Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Spirax Sarco HP45

- Page 1 6230150/6 IM-P623-03 ST Issue 6 HP45 Bimetallic Steam Trap Installation and Maintenance Instructions 1. Safety information 2. General product information 3. Installation 4. Commissioning 5. Operation 6. Maintenance 7. Spare parts 8. Fault finding Printed in the UK © Copyright 2006...

-

Page 2: Safety Information

Group 2 of the above mentioned Pressure Equipment Directive. The products’ use on other fluids may be possible but, if this is contemplated, Spirax Sarco should be contacted to confirm the suitability of the product for the application being considered. - Page 3 Allow time for temperature to normalise after isolation to avoid danger of burns. 1.9 Tools and consumables Before starting work ensure that you have suitable tools and /or consumables available. Use only genuine Spirax Sarco replacement parts. 1.10 Protective clothing Consider whether you and/or others in the vicinity require any protective clothing to protect against the hazards of, for example, chemicals, high / low temperature, radiation, noise, falling objects, and dangers to eyes and face.

-

Page 4: Residual Hazards

1.16 Returning products Customers and stockists are reminded that under EC Health, Safety and Environment Law, when returning products to Spirax Sarco they must provide information on any hazards and the precautions to be taken due to contamination residues or mechanical damage which may present a health, safety or environmental risk. -

Page 5: General Product Information

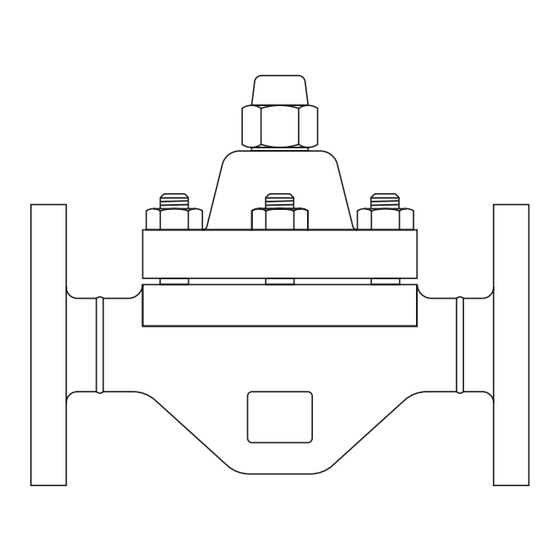

2. General product information 2.1 General description The Spirax Sarco HP45 bimetallic steam trap is made of forged steel, and designed for draining high pressure, high temperature steam lines and processes. This steam trap is specially designed for HP steam and has a reinforced stainless steel insert within the body and can be repaired inline. - Page 6 (797°F @ 653 psi g) Minimum operating temperature 0°C (32°F) Note: For lower temperatures consult Spirax Sarco Minimum inlet pressure for satisfactory operation 15 bar g (218 psi g) PMX Backpressure for correct operation must not exceed 90% of the upstream pressure...

-

Page 7: Installation

fluid may be at a temperature of 100°C (212°F). Drain connection Gate valve Gate valve 0.5 metre HP45 (20") 1 metre minimum (3 ft) Test valve Fig. 3 Recommended installation - Note: pipework to fall in the direction of flow. -

Page 8: Operation

The HP45 steam trap operates with no loss of steam and automatically and quickly drains air, non-condensable gases and large quantities of cold water on start-up. -

Page 9: Safety Note

The equipment needed to proceed with any maintenance programme is listed in Table 1. The HP45 trap has an external adjustment screw which permits flushing the trap seat and setting the discharge temperature of the condensate in the inlet line. - Page 10 Replacing the bimetallic element Spares available to repair (See Section 7). 6.3.1 Dismantling the steam trap: Isolate the steam trap. Remove the blind nut (9), the lock-nut (10) on the adjustment screw and the cover nuts (7) on the cover (6). Tighten the adjustment screw on the unit to disengage it from the cover using a screwdriver (maximum blade diameter 7 mm in order to insert it into the thread on the cover).

- Page 11 6.3.3 Adjustment: In a closed return system, close the discharge line and open the test valve. Open the upstream isolation valve slightly. Tighten the adjustment screw a few turns clockwise, and wait a few moments for the steam trap to reach the required temperature and for steam to be present. Move the adjustment screw up (anticlockwise) until the valve comes into contact with the valve seat.

-

Page 12: Spare Parts

Always order spares by using the description in the column headed 'Available spares' and state the size and model of the bimetallic steam trap. Example: 1 - Bimetallic assembly kit for a Spirax Sarco DN20 HP45 bimetallic steam trap. Fig. 6... -

Page 13: Fault Finding

8. Fault finding 1. Make sure upstream and downstream valves are open. 2. Check external strainers for clogging; blowdown or dismantle and clean. 3. Backpressure too high. Downstream system must be corrected. Backpressure will also lower the discharge temperature. Trap fails to pass 4. - Page 14 IM-P623-03 ST Issue 6...

- Page 15 IM-P623-03 ST Issue 6...

- Page 16 IM-P623-03 ST Issue 6...

Need help?

Do you have a question about the HP45 and is the answer not in the manual?

Questions and answers