Table of Contents

Advertisement

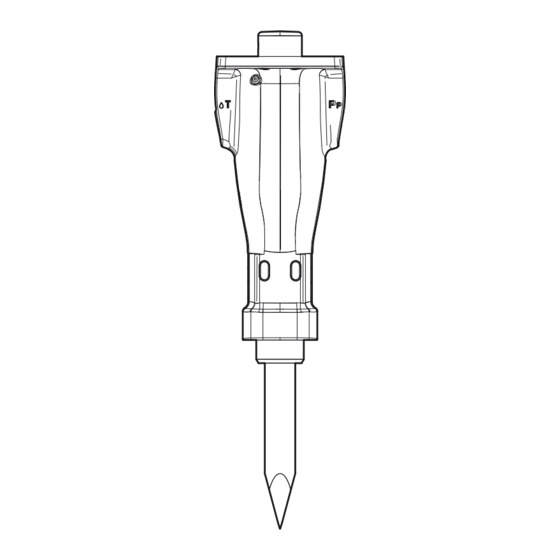

SBU

160, 220, 340

Safety and operating instructions

Hydraulic breakers

Interactive and updated spare part catalogues go to:

www.epiroc.com/docmine

For log in details please contact your local Epiroc office or dealer in your area

Static PDF spare part catalogues go to:

www.podshop.se/epiroc

© Construction Tools PC AB | 9800 0908 01 | 2023-05-12

Original Instructions

Advertisement

Table of Contents

Summary of Contents for Epiroc SBU 160

- Page 1 Hydraulic breakers Interactive and updated spare part catalogues go to: www.epiroc.com/docmine For log in details please contact your local Epiroc office or dealer in your area Static PDF spare part catalogues go to: www.podshop.se/epiroc © Construction Tools PC AB | 9800 0908 01 | 2023-05-12...

-

Page 3: Table Of Contents

Contents Table of Contents 1 Introduction .......................... 5 About the Safety and operating instructions.................... 5 2 Safety instructions ........................ 5 Signal words ............................... 5 Qualification ................................ 6 Intended use................................ 6 Use other than intended............................. 6 Personal protective equipment ......................... 6 Drugs, alcohol or medication .......................... - Page 4 11.2 Capacities................................ 25 11.3 Noise declaration statement.......................... 26 11.4 Flow diagrams for the correct operating pressure.................. 27 11.4.1 SBU 160: 100–150 bar............................ 27 11.4.2 SBU 220: 100–150 bar............................ 28 11.4.3 SBU 340: 100–150 bar............................ 28 12 EC Declaration of Conformity.................... 29 12.1 EC Declaration of Conformity (EC Directive 2006/42/EC) ................

-

Page 5: Introduction

Safety and operating instructions 1 Introduction 2 Safety instructions Epiroc is a leading productivity partner for the mining, in- To reduce the risk of serious injury or death to yourself frastructure and natural resources industries. With cut- or others, read and understand the Safety and operating... -

Page 6: Qualification

Safety and operating instructions 2.2 Qualification 2.4 Use other than intended Transporting the hydraulic attachment is only permitted Never operate the hydraulic breaker in an environment if carried out by people who: where there is a risk of explosions. Explosions will result in serious injury or death. -

Page 7: Installation, Precautions

Safety and operating instructions Carriers without sufficient load capacity will not provide 2.8.2 Assembly or disassembly the required degree of stability and could even fall over WARNING Moving parts during hydraulic breaker use, causing injury and dam- age. Risk for leaking oil and personal injury, such as crushed hands and fingers. - Page 8 Safety and operating instructions u Wash your hands and face thoroughly as soon as Some dusts and fumes created by drilling, breaking, hammering, sawing, grinding and other construction ac- possible upon leaving the exposure area, and always tivities contain substances known to the State of Califor- before eating, drinking, using tobacco products, or nia and other authorities to cause respiratory disease, making contact with other persons.

-

Page 9: Maintenance, Precautions

Safety and operating instructions ate high velocity projectiles that can cause bodily injury. WARNING Machine modification In addition, objects falling from a height can cause bodily Any machine modification may result in bodily injuries to injury. To reduce risks: yourself or others. u Close off the working area. -

Page 10: Overview

Safety and operating instructions 3 Overview To reduce the risk of serious injury or death to your- self or others, read the Safety instructions section found on the previous pages of this manual before operating the machine. 3.1 Design and function SBU is a range of rig mounted hydraulic breakers de- signed for all kinds of demolition works. -

Page 11: Noise Level Label

Safety and operating instructions A. Machine type NOTICE Only certified personnel are allowed to work with the accumulator. B. Maximum hydraulic oil pressure C. Serial number D. The warning symbol together with the book symbol 3.4 Guarantee means that the user must read the safety and oper- ating instructions before the machine is used for the The guarantee or product liability will be invalidated by first time. -

Page 12: Transport

4.3 Transport using a lorry Symbol Put the hydraulic breaker on an anti-slip mat at the lorry. Secure the machine to the loading surface with straps. SBU 160 G ¼ in. G ¼ in. G ¾ in. Observe all the applicable national and regional regula- SBU 220 G ¼... -

Page 13: Hydraulic Oil

This is to make sure that the hydraulic oil is clean. Use the same routine when changing a hydraulic oil Symbol hose. 1. Connect the pressure and return hose. SBU 160 G ¼ in. G ½ in. G ¼ in. SBU 220 G ¼... - Page 14 2. Carefully lower the stick of the boom into the adapter. Adapter plate Tightening torque WARNING Moving parts can crush and cut SBU 160 170 Nm (125 ft lbs) u Never check bores or passages with hands or fin- gers.

-

Page 15: Pressure Adjustment

Safety and operating instructions When connecting water flushing the plug in the front of 5.4 Pressure adjustment the breaker must be exchanged with a water nozzle. See The hydraulic breaker is equipped with a pressure relief the Spare parts list for ordering a new water nozzle. valve which secures the breaker. - Page 16 Safety and operating instructions 1. Shut the carrier's engine off. NOTICE When mounting a new working tool, it is es- pecially important to lubricate plentifully. 2. Dismount the working tool, use a lifting strap to re- duce the risk of personal injury. 5.

-

Page 17: Operation

Safety and operating instructions The oil temperature in the hydraulic attachment must be 6 Operation between 0 °C (32 °F) and +80 °C (176 °F) when operat- ing the breaker. WARNING Risk of explosion The full capacity of the hydraulic attachment can be If the hydraulic attachment is equipped with HATCON achieved when the oil temperature is approx. - Page 18 Safety and operating instructions n Direct the hydraulic breaker in a position 90° towards the object. n Use the correct feed pressure. When the feed pres- sure is correct the hydraulic breaker is working at its best and the vibrations are at a minimum. Also the wear on the bushing and inserted tool is kept to a minimum.

-

Page 19: Breaking Under Water

Safety and operating instructions 6.2.3 Breaking under water Hydraulic breakers can be used for operating under wa- n The hydraulic breaker or the working tool is not to be ter. used as a lifting device. When lifting heavy compo- nents use the hook on the carrier arm. 1.5-2 NOTICE When operating under water the hydraulic breaker must be fed with compressed air to keep the... -

Page 20: Maintenance

Dispose of the water in accordance with the applica- high temperatures a standard type of grease will melt ble regulations to avoid environmental hazards. and run. To avoid this always use Epiroc chisel paste. 7.2 Every second hour 7.2.2 Central lubrication system We recommend Epiroc's central lubrication system. -

Page 21: Wear Limits

Overhauling must be done after one year of continuous A mm (in.) B mm (in.) operation. Overhauling must for safety reasons be per- formed by authorised personnel at an authorised work- SBU 160 52 (2.0) 48 (1.9) shop. SBU 220 68 (2.7) -

Page 22: Storage

The following measures are required to prevent prema- ture hydraulic breaker failure, after it has been stored for over twelve months: n Contact the Epiroc Customer Center / Dealer in your area. n Professionals trained by Construction Tools will dis- assemble the hydraulic breaker properly and: –... -

Page 23: Troubleshooting

Safety and operating instructions 10 Troubleshooting 10.1 Hydraulic breaker does not start Cause Remedy Pressure and tank hoses are Check that the connections of the pressure and tank Carrier driver mixed up. hoses are correct.See section "Hoses and connection". Shut off valve in pressure and/or Check the shut off valve and open it. -

Page 24: Operating Temperature Too High

Safety and operating instructions Cause Remedy Inside diameter of tank hose too Check the inside diameter and change if necessary. Workshop small. Observe the minimum inside diameter! See section "Hoses and connections". Return pressure too high. Check and lower the return pressure. Customer Center/ Dealer in your area Hydraulic oil temperature in the... -

Page 25: Technical Data

Safety and operating instructions 11 Technical data 11.1 Machine data SBU 160 SBU 220 SBU 340 Service weight, kg (lb) 160 (360) 225 (494) 330 (725) Delivery weight, kg (lb) 132 (290) 177 (390) 248 (547) Suitable carrier weight class, t (lbs) 2.2-5.0... -

Page 26: Noise Declaration Statement

Safety and operating instructions 11.3 Noise declaration statement SBU 160 SBU 220 SBU 340 Sound pressure dB(A) Sound power dB(A) Sound pressure level according to EN ISO 3744 in accordance with directive 2000/14/EC at 10 metres distance. Guaranteed sound power according to EN ISO 3744 in accordance with directive 2000/14/EC inclusive spread in pro- duction. -

Page 27: Flow Diagrams For The Correct Operating Pressure

The carrier’s oil flow can be restricted to achieve the right operating pressure. Restrictors can be ordered from the spare parts list. The diagrams show oil flow at viscosity 32 cSt. 11.4.1 SBU 160: 100–150 bar The flow diagram is valid for applications with back pressure up to 10 bar. For applications where the back pressure ex- ceeds 10 bar, a restrictor must be chosen regarding the working pressure in each specific case. -

Page 28: Sbu 220: 100-150 Bar

Safety and operating instructions 11.4.2 SBU 220: 100–150 bar The flow diagram is valid for applications with back pressure up to 10 bar. For applications where the back pressure ex- ceeds 10 bar, a restrictor must be chosen regarding the working pressure in each specific case. In these cases, apart from the restrictors specified in the flow diagram below, it is possible to choose a Restrictor with Ø... -

Page 29: Ec Declaration Of Conformity

2006/42/EC (Machinery Directive) and 2000/14/EC (Noise Directive). Hydraulic breaker Guaranteed sound Measured sound Pmax (bar) Weight (kg) power level [dB(A)] power level [dB(A)] SBU 160 SBU 220 SBU 340 Technical Documentation authorised representative: Olof Östensson Construction Tools PC AB Dragonvägen 2 Kalmar... - Page 32 Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers, and drawings. epiroc.com...

Need help?

Do you have a question about the SBU 160 and is the answer not in the manual?

Questions and answers