Subscribe to Our Youtube Channel

Summary of Contents for MGE UPS Systems SAM

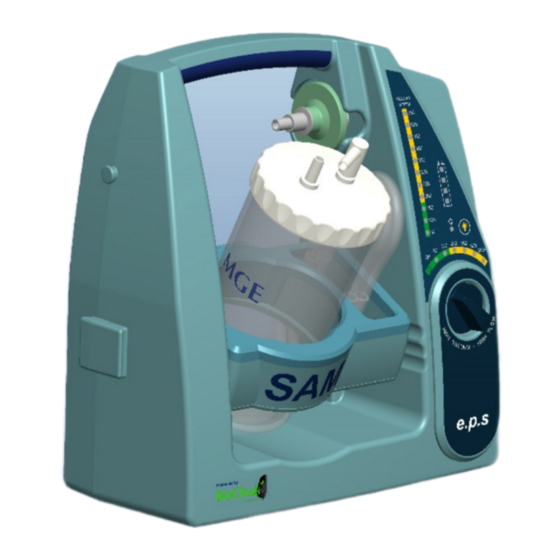

- Page 1 SAM e.p.s Portable Suction Operating and Maintenance Manual MG Electric (Colchester) Ltd Altbarn Close, Colchester, Essex, CO4 9HY, United Kingdom Tel: +44 (0) 1206 842244, Fax: +44 (0) 1206 845849 e-mail: sales@mgelectric.co.uk www.mgeworldwide.com...

- Page 2 Operation and Maintenance Manual Dear Customer, We take this opportunity to thank you for purchasing a SAM Medical Suction Unit. Please read the operating instructions and listed precautions thoroughly before attempting to operate the unit. MG Electric manufactures its range in accordance with the requirements of BS EN ISO 9001 and BS EN ISO 13485.

- Page 3 2012/19/EU Warning The SAM e.p.s must never be operated in the presence of flammable gas, or without a suitable filter. Only use the unit in environmental conditions as specified in the maintenance section. Do not immerse the unit in water or other liquids – this may cause damage and create an electrical hazard.

- Page 4 Control Knob Collection Vessel – the SAM e.p.s unit has been designed to accept a reusable collection vessel or various disposable liner systems as shown in this manual. The collection vessel sits securely in a tilting cradle. The standard unit is fitted with the SAM 1 reusable collection vessel. Only collection systems approved by MG Electric can be used with the SAM e.p.s.

- Page 5 3 hours, but subsequent charging times will be much reduced. After the initial charge - The SAM e.p.s may be used whilst the batteries are charging through an external supply mains but the charging process will provide trickle charge only.

- Page 6 Overflow Protection Valve The Overflow Protection valve in the SAM 1 is designed to shut off the vacuum to the collection container when the fluid level reaches approximately 1000ml. When the valve operates, the SAM e.p.s must be switched off and the full container replaced by an empty one.

- Page 7 • not rise above the ‘DO NOT FILL ABOVE THIS LINE’ mark on the canister. At the end of the procedure, the SAM unit should remain switched on while the patient suction tubing • is removed from the patient port and discarded.

- Page 8 - Switch on the SAM e.p.s. The SAM e.p.s must be connected to an external supply mains when available and on a regular basis. • The battery will lose useable charge over several days if not connected to an external supply mains.

- Page 9 When using the SAM e.p.s unit via the ac supply mains it is important - The location of the SAM e.p.s must always allow for the removal of the power lead to enable the unit to be isolated from the mains power supply if necessary and it must be located on a firm and stable base avoiding causing any trip hazard.

-

Page 10: Maintenance

Connector Filter Capsule Weekly Maintenance If it is not possible to put the SAM e.p.s. on continuous charge when not in use, make sure the battery • is fully charged at least once a week. Monthly Maintenance Check the vacuum and the flow at the collection container top. - Page 11 SAM e.p.s – UK Operation and Maintenance Manual Resetting the service Light Internally (during a maintenance service) - The service light may be cancelled by resetting internally – refer to data capture section. This is via the Data connection port on the main PCB. This method allows for the downloading of the stored data before reset.

- Page 12 The equipment should be stored in its original packaging providing no external damage is evident. When the unit is held in storage, or used very infrequently, Particular care must be taken when inspecting flexible components, such as valves, to ensure embrittlement has not occurred. SAM units should be stored in a cool, dry environment.

- Page 13 To clean the outside case of the SAM suction unit – disconnect the unit from the power supply - wipe over with a clean damp cloth or use an appropriate mild disinfectant solution (following the manufacturers instructions) - avoiding excessive moisture.

- Page 14 SAM e.p.s – UK Operation and Maintenance Manual Circuit Diagram Isolate the mains supply before removal of rear cover! Disconnect and remove the battery before removal of the rear cover. MAIN EXTERNAL INPUT AC FRONT RIBBON...

-

Page 15: Hydrophobic Filter

Operation and Maintenance Manual The life of the battery is dependent on its ability to hold sufficient charge to operate the SAM e.p.s. The chemical process of continual charge and discharge has an effect on that ability over a period. The battery in time, will reach a point whereby it is unable to hold a sufficient charge to satisfactorily operate the unit and achieve the performance outlined above. - Page 16 Operation and Maintenance Manual OPTIONS AND RECOMMENDED SPARES THE SAM e.p.s is a robust and fully portable high vacuum suction unit. User Instruction Manuals are offered in English. Other languages are available on request. The unit comes complete with an autoclavable 1 litre fluid collection container, and disposable hydrophobic filter as standard.

- Page 17 All spares (except Liners) detailed in the following section can be purchased by the user. It is recommended that only competent persons should undertake the replacement of spare parts. Collection Systems – the following collection systems have been approved for use with the SAM e.p.s. SAM 1 Standard...

- Page 18 SAM e.p.s – UK Operation and Maintenance Manual Abbott ‘Receptal’ Liner MSP1475 99-261 Canister 98-182 Serres System Vacuum Elbow Patient 05-0155 Elbow 1 Litre Canister Serres Collection MSP1385 1 Litre Liner 05-0118 Container MSP1394 05-0119 Vac-Sax System Hose Adaptor MSP1370...

- Page 19 SAM e.p.s – UK Operation and Maintenance Manual General Layout Only trained qualified persons should attempt to dismantle the SAM e.p.s unit. Manual 156 - Issue 08 Page 19 of 28...

- Page 20 SAM e.p.s – UK Operation and Maintenance Manual Trouble Shooting Fault Condition Action The unit does not operate with the External Power Indicator is not lit Check power cord connections AC or DC Power Cord connected. when the Operating Knob is set to and the external AC or DC power Off.

-

Page 21: Technical Specification

SAM e.p.s – UK Operation and Maintenance Manual TECHNICAL SPECIFICATION General Dimensions Performance classification: Battery Powered Portable Suction (ISO 10079-1). Free-air flow (litres/minute): 30-lt/min. nominal minimum. Vacuum: SAM e.p.s 550mm hg minimum. All vacuum measurements are quoted at sea level and flow rates are taken at filter point on unit. - Page 22 (including other medical devices). The purpose of this testing is to ensure the SAM e.p.s is not likely to adversely affect the normal operation of other such equipment and that other such equipment is not likely to adversely affect the normal operation of the SAM e.p.s.

- Page 23 Operation and Maintenance Manual Guidance and manufacturer’s declaration – electromagnetic immunity The SAM e.p.s is intended for use in the electromagnetic environment specified below. The customer or the user of the SAM e.p.s should assure that it is used in such an environment.

- Page 24 Operation and Maintenance Manual Guidance and manufacturer’s declaration – electromagnetic immunity The SAM e.p.s is intended for use in the electromagnetic environment specified below. The customer or the user of the SAM e.p.s should assure that it is used in such an environment.

- Page 25 Portable and mobile RF communications equipment and the SAM e.p.s The SAM e.p.s is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the SAM e.p.s can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the SAM e.p.s as...

- Page 26 • The software will open up. • Select the Com port that the SAM e.p.s is connected to on the computer and then click ‘Read Log’ to • display the information on screen. The following screen shows an example of what may be seen.

- Page 27 SAM e.p.s – UK Operation and Maintenance Manual For Non-windows Systems For non-windows based systems, a simple terminal emulator may be used to access the data. The Baud rate is 9600, 8 data bits, no parity. To retrieve the data enter #PRINT followed by carriage return. To reset the data enter #RESET again followed by carriage return.

- Page 28 High vacuum pipeline regulator - remote probe & mobile trolley Research and Development Since 1954, when MGE produced their first surgical suction units, the SAM range has become accepted as the industry standard, both in the U.K. and throughout the world.

Need help?

Do you have a question about the SAM and is the answer not in the manual?

Questions and answers