Spirax Sarco EasiHeat Installation And Maintenance Instructions Manual

Hide thumbs

Also See for EasiHeat:

Table of Contents

Summary of Contents for Spirax Sarco EasiHeat

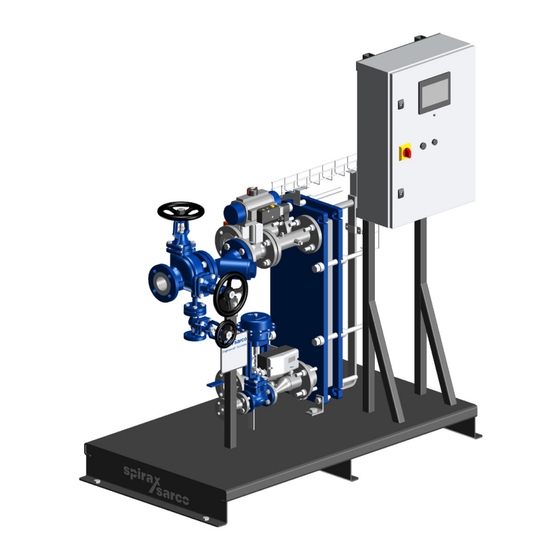

- Page 1 6500851/1 IM-P565-09 TES Issue 1 EasiHeat Installation and Maintenance Instructions EasiHeat Dual Control System EasiHeat Steam Control System EasiHeat Condensate Control System EasiHeat IM-P565-09 TES Issue 1 © Copyright 2023...

-

Page 2: Table Of Contents

5. Fault finding 6. Maintenance General High-limit device testing Scale formulation Local isolator Batteries/Maintenance Functional test of safety compenents Smart fuse Component map Component naming convention Component definitions Page numbers to be updated when document is approved EasiHeat IM-P565-09 TES Issue 1... -

Page 3: Safety Information

Lifting The EasiHeat system should be lifted by a suitable forklift truck, from the base, placed in position and securely bolted to the floor when required. The customer is responsible for the safe lifting of the EasiHeat system. - Page 4 Referring to the installation and maintenance instructions and the nameplate of the unit and the Technical Specifications, check that the product is suitable for intended use/application. EMEA - The EasiHeat heating system complies with the requirements of the EU Pressure Equipment Directive/UK Pressure Equipment (Safety) Regulations and is marked.

- Page 5 Features are available with this product to enable monitoring to reduce the risk. 1.14 Tools and consumables Before starting work, make sure you have suitable tools and/or consumables on hand. Use only genuine Spirax Sarco replacement parts. 1.15 Protective clothing Consider whether you and/or others require protective clothing to protect against hazards, such as chemicals, high/low temperatures, radiation, noise, falling objects and danger to eyes and face.

- Page 6 1.18 Storage Note: If the EasiHeat cannot be installed and put into operation immediately upon receipt at the jobsite, certain precautions are necessary to prevent deterioration during storage. Responsibility for integrity of the heat exchangers must be assumed by the user. Spirax Sarco will not be responsible for damage, corrosion or other deterioration of heat exchanger equipment during transit and storage.

- Page 7 Customers and stockists are reminded that, under EC Health, Safety and Environment Law, when returning products to Spirax Sarco, they must provide information regarding any hazards and precautions to be taken due to contamination residues or mechanical damage which may represent a risk to health, safety or the environmental. This information must be provided in writing, including Health and Safety datasheets relating to any substances identified as hazardous or potentially hazardous.

-

Page 8: General Product Information

2.1 Description EasiHeat systems use steam to provide accurate heating of low temperature hot water (HTG), domestic hot water (DHW) or hot water for processes. Systems can be sized for any heating duty from 70 kW to approximately 3.5 MW and are supplied fully assembled and pressure tested, ready for installation. - Page 9 Fig. 1b EasiHeat Steam Control System Fig. 1c EasiHeat Condensate Control system EasiHeat IM-P565-09 TES Issue 1...

-

Page 10: Installation

2" 2" ½" EHHCC (T8) EL or PN 3" 3" ¾" EHHCC (T10) EL or PN 4" 4" 1" * EHHDC has the same dimensions as the EHHCC versions Options selected may impact overall dimensions. EasiHeat IM-P565-09 TES Issue 1... -

Page 11: Steam And Condensate Connections

3.2 Steam and condensate connections It is important that the steam supply (and compressed air if pneumatic actuation is selected) to the EasiHeat unit is supplied as dry and as clean as possible, in accordance with good steam engineering practice. -

Page 12: Electrical Specifications

Steam Control Valve (F4) and Split range steam control valve/ 5A (slow blow) Condensate control valve analog position feedback (F5) F6 24V 4-20 mA 0.5A (Slow blow) The following are available for customer connection to the EasiHeat system if required: 3.5.2 Customer connections Volt free contacts Terminal designation Description... - Page 13 4-20 mA Analog Input RBX2 VB32 auxiliary control valve/VB41 condensate control valve retransmission 4-20 mA Analog Input RBX3 Hot Water setpoint transmission 4-20 mA Analog Input RBX4 TA21 Water outlet temperature retransmission 4-20 mA Analog Input Fig. 4 EasiHeat IM-P565-09 TES Issue 1...

- Page 14 M12 Sensor/Component connector layout Fig. 5 EasiHeat IM-P565-09 TES Issue 1...

-

Page 15: Commissioning

4. Commissioning For correct commissioning, we recommend the service and support of a Spirax Sarco engineer. Please contact your local Spirax Sarco representative for more details. 4.1 Pre-commissioning inspection (initial start-up) Ensure all bolts and fasteners have been correctly tightened before commissioning. -

Page 16: Flow Meter Commissioning Procedure

Note : A change of the operating mode leads to a restart of the device. The parameter settings are saved in the respective operating mode, i.e. when the operating mode is changed, the settings are not lost EasiHeat IM-P565-09 TES Issue 1... - Page 17 4.3.4 Flowmeter orientation If for any reason the flow meter has been or needs to be removed from the EasiHeat system it is important to understand the following:; To achieve the optimum measuring accuracy, mount the sensor in a way that the flow goes to the larger of the two key surfaces and do not go beyond the end stop."...

-

Page 18: Hmi Commissioning

Ensure that section 4.2 has been completed before continuing. Note : 1. This stage may have been completed from factory. 2. For comprehensive detail on the start-up/running of the EasiHeat please see IM-P565-10. 3. Tap welcome screen 4. Select language... - Page 19 5. Select engineering units, set date and time 6. Insert product nomenclature from product documentation pack EasiHeat IM-P565-09 TES Issue 1...

- Page 20 7. Select controls 8. Select operating conditions 9. Complete commissioning by selecting green tick EasiHeat IM-P565-09 TES Issue 1...

-

Page 21: Start-Up Procedure

If start button is not visible check for alarms and diagnostic messages, or manual controls (see operating instructions IM-P565-10 for more details) 3. Monitor status messages 4. When the status message reads 'running' the start-up is complete EasiHeat IM-P565-09 TES Issue 1... -

Page 22: Shutdown

4.6 Shutdown 1. Navigate to home screen 2. Push stop button 3. Monitor status messages 4. When the status message reads 'standby' the shutdown is complete EasiHeat IM-P565-09 TES Issue 1... -

Page 23: Fault Finding

Pump is blocked, worn or experiencing Maintain pump or replace completely loss of power PID Tuning being incorrect for installation Retune the EasiHeat system Investigate hot water system to ensure Unstable flow on the water/secondary side flowrate is within specified operating... - Page 24 Scaling value incorrect match those on the HMI (this data is found Remote set point is not showing on the Spirax Sarco engineers 4-20 mA correctly page) Polarity of 4-20 mA incorrect Rewire as per electrical drawings.

-

Page 25: Maintenance

For maintenance of the individual components that make up the system, please see the relevant product specific IMI’s for the components concerned. To open the panel of the EasiHeat system you require the standard panel key supplied with the unit. For a system specific service and maintenence plan that encompasses routine preventative maintenence actions please contact your local Spirax Sarco sales office. -

Page 26: Batteries/Maintenance

Only a suitably qualified person should replace the batteries of the UPS when this is required. To replace the batteries of the UPS, ensure the EasiHeat unit is turned off and the UPS is not supplying power to the panel. -

Page 27: Functional Test Of Safety Compenents

The EasiHeat is equipped with an electronic circuit protection module, sometimes called a “smart fuse”. This allows programmatic resets of voltage supplies in the event of a tripped fuse. The EasiHeat control software will attempt to reset channels in the event of a trip. -

Page 28: Component Map

The naming convention for the system map do not correlate to the specific parts and part numbers. The tag names are specific to the EasiHeat system and are not tied to specific component models. To identify a particular component, reference the component tag number to the Bill Of Materials for the specific model of Easiheat. -

Page 29: Component Definitions

Numbering of the Areas begins with the inlet flow of the process fluid at Area 0. When the process fluid undergoes a change or state change, the Area number increases until it leaves the Easiheat. The inlet of the control fluid begins with the next available Area number. At each state change of the control fluid, increase the Area number until the control fluid leaves the package. - Page 30 - VEX2 Steam control valve air pressure dump valve. - VEX3 Auxiliary/condensate control valve air pressure dump valve Pump trap motive steam port AREA X Plant steam AREA X AREA 5 Condensate Fig. 9 EasiHeat Schematic Motive steam inlet EasiHeat IM-P565-09 TES Issue 1...

- Page 31 AREA 2 AREA 4 AREA 1 Supply water Service For technical assistance contact our nearest Office or Agency. Warranty Ascertained partial or complete non-compliance with these regulations will result in forfeiture of the related warranty. EasiHeat IM-P565-09 TES Issue 1...

- Page 32 EasiHeat IM-P565-09 TES Issue 1...

Need help?

Do you have a question about the EasiHeat and is the answer not in the manual?

Questions and answers