Summary of Contents for Carrier TRANSICOLD 69NT40-541-200

- Page 1 Container Refrigeration OPERATIONS AND SERVICE 69NT40-541-200 TO 299 Container Refrigeration Units T-317 Rev B...

- Page 3 OPERATIONS AND SERVICE 69NT40-541-200 TO 299 Container Refrigeration Units © 2017 Carrier Corporation Printed in USA July 2017 ●...

- Page 5 TABLE OF CONTENTS PARAGRAPH NUMBER PAGE SAFETY SUMMARY ..............1–1 GENERAL SAFETY NOTICES .

-

Page 6: Table Of Contents

3.1.2 Fresh Air Makeup Vent ........... . . 3–1 3.1.3 Evaporator Section . - Page 7 4.6.13 DataCORDER Alarms ........... . 4–18 OPERATION .

- Page 8 7.2.1 Removal ..............7–2 MANIFOLD GAUGE SET .

- Page 9 7.21 CONTROLLER ............. 7–30 7.21.1 Handling Controller .

- Page 11 LIST OF ILLUSTRATIONS FIGURE NUMBER Page Figure 3.1 Refrigeration Unit - Front Section ..........3–1 Figure 3.2 Evaporator Section .

- Page 12 Figure 7.20 Evaporator Fan Assembly ........... . . 7–25 Figure 7.21 Suction Modulation Valve (SMV) .

- Page 13 LIST OF TABLES TABLE NUMBER Page Table 3–1 Safety and Protective Devices ........... . 3–9 Table 4–1 Key Pad Function .

- Page 15 SECTION 1 SAFETY SUMMARY GENERAL SAFETY NOTICES The following general safety notices supplement the specific warnings and cautions appearing elsewhere in this manual. They are recommended precautions that must be understood and applied during operation and mainte- nance of the equipment covered herein. The general safety notices are presented in the following three sections labeled: First Aid, Operating Precautions and Maintenance Precautions.

- Page 16 SPECIFIC WARNING AND CAUTION STATEMENTS The statements listed below are applicable to the refrigeration unit and appear elsewhere in this manual. These recommended precautions must be understood and applied during operation and maintenance of the equipment covered herein. WARNING Beware of unannounced starting of the evaporator and condenser fans. The unit may cycle the fans and compressor unexpectedly as control requirements dictate.

- Page 17 WARNING Oakite No. 32 is an acid. Be sure that the acid is slowly added to the water. DO NOT PUT WATER INTO THE ACID - this will cause spattering and excessive heat. WARNING Wear rubber gloves and wash the solution from the skin immediately if accidental con tact occurs.

- Page 18 CAUTION When a failure occurs during automatic testing the unit will suspend operation awaiting opera- tor intervention. CAUTION When Pre-Trip test Auto 2 runs to completion without being interrupted, the unit will terminate pre-trip and display “Auto 2" “end.” The unit will suspend operation until the user depresses the ENTER key! CAUTION The unit will remain in the full cooling mode as long as the emergency bypass switch is in the...

- Page 19 CAUTION Use only Carrier Transicold approved Polyol Ester Oil (POE) - Mobil ST32 compressor oil with R-134a. Buy in quantities of one quart or smaller. When using this hygroscopic oil, immediately reseal. Do not leave container of oil open or contamination will occur.

- Page 21 INTRODUCTION INTRODUCTION The Carrier Transicold model 69NT40-541-200 to 299 series units are of lightweight aluminum frame construction, designed to fit in the front of a container and serve as the container's front wall. They are one piece, self-contained, all electric units which includes cooling and heating systems to provide precise temperature control.

- Page 22 2.3.7 Interrogator Units that use the DataCORDER function are fitted with interrogator receptacles for connection of equipment to download the recorded data. Two receptacles may be fitted, one accessible from the front of the container and the other mounted inside the container (with the USDA receptacles). 2.3.8 Remote Monitoring The unit may be fitted with a remote monitoring receptacle.

- Page 23 2.3.20 230 Volt Cable Units equipped with an autotransformer require an additional power cable for connection to the 230 volt source. Var- ious power cable and plug designs are available. The plug options tailor the cables to each customers requirements. 2.3.21 Cable Restraint Various designs are available for storage of the power cables.

-

Page 25: Fresh Air Makeup Vent

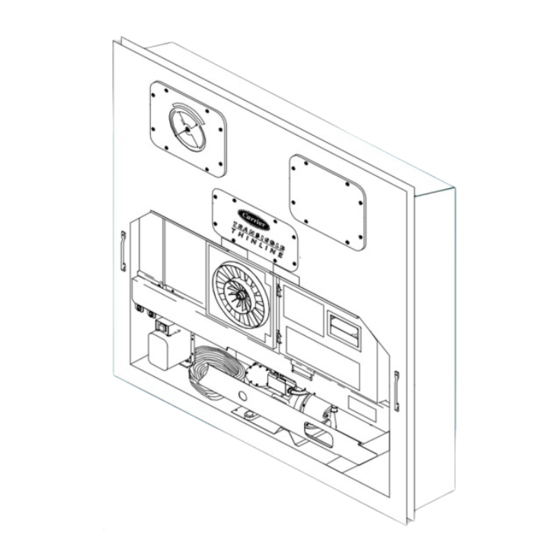

SECTION 3 DESCRIPTION GENERAL DESCRIPTION 3.1.1 Refrigeration Unit - Front Section The unit is designed so that the majority of the components are accessible from the front, see Figure 3.1. The upper access panels allow entry into the evaporator section, and the center access panel allows access to the ther- mostatic expansion valve and evaporator coil heaters. -

Page 26: Evaporator Section

3.1.3 Evaporator Section The evaporator section (Figure 3.2) contains the temperature recorder bulb or return recorder sensor, return tempera- ture sensor, thermostatic expansion valve, dual-speed evaporator fans (EM1 and EM2), evaporator coil and heater, drain pan heater, defrost heaters, defrost temperature sensor, heat termination thermostat, and heat exchanger. The evaporator fans circulate air through the container by pulling it in the top of the unit, directing it through the evaporator coil, where it is heated or cooled, and discharging it at the bottom. -

Page 27: Figure 3.3 Compressor Section

Figure 3.3 Compressor Section 1. Power Autotransformer (TRANS) 9. Quench Expansion Valve 2. Power Cables and Plug 10. Stepper Motor Suction Modulation Valve (SMV) 3. Compressor Sight Glass View Port 11. Suction Flange 4. Compressor Guard 12. Compressor Sight Glass 5. -

Page 28: Air-Cooled Condenser Section

3.1.4 Air-Cooled Condenser Section The air cooled condenser section (Figure 3.4) consists of the condenser fan, condenser coil, receiver with sight glass/moisture indicator, quench valve, manual liquid line valve, and filter-drier. The condenser fan pulls air in the bottom of the coil and it is discharged horizontally out through the condenser fan grille. Figure 3.4 Air-Cooled Condenser Section 1. -

Page 29: Water-Cooled Condenser Section

3.1.5 Water-Cooled Condenser Section The water-cooled condenser section (Figure 3.5) consists of a water-cooled condenser, sight glass, quench expansion valve, rupture disc, condenser pressure transducer, filter-drier, water couplings, and water pressure switch. The water cooled condenser replaces the standard unit receiver. Figure 3.5 Water-Cooled Condenser Section 1. -

Page 30: Control Box Section

3.1.6 Control Box Section The control box (Figure 3.6) includes the manual operation switches, circuit breaker (CB-1), compressor, fan and heater contactors, control power transformer, fuses, key pad, display module, current sensor module, controller module, and the communications interface module. 3.1.7 Communications Interface Module The communications interface module is a slave module which allow communication with a master central monitor-... -

Page 31: Refrigeration System Data

REFRIGERATION SYSTEM DATA a. Compressor/Motor Number of Cylinders Assembly Model 06DR Weight (Dry) 118 kg (260 lb) Approved Oil Castrol Icematic SW-20 Oil Charge 3.6 liters (7.6 U.S. pints) Oil Sight Glass The oil level range, with the compressor off, should be between the bottom and one-eighth level of the sight glass. -

Page 32: Electrical Data

ELECTRICAL DATA CB-1 Trips at 29 amps a. Circuit Breaker CB-2 (50 amp) Trips at 62.5 amps CB-2 (70 amp) Trips at 87.5 amps b. Compressor 17.6 amps @ 460 vac Full Load Amps (FLA) Motor (with current limiting set at 21 amps) 380 vac, Single Phase, 460 vac, Single Phase, 50 hz... -

Page 33: Safety And Protective Devices

ELECTRICAL DATA (CONTINUED) h. Compressor Crankcase Heater 180 watts @ 460 vac Orange wire Power Red wire Output Brown wire Ground Input voltage 5 vdc Output voltage 0 to 3.3 vdc i. Humidity Sensor Output voltage readings verses relative humidity (RH) percentage: 0.99 V 1.65 V 2.31 V... -

Page 34: Refrigeration Circuit

REFRIGERATION CIRCUIT Starting at the compressor, (see Figure 3.7, upper schematic) the suction gas is compressed to a higher pressure and temperature. The gas flows through the discharge service valve into the pressure regulator valve. During periods of low ambient operation, the pressure regulator valve modulates the flow of refrigerant to maintain a preset minimum discharge pressure. -

Page 35: Figure 3.7 Refrigeration Circuit Schematic With Receiver

Figure 3.7 Refrigeration Circuit Schematic with Receiver Circuit with Receiver 1. High Pressure Switch 9. Rupture Disc 2. Discharge Pressure Regulator Valve 10. Moisture-Liquid Indicator 3. Air-Cooled Condenser 11. Filter-Drier 4. Evaporator 12. Receiver 5. Thermostatic Expansion Valve 13. Suction Modulation Valve (SMV) 6. -

Page 36: Figure 3.8 Refrigeration Circuit Schematic With Water Cooled Condenser

Figure 3.8 Refrigeration Circuit Schematic with Water Cooled Condenser Circuit with Water Cooled Condenser 1. High Pressure Switch 9. Rupture Disc 2. Discharge Pressure Regulator 10. Moisture-Liquid Indicator 3. Air-Cooled Condenser 11. Condenser Pressure Transducer (CPT) 4. Evaporator 12. Filter-Drier 5. -

Page 37: Microprocessor

SECTION 4 MICROPROCESSOR TEMPERATURE CONTROL MICROPROCESSOR SYSTEM The temperature control Micro-Link 3 microprocessor system (see Figure 4.1) consists of a key pad, display mod- ule, control module (controller), and interconnecting wiring. The controller houses the temperature control software and the DataCORDER Software. The temperature control software functions to operate the unit components as required to provide the desired cargo temperature and humidity. -

Page 38: Key Pad

4.1.1 Key Pad The key pad (Figure 4.2 is mounted on the right-hand side of the control box. The key pad consists of eleven push button switches that act as the user's interface with the controller. Descriptions of the switch functions are provided Table 4–1. -

Page 39: Display Module

4.1.2 Display Module The display module (Figure 4.3) consists of five digit displays and seven indicator lights. The indicator lights include: 1. Cool - White LED: Energized when the refrigerant compressor is energized. 2. Heat - Orange LED: Energized to indicate heater operation in the heat or defrost mode. 3. -

Page 40: Controller

4.1.3 Controller CAUTION Do not remove wire harnesses from controller unless you are grounded to the unit frame with a static safe wrist strap. CAUTION Unplug all controller wire harness connectors before performing arc welding on any part of the container. -

Page 41: Modes Of Operation

To access the function codes, perform the following: a. Press the CODE SELECT key, then press an arrow key until the left window displays the desired code number. b. The right window will display the value of this item for five seconds before returning to the normal display mode. -

Page 42: Condenser Pressure Control

4.3.6 Condenser Pressure Control When configuration variable CnF14 is set to “In” the condenser pressure control logic is activated to maintain dis- charge pressures above 130 psig in low temperature ambients. The logic turns the condenser fan on or off in accordance with the condenser pressure transducer reading. -

Page 43: Perishable Mode - Dehumidification

4.3.10 Perishable Mode - Dehumidification The dehumidification mode is provided to reduce the humidity levels inside the container. The mode is activated when a humidity value is set at function code Cd33. The display module SUPPLY led will flash ON and OFF every second to indicate that the dehumidification mode is active. -

Page 44: Temperature Control - Frozen Mode

Bulb mode is terminated when: 1. Bulb mode code Cd35 is set to “Nor.” 2. Dehumidification code Cd33 is set to “Off.” 3. The user changes the set point to one that is in the frozen range. When bulb mode is disabled by any of the above, the evaporator fan operation for dehumidification reverts to “alt” and the DTS termination setting resets to the value determined by controller configuration variable CnF41. -

Page 45: Unit Pre-Trip Diagnostics

Some alarms requiring compressor shutdown have time delays before and after to try to keep the compressor on line. An example is alarm code “LO”, (low main voltage), when a voltage drop of over 25% occurs, an indication is given on the display, but the unit will continue to run. An alarm is indicated by flashing an alarm code on the display panel, and for some alarms, by the alarm light illuminating. -

Page 46: Datacorder

Figure 4.1) which may be used with the Carrier Transicold Data Reader to down load data. A personal computer with Carrier Transicold Data View software may also be used to download data and configure settings. The DataCORDER consists of: •... -

Page 47: Datacorder Software

4.6.2 DataCORDER Software The DataCORDER Software is subdivided into the Configuration Software, Operational Software and the Data Memory. a. Operational Software The Operational Software reads and interprets inputs for use by the Configuration Software. The inputs are labeled Function Codes. There are 35 functions (see Table 4–8) which the operator may access to examine the current input data or stored data. -

Page 48: Table 4-3 Datacorder Standard Configurations

A list of the data points available for recording follows. Changing the configuration to generic and selecting which data points to record may be done using the Carrier Transicold Data Retrieval Program. -

Page 49: Figure 4.5 Figure 3- 5 Standard Configuration Report

Figure 4.5 Figure 3- 5 Standard Configuration Report Raw Data Report for ABC1234567 May 31, 2003 to Jun 04, 2003 System Configuration at the Time of Interrogation: Interrogated On Sept 05, 2003 Extracted by DataLine Rev 1.0.0 Controller Software: 5120 Controller Serial #: 04163552 Bill of Lading #: 1 Origin:... -

Page 50: Logging Interval (Dcf03)

4.6.4 Logging Interval (dCF03) The user may configure four time intervals between data recordings. Data is logged at exact intervals in accor- dance with the real time clock. The clock is factory set at Greenwich Mean Time. 4.6.5 Thermistor Format (dCF04) The user may configure the format in which the thermistor readings are recorded. -

Page 51: Datacorder Communications

Data retrieval from the DataCORDER can be accomplished by using one of the following; DataReader, DataLine/ DataView or a communications interface module. a. DataReader The Carrier Transicold Data Reader (see Figure 4.6) is a simple to operate hand held device designed to extract data from the DataCORDER and then upload it to a personal computer. -

Page 52: Usda Cold Treatment

NOTE The DataBank file format is: READ05xx.ML3 where “xx” is the version number. This file should be the only file other than saved down loads (dcx files) inside the card memory. Any other files may result in card corruption. 1. The unit trip data can be downloaded with the Data Bank card if the battery pack has sufficient charge or the unit can be plugged into power. -

Page 53: Usda Cold Treatment Procedure

In response to the demand to replace fumigation with this environmentally sound process, Carrier has integrated Cold Treatment capability into its microprocessor system. These units have the ability to maintain supply air tem- perature within one-quarter degree Celsius of setpoint and record minute changes in product temperature within the DataCORDER memory, thus meeting USDA criteria. -

Page 54: Datacorder Alarms

4.6.13 DataCORDER Alarms Alarm display is an independent DataCORDER function. If an operating parameter is outside of the expected range or a component does not return the correct signals back to the DataCORDER an alarm is generated. The DataCORDER contains a buffer of up to eight alarms. A listing of the DataCORDER alarms is provided in Table 4–... - Page 55 Table 4–4 Controller Configuration Variables (Continued) CONFIG. # TITLE DEFAULT OPTION CnF17 Discharge Pressure Sensor Out (No) In (Yes) CnF18 Heater Old (Low Watt) nEW (High Watt) CnF19 Controlled Atmosphere Out (No) In (Yes) CnF20 Suction Pressure Sensor Out (No) In (Yes) CnF21 Autotransformer...

-

Page 56: Table 4-5 Controller Function Codes

Table 4–5 Controller Function Codes CODE # TITLE DESCRIPTION NOTE If the function is not applicable, the display will read “-----” Display Only Functions Displays the SMV percent open. The right display reads 100% when the valve Suction Modulation Cd01 is fully open and 0% when the valve is fully closed. - Page 57 Table 4–5 Controller Function Codes (Continued) CODE # TITLE DESCRIPTION This code indicates the dash number of the model for which the Controller is con Cd20 Config/Model # figured (i.e., if the unit is a 69NT40-541-100, the display will show “41100”). Humidity Water This code displays the status of the humidity water pump (-----, forward, re verse Cd21...

- Page 58 Table 4–5 Controller Function Codes (Continued) CODE # TITLE DESCRIPTION If all of the control sensors are out of range (alarm code AL26) or there is a probe circuit calibration failure (alarm code AL27), the unit will enter the shutdown state defined by this setting.

- Page 59 Table 4–5 Controller Function Codes (Continued) CODE # TITLE DESCRIPTION This code is enabled only if in the dehumidification mode (code Cd33) and bulb mode (Cd35) has been set to “bulb”. If these conditions are not met, “alt” will be displayed (indicating that the evaporator fans will alternate their speed) and the Evaporator Speed display cannot be changed.

-

Page 60: Table 4-6 Controller Alarm Indications

Table 4–6 Controller Alarm Indications CODE # TITLE DESCRIPTION Alarm 11 is applicable to units with Single Evaporator Fan Capa- bility (CnF32 set to 1EFO) only. The alarm is triggered if the evap- AL11 Evaporator Motor 1 IP Trip orator fan motor #1 internal protector opens. If the alarm is active, probe check is deactivated. - Page 61 Table 4–6 Controller Alarm Indications (Continued) CODE # TITLE DESCRIPTION During start-up diagnostics, the EEPROM is examined to deter- mine validity of its contents. This is done by testing the set point and the alarm list. If the contents are invalid, Alarm 51 is activated. During control processing, any operation involving alarm list activ- AL51 Alarm List Failure...

- Page 62 Table 4–6 Controller Alarm Indications (Continued) CODE # TITLE DESCRIPTION Alarm 60 is an indication of a probable failure of the defrost tem- perature sensor (DTS). It is triggered by the opening of the heat termination thermostat (HTT) or the failure of the DTS to go above set point within two hours of defrost initiation.

- Page 63 Table 4–6 Controller Alarm Indications (Continued) CODE # TITLE DESCRIPTION NOTE If the Controller is configured for four probes without a DataCORDER, the DataCORDER alarms AL70 and AL71 will be processed as Controller alarms AL70 and AL71. The Controller performs self-check routines. if an internal failure occurs, an "ERR"alarm will appear on the display.

-

Page 64: Table 4-7 Controller Pre-Trip Test Codes

Table 4–7 Controller Pre-Trip Test Codes CODE # TITLE DESCRIPTION NOTE “Auto” or “Auto1” menu includes the: P, P1, P2, P3, P4, P5, P6 and rSLts. “Auto2” menu includes P, P1, P2, P3, P4, P5, P6, P7, P8, P9, P10 and rSLts.”Auto3 menu includes P, P1, P2, P3, P4, P5, P6, P7, P8 and rSLts All lights and display segments will be energized for five seconds at the start of the pre-trip. - Page 65 Table 4–7 Controller Pre-Trip Test Codes (Continued) CODE # TITLE DESCRIPTION Setup: The high speed Evaporator Fan is turned off, a current draw test is done after 10 seconds. High Speed Evaporator P4-1 Fan Motors Off Pass/Fail Criteria: Passes if change in current draw is within the range specified.

- Page 66 Table 4–7 Controller Pre-Trip Test Codes (Continued) CODE # TITLE DESCRIPTION Setup: The compressor suction temperature is measured with the Quench valve closed. The Quench valve is energized and the suction temperature drop is checked. P6-3 Quench Valve Test Pass/Fail Criteria: Passes if suction temperature is within the valid range.

- Page 67 Table 4–7 Controller Pre-Trip Test Codes (Continued) CODE # TITLE DESCRIPTION Requirements: Test P7-0 must pass for this test to execute. Setup: The con denser fan is started and a 60 second timer is started. High Pressure P7-1 Switch Open Pass/Fail Criteria: Passes the test if the high pressure switch (HPS) closes within the 60 second time limit, otherwise, it fails.

- Page 68 Table 4–7 Controller Pre-Trip Test Codes (Continued) CODE # TITLE DESCRIPTION Setup: After completion of the defrost test, the testing proceeds directly to test P10-1 if the container temperature is above 7°C (45°F). If the con- tainer temperature is below 7°C, a 180 minute timer will be started, the set point will be set to 7°C and the control will be placed in normal heat.

-

Page 69: Table 4-8 Datacorder Function Code Assignments

Table 4–8 DataCORDER Function Code Assignments CODE # TITLE DESCRIPTION NOTE Inapplicable Functions Display “-----” To Access: Press ALT. MODE key Recorder Supply Current reading of the supply recorder sensor. Temperature Recorder Return Current reading of the return recorder sensor. Temperature USDA 1,2,3 dC3-5... -

Page 70: Table 4-9 Datacorder Pre-Trip Result Records

Table 4–9 DataCORDER Pre-Trip Result Records TEST # TITLE DATA Heater On Pass/Fail/Skip Result, Change in current for Phase A, B, and C Heater Off Pass/Fail/Skip Result, Change in currents for Phase A, B, and C Pass/Fail/Skip Result, Water pressure switch (WPS) - Open/Closed, Condenser Fan On Change in currents for Phase A, B, and C Condenser Fan Off... -

Page 71: Table 4-10 Datacorder Alarm Indications

Table 4–10 DataCORDER Alarm Indications CODE # TITLE DESCRIPTION To Access: Press ALT. MODE key The supply recorder sensor reading is outside of the range of -50°C to 70°C (-58°F to +158°F) or, the probe check logic has determined there is a fault Recorder Supply with this sensor. -

Page 73: Operation

SECTION 5 OPERATION INSPECTION (BEFORE STARTING) WARNING Beware of unannounced starting of the evaporator and condenser fans. The unit may cycle the fans and compressor unexpectedly as control requirements dictate. a. If container is empty, check inside for the following: 1. -

Page 74: Adjust Fresh Air Makeup Vent

1. Make sure that the start-stop switch (ST, on control panel) and circuit breakers CB-1 (in the control box and CB-2 (on the transformer) are in position “0” (OFF). Plug in and lock the 460 vac power plug at the recepta- cle on the transformer. -

Page 75: Lower Fresh Air Makeup Vent

Figure 5.2 Make Up Air Flow Chart 69NT40 FRESH AIR MAKEUP ZERO EXTERNAL STATIC 50HZ FLOW T-BAR (CMH) 1/2” T-BAR 5/8” T-BAR 3” 0 10 20 30 40 50 60 70 80 90 100 PERCENT OPEN For 60Hz operation multiply curves by 1.2 5.3.2 Lower Fresh Air Makeup Vent a. -

Page 76: Fresh Air Position Sensor

5.3.3 Fresh Air Position Sensor The VPS allows the user to determine position of the fresh air vent via function code 45. This function code is accessible via the code select key. The vent position will display for 30 seconds whenever motion corresponding to 5 CMH (3 CFM) or greater is detected. -

Page 77: Connect Remote Monitoring Receptacle

CONNECT REMOTE MONITORING RECEPTACLE If remote monitoring is required, connect remote monitor plug at unit receptacle. When the remote monitor plug is connected to the remote monitoring receptacle, the following remote circuits are energized: CIRCUIT FUNCTION Sockets B to A Energizes remote cool light Sockets C to A Energizes remote defrost light... -

Page 78: Complete Inspection

5.7.4 Complete Inspection Allow unit to run for 5 minutes to stabilize conditions and perform a pre-trip diagnosis in accordance with the PRE- TRIP DIAGNOSIS. PRE-TRIP DIAGNOSIS CAUTION Pre-trip inspection should not be per formed with critical temperature cargoes in the container. CAUTION When Pre-Trip key is pressed, dehumidification and bulb mode will be deactivated. -

Page 79: Observe Unit Operation

When an automatic test fails, it will be repeated once. A repeated test failure will cause “FAIL” to be shown on the right display, with the corresponding test number to the left. The user may then press the DOWN ARROW to repeat the test, the UP ARROW to skip to the next test or the PRE-TRIP key to terminate testing. -

Page 80: 5.10 Sequence Of Operation

b. Probe Diagnostic Logic - Special If the probe check option is configured for special the above criteria are applicable. A defrost with probe check will be initiated if 25 of 30 readings or 10 consecutive readings are outside of the limits. In this configuration, a probe check will not be run as a part of a normal defrost, but only as a part of a defrost initi- ated due to a diagnostic reading outside of the limits. -

Page 81: Figure 5.4 Controller Operation - Frozen Mode

Figure 5.4 Controller Operation - Frozen Mode 5–9 T-317... -

Page 82: Sequence Of Operation - Perishable Mode Cooling

5.10.1 Sequence of Operation - Perishable Mode Cooling NOTE In the Conventional Perishable Mode of operation the evaporator motors run in high speed. In the Economy Perishable Mode the fan speed is varied. NOTE In low temperature ambients the condenser fan will be cycled by the controller to maintain proper con- densing pressure. -

Page 83: Sequence Of Operation - Perishable Mode Heating

5.10.2 Sequence of Operation - Perishable Mode Heating NOTE The unit will heat only when in the Perishable Mode, relay TH is electronically locked out when in the Frozen Mode. a. If the air temperature decreases 0.5°C (0.9°F) below set point, the system enters the heating mode. (See Figure 5.3). -

Page 84: Sequence Of Operation - Frozen Mode Cooling

5.10.3 Sequence of Operation - Frozen Mode Cooling NOTE 1. In the Frozen Mode of operation the evaporator motors run in low speed. 2. In low temperature ambients the condenser fan will be cycled by the controller to maintain proper con- densing pressure. -

Page 85: Sequence Of Operation - Defrost

5.10.4 Sequence of Operation - Defrost The defrost cycle may consist of up to three distinct operations. The first is de-icing of the coil, the second is a probe check cycle and the third is snap freeze. Defrost may be requested by any one of the following methods: 1. - Page 86 When a request for defrost is made by probe check, the unit will enter defrost when the Defrost Temperature Sen- sor reading is at or below 25.6°C(78°F). The unit will terminate defrost when the Defrost Temperature Sensor read- ing rises above 25.6°C(78°F) When a request for defrost is made by demand defrost, the unit will enter defrost when the reading at the Defrost Temperature Sensor is at or below 18°C (64.4°F).

-

Page 87: Troubleshooting

SECTION 6 TROUBLESHOOTING REMEDY/ CONDITION POSSIBLE CAUSE REFERENCE SECTION UNIT WILL NOT START OR STARTS THEN STOPS External power source OFF Turn on Start-Stop switch OFF or defective Check No power to unit Circuit breaker tripped or OFF Check Autotransformer not connected 5.2.2 Circuit breaker OFF or defective Check... -

Page 88: Unit Runs But Has Insufficient Cooling

REMEDY/ CONDITION POSSIBLE CAUSE REFERENCE SECTION UNIT RUNS BUT HAS INSUFFICIENT COOLING Compressor Compressor valves defective Abnormal pressures Controller malfunction Evaporator fan or motor defective 7.16 Refrigeration System Suction modulation valve malfunction 7.18 Condenser Pressure Transducer defective Check Shortage of refrigerant 7.7.1 UNIT WILL NOT HEAT OR HAS INSUFFICIENT HEATING Start-Stop switch OFF or defective... -

Page 89: Abnormal Pressures (Cooling)

REMEDY/ CONDITION POSSIBLE CAUSE REFERENCE SECTION Heater contactor or coil defective Replace Initiates but does not defrost Heater(s) burned out 7.15 Frequent defrost Wet load Normal ABNORMAL PRESSURES (COOLING) Condenser coil dirty 7.10 Condenser fan rotating backwards 7.11 Condenser fan inoperative 7.11 High discharge Refrigerant overcharge or noncondensibles... -

Page 90: 6.10 No Evaporator Air Flow Or Restricted Air Flow

REMEDY/ CONDITION POSSIBLE CAUSE REFERENCE SECTION 6.10 NO EVAPORATOR AIR FLOW OR RESTRICTED AIR FLOW Frost on coil Evaporator coil blocked Dirty coil 7.15 Evaporator fan motor internal protector open 7.16 Evaporator fan motor(s) defective 7.16 No or partial evaporator air flow Evaporator fan(s) loose or defective 7.16 Evaporator fan contactor defective... -

Page 91: Service

SECTION 7 SERVICE NOTE To avoid damage to the earth's ozone layer, use a refrigerant recovery system whenever removing refrigerant. When working with refrigerants you must comply with all local government environmental laws. In the U.S.A., refer to EPA section 608. REPAIRING THE REFRIGERATION SYSTEM The unit is designed as a hermetic system, which reduces the number of potential leak-points for refrigerant. -

Page 92: Removal

Figure 7.1 Piercing Valve Hand Valve 1/4” S.A.E. Connector Gasket Piercing Needle U-Shaped Block 7.2.1 Removal Reverse the steps in Section 7.2.b. MANIFOLD GAUGE SET The manifold gauge set can be used to determine system operating pressure, add a refrigerant charge, and to equalize or evacuate the system. -

Page 93: Refrigerant Recovery

Figure 7.3 Manifold Gauge Set Connection To High Side To Low Side Blue Hose Red Hose Yellow Hose Blue Knob Knob 1. Manifold Gauge Set 4. Hose Fitting w/O-ring (M14 x 1.5) 2. Hose Fitting (0.500-16 Acme) 5. High Side Field Service Coupling 3. -

Page 94: Refrigerant Leak Checking

WARNING Before proceeding with the repair make certain that the stepper motor suction modulation valve (SMV) is open (refer to section 6.18) and that there is no positive pressure in the system. 7. To reduce the time required for evacuation, dehydration and refrigerant charging of the system, perform the following steps. -

Page 95: Evacuation And Dehydration

Essential tools to properly evacuate and dehydrate any system include a vacuum pump (8 m /hr = 5 cfm volume displacement) and an electronic vacuum gauge. (The pump is available from Carrier Transicold, P/N 07-00176-11.) c. If possible, keep the ambient temperature above 15.6°C (60°F) to speed evaporation of moisture. If the ambient temperature is lower than 15.6°C (60°F), ice might form before moisture removal is complete. -

Page 96: Refrigerant Charge

REFRIGERANT CHARGE 7.7.1 Checking the Refrigerant Charge NOTE To avoid damage to the earth's ozone layer, use a refrigerant recovery system whenever removing refrigerant. When working with refrigerants you must comply with all local government environmental laws. In the U.S.A., refer to EPA section 608. a. -

Page 97: Figure 7.4 Vacuum Pump Connections

d. Refer to the pressure temperature curves in Figure 7.31. e. If the discharge/suction pressures are within the normal operating system pressures, then the charge should be correct. f. If the discharge pressure is more than ten psig below the curve, add three pounds of R-134a refrigerant through the suction line process tube. -

Page 98: Compressor

COMPRESSOR WARNING Make sure power to the unit is OFF and power plug disconnected before replacing the compressor. NOTES 1. The compressor should not operate in a vacuum greater than 500 mm/hg (20 inches/hg). 2. The service replacement compressor is sold without shutoff valves (but with valve pads), and without terminal box and cover. -

Page 99: Compressor Disassembly

h. Remove compressor mounting bolts from mounting plate and install mounting plate on replacement compressor. Install replacement compressor terminal wiring kit, following instructions included with kit. Install high pressure switch on compressor. k. Install compressor and mounting plate in unit. Connect junction box(es) to compressor and connect all wiring per wiring diagram. -

Page 100: Figure 7.6 Exploded View Of Valve Plate

Figure 7.6 Exploded View of Valve Plate JACK HERE 1. Cylinder Head Gasket 5. Valve Plate 2. Discharge Valve Screw & Lockwasher 6. Valve Plate Assembly 3. Discharge Valve Stop 7. Valve Plate Gasket 4. Discharge Valve - - - - - Figure 7.7 Bottom Plate Removed 1. -

Page 101: Figure 7.8 Oil Pump And Bearing Head

e. Match mark each connecting rod cap (see Figure 7.7) and connecting rod for correct reassembly. Remove the bolts and connecting rod caps. Push the piston rods up as far as they will go without having the piston rings extend above the cylinders. CAUTION The copper tube which connects to the oil suction strainer extends out the bottom with the bot- tom plate removed. -

Page 102: Figure 7.9 Low Profile Oil Pump

Figure 7.9 Low Profile Oil Pump 1. Capscrews 7. O-Ring 2. Cover 8. Oil Pump & Bearing 3. Reversing Assembly 9. Set Screw 4. Pinion 10. Relief Valve 5. Gear 11. Pin 6. Drive 12. Gasket - - - - - h. -

Page 103: Figure 7.11 Equalizing Tube And Lock Screw Assembly

Remove the refrigerant suction strainer. If it is removed with ease it may be cleaned with solvent and replaced. If the strainer is broken, corroded or clogged with dirt that is not easily removed, replace the strainer. Install new gaskets upon reassembly. Block the compressor crankshaft so that it cannot turn. -

Page 104: Compressor Reassembly

7.8.3 Compressor Reassembly Clean all compressor parts, use a suitable solvent with proper precautions. Coat all moving parts with the proper compressor oil before assembly. Refer to Table 7–8 for applicable compressor torque values. 7.8.4 Preparation a. Suction and Discharge Valves If the valve seats look damaged or worn, replace valve plate assembly. -

Page 105: Installing The Components

Compressor Oil Level CAUTION Use only Carrier Transicold approved Polyol Ester Oil (POE) - Castrol-Icematic SW20 compres- sor oil with R-134a. Buy in quantities of one quart or smaller. When using this hygroscopic oil, immediately reseal. Do not leave container of oil open or contamination will occur. -

Page 106: High Pressure Switch

b. Adding Oil with Compressor in System In an emergency where an oil pump is not available, oil may be drawn into the compressor through the liquid line process tube. CAUTION Extreme care must be taken to ensure the manifold common connection remains immersed in oil at all times. -

Page 107: Checking High Pressure Switch

7.9.2 Checking High Pressure Switch WARNING Do not use a nitrogen cylinder without a pressure regulator. Do not use oxygen in or near a refrigeration system as an explosion may occur. NOTE The high pressure switch is non-adjustable. a. Remove switch as outlined in Section 7.9.1 b. -

Page 108: 7.11 Condenser Fan And Motor Assembly

7.11 CONDENSER FAN AND MOTOR ASSEMBLY WARNING Do not open condenser fan grille before turning power OFF and disconnecting power plug. The condenser fan rotates counter-clockwise (viewed from front of unit), pulls air through the condenser coil, and discharges horizontally through the front of the unit. To replace motor assembly: a. - Page 109 NOTE When Oakite compound No. 32 is being used for the first time, the local Oakite Technical Service rep- resentative should be called in for their suggestions in planning the procedure. They will advise the reader on how to do the work with a minimum dismantling of equipment: how to estimate the time and amount of compound required;...

-

Page 110: Figure 7.16 Water-Cooled Condenser Cleaning - Forced Circulation

Figure 7.16 Water-Cooled Condenser Cleaning - Forced Circulation Centrifugal pump Close vent pipe valve Vent 30 GPM at 35’ head when pump is running Globe valves Priming connection Pump Suction Condenser Tank Remove water regulating valve Return Pump support Fine mesh screen 6. -

Page 111: 7.13 Filter-Drier

9. Following the water flush, circulate a 56.7 gram (2 ounce) per 3.785 liter (1 U.S. gallon) solution of Oakite No. 22 thru the tubes to neutralize. Drain this solution. 10. Flush the tubes thoroughly with fresh water. NOTE If the condenser cooling water is not being used as drinking water or is not re-circulated in a closed or tower system, neutralizing is not necessary. -

Page 112: Checking Superheat

7.14.1 Checking Superheat NOTE Proper superheat measurement should be completed at -18°C (0°F) container box temperature where possible. a. Open the heater access panel (see Figure 3.1) to expose the expansion valve. b. Attach a temperature sensor near the expansion valve bulb and insulate. Make sure the suction line is clean and that firm contact is made with the sensor. -

Page 113: Semi-Hermetic Valve Replacement

b. Installing the Expansion Valve 1. Clean the suction line with sandpaper before installing bulb to ensure proper heat transfer. Apply thermal grease to the indentation in the suction line. 2. Strap the thermal bulb to the suction line, making sure bulb is placed firmly into the suction line. See Figure 7.18 for bulb placement. -

Page 114: Evaporator Coil Replacement

7.15.1 Evaporator Coil Replacement a. Pump unit down. (Refer to Section 7.4) b. With power OFF and power plug removed, remove the screws securing the panel covering the evaporator section (upper panel). c. Disconnect the defrost heater wiring. d. Disconnect the defrost temperature sensor (see Figure 3.2) from the coil. -

Page 115: Assemble The Evaporator Fan Assembly

c. Remove the four 1/4-20 x 3/4 long bolts that are located under the fan that support the motor and stator housing. Remove the motor and plastic spacer. Figure 7.20 Evaporator Fan Assembly 1. Stator 6. Impeller Fan 2. Flat washer, 1/4 7. -

Page 116: Removing The Capacitor

b. Motor running in wrong direction (after checking for correct wiring application). c. Motor will not start, and IP-Em's are not open. 7.17.2 Removing The Capacitor WARNING Make sure power to the unit is OFF and power plug disconnected before removing capacitor(s). -

Page 117: Precheck Procedure

7.18.1 Precheck Procedure a. Check unit for abnormal operation. b. Check charge. If refrigerant is low repair as required and again check operation. c. If sufficient capacity cannot be maintained or unit is tripping excessively on high pressure switch (HPS) in high ambients, check coils and clean if required. -

Page 118: Checking The Stepper Valve

Checking with SMA-12 portable stepper drive tester The SMA-12 portable stepper drive tester (Carrier Transicold P/N 07-00375-00) is a battery operated stepper drive which will open and close the SMV, which allows a more thorough check of the motor. -

Page 119: 7.19 Autotransformer

7.19 AUTOTRANSFORMER If the unit does not start, check the following: a. Make sure the 460 vac (yellow) power cable is plugged into the receptacle (item 3, Figure 4.1) and locked in place. b. Make sure that circuit breakers CB-1 and CB-2 are in the “ON” position. If the circuit breakers do not hold in, check voltage supply. -

Page 120: Figure 7.22 Controller Section Of The Control Box

4. Test Points - - - - - a. Obtain a grounding wrist strap (Carrier Transicold part number 07-00-304-00)and a static dissipation mat (Carrier Transicold part number 07-00304-00. The wrist strap, when properly grounded, will dissipate any potential buildup on the body. The dissipation mat will provide a static-free work surface on which to place and/or service the controller. - Page 121 7.21.2 Controller Trouble-Shooting A group of test points (TP, see Figure 7.22) are provided on the controller for trouble-shooting electrical circuits (see schematic diagram, Figure 8.2). A description of the test points follows: NOTE Use a digital voltmeter to measure ac voltage between TP's and ground (TP9), except for TP8. TP 6 This test point enables the user to check if the internal This test point enables the user to check if the control-...

- Page 122 b. Procedure for loading Configuration Software 1. Turn unit OFF using start-stop switch (ST). 2. Insert the programming card for Operational Software into the programming/software port. (See Figure 7.22) 3. Turn unit ON using start-stop switch (ST). 4. The Display module will show “nt40” on the left LCD display and “541###” on the right LCD display. “###” will indicate the dash number for a given unit model number, use the UP or DOWN ARROW key to scroll through the list to obtain the proper model dash number.

-

Page 123: Table 7-1 Sensor Temperature/Resistance Chart

3. After the enter key has been pressed CAL for calibration is displayed. 4. Press the ALT MODE key on the display and hold for five seconds. 5. After the calibration has been completed, Code 45 will display 0 CMH / CFM. 7.23 TEMPERATURE SENSOR SERVICE Procedures for service of the Return Recorder, Return Temperature, Supply Recorder, Supply Temperature, Ambi- ent, Defrost Temperature, Compressor Discharge and Compressor Suction temperature sensors are provided in... -

Page 124: Figure 7.23 Sensor Types

Figure 7.23 Sensor Types Sensor 40mm (1- -1/2 inch) Mounting Stud Type 6.3mm (1/4- -inch) 40 mm (1-1/2 inches) 6.3- -mm (1/4- -inch) Bulb Type Sensor d. Prepare the cables by cutting wires to the opposite of the sensor. (See Figure 7.24.) When installing a single wire color two wire sensor, cut one wire of existing two wire cable 40 mm (1-1/2... -

Page 125: Figure 7.24 Sensor And Cable Splice

Figure 7.24 Sensor and Cable Splice REPLACEMENT 2- -WIRE TO 2- -WIRE OR 3- -WIRE TO 3- -WIRE Cable Sensor REPLACEMENT FOR DUAL, SINGLE SENSOR CONFIGURATION Cables BLACK Sensor Heat Shrink Tubing Large Heat Shrink Tubing RED/WHITE 7.23.3 Sensor Re-Installation a. -

Page 126: Figure 7.27 Electronic Partlow Temperature Recorder

7.24 ELECTRONIC PARTLOW TEMPERATURE RECORDER The microprocessor based temperature recorder is designed to interface with the DataCORDER to log tempera- ture with time. The electronic recorder will automatically record the return air, supply air, or both, based on the set- ting of temperature controller configuration code CnF37, refer to. - Page 127 If the power has been OFF for more than thirty days, the recorder will NOT re-synchronize (the chart will not advance to present time), the pen tip will move to the currently recorded temperature, and the recorder will resume normal temperature recording. 7.24.1 Replacing the Recorder a.

- Page 128 Introduction This procedure provides instructions for repair of the Carrier Transicold composite control box. Damage to the con- trol box may be in the form of a chip or hole, a crack, a damaged thread insert or damage to the door hinge inserts.

- Page 129 The threaded brass inserts that are molded into the control box will need to be replaced if the threads become stripped, or if the insert becomes loose. The inserts and epoxy are contained in repair kit, Carrier Transicold part number 76-50084-00 (see Table 7–3).

-

Page 130: Figure 7.28 Door Hinge Repair

Figure 7.28 Door Hinge Repair Materials needed: 1. Cut two square pieces of 3 mm thick (1/8 inch) aluminum or stainless steel approximately 40 mm (1 5/8”) square. These squares will serve as backing plates. 2. Two nuts, bolts (10 - 24 x 1") and washers for each insert that needs repair. a. -

Page 131: Table 7-3 Insert Repair Kit

Table 7–3 Insert Repair Kit ITEM DESCRIPTION PART NUMBER Insert Repair Kit - Includes 76-50084-00 Insert - 17.53 x 9.91 mm (.690 x.390 in) 1/4-20 Threads 34-06231-01 Insert - 15.88 x 6.35 mm (.625 x.250 in) 10-24 Threads 34-06231-03 Insert - 25.15 x 7.54 mm (.990 x.297 in) 10-24 Threads 34-06231-04 Insert - 10.16 x 9.53 mm (.400 x.375 in) 10-24 Threads 34-06231-05... -

Page 132: Figure 7.29 Insert Location

Figure 7.29 Insert Location INSERT PART NUMBERS 34-06231-## WHERE THE ## IS AS INDICATED T-317 7–42... -

Page 133: Figure 7.30 Communications Interface Installation

7.27 COMMUNICATIONS INTERFACE MODULE INSTALLATION Figure 7.30 Communications Interface Installation Communications interface Module Units with communication interface module provision have the required wiring installed. The provision wiring kit (part number 76-00685-00), includes three pre-addressed wires installed between the circuit breaker and commu- nication interface module locations. -

Page 134: Table 7-5 Recommended Bolt Torque Values (Dry, Non-Lubricated For 18-8 Stainless Steel)

Table 7–5 Recommended Bolt Torque Values (Dry, Non-Lubricated for 18-8 Stainless Steel) BOLT DIA. THREADS in-lb ft-lb Free Spinning 5/16 14.9 27.1 7/16 58.3 9/16 77.3 1104 124.7 1488 168.1 Non Free Spinning (Locknuts etc.) 82.5 5/16 145.2 12.1 16.4 22.0 29.8 7/16... -

Page 135: Table 7-7 Required Tools

Table 7–6 Wear Limits For Compressors (Continued) CYLINDERS Bore 2.0010 50.8254 .0020 0.0508 Piston (Diameter) 1.9860 50.4444 .0020 0.0508 Piston Pin (Diameter) 0.6873 17.4574 .0010 0.0254 Piston Ring Gap 0.013 00.3302 0.0050 00.1270 .0250 0.6350 Piston Ring Side Clearance 0.002 00.0508 0.0010 00.0254... -

Page 136: Table 7-8 Compressor Torque Values

Table 7–8 Compressor Torque Values SIZE TORQUE RANGE THREADS DIAMETER USAGE PER INCH ft-lb (inches) 1/16 27 (pipe) 8 - 12 11 - 16 Pipe Plug - Crankshaft 20 (pipe) 6 - 10 8 - 13 Oil Return Check Valve - Crankcase 20 (pipe) 20 - 25 27 - 34... -

Page 137: Table 7-9 R-134A Temperature - Pressure Chart

Table 7–9 R-134a Temperature - Pressure Chart Temperature Vacuum Temperature Pressure °F °C “/hg cm/hg kg/cm °F °C psig kg/cm 14.6 49.4 37.08 0.49 24.5 168.9 1.72 1.69 12.3 41.6 31.25 0.42 26.1 180.0 1.84 1.80 32.8 24.64 0.33 27.8 191.7 1.95 1.92... -

Page 138: Figure 7.31 R-134A Compressor Pressure And Motor Current Curves Vs Ambient Temp (1 Of 2)

Figure 7.31 R-134a Compressor Pressure and Motor Current Curves vs Ambient Temp (1 of 2) Note: Curves to be used as troubleshooting guide only for model series 69NT40 with fresh air makeup vent closed, unit powered on 460 VAC/60hz and SMV 100% open. (Bar) psig (22.0) -

Page 139: Figure 7.32 R-134A Compressor Pressure And Motor Current Curves Vs Ambient Temp (2 Of 2)

Figure 7.32 R-134a Compressor Pressure and Motor Current Curves vs Ambient Temp (2 of 2) (Bar) psig (.97) (.83) (.69) (.55) 35 F (1.7 C) Box (.41) (.28) (.14) 0 F (--17.8 C) Box (- -.14) - -2 (- -.28) - -4 (- -.41) - -6... - Page 140 T-317 7–50...

- Page 141 SECTION 8 ELECTRICAL WIRING SCHEMATICS INTRODUCTION This section contains the Electrical Schematics and Wiring Diagrams. The diagrams are presented as follows: Figure 8.1 – Provides the legend for use with all figures. Figure 8.2 – Provides the schematic diagram for units covered in this manual. Figure 8.3 –...

-

Page 142: Figure 8.1 Legend

Figure 8.1 Legend LEGEND SYMBOL DESCRIPTION (Schematic Location) SYMBOL DESCRIPTION (Schematic Location) AMBS AMBIENT SENSOR (E- -19) HUMIDITY SENSOR (G- -20) BYPASS MODULE (D- -20) HOSE HEATER SAFETY THERMOSTAT (G- -14) CIRCUIT BREAKER - - 460 VOLT (J- -1) HEAT TERMINATION THERMOSTAT (F- -12) CIRCUIT BREAKER - - AUTO TRANSFORMER (D- -1) HUMIDITY WATER HEATER (Figure 8-3) CRANKCASE HEATER (T- -2) -

Page 143: Figure 8.2 Schematic Diagram

Figure 8.2 Schematic Diagram 8–3 T-317... -

Page 144: Figure 8.3 Schematic Diagram - Transfresh And Vent Position Sensors (Vps)

Figure 8.3 Schematic Diagram - TransFRESH and Vent Position Sensors (VPS) SEE FIGURE SEE FIGURE 7--2 7--2 TO KB7 TransFRESH CONTROLLER Upper Air Exchange VPS Lower Air Exchange VPS T-317 8–4... -

Page 145: Figure 8.4 Schematic Diagram, Wiring Diagram - Electronic Partlow Recorder

Figure 8.4 Schematic Diagram, Wiring Diagram - Electronic Partlow Recorder NOTE: STANDARD CONTROLLER JUMPERS: MA3 TO MA7 AND MA9 TO MA11 (SEE Figure 8-2 ) ARE REMOVED IN THIS APPLICATION NOTE: STANDARD CONTROLLER JUMPERS: MA3 TO MA7 AND MA9 TO MA11 (SEE Figure 8-2) ARE REMOVED IN THIS APPLICATION 8–5 T-317... - Page 146 Figure 8.5 Unit Wiring Diagram - 1 of 2 UPPER VPS [DF11] TRC2 TRC1 WIRES TO TR X2: DF--(TFC), P--(TFC), CIB1, GRD, CHA2, RMA, KA12, EFA2, HRA2 & CR8 ECG1 LOWER VPS (ICF MAY BE IN CONTROL BOX) T-317 8–6...

- Page 147 Figure 8.6 Unit Wiring Diagram - 2 of 2 [UVPS1] [UVPS2] [HPRB] NOTE: RM MAY BE OUTSIDE UVPS3 TFC1 CFA1 [RMC] NOTE: WHEN EB, ED, BM OR CFS IS/ARE INSTALLED, WIRE DESTINATIONS CHANGE FROM THE STANDARD. ADDRESSES FOR THE CHANGED DESTINATIONS ARE SHOWN IN BRACKETS “[XXX]”. 8–7 T-317...

- Page 149 Compressor Oil Level 7-15 230 Volt Cable 2-3 Compressor Reassembly 7-14 460 Volt Cable 2-2 Compressor Section 3-3 69NT40-541-200/299 Introduction 2-1 Compressor/Motor Assembly 3-7 Condenser Coil 2-2 Condenser Coils 7-17 Abnormal Noise or Vibration 6-3 Condenser Fan and Motor Assembly 7-18...

- Page 150 Disassemble the Evaporator Fan Assembly 7-24 Interrogator 2-2 Display Module 4-3 Drain Pan Heaters 3-8 Key Pad 4-2 Electrical Data 3-8 Electronic Partlow Temperature Recorder 7-36 Labels 2-3 Emergency Shipboard Refrigerant Charging 7-6 Logging Interval (dCF03) 4-14 Evacuate and Dehydration 7-5 Lower Air (Fresh Air Make Up) 2-3 Evaporator 2-3 Lower Fresh Air Makeup Vent 5-3...

- Page 151 R-134a Temperature - Pressure Chart 7-47 Temperature Control - Frozen Mode 4-8 Refrigerant Charge 3-7 Temperature Control - Perishable Mode 4-5 Refrigerant Leak Checking 7-4 Temperature Readout 2-1 Refrigerant Recovery 7-3 Temperature Recorder 2-2 Refrigeration Circuit 3-10 Temperature Sensor Service 7-33 Refrigeration System Data 3-7 Thermistor Format (dCF04) 4-14 Refrigeration Unit - Front Section 3-1...

- Page 154 Carrier Transicold Division, Carrier Corporation A part of UTC Building & Industrial Systems, a business unit of United P.O. Box 4805 Technologies Corporation. Stock symbol UTX. Syracuse, NY 13221 USA www.carrier.transicold.com...

Need help?

Do you have a question about the 69NT40-541-200 and is the answer not in the manual?

Questions and answers