Table of Contents

Summary of Contents for BLACKMER V Series

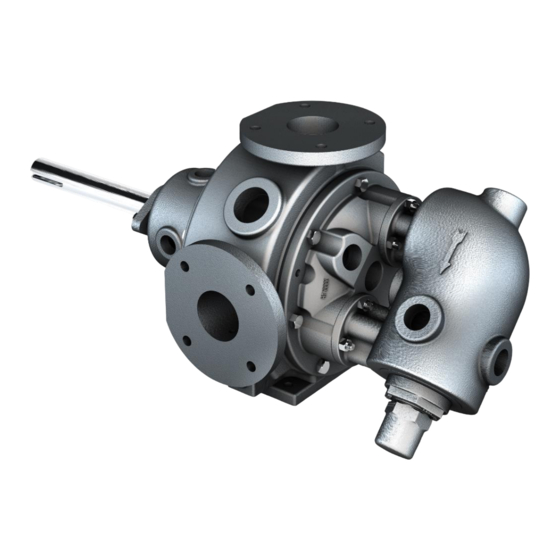

- Page 1 960702 BLACKMER GEAR PUMP INSTRUCTIONS NO. 1903-a00 Section 1903 INSTALLATION OPERATION AND MAINTENANCE INSTRUCTIONS Effective October 2022 MODELS: V-SERIES Replaces September 2022 V Series Internal Gear Pumps Where Innovation Flows 1903-a00...

- Page 2 Blackmer Gear Pumps are covered by one or more of the following patents: U.S. Patent Nos. 7549205, 7137793, 7183683, 8,608,465B2 Australian Patent No. AU2005233534B2; Korean Patent No. 10-2006- 7023162;...

-

Page 3: Table Of Contents

Table of Contents SECTION 1 CAUTIONS—READ FIRST! ......................4 SECTION 2 PUMP DESIGNATION SYSTEM ....................5 SECTION 3 HOW IT WORKS—INTERNAL GEAR TECHNOLOGY ............. 8 SECTION 4 SUGGESTED INSTALLATION & OPERATION ..............9 SECTION 5 MAINTENANCE ..........................12 SECTION 6 DISASSEMBLY .......................... -

Page 4: Cautions-Read First

CAUTION: Prevention of static sparking – If static sparking occurs, fire or explosion could result. Pump, valves and CAUTION: When selecting a V Series pump for an containers must be grounded to a proper grounding point application, you must first ensure that the pump components when handling flammable fluids and whenever discharge of are compatible with the process media. -

Page 5: Pump Designation System

S E C T I O N 2 Pump Designation System EXAMPLE: V2-254WDA/4ART/BPGNA/N/CHN/000 EXTERNAL INTERNAL SEAL TYPE / SEAL JACKET SPECIALTY MODEL CLEARANCE PORTS ORIENTATION BUSHINGS RELIEF VALVE MATERIAL MATERIAL MATERIAL FACES OPTIONS CODE N = NO RELIEF 2.5A VALVE MATERIAL CODES MODELS BUSHINGS... - Page 6 EXAMPLE: CXXXX_BSDCSXXX_GYYYYRZZ_MXXXZHPYYYY_ZZZV XXHz_AAA/B/WEG V2-254WDA/4ART/BPGNA/N/CHN/000 CERT BASEPLATE GEAR CERTIFIED BASEPLATE GEARBOX MOTOR MOTOR MOTOR MOTOR MOTOR MATERIAL PERFORMANCE BASEPLATE REDUCER MOTOR MOTOR INVERTER HYDRO LENGTH FRAME FRAME SPEED FREQ. ENCLOSURE CERT CERT TESTS SELECTED VOLTAGE DUTY TEST SIZE (RPM) (Hz) RATING CODE RATIO BSDCS...

- Page 7 102 (450) 5.2 (75) >20 cSt 232° (450°) Maximum pressure listed reflects maximum differential pressure and maximum allowable working pressure. Values listed in table are nominal and for reference only. To ensure proper pump selection, always refer to Blackmer CHOICE 1903-a00...

-

Page 8: How It Works-Internal Gear Technology

How It Works—Internal Gear Technology The V SERIES GEAR PUMP is a rotating, positive displacement pump. These drawings show the flow pattern through the pump upon its initial rotation. It is assumed that the pump has no fluid in it prior to its initial rotation. -

Page 9: Suggested Installation & Operation

Suggested Installation and Operation V Series gear pumps are designed to meet the performance requirements of even the most demanding pumping applications. They have been designed and manufactured to the highest standards and are available in a number of different sizes to meet your pumping needs. - Page 10 V Series gear pumps are positive displacement pumps; as such, care must be used in protecting piping and components used in your system. Pumps equipped with an internal relief valve are designed to protect the pump only. A system relief valve should be installed along with the pump's internal relief valve.

- Page 11 PRESSURE RELIEF VALVES • V Series pumps are positive displacement pumps, which means the system must have provisions for pressure relief protection, such as a relief valve mounted directly on the pump or inline with the system. Alternatively, the system can be installed with a torque-limiting device or a rupture disk.

-

Page 12: Maintenance

Maintenance GENERAL MAINTENANCE CLEANING: V Series pumps must be maintained and kept as clean as possible. This will allow for quick inspection, adjustment and repair work. LUBRICATION: Use multi-purpose NLGI #2 grease on all lubrication fittings every 500 hours of operation. Do not over-grease. - Page 13 CARTRIDGE TRIPLE-LIP SEAL MAINTENANCE Blackmer offers a cartridge triple-lip seal as an alternative for packing. The seal comes pre-lubricated with Magnalube high- temperature grease. Do not remove the plugs from the gland or attempt to install flush lines because this could cause the grease to be lost.

-

Page 14: Disassembly

S E C T I O N 6 Disassembly WET END DISASSEMBLY Remove the screws that hold the head to the casing. Remove the head from the pump using either jacking screws or prying bar. WARNING: Protect the idler gear from falling as it may become loose during removal of the head. -

Page 15: Reassembly

S E C T I O N 7 Reassembly WET END ASSEMBLY Clean all parts thoroughly before assembly. Install the RBS bushing. If the bushing has a lubrication groove, install the bushing with lubrication groove facing towards the bottom of the RBS. If applicable, align the radial lubrication hole on the bushing with a grease hole on the RBS. For 55, 133 and 254 size pumps, attach the rear plate and gasket to the case. - Page 16 TABLE A – HEAD GASKET SETS Pump Models Starting Gasket Set Gasket Set Provided V2-55 1 - .006”, 1 - .015” 2 - .006”, 1 - .015” V2-133, 254 & 423 1 - .006”, 1 - .015” 1 - .006”, 2 - .015” TABLE B –...

-

Page 17: Troubleshooting

S E C T I O N 8 Troubleshooting PUMP RUNS, BUT LITTLE PRODUCT FLOWS • Pump speed is too slow. • Suction piping strainer is too small or obstructed. • Suction pipe or port is not immersed deep enough within the liquid. •... - Page 18 Notes 1903-a00...

-

Page 19: Warranty

Since the use of Blackmer Internal Gear Pump equipment is beyond our control, we cannot guarantee the suitability of any internal gear pump or part for a particular application and Blackmer shall not be liable for any consequential damage or expense arising from the use or misuse of its products on any application. - Page 20 PSG Grand Rapids 1809 Century Avenue SW Grand Rapids, MI 49503 USA P: +1 (616) 241-1611 • F: +1 (616) 241-3752 info@blackmer.com blackmer.com Where Innovation Flows reserves right to modify information and illustrations contained this document without prior notice. This is non-contractual document.

Need help?

Do you have a question about the V Series and is the answer not in the manual?

Questions and answers