Subscribe to Our Youtube Channel

Summary of Contents for Epiroc SBU 220

- Page 1 160, 220, 340 Safety and operating instructions Hydraulic breakers © Construction Tools PC AB | 9800 0908 01 | 2018-04-11 Original instructions...

-

Page 3: Table Of Contents

SBU 160, 220, 340 Contents Contents Introduction ..............................5 About the Safety and operating instructions ....................5 Safety instructions ............................5 Safety signal words ..........................5 Personal precautions and qualifications ....................5 Transport ............................... 5 Installation, storage, maintenance and disposal ..................5 Operation ............................... - Page 4 Noise declaration statement ........................24 Flow diagrams for the correct operating pressure ................25 SBU 160: 100–150 bar ........................25 SBU 220: 100–150 bar ........................26 SBU 340: 100–150 bar ........................26 EC Declaration of Conformity ........................27 EC Declaration of Conformity (EC Directive 2006/42/EC) ..............27 ©...

-

Page 5: Introduction

Introduction will result in death or serious injury. WARNING Indicates a hazardous Epiroc is a leading productivity partner for the situation which, if not avoided, could result in death or mining, infrastructure and natural resources serious injury. industries. With cutting-edge technology, Epiroc... -

Page 6: Testing

Safety and operating instructions SBU 160, 220, 340 Testing Installation, precautions Testing of the hydraulic installation must only be carried out by professional technicians. The Hydraulic system technicians must be authorised to approve a hydraulic installation in accordance with national directives. -

Page 7: Operation, Precautions

SBU 160, 220, 340 Safety and operating instructions Never check bores or passages with hands or ► WARNING Dust and fume hazard fingers. Dusts and/or fumes generated or dispersed when Any boom movements must only be done in ► using the machine may cause serious and cooperation with the personnel mounting the permanent respiratory disease, illness, or other hydraulic breaker. -

Page 8: Maintenance, Precautions

Safety and operating instructions SBU 160, 220, 340 instructions. Incorrect selection or lack of WARNING Projectiles maintenance of consumables/ inserted tools/ Failure of the work piece, of accessories, or even other accessories may cause an unnecessary of the hydraulic breaker itself may generate high increase in dust or fumes. -

Page 9: Storage, Precautions

SBU 160, 220, 340 Safety and operating instructions Storage, precautions Installation of a start circuit on the hydraulic ► breaker must be made in a way that avoids any unintentional starts. WARNING Heavy hydraulic breaker and A foot pedal on the carrier must be equipped ►... -

Page 10: Overview

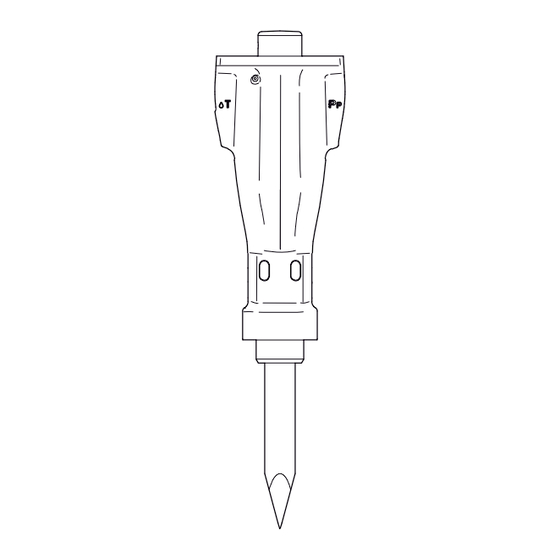

Safety and operating instructions SBU 160, 220, 340 Overview To reduce the risk of serious injury or death to yourself or others, read the Safety instructions section found on the previous pages of this manual before operating the machine. Design and function SBU is a range of rig mounted hydraulic breakers designed for all kinds of demolition work. -

Page 11: Noise Level Label

SBU 160, 220, 340 Safety and operating instructions B. Maximum hydraulic pressure Guarantee C. Serial number D. The warning symbol together with the book The guarantee or product liability will be symbol means that the user must read the invalidated by the following: safety and operating instructions before the Use other than intended •... -

Page 12: Transport Using A Lorry

Put the hydraulic breaker on an anti-slip mat at the lorry. Secure the machine to the loading surface with straps. SBU 160 ⁄ ⁄ ⁄ Observe all the applicable national and regional SBU 220 ⁄ ⁄ ⁄ regulations on securing loads. SBU 340 ⁄ ⁄... -

Page 13: Assembly

2. Place the adapter plate on the hydraulic breaker. Assembly 3. If the NYLOK BLUE PATCH (Known as Tuf- Lok® in Europe) screws from Epiroc are not available we recommend using NORD-LOCK® Circulate the hydraulic oil before connecting the washers under bolts and nuts. -

Page 14: Pressure Adjustment

Safety and operating instructions SBU 160, 220, 340 Pressure adjustment The hydraulic breaker is equipped with a pressure relief valve which secures the breaker. The operating pressure of the machine (max 150 bar) is checked and adjusted by a pressure gauge while operating the hydraulic breaker. -

Page 15: Working Tool

SBU 160, 220, 340 Safety and operating instructions Use a ¼ in. hydraulic hose with a JIC connection as a proper water hose. Contact your nearest authorised workshop for further instructions. NOTICE It is recommended to use water flushing to reduce the wear on the hydraulic breaker during tunnel and dust-intensive applications. -

Page 16: Operation

Safety and operating instructions SBU 160, 220, 340 CAUTION Temperature hazard The hydraulic breaker and the hydraulic oil system of the carrier can be damaged if the hydraulic breaker is used at higher or lower temperatures. Only start the hydraulic breaker when the ►... -

Page 17: Operating

SBU 160, 220, 340 Safety and operating instructions ◆ Operating Start near the edge and work your way in towards the middle. Never start in the middle of large objects. Risk area Before starting the hydraulic breaker, make sure that no persons are in the risk area, 20 meters both horizontally and vertically from the hydraulic breaker. -

Page 18: Breaking Under Water

Safety and operating instructions SBU 160, 220, 340 ◆ Never use the hydraulic breaker as a sledge hammer to demolish material. ◆ Avoid idling strokes; it causes wear on both working tool and tool retainers. ◆ Never use the hydraulic breaker to move debris. -

Page 19: Special Applications

To avoid this always use Epiroc chisel paste. © Construction Tools PC AB | 9800 0908 01 | 2018-04-11... -

Page 20: Central Lubrication System

Central lubrication system The working tool may never be sharpened by forging. Sharpening must only be performed by We recommend Epiroc's central lubrication milling, grinding, or turning. system. When this system is fitted on the carrier, grease is pumped continuously from a lubrication... -

Page 21: Every Year

SBU 160, 220, 340 Safety and operating instructions Every year Overhauling must be done after one year of continuous operation. Overhauling must for safety reasons be performed by authorised personnel at an authorised workshop. Storage WARNING Hydraulic breaker and working tool are heavy If the breaker or working tool topple over or fall down it can result in material damage and personal... -

Page 22: Troubleshooting

Safety and operating instructions SBU 160, 220, 340 Troubleshooting Hydraulic breaker does not start Cause Remedy Pressure and tank hoses are mixed up. Check that the connections of the pressure and tank Carrier driver hoses are correct. See section "Hoses and connection". Shut off valve in pressure and/or tank Check the shut off valve and open it. -

Page 23: Hydraulic Breaker Operates Too Slow

SBU 160, 220, 340 Safety and operating instructions Hydraulic breaker operates too slow Cause Remedy Insufficient hydraulic oil delivery volume. Check the engine speed and/or mode stage of the carrier Carrier driver and the operation pressure and adjust. Check the carrier's pressure and the size of the restrictor. Valve in pressure and/or tank hoses partly Check the valve and open. -

Page 24: Technical Data

Safety and operating instructions SBU 160, 220, 340 Technical data Machine data SBU 160 SBU 220 SBU 340 Part number 8460 0300 45 8460 0300 55 8460 0300 65 Service weight, kg (lb) 160 (360) 225 (494) 330 (725) Delivery weight, kg (lb) -

Page 25: Flow Diagrams For The Correct Operating Pressure

SBU 160, 220, 340 Safety and operating instructions These declared values were obtained by laboratory type testing in accordance with the stated directive or standards and are suitable for comparison with the declared values of other tools tested in accordance with the same directive or standards. -

Page 26: Sbu 220: 100-150 Bar

Safety and operating instructions SBU 160, 220, 340 SBU 220: 100–150 bar The flow diagram is valid for applications with back pressure up to 10 bar. For applications where the back pressure exceeds 10 bar, a restrictor must be chosen regarding the working pressure in each specific case. -

Page 27: Ec Declaration Of Conformity

Hydraulic breaker Guaranteed sound Measured sound Pmax (bar) Weight (kg) power level [dB(A)] power level [dB(A)] SBU 160 SBU 220 SBU 340 Technical Documentation authorised representative: Conny Sjöbäck Construction Tools PC AB Dragonvägen 2 391 27 Kalmar General Manager: Jenny Heimersson... - Page 28 Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers, and drawings. epiroc.com...

Need help?

Do you have a question about the SBU 220 and is the answer not in the manual?

Questions and answers