Iseki SSM60 Operation & Service Manual

Mower deck for th4365,4335,4295

Hide thumbs

Also See for SSM60:

- Operation & service manual (78 pages) ,

- Operation manual (76 pages) ,

- Operators & service manual (55 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Iseki SSM60

- Page 1 I S E K I M O W E R D E C K O p e r a t i o n & S e r v i c e M a n u a l MODEL: SSM60 FOR TH4365,4335,4295...

-

Page 2: Introduction

ISEKI MOWER DECK INTRODUCTION Thank you very much for purchasing an ISEKI mower deck. This operator’s manual provides the information necessary for operating and maintaining your mower deck safely and properly. The contents are mainly composed of the following two items: SAFETY INSTRUCTION: Essential items which you should observe while operating the mower deck. -

Page 3: Table Of Contents

SSM60 TABLE OF CONTENTS INTRODUCTION ............1 INSPECTION AND REPLACEMENT OF THE DRIVE BELT ............33 TABLE OF CONTENTS ..........2 INSPECTION AND REPLACEMENT OF THE BLADES ............... 35 FOR SAFE OPERATION ........... 3 INSPECTION OF GAUGE WHEELS ....37 1. -

Page 4: For Safe Operation

FOR SAFE OPERATION FOR SAFE OPERATION DANGER: Failure to observe the following safety instructions can result in serious injury or death. As the owner or operator of the tractor, you are responsible for pre- venting accidents or injuries. 1. HOW TO BE A SAFE OPERATOR 1.1. -

Page 5: Before Starting The Tractor

SSM60 1.9. Inspect the tractor periodically. If not, this may not only shorten the tractor’s service life but also make safe and efficient operation impossible. 1.10. Never use the tractor out of normal usage even if it is not mentioned at this operation manual. - Page 6 FOR SAFE OPERATION 2.12. Use only attachments and accessories ap- proved by the manufacturer and install and operate them as directed. 2.13. When your tractor is equipped with an imple- ment other than a standard mower deck, such as a collector, a cabin, etc., never fail to ask your dealers about machine balance.

-

Page 7: Operation Of The Tractor

SSM60 3. OPERATION OF THE TRACTOR 3.1. When the tractor is running, stay away from the discharge opening, the cutting unit(s), and all moving parts. 3.2. During operation, never allow anyone, especially children, and animals to be in the vicinity of the tractor. - Page 8 FOR SAFE OPERATION 3.15. Never rest a foot on the brake pedal. If so, the brakes disc wear rapidly, which may lead to serious accidents. 3.16. Travelling set with the cruise lever should be restricted only to operations in specious, flat areas with an unobstructed view and used with the range shift lever always kept in the low speed position.

- Page 9 SSM60 3.25. When driving over a levee tractor, stop the mower blades, lift up the mower deck, and move the tractor straight to the levee and make it climb over slowly. Avoid climbing over a levee too high, or the tractor may fall sideways or turn over.

-

Page 10: Operation On A Slope

FOR SAFE OPERATION 4. OPERATION ON A SLOPE DANGER: Slopes are a major factor re- lated to accidents with tractors, resulting in severe injuries. We cannot recomend the tractor with mower deck be oparated on a slope. All slopes require extra caution; no slope is safe. -

Page 11: Mounting And Dismounting Of The Mower Drive Shaft

SSM60 4.5. Never perform mowing operation on wet grass. 4.6. Be sure to shift the 4WD lever to the 4WD position. 4.7. Never use the cruise control during mowing operation. 4.8. Choose a low gear to prevent the need to stop or shift gears on a slope. -

Page 12: Inspection And Maintenance

FOR SAFE OPERATION 6. INSPECTION AND MAINTENANCE 6.1. Never start the engine in a closed place. Exhaust fumes contain poisonous carbon monoxide, so sufficient ventilation should be provided when starting the engine indoors. 6.2. Be sure to wear safety glasses and gloves when servicing the tractor. - Page 13 SSM60 8654-306-006-10 I 8654 C aged or worn parts should be replaced with ISEKI genuine spare parts. Unauthorized parts may cause breakdown of the tractor, accidents, and ISEKI warranty to expire. 6.18. Keep all fasteners tight, especially those that hold the cutting means(s).

-

Page 14: Safety Labels

FOR SAFE OPERATION SAFETY LABELS The following labels are stuck on the mower. You should of course read the safety instructions in the manual. But never fail to read the labels on the machine as well. Their respective code numbers are also mentioned below, so order replacements from your dealer if any of them are lost or damaged. -

Page 15: Position Of The Safety Labels

SSM60 POSITION OF THE SAFETY LABELS Pay attention to the safety labels on the mower, and observe the instructions they give to avoid physical injuries. FIG. 1-4 MAINTENANCE OF THE SAFETY LABELS - The labels should always be clearly seen, that is, nothing should obscure them. -

Page 16: General Information

Each mower is identified by means of model and se- rial numbers. To ensure prompt, efficient service when ordering parts or requesting repairs from authorized ISEKI Dealer, record these numbers in the spaces provided. Machine Model Number: Machine Serial Number:... -

Page 17: Specifications

SSM60 SPECIFICATIONS Model SSM60-TH4335E4 TH4365FH Suitable Machine TH4295F/FH TH4335F/FH Type Rotary Mower Discharge Type Side Discharge Cutting Width mm (inch) 1,524 (60”) Number of Blades Dimension Overall Length mm (inch) 1,011 (39.8) Overall Width mm (inch) 1,928 (75.9) Overall Height mm (inch) 345 (13.6) -

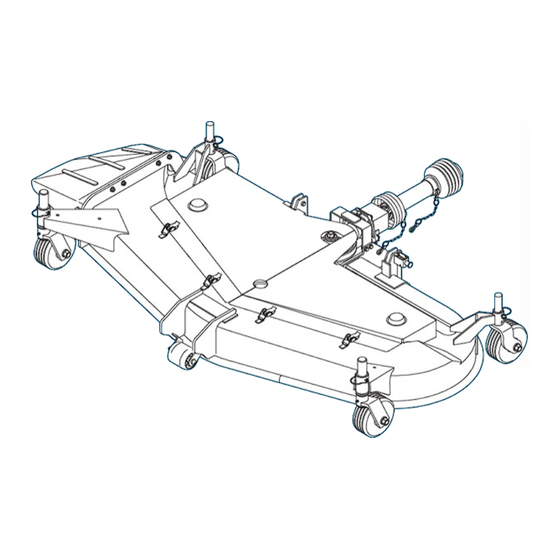

Page 18: Name Of Major Components

NAME OF MAJOR COMPONENTS NAME OF MAJOR COMPONENTS Mower deck Gear box Universal joint Discharge cover Belt cover (LH) Belt cover (RH) Stopper Pulley cover Universal joint cover (10) Belt (11) Pulley (12) Tension arm (13) Blade (14) Front gauge wheel (15) Rear gauge wheel (16) Roller FIG. -

Page 19: Assembling Instruction

SSM60 ASSEMBLING INSTRUCTION Assembling mower deck onto tractor should be done on flat ground. Bolts should be tightened up according with the standard torque. INSTALLATION OF PACKING PARTS TO TRACTOR 1. Take out the all parts from box, then confirm them with referring to the FIG. of packing parts list. - Page 20 ASSEMBLING INSTRUCTION 3. Assemble the BRACKET/MID on tractor. Parts list No. 7.8.22.25 FIG. 5-3 FIG. 5-4 Tightening torque 205.8~245.0 N•m 4. Remove 8 pcs of bolt attached on the machine before assembling BRACKET/REAR/RH and LINK/REAR. FIG. 5-5...

- Page 21 SSM60 5. Assemble LINK/REAR with inserting shaft into the hole of BRACKET/REAR/LH. Parts list No. 3.11.23.24 FIG. 5-6 FIG. 5-7 FIG. 5-8 Tightening torque 89.2~104.9 N•m...

- Page 22 ASSEMBLING INSTRUCTION 6. Assemble the ARM/MID. Parts list No. 9.10.15.16.17 FIG. 5-9 7. Remove 3 pcs of bolt attached on the machine before installing BRACKET/CYLINDER. *Remove them *Remove them if bolt is welded. if bolt is welded. FIG. 5-10...

- Page 23 SSM60 8. Assemble the BRACKET/CYLINDER. Parts list No. 12.23.24 Tightening torque 89.2~104.9 N•m FIG. 5-11 9. Assemble the cylinder between LINK/REAR and BRACKET/CYLINDER by pin and clip. Parts list No. 4.13.14.17.20 FIG. 5-12 FIG. 5-13...

-

Page 24: Matching Mower Deck With Tractor

ASSEMBLING INSTRUCTION 10. Connect ELBOW/1/4-PT3/8 to connector of the auxiliary control valve on the machine. Fix the hose with band so that hose does not inter- fere the shifting lower link. Parts list No. 4.18.19.20 FIG. 5-14 11. Start the engine of tractor and check the movement of cylinder by using the auxiliary control lever. - Page 25 SSM60 3. Assemble the universal joint. FIG. 5-17 4. Assemble the ARM/FRONT. Parts list No. IMPORTANT: In case the width of FRONT/BRACK- ET and ARM/FRONT do not match with each other, which are installed on tractor, put the PLATE/I/30X130 on the middle of tractor and BRACKET/ ARM.

- Page 26 ASSEMBLING INSTRUCTION * In case mower deck does not lift up parallel, adjust ARM/FRONT the ARM/FRONT and LINK/REAR. FIG. 5-20 * In case increasing lifting height of mower deck, ad- LINK/REAR just the LINK/REAR. (Shorten the LINK/REAR.) (Pay attention to the interference with tractor.) Be careful if the clearance between ground and lower surface of mower deck is more than 150 mm.

-

Page 27: Mower Operation

Lost or damaged ones should be re- placed with new ISEKI’s genuine parts. Especially before starting the mower, be sure to inspect visually to see that the blade and blade tightening bolts are not worn, damaged or loose. -

Page 28: Height Adjust System

MOWER OPERATION HEIGHT ADJUST SYSTEM STARTING MOWING OPERATION Height adjust system is standardly equipped on this - Mow only in daylight. tractor. During the operation on soft ground, when the height adjust system is used, it helps to decrease - Pay attention to the safety around the machine to the mark of mower gauge wheel on the ground. -

Page 29: Stopping The Mower

SSM60 e. Hydrostatic transmission model: EMERGENCY STOP - Shift the throttle lever to the high-speed position. Stop the tractor and mower immediately when any of the following abnormalities is encountered. - Disengage the parking pedal. - Abnormal noise - Depress the HST forward travel pedal gradually... -

Page 30: Efficient Mowing

MOWER OPERATION EFFICIENT MOWING - Be sure to mow at full throttle. - Choose an adequate traveling speed in accor- dance with the height of grass to be cut. - Low cutting height will lead to poor mowing ef- ficiency and rapid blade wear. - When the screens for the air-intake openings are clogged with dust, clean them at once. - Page 31 SSM60 3) For mowing tall grass a. Mow grass twice. First, mow to prepare the grass height to make it low enough for the next finishing pass. Then fin- ish to a desired grass height. Shift the second traveling pass sideways by 20cm (8 inch.) or so, or travel perpendicular to the prec-...

-

Page 32: Inspection And Service Of Each Part

INSPECTION AND SERVICE OF EACH PART INSPECTION AND SERVICE OF EACH PART INSPECTION AND REPLACEMENT OF THE GEAR 1) Inspection of oil level IMPORTANT: Check oil level after every 50 hours of operation. Remove the level plug located on the left side wall of the gear case. - Page 33 SSM60 2) Replacement of oil IMPORTANT: Replace oil after the initial 50 hours of operation and then after every 200 hours of operation. a. Remove the mower blade which is attached the shaft of the gear case referring to the instructions for the replacement of the mower blades.

-

Page 34: Inspection And Replacement Of The Drive Belt

INSPECTION AND SERVICE OF EACH PART INSPECTION AND REPLACEMENT OF THE DRIVE BELT 1) Pre-operation check: Check if the belt is tensioned properly. When its tension is correct, the clearances between coils of the ten- sion spring should be 1 to 1.2 mm (0.04 - 0.05 inch). 2) Inspection of the belt tension: a. - Page 35 Loosen the tension rod. b. Disengage the belt from the pulleys and install a new one. NOTE: Use a belt specified by ISEKI. c. Adjust the spring tension with the tension rod as shown in “Inspection of the belt tension”.

-

Page 36: Inspection And Replacement Of The Blades

INSPECTION AND SERVICE OF EACH PART INSPECTION AND REPLACEMENT OF THE BLADES 1) Inspection of the blades CAUTION: Be sure to wear gloves when inspecting or replacing the blades to avoid cutting your hands. a. Raise the mower to its highest level. Inspect the blades for wear and deformation. - Page 37 Loosen the blade tightening blade. c. Replace old blades with new ones. NOTE: Insist on ISEKI genuine blades when replacing. FIG. 7-7 d. Tighten the bolt for blade temporarily to determine the height difference between blades.

-

Page 38: Inspection Of Gauge Wheels

INSPECTION AND SERVICE OF EACH PART INSPECTION OF GAUGE WHEELS Gauge wheels are very important parts to set the grass-cutting height. When a wheel does not turn smoothly or is deformed, replace it with a new gauge wheel immediately. INSPECTION OF ROLLERS Make sure that all rollers turn smoothly. -

Page 39: Washing The Machine

SSM60 WASHING THE MACHINE CAUTION: If you use high pressure washer, be sure to use in accordance with operation manual and safety label of washer. In case of irregular using, it may cause personal injury and damaging of machine. CAUTION: Set the nozzle of hose ‘spread’ and keep the distance more than 60 cm in order to avoid damaging of mower deck and tractor. -

Page 40: Lubrication And Greasing Points

LUBRICATION AND GREASING POINTS FIG. 8-1 Description Lubrication to be used Quantity Gear Box ASSY ISEKI Hypoid gear oil 80# 930 - 950 cc Metal ASSY Inject until grease overflows from lip of oil seal Tension Arm ASSY Wheel Fork... -

Page 41: Disassembly And Reassembly

SSM60 DISASSEMBLY AND REASSEMBLY - As for the detachment of the mower from the tractor. - Remove the belt covers and other necessary parts to check the belts and other components for wear, damage, inspect or service each part if required. - Page 42 DISASSEMBLY AND REASSEMBLY FIG. 9-2 IMPORTANT: • Inspect the oil seals for wear and de- formation. (Oil seals are fundamentally consumable parts, so disassemble ones should be replaced with new ones.) • When installing on oil seal, take care not to allow the lips of the oil seal to turn up or the oil seal to be installed slanted.

-

Page 43: Storing Of The Mower Deck

Check the V-belt and loosen the adjustable tensioner. h. Remove all rust and touch up where paint has peeled off with touch-up paint supplied by ISEKI. i. Check each part for damage and repair or replace damaged ones for the next operation. -

Page 44: Troubleshooting

TROUBLESHOOTING TROUBLESHOOTING Troubles Presumable causes Remedies • Drive belt is not installed properly • Check belt and correct • Blades are installed upside down • Re-install them correctly • Grass is too moist • Wait until grass becomes dry • Too tall grass •... - Page 45 SSM60 Troubles Presumable causes Remedies • Broken or unbalanced blades • Replace them with new ones • Loose blade tightening nuts • Re-tighten them • Clogged inside of mower or • Clean foreign matter caught in a pulley • Excessive noise and vibration •...

-

Page 46: Packing Parts List

PACKING PARTS LIST PACKING PARTS LIST FIG. 12-1 PART CODE PART NAME PART CODE PART NAME DECK/MOWER/60/TH 8657-610-051-00 PIN/15X88 ARM/FRONT 8654-610-001-00 PIN/15X71 LINK/REAR 8657-608-052-00 PIN/16X43 CYLINDER 8657-608-053-10 PIN/12X42 8655-608-041-00 BRACKET/FRONT/LH 1427-317-003-00 CLIP 8655-608-042-00 BRACKET/FRONT/RH 1342-402-006-00 BAND/250 8662-608-450-00 BRACKET/MID/LH COMP 1683-273-054-00 ELBOW/1/4-PT3/8 8662-608-460-00 BRACKET/MID/RH... - Page 47 SSM60...

- Page 48 DECLARATION OF CONFORMITY ISEKI & CO., LTD. 3-14 Nishi-Nippori 5-Chome Arakawa-ku 116-8541 Tokyo Japan declare under our sole responsibility that the products described below. Generic denomination: Agricultural machine Function: Agricultural, forestry use and ground care TH4295 TH4335 TH4365 SSM60 to which this declaration relates are in conformity with the following directives:...

- Page 50 SSM60 FOR TH4365,4335,4295 Overseas Business Division 5-3-14, Nishi-Nippori, Arakawa-ku, Tokyo 116-8541, Japan Phone: (03) 5604-7658 Fax: (03) 5604-7703 OM/SM-SSM60F-TH5/-EN-10 1108-01-40 Printed in Japan...

Need help?

Do you have a question about the SSM60 and is the answer not in the manual?

Questions and answers