Summary of Contents for Riello 40 G5X C

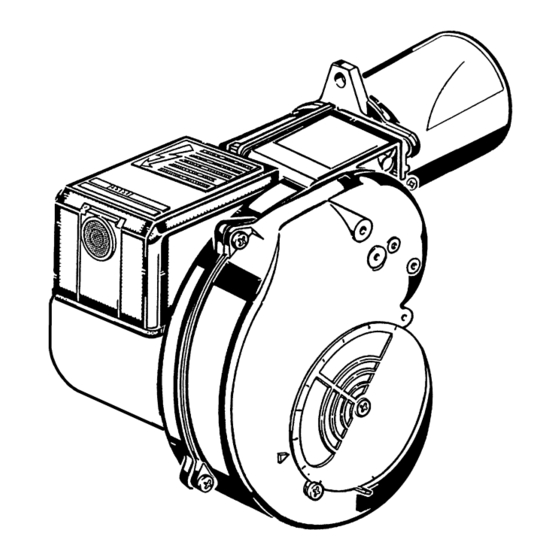

- Page 1 Installation, use and maintenance instructions Kerosene and Gas oil burner One stage operation CODE MODEL TYPE 20039832 RIELLO 40 G5X C 448T54 20040210 (6) - 08/2022...

- Page 2 Original instructions...

-

Page 3: Table Of Contents

Contents Information and general warnings............................3 Information about the instruction manual........................3 1.1.1 Introduction ..................................3 1.1.2 General dangers ................................3 1.1.3 Danger: live components ..............................3 Guarantee and responsibility ............................4 Guidance for the use of bio fuel blends up to 10% where gas oil use is permitted by the appliance Manufacturer ..4 1.3.1 Information and general instructions.......................... - Page 4 Contents 8.2.1 Maintenance frequency ..............................20 8.2.2 Checking and cleaning ..............................20 8.2.3 Safety components................................21 Faults / Solutions ..................................22 20040210...

-

Page 5: Information And General Warnings

Information and general warnings Information and general warnings Information about the instruction manual 1.1.1 Introduction 1.1.3 Danger: live components The instruction manual supplied with the burner: This symbol indicates operations which, if not car- is an integral and essential part of the product and must not ried out correctly, lead to electric shocks with le- be separated from it;... -

Page 6: Guarantee And Responsibility

All components within the hydraulic circuit suitable for manual, operating negligence, incorrect installa- bio fuel use and supplied by Riello will be identified as Bio com- tion and carrying out of non authorised modifica- patible. No warranty is given in relation to the use of components... -

Page 7: Information And General Instructions

If this is not completed then due to the hydro- In no event shall Riello (and its subsidiaries) be liable for any in- scopic nature of Bio fuel, it will effectively clean the tank,... -

Page 8: Safety And Prevention

Safety and prevention Safety and prevention Introduction The burners have been designed and built in compliance with the type and pressure of the fuel, the voltage and frequency of the current regulations and directives, applying the known technical electrical power supply, the minimum and maximum deliveries for rules of safety and envisaging all the potential danger situations. -

Page 9: Technical Description Of The Burner

In case of use with gas oil containing up to 10% Screw with two nuts for flange..........No. 1 Bio blend, it will be essential to use flexible oil lines and hydraulic jack suitable for bio fuel use. Please contact Riello for further information. 20040210... -

Page 10: Burner Dimensions

Technical description of the burner Burner dimensions Flange Burner D4586 Fig. 2 Firing rate The MAXIMUM OUTPUT is chosen from within the diagram area The work point may be found by plotting a vertical line from the (Fig. 3). desired delivery and a horizontal line from the pressure in the combustion chamber. -

Page 11: Installation

Installation Installation Notes on safety for the installation After carefully cleaning all around the area where the burner will The installation of the burner must be carried out be installed, and arranging the correct lighting of the environ- by qualified personnel, as indicated in this manual ment, proceed with the installation operations. -

Page 12: Installer/Servicer Notes For The Use Of Gas Oil With Bio Blends Up To 10% Where Gas Oil Use Is Permitted By The Appliance Manufacturer

The burner hydraulic components and flexible oil lines must burner technical manual). be suitable for bio fuel use (check with Riello if in doubt). If a Bio blend is in use the installer must seek information Riello have carefully chosen the specification of the bio com-... -

Page 13: Securing The Burner To The Boiler

Installation Securing the burner to the boiler Put on the flange 1)(Fig. 6) the screw 2) and two nuts 3). It is necessary that the insulating gasket 5)(Fig. 9) is placed between the boiler door and the burner flange. If necessary, the insulating gasket can be modified as shown in Fig. -

Page 14: Hydraulic Systems

Bio blend, it will be essential to use flexible oil lines suitable for bio fuel use. WARNING Please contact Riello for further information. It is strongly recommended a periodic check of the pump pressure operation (annually or better every six months, if the burner operation is contin- uous). -

Page 15: One Pipe System

Usually the tank is lower than the burner. You are advised to use additional filters on the fuel supply line. Riello recommends a good quality fuel filter at the CAUTION tank (Fig. 11 - Fig. 12) and a secondary filter (60 ... -

Page 16: Two Pipe System

You are advised to use additional filters on the fuel supply line. Riello recommends a good quality fuel filter at the CAUTION tank (Fig. 13) and a secondary filter (60 for gas oil and 15 for kerosene) are used to protect the burner pump and nozzle from contamination. -

Page 17: Electrical System

Electrical system Electrical system Notes on safety for the electrical wiring The electrical wiring must be carried out with the electrical supply disconnected. Electrical wiring must be carried out by qualified personnel and in compliance with the regulations currently in force in the country of destination. -

Page 18: Electrical Wiring

Electrical system Electrical wiring 50Hz - 230V Main switch TO BE COMPLETED BY THE INSTALLER Fuse T6A Limit thermostat Safety thermostat Burner-earth Remote lock-out signal (230V - 0.5A max.) CARRIED-OUT IN THE FACTORY Oil valve Black Motor Capacitor D5228 Fig. 14 ... -

Page 19: Start-Up, Calibration And Operation Of The Burner

Start-up, calibration and operation of the burner Start-up, calibration and operation of the burner Notes on safety for the first start-up The first start-up of the burner must be carried out Check the correct working of the adjustment, com- by qualified personnel, as indicated in this manual mand and safety devices. -

Page 20: Pump Pressure

Start-up, calibration and operation of the burner 7.4.1 Nozzles recommended Angle 60°: in most cases. Angle 80°: in case of flame detachment, during ignitions at low Monarch type R - NS temperatures. Delavan type W - A - E - B Steinen type H - Q For 0.85 - 1.00 - 1.10 GPH nozzle it is advisable to use, if pos-... -

Page 21: Burner Start-Up Cycle

Start-up, calibration and operation of the burner Burner start-up cycle Normal Lock-out due to failure to light Thermostat Motor Ignition transformer Valve Flame Lock-out lamp D5229 ~ 5s ~ 12s ~ 12s Fig. 18 20040210... -

Page 22: Maintenance

Check for excess wear or loose screws and clean the outside of lines suitable for bio fuel use. the burner. Please contact Riello for further information. Electrodes Any contact with elements such solvents, thinners Check the correct position of electrodes. -

Page 23: Safety Components

Maintenance Combustion 8.2.3 Safety components The safety components must be replaced at the end of their life In case the combustion values found at the beginning of the inter- cycle indicated in Tab. G. The specified life cycles do not refer to vention do not respect the standards in force or, in any case, do the warranty terms indicated in the delivery or payment not correspond to a proper combustion, contact the Technical As-... -

Page 24: Faults / Solutions

Faults / Solutions Faults / Solutions Here below you can find some causes and the possible solutions When lock out lamp lights the burner will attempt to light only after for some problems that could cause a failure to start or incorrect pushing the reset button. - Page 28 RIELLO S.p.A. I-37045 Legnago (VR) Tel.: +39.0442.630111 http:// www.riello.it http:// www.riello.com Subject to modifications...

Need help?

Do you have a question about the 40 G5X C and is the answer not in the manual?

Questions and answers