Table of Contents

Advertisement

Quick Links

OPERATING AND MAINTENANCE

CONTENTS

1.0.

2.0.

TECHNICAL DATA TABLE

3.0.

DEFINITION OF DIAPHRAGM PUMP

4.0.

5.0.

6.0.

INSTRUCTIONS AND MANUAL OF DIAPHRAGM PUMP

7.0.

Attachment-1 Pump Performance Charts

Attachment-2 Gisan Warranty

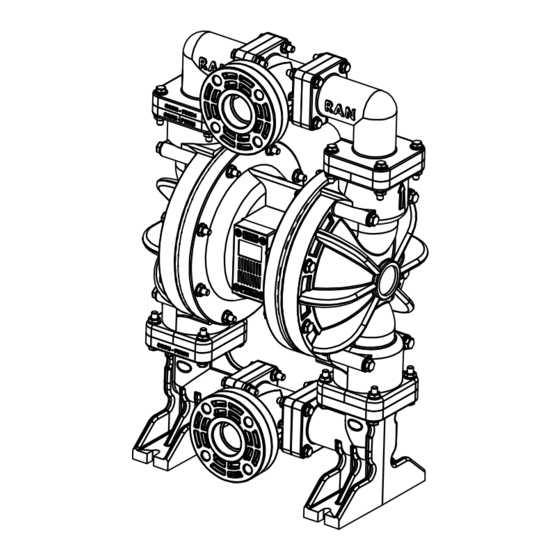

RAN 2" F50-PX MODEL

DIAPHRAGM PUMP

MANUAL

Gisan Machinery Industry and Trade Co. Ltd.

www.ranpump.com

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ranpump F50-PX

-

Page 1: Table Of Contents

RAN 2” F50-PX MODEL DIAPHRAGM PUMP OPERATING AND MAINTENANCE MANUAL CONTENTS 1.0. IMPORTANT SAFETY REQUIREMENTS 2.0. TECHNICAL DATA TABLE 3.0. DEFINITION OF DIAPHRAGM PUMP 4.0. HANDLING, MOVING, OPENING PACKAGE OF DIAPHRAGM PUMP 5.0. MOUNTING AND CONNECTING OF DIAPHRAGM PUMP 6.0. -

Page 2: Important Safety Requirements

1.0. IMPORTANT SAFETY REQUIREMENTS a- This equipment is for professional use only. Observe all warnings. Read and understand all instruction manuals, warning labels, and tags before you operate the equipment. b- CAUTION: This manual contains important instructions and safety cautions on diaphragm pumps. - Page 3 WARNING ! Always wear appropriate clothing and equipment, such as eye protection and breathing apparatus, to protect yourself. WARNING ! Improper handling, splashing in the eyes, ingestion, or bodily contamination of hazardous fluids or inhaling toxic vapors can cause extremely serious injury or death. Observe all the following precautions when handling known or potentially hazardous fluids.

- Page 4 2.0. DIAPHRAGM PUMP TECHNICAL DATA 2’’ POLYPROPYLENE PUMP Description Unit Value 2’’ Polypropylene Pump Type Inch Max. fluid working pressure 8 (0,8 Mpa, 120 Psi) Air feeding pressure range 1- 8 Max. Air consumption m3/min Fluid per cycle ltr/cycle Max. Head (for water viscosity) Max.

- Page 5 RIGHT STROKE MIDDLE STROKE LEFT STROKE Compressed air is directed to When the pressurized At completion of the stroke, the back side of diaphragm B diaphragm, diaphragm B, the air valve again redirects by the air valve. The reaches the limit of its air to the back side of compressed air moves the discharge stroke, the air valve...

- Page 6 3.1.Diaphragm pump has the name plate shown on diagram 1 Figure 1- Pump Name Plate 3.2. Diaphragm pump coding system X X - X X INLET BODY DIAPHRAGM OUTLET MATERIAL MATERIAL B = 1/2” A = Aluminium 0 = Buna- N DIAPHRAGM C = 3/4”...

-

Page 7: Handling, Moving, Opening Package Of Diaphragm Pump

3.4. Diaphragm pump main dimensions Figure 3 – Diaphragm pump main dimensions 4.0. HANDLING, MOVING, OPENING THE PACKAGE OF DIAPHRAGM PUMP Handle the pump from manifolds to lift. 2 and 3 inch pumps must be handled by at least two persons. -

Page 8: Mounting And Connecting Of Diaphragm Pump

5.0. MOUNTING AND CONNECTION OF DIAPHRAGM PUMP A typical setup configuration is shown in figure . Further information and consultation on pump setup can be provided by your Ran Pump distributor. ALWAYS USE ORIGINAL RAN PUMP PARTS AND ACCESSORIES. FAILURE TO DO SO WILL INVALIDATE THE GUARANTEE Pump should fixed firmly to the ground or platform and should be fitted in a perpendicular position as shown in Figure 5. - Page 9 5.2. Tightening the bolts before first use After you unpack the pump, and before you use it for the first time, check and tighten external fasteners. Tighten the fluid cover screws first, then the manifold screws. (Refer to Figure 7 for torque figures).

- Page 10 Figure 8a - Typical installation scheme 5.5. Fluid line 5.5.1. Fluid suction line 1- Use a conductive hose or pipe. 2- Screw fluid fitting into the pump inlet tightly. 3- If the inlet fluid pressure is more than 25% of the outlet working pressure, ball check valves will not close fast enough, result will be inefficient pump operation.

- Page 11 CAUTION ! It is advisable to install a pressure relief system (bypass line)to relieve high levels of pressure that may occur if the pump is pressurised for a long period when not operating. On some uncontrolled systems the back pressure generated from a closed outlet hose can cause the pump to stop or even reverse operation.

- Page 12 5.6. Ventilating exhaust air You must vent the exhaust to a safe place, away from people, animals, food, and all sources of ignition when pumping flammable or hazardous fluids. Note that when there is a tear on the diaphragm, the media in the pump will be exhausted together with the air. To avoid this, exhaust the gas away from the operation environment.

- Page 13 WARNING ! Diaphragm pumps are sold as pump unit only. Installing a control device (if needed) is responsibility of the operator. If the power supply of the pump (compressor) is stopped, the air inlet to the pump must be cut off immediately. Otherwise when compressor restarts, pump may start unexpectedly.

-

Page 14: Assembly And Dismantling Of Parts

6.4. Pressure relief procedure 1- Shut off the air valve. To relieve the air between the air valve and the pump, use the Air Pressure Discharge Valve. 2- Shut off the Fluid Valve. Place a container under the Fluid Pressure Discharge Valve and open the valve. - Page 15 7.2. Changing the diaphragms Tools Required - Lithium-base grease (non-freezing silicone grease) - 17 mm wrench - 15 mm wrench - 32 mm wrench - Torque wrench WARNING! Transferred liquid enters air chamber of pump when the diaphragm ruptures. Liquid can damage the pilot valve o-rings and the air valve o-rings due to its chemical behaviour.

- Page 16 7.3 Air valve repair Tools Required - 6 mm allen key - Philips-head screwdriver - Lithium-base grease (non-freezing silicone grease) NOTE: Hold the air valve in a vertical position. If the core is sliding with its own weight in the valve body, valve z-rings must be changed.

-

Page 17: Periodic Maintenance

8.0 PERIODIC MAINTENANCE 8.1 Cleaning and storage of the pump Do not let your fluid dry in the pump or in the hoses. It may harm the pump. Clean the pump regularly by pumping a suitable solvent for your fluid until the pump is cleaned. Make sure the fluids you are using are compatible with your diaphragm material. - Page 18 8.6 Troubleshooting PROBLEM CAUSE SOLUTION 1- Pump cycles at Worn check valve balls, seats or o- stall or fails to hold Replace. rings. pressure at stall. Disassamble and clean air valve. Air valve is stuck or dirty. Use ONLY filtered air. Check valve ball severely worn and Replace ball and seat.

-

Page 19: Storage Of Diaphragm Pump

Fax: 00 90 212 875 03 18 Address: Birlik Sanayi sit. 3. Cadde No: 83 Beylikdüzü İstanbul E-mail / Web : info@ranpump.com / www.ranpump.com CAUTION : PUMPS RETURNED TO GISAN FOR SERVICING. THE PUMP SHOULD BE THOROUGHLY CLEANED AND EMPTY AND PACKAGED SECURELY AND SAFELY TO PROTECT PEOPLE AND THE ENVIRONMENT. -

Page 20: Ordering Spare Parts

12.0 ORDERING SPARE PARTS No spare parts supplied with the diaphragm pump. Contact us using above method to order. CODE PARTS CODE PARTS F1051 Center section F1952 Limitation (PTFE Pump) F1251 Shaft seat Flange O-ring F1152 Shaft seat O-ring F1651 Diaphragm flange Back up diaphragm (PTFE Pump) F1151 Shaft O-ring... - Page 21 Figure 13a: Pump assembly scheme for RAN 2”.

- Page 22 ATTACHMENT-1 2" DIAPHRAGM PUMP PERFORMANCE CHARTS *Reduce the flow rate by 20% if there are Teflon diaphragms on your pump.

- Page 23 Gisan Makine San. Tic. Ltd. Şti. Birlik Sanayi Sitesi 3. Cadde No: 83 Beylikdüzü Istanbul Turkey Tel. : 00 90 212 875 03 17 (pbx) Faks:00 90212 875 03 18 E-mail / Web : info@ranpump.com / www.ranpump.com...

- Page 24 Gisan Makine San. Tic. Ltd. Şti. Birlik Sanayi Sitesi 3. Cadde No: 83 Beylikdüzü Istanbul Turkey Tel. : 00 90 212 875 03 17 (pbx) Faks:00 90212 875 03 18 E-mail / Web : info@ranpump.com / www.ranpump.com 25082012...

Need help?

Do you have a question about the F50-PX and is the answer not in the manual?

Questions and answers