Summary of Contents for Clarke HUNTER 30

- Page 1 HUNTER 30 HUNTER 30 AIR COMPRESSOR AIR COMPRESSOR OPERATION & MAINTENANCE INSTRUCTIONS © 1011...

-

Page 2: Table Of Contents

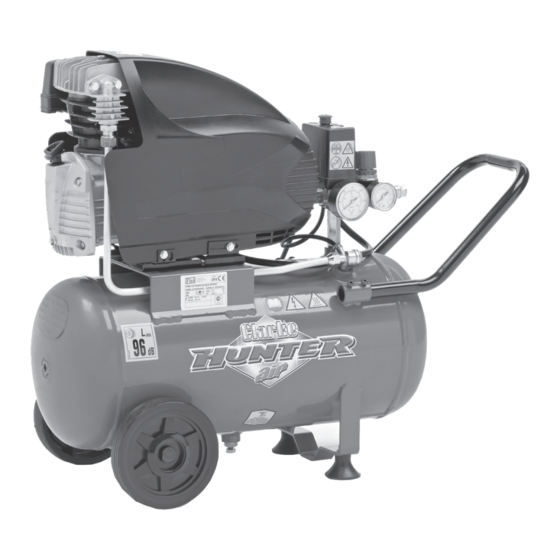

Thank you for purchasing this air compressor which is fitted with a 24 litre air reservoir. Please read this leaflet thoroughly and carefully follow all instructions. In doing so you will ensure the safety of yourself and that of others around you, and you can look forward to the compressor giving you long and satisfactory service. -

Page 3: Safety Precautions

SAFETY PRECAUTIONS WARNING! As with all machinery, there are certain hazards involved with their operation and use. Exercising respect and caution will considerably lessen the risk of personal injury. However, if normal safety precautions are overlooked, or ignored, personal injury to the operator, or damage to property may result. It is in your own interest to read and pay attention to the following rules: WARNING! When using the air compressor, you should follow basic safety precautions... - Page 4 SAFETY PRECAUTIONS TRAINING: Before use, you should be familiar with the instructions in this booklet. In particular, you should pay attention to the procedure for stopping the compressor in an emergency. OPERATE THE AIR COMPRESSOR AT THE CORRECT VOLTAGE: Make sure that the mains supply voltage is the same as the voltage shown on the rating plate.

- Page 5 SAFETY PRECAUTIONS AVOID UNINTENTIONAL STARTING: When connecting to the mains, make sure the red button on top of the air compressor is in the off position. MOVING THE COMPRESSOR: Always move the compressor using the appropriate grips or handles. ADEQUATE VENTILATION: The compressor should only be used in areas with adequate ventilation and should not be exposed to heat, or used near inflammable substances.

- Page 6 SAFETY PRECAUTIONS DO NOT USE THIS COMPRESSOR TO INFLATE SMALL, LOW-PRESSURE OBJECTS: Items such as children’s toys or footballs can explode if over-inflated. ONLY USE RECOMMENDED PARTS: To avoid the risk of bursting, only hoses with a rated pressure of 10 bar, or more should be used. Never attempt to repair faulty hoses.

- Page 7 SAFETY PRECAUTIONS USING THE COMPRESSOR FOR PAINTING: • Do not work in enclosed areas or near naked flames. • Make sure that the area in which you are working has good ventilation. • Protect your nose and mouth with a suitable face mask. •...

-

Page 8: Warning Symbols

WARNING SYMBOLS READ THIS INSTRUCTION BOOKLET CAREFULLY BEFORE POSITIONING, OPERATING OR ADJUSTING THE COMPRESSOR. Risk of electric shock. The compressor must be disconnected from the mains supply before removing any covers. Do not use in a damp environment. Risk of accidental start-up. The compressor could start automatically in the event of a power cut and subsequent reset. -

Page 9: Electrical Connections

ELECTRICAL CONNECTIONS Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply through an approved 13 amp BS 1363 plug, or a suitably fused isolator switch. WARNING! THIS APPLIANCE MUST BE EARTHED IMPORTANT: The wires in the mains lead are coloured in accordance with the following code: Green &... -

Page 10: Parts Identification

PARTS IDENTIFICATION Air Filter Compressed air reservoir On/Off switch (red button) 10 Transportation wheel Main reservoir pressure gauge 11 Motor housing Output pressure regulator 12 Pressure regulator and cut-out Output pressure gauge 13 Oil dipstick Handle 14 Outlet tap Support foot 15 Oil drain screw Drain valve... -

Page 11: Assembly

ASSEMBLY WARNING! Before assembling and using the air compressor, make sure that you have read and understood all of the safety instructions. Installation Take care when lifting the compressor from the packaging. CAUTION! Do not lift the compressor by the pressure regulator and cut-out. Get assistance if necessary. - Page 12 Lift the dipstick out of the oil reservoir. See figure 3. Ensure the oil level is between the min and max marks on the dipstick. See figure 4. • If needed top up the reservoir with Clarke SAE 40 compressor oil, available from your Clarke dealer. Figure 4...

-

Page 13: Preparation For Use

PREPARING FOR USE Before connecting your compressor to the mains supply, check the following:- • The mains voltage is 230V. • The ON/OFF switch is in the OFF (lower) position. • The pressure regulator should be set at its lowest setting, i.e. turned fully anticlockwise. -

Page 14: Operating Instructions

OPERATING INSTRUCTIONS Switching the air compressor ON The compressor will make a continuous loud noise when the tank is charging - this is normal. Lift the red On/Off switch located on top of the pressure regulator and cut- out. • The compressor will charge the main tank to 10 bar (145 psi) then switch off. - Page 15 OPERATING INSTRUCTIONS Switching the air compressor OFF To switch the air compressor off, Close the outlet tap and press down on the on/off button (red button) located on top of the pressure regulator and cut-out. Switch off the mains supply and remove the plug. •...

- Page 16 OPERATING INSTRUCTIONS Draining the reservoir CAUTION! It is important to drain the reservoir before storage. Pressing the red on/off button down to switch the air compressor off and remove the plug from the mains supply. • Place a suitable container beneath the compressor to catch any condensate.

-

Page 17: Routine Maintenance

Daily Check Oil Ensure the oil level is between the min and max marks on the dipstick. See page 12 and top-up if necessary - (use Clarke SAE 40 compressor oil, available from your local dealer). Drain the tank After use, always open the drain valve to ensure that any liquid that may have condensed, is drained off. - Page 18 • Make sure that all bolts are securely tightened. • Clean all the external parts of the compressor. After the first 100 hours use, replace the oil completely using Clarke SAE 40 compressor oil. Then replace the oil after every 500 hours of operation or every 6 months.

-

Page 19: Troubleshooting

TROUBLE SHOOTING With considerate use, your Clarke HUNTER Air Compressor should provide you with long and trouble free service. Routine checks should be made on both the electrical supply as well as on all the compressed air lines and connections. If any fault appears, the reason for which is not immediately obvious, we recommend that you contact your local Clarke dealer. -

Page 20: Specifications

SPECIFICATIONS Electrical Supply ........230 V, 1 Phase 50Hz Max. Operating Pressure ....... 10 bar / 145 psi Motor Rating ........... 2 HP Air Displacement ........8 cuft/min Air Receiver ..........24 litre Net Weight ..........24 kg Dimensions ( L x W x H ) ......710x 307x 590mm Duty Cycle .......... -

Page 21: Parts Diagram

PARTS DIAGRAM... -

Page 22: Parts List

FN116NC0003 AUTO DISCHARGE VALVE FN011000183 SPARE PARTS AND SERVICE For spare parts and service, please contact your nearest dealer, or Clarke International, on one of the following numbers. PARTS & SERVICE TEL: 020 8988 7400 PARTS & SERVICE FAX: 020 8558 3622 or e-mail as follows: PARTS: parts@clarkeinternational.com... -

Page 23: Declaration Of Conformity

DECLARATION OF CONFORMITY...