigger unit INT69 G in the terminal box. In case of excess temperature in the motor winding, the INT69 G deactivates the motor contactor. -

Page 19: Oil Sump Heater

5| Electrical connection Relay position INT69 G Gauge state Relay position Deactivated state 11-12 INT69 G switch-on 11-14 B2 12 14 11 Remove PTC connector 11-12 Fig. 16 Insert PTC connector 11-12 Reset after mains on 11-14 5.7 Oil sump heater In order to avoid damage to the compressor, the compressor is equipped with an oil sump heater as a standard feature. -

Page 20: Commissioning

5| Electrical connection Rotational speed 0 - f-min f-min - f-max range Start-up time < 1 s ca. 4 s immediately Switch-off time f-min/f-max see chapter: Technical data: adjustable frequency range 6 | Commissioning 6.1 Preparations for start-up INFO In order to protect the compressor against inadmissible operating conditions, high-pressure and low-pressure pressostats controls are mandatory on the installation side. -

Page 21: Evacuation

6 | Commissioning Carry out the leak test on the refrigerating plant in accordance with EN 378-2 or a corresponding safety standard, while always observing the maximum permissible overpressure for the compressor. Only dry test gases may be used for the leak test, e.g. nitrogen N2 min. 4.6 (= purity 99.996 % or higher). -

Page 22: Start-Up

6 | Commissioning A refrigerant supplement, which may become necessary after start-up, can be topped up in vapour form on the suction side. ATTENTION Avoid overfilling the machine with refrigerant! Do not charge liquid refrigerant into the suction-side on the compressor. -

Page 23: Decompression Valves

6 | Commissioning 6.8 Decompression valves ATTENTION The compressor is fitted with two decompression valves. One valve each on the suction and discharge side. If excessive pressures are reached, the valves open and prevent further pressure increase. Thereby CO is blown off to the ambient! In the event that a pressure relief valve activates repeatedly, check valve and replace if necessary as during blow-off extreme con- ditions can occur, which may result in a permanent leak. -

Page 24: Avoiding Slugging

6 | Commissioning 6.9 Avoiding slugging ATTENTION Slugging can result in damage to the compressor and cause refrigerant to leak. To prevent slugging: The complete refrigeration plant must be properly designed. All components must be compatibly rated with each other with regard to output (particularly the evaporator and expansion valves). -

Page 25: Work To Be Carried Out

7.3 Spare part recommendation Available spare parts and accessories can be found on our compressor selection tool under vap.bock.de as well as at bockshop.bock.de. Only use genuine Bock spare parts! 7.4 Lubricants / oil... -

Page 26: Technical Data

8 | Technical data Oil charge (sight glass centre) Oil charge (ex works) Suction line Discharge line Weight permissible fre- 30 - 70 quency range Starting current (rotor locked) Max. power consumption Max. operating current 220-240 V ∆ / 380-420 V Y - 3 - 50 Hz Voltage 265-290 V ∆... - Page 27 8 | Technical data...

- Page 28 8 | Technical data Oil charge (sight glass centre) Oil charge (ex works) Suction line Discharge line Weight permissible fre- 30 - 70 quency range Starting current (rotor locked) Max. power consumption Max. operating current 220-240 V ∆ / 380-420 V Y - 3 - 50 Hz Voltage 265-290 V ∆...

- Page 29 8 | Technical data...

-

Page 30: Dimensions And Connections

9 | Dimensions and connections Anschlüsse / + 0,08 Connections Saugabsperrventil 13,82 Centre of gravity Suction line valve, Druckabsperrventi Discharge line valv Anschluss Saugse Anschlüsse / Connection suctio + 0,08 + 0,08 Connections Anschluss Saugse Saugabsperrventil, R 13,82 13,82 Connection suctio Suction line valve, tub Anschluss Drucks Druckabsperrventil, R... - Page 31 9 | Dimensions and connections Suction line see technical data, chapter 8 Discharge line 1 / 8 “ NPTF Connection suction side, not lockable 7 / 16 “ UNF Connection suction side, lockable 1 / 8 “ NPTF Connection discharge side, not lockable 7 / 16 “...

-

Page 32: Declaration Of Incorporation

BOCK ® Declaration of incorporation for incomplete machinery in accordance with EC Machinery Directive 2006/42/EC, Annex II 1. B Manufacturer: Bock GmbH Benzstraße 7 72636 Frickenhausen, Germany We, as manufacturer, declare in sole responsibility that the incomplete machinery Name: Semi-hermetic compressor Types: HG(X)12P/60-4 S (HC) .... -

Page 33: Service

11| Service Dear customer, If you have any questions about installation, operation and accessories, please contact our technical service or specialist wholesaler and/or our representative. The Bock service team can be contacted by phone +49 (0)7022 9454-0 or via service@bock.de. Yours faithfully Bock GmbH... - Page 34 BOCK ® Bock GmbH Benzstraße 7 72636 Frickenhausen Germany Phone +49 7022 9454-0 +49 7022 9454-137 www.bock.de © Bock GmbH. All rights reserved. Subject to modifications.

Need help?

Do you have a question about the HGX24/55 MLP 6 CO2 T and is the answer not in the manual?

Questions and answers