Summary of Contents for Alfa Laval Smart Heat Exchanger

- Page 1 Smart Heat Exchanger Installation Manual for Connectivity Sensor Kit Installation Manual Lit. Code 200005979-1-EN-GB BRITISH ENGLISH...

- Page 2 © Alfa Laval 2023-04 This document and its contents are subject to copyrights and other intellectual property rights owned by Alfa Laval AB (publ) or any of its affiliates (jointly “Alfa Laval”). No part of this document may be copied, re-produced or transmitted in any form or by any means, or for any purpose, without Alfa Laval’s prior express written permission. Information and services provided in this document are made as a benefit and service to the user, and no representations or warranties are made about the accuracy or suitability of this information and these services for any purpose.

- Page 3 English Magyar Use the QR code, or visit www.alfalaval.com/gphe- Használja a QR-kódot, vagy látogasson el a manuals, to download a local language version of the www.alfalaval.com/gphe-manualswebhelyre a manual. kézikönyv helyi nyelvű változatának letöltéséhez. العربية Italiano ، للدليل المحلية اللغة إصدار لتنزيل...

- Page 4 Pусский Чтобы загрузить руководство на другом языке, воспользуйтесь QR-кодом или перейдите по ссылке www.alfalaval.com/gphe-manuals. Slovenski Če želite prenesti lokalno jezikovno različico priročnika, uporabite kodo QR ali obiščite spletno stran www.alfalaval.com/gphe-manuals. Slovenský Použite QR kód alebo navštívte stránku www.alfalaval.com/gphe-manuals a stiahnite si verziu príručky v miestnom jazyku.

-

Page 5: Table Of Contents

Contents 1 Introduction ........................7 Intended use......................7 Environmental compliance..................8 2 Safety ..........................9 Safety considerations....................9 Definitions of expressions..................9 Personal protective equipment................10 Working at height.....................11 3 Components .......................13 Connectivity sensor kit.....................13 Gateway........................15 4 Installation process ....................17 5 Installation ........................ - Page 6 This page is intentionally left blank.

-

Page 7: Introduction

Alfa Laval service. All other use is prohibited. Alfa Laval will not be held responsible for injury or damage if the equipment is used for any other purpose than the intended use described above. -

Page 8: Environmental Compliance

If there is any uncertainty regarding what material a component is made of, contact the local Alfa Laval sales company. Use a certified (ISO 14001 or similar) scrapping or waste handling company. -

Page 9: Safety

2.1 Safety considerations The plate heat exchanger shall be used and maintained in accordance with Alfa Laval’s instructions in this manual. Incorrect handling of the plate heat exchanger may result in serious consequences with injuries to persons and/or property damage. Alfa Laval will not accept responsibility for any damage or injury resulting from not following the instructions in this manual. -

Page 10: Personal Protective Equipment

2 Safety 2.3 Personal protective equipment Protective shoes A shoe with a reinforced toe cap to minimize foot injuries caused by dropped articles. Protective helmet Any helmet designed to protect the head from accidental injury. Protective goggles A pair of tight-fitting eyeglasses worn to protect the eyes from hazards. Protective gloves Gloves that protects the hand from hazards. -

Page 11: Working At Height

Safety 2 2.4 Working at height If the installation requires working at a height of two meters or higher, safety arrangements must be taken in consideration. WARNING Risk of falling. For any kind of work at height, always ensure that safe means of access is available and used. - Page 12 This page is intentionally left blank.

-

Page 13: Components

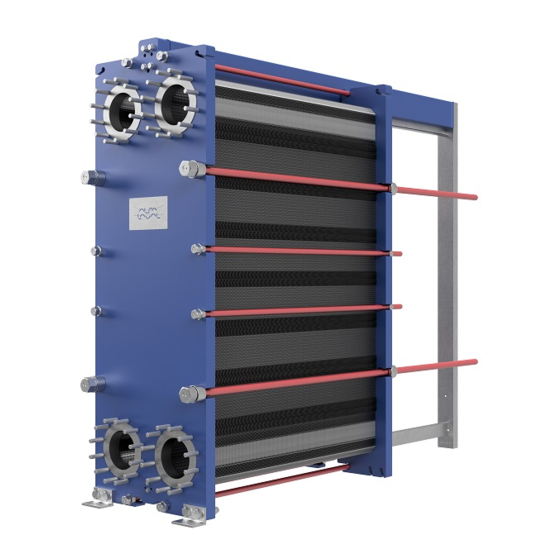

3 Components The installation consists of the connectivity sensor kit and the gateway. See Chapter Technical data for detailed information. 3.1 Connectivity sensor kit The connectivity sensor kit consists of the components listed in the table below. Denomination Design Amount Sensor Communication box Y connection cable... - Page 14 3 Components Cable holder Cable ties Sensor insulation Power cable connector 200005979-1-EN-GB...

-

Page 15: Gateway

Components 3 3.2 Gateway The gateway consists of the components listed in the table below. Denomination Design Amount Router Pole mounting strap Extra top screw cover Cable gland USB hole silicone plug Mounting bracket Slotted screwdriver Anchor Screw Quick start guide 200005979-1-EN-GB... - Page 16 This page is intentionally left blank.

-

Page 17: Installation Process

4 Installation process The installation of a connectivity sensor kit should be performed in the sequence: 1. Shut down the media flow to the plate heat exchanger. See the plate heat exchanger instruction manual. 2. Drain the plate heat exchanger. See the plate heat exchanger instruction manual. - Page 18 This page is intentionally left blank.

-

Page 19: Installation

5 Installation The sensors are marked 1, 2, 3, and 4. They must be installed at the corresponding connection: • Sensor marked 1 — colour red — at connection (1) — marked S1 on the plate heat exchanger • Sensor marked 2 — colour yellow — at connection (2) — marked S2 on the plate heat exchanger •... - Page 20 5 Installation 0-50 mm Figure 2: Top ports S1 and S4 — Sensor marked 1 and sensor marked 4 0-50 mm Figure 3: Bottom ports S2 and S3 — Sensor marked 2 and sensor marked 3 200005979-1-EN-GB...

-

Page 21: Connectivity Sensor Kit

Installation 5 5.1 Connectivity sensor kit There are two installation options: • Installation on a plate heat exchanger equipped with instrument flanges prepared with holes for sensors. See Section Install on instrument flanges. • Installation on the pipe, when the plate heat exchanger is not equipped with instrument flanges prepared with holes for sensors. -

Page 22: Connectivity Sensor Kit - Install On Instrument Flanges

5 Installation 5.1.1 Connectivity sensor kit — Install on instrument flanges The communication box and the cable holders are magnetic and can easily be positioned and moved in any desired way. NOTE The socket wrench size of the sensor is 27 mm. Use an extender if necessary. NOTE Risk of equipment not functioning The communication box can be run on the batteries for a period of time but it is highly recommended to... - Page 23 Installation 5 Fit and tighten the sensor marked 1 on the instrument flange on the S1 port. Tighten to torque 70 Nm (51 lb-ft). Put grease on the threads of the sensor marked 2. Fit and tighten the sensor marked 2 on the instrument flange on the S2 port.

- Page 24 5 Installation Fit and tighten the sensor marked 3 on the instrument flange on the S3 port. Tighten to torque 70 Nm (51 lb-ft). Put grease on the threads of the sensor marked 4. 10 Fit and tighten the sensor marked 4 on the instrument flange on the S4 port.

- Page 25 Installation 5 11 Place the communication box where suitable. Preferably somewhere centrally on the frame plate, between the sensors. 12 Connect the signal cables from the top sensors to the communication box. The extension cables and the Y connection cables can be configured in the most suitable combinations for a nice installation.

- Page 26 5 Installation 15 Fit a piece of sensor insulation over each sensor and connection pipe. If necessary cut off the sensor insulation. NOTE It is recommended to install batteries even if they are not included in the kit. For battery type see Section Technical data.

- Page 27 Installation 5 17 Loosen the four screws (1) and swing out the communication box lid. 18 Put the batteries in place. A blue led should flash one time. 19 Close the communication box lid. 20 Tighten the four screws. 21 Fold the top and bottom flaps back. 22 Connect a power supply cable.

-

Page 28: Connectivity Sensor Kit - Install On Pipes

5 Installation 5.1.2 Connectivity sensor kit — Install on pipes When the connectivity sensors are installed on the pipes connected to the plate heat exchanger, a preparation of the pipes must be made. If the connectivity sensors should be installed on a plate heat exchanger in operation, the flow through the plate heat exchanger must be stopped. - Page 29 Installation 5 Drill and thread a G1/2” straight internal thread hole through the socket (1) and the pipe (2). G1/2” G1/2” G1/2” NOTE Risk of damage to equipment Metal splints can cause damage to the plate heat exchanger. Clean the inside of the pipe thoroughly from metal splints.

- Page 30 5 Installation Make sure to orient the sockets so that the connectivity sensors can be positioned correctly according to the illustration. Put grease on the threads of the sensor marked 1. Fit and tighten the sensor marked 1 on the socket of the pipe connected to the S1 port.

- Page 31 Installation 5 10 Fit and tighten the sensor marked 2 on the socket of the pipe connected to the S2 port. Tighten to torque 70 Nm (51 lb-ft). 11 Put grease on the threads of the sensor marked 3. 12 Fit and tighten the sensor marked 3 on the socket of the pipe connected to the S3 port.

- Page 32 5 Installation 14 Fit and tighten the sensor marked 4 on the socket of the pipe connected to the S4 port. Tighten to torque 70 Nm (51 lb-ft). 15 Place the communication box where suitable. Preferably somewhere centrally on the frame plate, between the sensors.

- Page 33 Installation 5 18 Use the magnetic cable holders and the cable ties to arrange the Y connection cables properly. 19 Fit a piece of sensor insulation over each sensor and connection pipe. If necessary cut off the sensor insulation. 200005979-1-EN-GB...

- Page 34 5 Installation NOTE It is recommended to install batteries even if they are not included in the kit. For battery type see Section Technical data. Fold up the top and bottom flaps on communication box. 21 Loosen the four screws (1) and swing out the communication box lid.

- Page 35 Installation 5 23 Close the communication box lid. 24 Tighten the four screws. 25 Fold the top and bottom flaps back. 26 Connect a power supply cable. See Chapter Technical data or the communication box sign for correct power configuration. 27 Use a magnetic cable holder and the cable tie to arrange the power supply cable properly.

-

Page 36: Gateway

The distance can be greater if some demands on the positioning are fulfilled. Please consult Alfa Laval. • The gateway should be installed in an area where there is possibility for good connection with surrounding mobile networks. -

Page 37: Gateway - Install On A Flat Surface

Installation 5 5.2.1 Gateway — Install on a flat surface NOTE Risk of personal injury The mounting bracket has sharp edges that can cause personal injury. Use protective gloves when handling the mounting bracket. Assemble the mounting bracket (1) using the screws (2). - Page 38 5 Installation Connect a ground cable (3) to the router. Assemble the cable gland on the 12 VDC power cable. Connect the 12 VDC power cable to the router and tighten the cable gland. 200005979-1-EN-GB...

-

Page 39: Gateway - Install On A Pole

Installation 5 5.2.2 Gateway — Install on a pole NOTE Risk of personal injury The mounting bracket has sharp edges that can cause personal injury. Use protective gloves when handling the mounting bracket. Assemble the mounting bracket (1) using the pole mounting straps (2). - Page 40 5 Installation Connect a ground cable (3) to the router. Assemble the cable gland on the 12 VDC power cable. Connect the 12 VDC power cable to the router and tighten the cable gland. 200005979-1-EN-GB...

-

Page 41: Commissioning

2. Note the plate heat exchanger serial number. 3. Report both the communication box MAC address and the heat exchanger serial number to your Alfa Laval representative. 4. Now the connectivity sensor kit is paired with the plate heat exchanger and they should remain as a pair. - Page 42 This page is intentionally left blank.

-

Page 43: Maintenance

7 Maintenance This section describes all maintenance necessary for the components included in the kit. 7.1 Batteries NOTE Batteries are not included in the kit This section is only valid if you have installed batteries in the communication box. 7.1.1 Batteries — Change This instruction is only valid if you have installed batteries in the communication box. - Page 44 7 Maintenance Loosen the four screws (1) and swing out the communication box lid. Remove the old batteries. Put the new batteries in place. A blue led should flash one time. Close the communication box lid. Tighten the four screws. Fold the top and bottom flaps back.

-

Page 45: Communication Box

Maintenance 7 7.2 Communication box 7.2.1 Communication box — Reset Fold up the top and bottom flaps on communication box. Loosen the four screws (1) and swing out the communication box lid. 200005979-1-EN-GB... - Page 46 7 Maintenance Press the reset button. Close the communication box lid. Tighten the four screws. Fold the top and bottom flaps back. 200005979-1-EN-GB...

-

Page 47: Sensor

Maintenance 7 7.3 Sensor 7.3.1 Sensor — Clean The sensors should normally be cleaned at the same time as the plate heat exchanger is cleaned. The instruction assumes that cleaning of the plate heat exchanger is ongoing according to the instruction in the plate heat exchanger maintenance manual. - Page 48 This page is intentionally left blank.

-

Page 49: Technical Data

8 Technical data 8.1 Sensor kit (per unit) • Combined sensors for temperature and pressure measurement (4 pieces) • Stainless 1.4404 (316L) sensor bodies • G½" straight threads (not NPT) sensor connection • Temperature range -15 ⁰C to +120 ⁰C (5 ⁰F to +248 ⁰F) •... -

Page 50: Gateway (Per Area)

8 Technical data 8.2 Gateway (per area) • 1x IoT Gateway / site or area • Sensor Kit communication: Wireless BLE • Wireless range (depending on the area): BLE range typically 50 m (54 yards) • Cellular Connection; 2G, 3G, or 4G LTE •... -

Page 51: Cloud Solution And Security

Technical data 8 8.3 Cloud solution and security Alfa Laval Cloud provided via MS Azure. The device The connection The cloud • Designed to reduce the • Secure connection • Azure Assume breach risk of attacks and • Safe message delivery •... - Page 52 This page is intentionally left blank.

-

Page 53: Troubleshooting

9 Troubleshooting If you experience problem with your equipment, try the following solutions. Problem Cause Actions to solution 1. Check that the power supply connector is properly connected. No power supply connec- ted. 2. Verify that there is power to the power supply cable. - Page 54 9 Troubleshooting Problem Cause Actions to solution 1. Check that the cable arrangement is proper- ly connected. 2. Check that there are Cable connection. no visual damages to the cables. 3. Replace the cables. 1. Follow instruction in No communication from Sensor box need a reset.

Need help?

Do you have a question about the Smart Heat Exchanger and is the answer not in the manual?

Questions and answers