Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

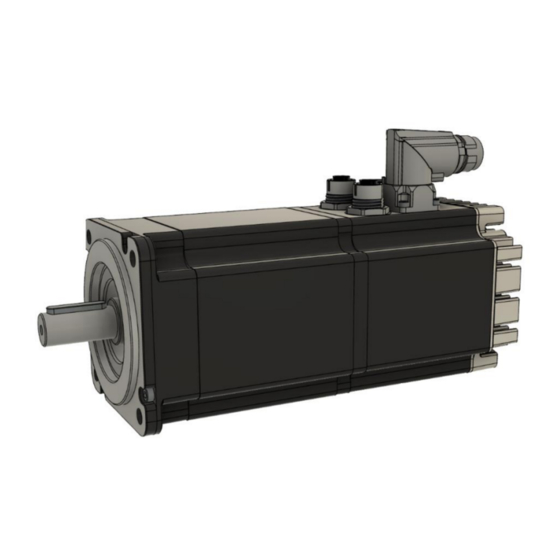

Summary of Contents for Motor Power Company DUET AD Series

- Page 1 Profinet Reference Manual DUET AD Version 1.1 20/01/2022...

- Page 2 Profinet Reference Manual - Pag. 1...

-

Page 3: Table Of Contents

Profinet Reference Manual - Pag. 2 1. Sommario General ......................5 Introduction ......................5 Notice: ........................ 5 PROFINET Compatibility ..................5 Document Versioning .................... 5 Profinet documentation ..................5 Wiring and pin assignment ................7 Connection ......................7 Pin assignment ..................... 7 Bus cable ...................... - Page 4 Profinet Reference Manual - Pag. 3 Profile Position Mode ................... 23 Functional Description .................... 23 Example: Profile Position ..................25 Homing Mode ..................... 27 Homing methods ....................29 Example: Homing ....................35 Profile Velocity Mode ................... 36 Example: Profile Velocity ..................37 Profile Torque Mode ....................

- Page 5 Profinet Reference Manual - Pag. 4 Range ........................46 PNU 669: Fault Register ..................53 PNU 663: Digital Inputs ..................54 PNU 664: Digital Outputs ..................55 PROFINET function blocks and data blocks for SIEMENS S7 ........56 Overview ......................56 Hardware configuration ..................

-

Page 6: General

This guide is delivered subject to the following conditions and restrictions: This guide contains proprietary information belonging to Motor Power Company srl. Such information is supplied solely for the purpose of assisting users of the Motor Power Company devices and servo drive in its installation and configuration. - Page 7 Profinet Reference Manual - Pag. 6 IEC 61784-2 "Industrial communication networks - Profiles - Part 2: Additional fieldbus profiles for real-time networks based on ISO/IEC 8802-3 (IEC 61784-2:2014)": This standard defines the real-time classes (RTC = real-time class) based on the reaction time. DUET AD only support PROFINET RT conformance Class A/B.

-

Page 8: Wiring And Pin Assignment

Profinet Reference Manual - Pag. 7 3. Wiring and pin assignment Connection For the DUET AD series, the PROFINET interface has been realized with two M12 female jacks. AD PROFINET C IGURE ONNECTION Follow the Installation Guide (available at www.motorpowerco.com in dedicated section) of the device to find out the entire pinout configuration. -

Page 9: Bus Cable

Profinet Reference Manual - Pag. 8 Bus cable A PROFINET copper cable is usually a 4-core, shielded copper cable. Like in the case of standard Ethernet applications, the maximum distance that can be covered by way of copper cables is limited to 100 m between the communication endpoints. -

Page 10: Profinet Connection

Profinet Reference Manual - Pag. 9 4. PROFINET connection Introduction PROFINET IO (Input - Output) enables the connection of decentralised field devices, such as I/Os, drives, valves, transducers, or analysis devices, to a central automation device, such as a PLC, PC, or process control system. -

Page 11: Master Overview

Profinet Reference Manual - Pag. 10 Master overview This section provides an overview of the necessary steps for the parameterisation and configuration of the master. The following procedure is recommended: • Add the GSDML file • Add servo drive to PROFINET network •... -

Page 12: Add Servo Drive To Profinet Network

Profinet Reference Manual - Pag. 11 Add servo drive to PROFINET network To integrate the servo drive into the PROFINET network, the servo drive must be selected in the hardware catalog. The DuetAD device can be found in “Other field devices > PROFINET IO > I/O > Hilscher Gesellschaft fur Systemautomation mbH >... -

Page 13: Specify The Device Name

Profinet Reference Manual - Pag. 12 Specify the device name Then, the device name must be specified. This method has been chosen for PROFINET, since names are easier to handle than complex IP addresses. After clicking the netX logo of the servo drive, the device name can be changed under "General"... - Page 14 Profinet Reference Manual - Pag. 13 PRONETA Basic is well suited for solving two tasks fundamental to the commissioning of PROFINET installations: • The “Network Analysis" task gives a quick overview of the devices connected to PROFINET. It features simple configuration options, like setting network parameters or assigning a network name to the devices which are part of the subnet the PRONETA PC is connected.

-

Page 15: I/O Cyclic Data

Profinet Reference Manual - Pag. 14 5. I/O Cyclic Data Cyclic I/O data are transmitted via the "IO Data CR" unacknowledged as real-time data between provider and consumer in an assignable time base. The cycle time can be specified individually for connections to the individual devices and are thus adapted to the requirements of the application. -

Page 16: Controller Data Input In Profile Position Mode (Mode Of Operation 1)

Profinet Reference Manual - Pag. 15 In next chapter will be described the mapping for any mode of operation supported by DUETAD.. NOTE: Changing mode of operation also change the content variables for data input and output, this is done automatically by drive Controller data input in profile position mode (Mode of operation 1): NOTE: Current limitation is not active if set to 0 in controller data output! Byte... -

Page 17: Controller Data Input In Profile Velocity Mode (Mode Of Operation 3)

Profinet Reference Manual - Pag. 16 current. When 0 this function is disabled. Spare Spare bytes BYTES NOT USED Controller data input in profile velocity mode (Mode of operation 3): Byte Parameter Designation Type Comments Statusword Drive’s statusword UNIT16 Mode of Drive’s mode of INT8 This value must be 3 for proper... -

Page 18: Controller Data Output In Current Mode (Mode Of Operation 4)

Profinet Reference Manual - Pag. 17 Mode of Drive’s mode of INT8 This value must be 4 for proper Operation operation operation Display Actual Actual position Int16 Current Spare Spare byte BYTES NOT USED Spare Spare byte BYTE NOT USED Actual Motor current INT 16... -

Page 19: Device Control

Profinet Reference Manual - Pag. 18 6. Device Control Application protocol CiA DS402 CANopen Communication protocol PROFINET Transmission system Ethernet User layer PROFINET layers 10-C AD PN IGURE OMMUNICATION ODEL Device Control and State Machine The power drive system finite-state automaton (PDS FSA) is a mathematical model that defines the behavior of the power drive system. -

Page 20: Indicating The Operating State

Profinet Reference Manual - Pag. 19 The power drive system is operated by the Controlword sent by the control device via the network. The state of the power drive system is reported by the Statusword produced by the drive device. The FSA is also controlled by error detection signals. - Page 21 Profinet Reference Manual - Pag. 20 Notes: Not Ready to Switch On “Not ready to operate” received from the controller. Switch On Disabled Ready to operate. Can read and write parameters. Motion functionality cannot be executed. Ready to Switch On Ready to operate.

- Page 22 Profinet Reference Manual - Pag. 21 Bit 10 = Target reached Bit 11 = Internal limit is active Bit 12 = Operating mode-specific Bit 13 = Operating mode-specific Bit 14 = Manufacturer-specific Bit 15 = Manufacturer-specific Notes: Bit 4 Bit 4=1 indicates whether the DC bus voltage is correct. If the voltage is missing or is too low, the device does not transition from operating state 3 to operating state 4.

-

Page 23: Starting And Changing An Operating Mode

Profinet Reference Manual - Pag. 22 Bits 0, 1, 2, 3 and 7 of the parameter Controlword allow you to switch between the operating states. Fieldbus State State Transition Bit 7: Bit 3: Bit 2: Bit 1: Bit 0: Comman Transitions Fault Enable... -

Page 24: Profile Position Mode

Profinet Reference Manual - Pag. 23 Profile Velocity Profile Torque Homing The parameter Mode of operation display (PNU 670) can be used to read the current operating mode, it could be read at byte 2 of Controller Data Input (IO). Profile Position Mode Description In the operating mode Profile Position, a movement to a desired target position is performed. - Page 25 Profinet Reference Manual - Pag. 24 Procedure • Set [Mode of operation (PNU 128)] to operating mode Profile position (1). • Set [Target position (PNU 556)] to the target position (unit = pulse). • Set [Profile velocity (PNU 161)] to profile velocity (unit = pulses per second). •...

-

Page 26: Example: Profile Position

Profinet Reference Manual - Pag. 25 Position demand Integer32 value 6063h Position actual Integer32 value Position actual Integer32 value Following error Unsigned32 window Position window Unsigned32 Position window Unsigned16 Immediately time Profile velocity Unsigned32 Next movement Following error Integer32 actual value Position demand Integer32 value... - Page 27 Profinet Reference Manual - Pag. 26 0 » 1 Starts a movement to a target position. New target values transmitted during a movement become immediately effective. Previous target will be ignored. The movement is stopped at the current target position.* Note: Target values include target position, target velocity, acceleration and deceleration.

-

Page 28: Homing Mode

Profinet Reference Manual - Pag. 27 Bit 15 = Manufacturer-specific Homing Mode Description In the operating mode Homing, a movement is performed to a defined position. This position is defined as the reference point. This chapter describes the method by which a drive seeks the home position (also called, the datum, reference point or zero point). - Page 29 Profinet Reference Manual - Pag. 28 Index Parameter Data Takes Type Effect PNU 540 Controlword Unsigned16 Immediately PNU 668 Statusword Unsigned16 PNU 128 Modes of Integer8 Immediately operation PNU 670 Modes of Integer8 operation display PNU 181 Home offset Integer32 Next movement PNU 179 Homing...

-

Page 30: Homing Methods

Profinet Reference Manual - Pag. 29 a homing operation is necessary. There are several, application-specific methods. The homing method is used for selection. The exact sequence of the homing operation is clearly described by the method. In some circumstances, a device has several methods to choose from, using the homing method. - Page 31 Profinet Reference Manual - Pag. 30 5- H IGURA OMING ON POSITIVE IMIT SWITCH AND INDEX PULSE Methods 3 and 4: Homing on the positive home switch and index pulse Using methods 3 or 4 the initial direction of movement is dependent on the state of the home switch.

- Page 32 Profinet Reference Manual - Pag. 31 6- H IGURA OMING ON POSITIVE HOME SWITCH AND INDEX PULSE Methods 5 and 6: Homing on the negative home switch and index pulse Using methods 5 or 6 the initial direction of movement is dependent on the state of the home switch.

- Page 33 Profinet Reference Manual - Pag. 32 7- H IGURA OMING ON NEGATIVE HOME SWITCH AND INDEX PULSE Methods 7 to 14: Homing on the home switch and index pulse These methods use a home switch which is active over only portion of the travel, in effect the switch has a ‘momentary’...

- Page 34 Profinet Reference Manual - Pag. 33 8- : H IGURA OMING ON THE HOME SWITCH AND INDEX PULSE POSITIVE INITIAL MOVE IGURA OMING ON THE HOME SWITCH AND INDEX PULSE NEGATIVE INITIAL MOVE...

- Page 35 Profinet Reference Manual - Pag. 34 Methods 17 to 30: Homing without an index pulse These methods are similar to methods 1 to 14 except that the home position is not dependent on the index pulse but only dependent on the relevant home or limit switch transitions. For example methods 19 and 20 are similar to methods 3 and 4 as shown in the following diagram.

-

Page 36: Example: Homing

Profinet Reference Manual - Pag. 35 Method 35: Homing on the current position In method 35 the current position is taken to be the home position. Example: Homing Starting the Operating Mode: The operating mode must be set in the parameter Mode of operation (PNU 128). Writing the parameter value activates the operating mode. -

Page 37: Profile Velocity Mode

Profinet Reference Manual - Pag. 36 Bit 13 = Homing error 1 = Homing error Bit 14 = Manufacturer-specific Bit 15 = Manufacturer-specific Profile Velocity Mode Description In the operating mode Profile Velocity, a movement is made with a desired target velocity. Procedure •... -

Page 38: Example: Profile Velocity

Profinet Reference Manual - Pag. 37 Velocity Integer32 Demand Value 606Ch Velocity Integer32 Actual Value Velocity Unsigned16 Immediately Window Velocity Unsigned16 Immediately Window Time 606Fh Velocity Unsigned16 Immediately Threshold Target Velocity Integer32 Immediately Example: Profile Velocity Starting the Operating Mode The operating mode must be set in the parameter Mode of operation (PNU 128). -

Page 39: Profile Torque Mode

Profinet Reference Manual - Pag. 38 Terminating the Operating Mode The operating mode is terminated when the motor is at a standstill and one of the following conditions is met: • Stop caused by Halt or Quick Stop • Stop caused by an error Statusword Information on the current movement is available via bits 10 and 12 in the parameter Statusword (PNU 668). - Page 40 Profinet Reference Manual - Pag. 39 12-S IGURA TRUCTURE OF THE ROFILE ORQUE Procedure • Set [Mode of operation (PNU 128)] to operating mode Profile Torque (4). • Set [Controlword (PNU 540)] to start the operating mode. • Set [Motor rated current (PNU 142)] to a value according to motor specifications (unit = A/100).

- Page 41 Profinet Reference Manual - Pag. 40 Statusword Unsigned16 Modes of Operation Integer8 Immediately Modes of Integer8 Operation Display Target Torque Integer16 Immediately 552h Motor rated current Unsigned32 142h...

-

Page 42: Units

Profinet Reference Manual - Pag. 41 7. Units This chapter define the available units and how to change for Gear Units, Position Units, Encoder Resolution, Acceleration Units and Velocity units. They are changeable directly by the UI with ModBus or via ProfiNET/IO records r/w. Opening the conversion factor window let one change the factors. -

Page 43: Conversion Factor For The Speed Units

Profinet Reference Manual - Pag. 42 PNU 233 ���������������� ���������� = �������������� ������������������ ∗ PNU 235 Parameter Default Value Position Conversion Factor Num Position Conversion Factor Den With default values encoder increments are equal to position increments. Conversion factor for the speed units The factor n is calculated from the factor for numerator (PNU 237) divided by the factor for denominator (PNU 237). -

Page 44: Conversion Factor For The Acceleration Units

Profinet Reference Manual - Pag. 43 Conversion factor for the acceleration units The factor n is calculated from the factor for numerator (PNU 241) divided by the factor for denominator (PNU 241). This factor converts acceleration in internal drive units (increments/seconds ��������������... -

Page 45: Function Block For R/W Parameters

Profinet Reference Manual - Pag. 44 FUNCTION BLOCK FOR R/W PARAMETERS You can use the RDREC (Read data record) and WRREC (Write data record) instructions with PROFINET. 12-RDREC&WRREC FB IGURE ORTAL FB WRREC Use the WRREC instruction to transfer a data RECORD with the record number INDEX to a DP slave/PROFINET IO device component addressed by ID, such as a module in the central rack or a distributed component (PROFINET IO).Assign the byte length of the data record to be transmitted. -

Page 46: Fb Rdrec

Profinet Reference Manual - Pag. 45 "WRREC_DB"( • req:=_bool_in_, • ID:=_word_in_, • index:=_dint_in_, • len:=_uint_in_, • done=>_bool_out_, • busy=>_bool_out_, • error=>_bool_out_, • status=>_dword_out_, • record:=_variant_inout_ 13-WRREC FB IGURE FB RDREC Use the RDREC instruction to read a data record with the number INDEX from the component addressed by the ID, such as a central rack or a distributed component(PROFINET IO).Assign the maximum number of bytes to read in MLEN. -

Page 47: Device Parameters List

Profinet Reference Manual - Pag. 46 14-RDREC IGURE Device parameters list Here below a table with description, size and address of each parameter to be considered for DUETAD PROFINET: NOTE: for a complete description of parameters please refer to DUET AD EtherCAT manual or to CANopen DS402 standard. - Page 48 Profinet Reference Manual - Pag. 47 I2T Time Unit16 I2T Time 0 … 65536 Coun 0 … Unit32 Line Per Revolution 4294967296 The maximum speed allowed for the motor in Max Motor either direction. It is used to User 0 … Unit32 ...

- Page 49 Profinet Reference Manual - Pag. 48 demand value. As it is in most cases used with user defined units, a transformation into increments with the position factor is necessary. If the position actual value is out of the following error window, an error occur.

- Page 50 Profinet Reference Manual - Pag. 49 out given in multiples of milliseconds, the corresponding bit 13 following error in the status word will be set to one. The reaction of the drive when a following error occurs, is manufacturer specific. When the actual position is within the position window during the defined position...

- Page 51 Profinet Reference Manual - Pag. 50 During homing the machine home position is found and once the homing is completed the zero position is offset from the home position by adding the home offset to the home position. All subsequent absolute moves shall be taken relative to this new zero position.

- Page 52 Profinet Reference Manual - Pag. 51 Acceleratio User 0 … n Factor Unit32 Acceleration Factor Num Unit 4294967296 Acceleratio User 0 … Unit32 Acceleration Factor Div n Factor Div Unit 4294967296 User Protection Unit16 I2T Protection type 0…2 Unit type Load ...

- Page 53 Profinet Reference Manual - Pag. 52 Bootloader 0 … 65536 666 Bootloader version version 0 … 65536 Status Word Unit16 Status Word This Parameter returns the Fault 669 Unit16 error code of the last error 0 … 65536 register ...

-

Page 54: Pnu 669: Fault Register

Profinet Reference Manual - Pag. 53 current settings of motion control parameters such as velocity, acceleration, deceleration, motion profile type etc. The target position is given in user defined position units. It is converted to position increments using the position factor. The target position will be interpreted as absolute or relative depending on the... -

Page 55: Pnu 663: Digital Inputs

Profinet Reference Manual - Pag. 54 9 VELOCITY_TRACKING_ERROR Speed following 0x200 error exceeded 10 OVERVELOCITY Maximum motor velocity 0x400 exceeded 11 DRIVE_OVERTEMPERATURE Maximum motor velocity 0x800 reached 13 FIELDBUS_CYCLE_TIME Profinet cyclic messages 0x2000 timeout PNU 663: Digital Inputs Indicates the state of the digital inputs. The digital inputs object has 32 bits. The first 16 bits (bits 0-15) indicate the status of various types of switches. -

Page 56: Pnu 664: Digital Outputs

Profinet Reference Manual - Pag. 55 If digital input 2 is on, bit 17 is set. If digital input 3 is on, bit 18 is set. PNU 664: Digital Outputs Indicates the state of the digital outputs. Sub-index 1 of this object indicates the state of the digital outputs. This sub-index has 32 bits. The bits in the first word (bits 0-15) indicates the status of the brake. -

Page 57: Profinet Function Blocks And Data Blocks For Siemens S7

Profinet Reference Manual - Pag. 56 9. PROFINET function blocks and data blocks for SIEMENS S7 Overview For the DUET AD and Siemens PLC systems (SIMATIC S7 control systems), special function block have been written. They support the easy integration of a servo drive into a PLC program with PROFINET functionality. -

Page 58: Integration Of The Servo Drive

Profinet Reference Manual - Pag. 57 Integration of the servo drive In order to integrate the DuetAD into the PROFINET network, the servo drive must be selected in the hardware catalog. The DuetAD head module must be dragged and dropped into the topology view of the device configuration. -

Page 59: Function Blocks For Duet Ad

In order to ensure a proper IO exchange in FB it is necessary to associate IO data to PLC tags. In these pages it is provided an example by Motor Power Company. First of all, create or copy a proper structure for the IO of the communication to ensure a proper... - Page 60 Profinet Reference Manual - Pag. 59 18-C IGURE ONTROLLER NPUTS WITH MAPPING 19- C IGURE ONTROLLER UTPUTS WITH MAPPING Then create the TAG TABLE with the address given to the device by the Tia Portal.

- Page 61 Profinet Reference Manual - Pag. 60 20-IO IGURE ADRESSESS FOR DEVICE IN ORTAL Use these addresses (I68 to I80 and Q68 to Q83) to fill the PLC Tag for Inputs and Ouputs by incrementing recusively the values. 13-PLC T IGURA AGS PAGE Once PLC Tags have been created they have to be used in FB in Input and Output as variables.

-

Page 62: Fb For Velocity Mode

Profinet Reference Manual - Pag. 61 FB for velocity mode 22-FB IGURE FOR PROFILE VELOCITY MODE Inputs: • o Target: Number of the data block containing the data for the Velocity Target(INT). o Input: I/O Data of the IO device that are input for the controller. (IO_Input Data Type) o Enable: This input is used to enable the servo drive in the Profile Velocity Mode. -

Page 63: Fb For Profile Position Mode

Profinet Reference Manual - Pag. 62 o Ready: This flag is set if motor is in operation enabled status. (BOOL) o Enabled: This flag is set if motor is enabled. (BOOL) o Continuos Motion: This flag is set if the motor is moving according to the thresholds set.(BOOL) o Fault: This flag is set if motor is in fault status.(BOOL) FB for profile position mode... - Page 64 Profinet Reference Manual - Pag. 63 o Begin: Starts a movement to a target position. (BOOL) o Abs/Rel: Next movement will take absolute target position (if false) or relative with respect to actual position (true). (BOOL) o Change Immediately See Profile Position Mode chapter and examples for proper use of this bit. (BOOL) o Alarm Reset: This flag will try to clear the fault if set to true.

-

Page 65: Fb For Homing Mode

Profinet Reference Manual - Pag. 64 FB for homing mode 24-FB IGURE FOR HOMING MODE Inputs: • o Homing Method: Homing type to be performed(INT8). o Input: I/O Data of the IO device that are input for the controller. (IO_Input Data Type) o Enable: This input is used to enable the servo drive in the Homing Mode. - Page 66 Profinet Reference Manual - Pag. 65 Axis will stop with quick stop deceleration profile (if true). With falling edge from true to false axis will restart with Profile Position Mode values. Outputs: • o Output: I/O Data of the IO device that are output for the controller. (IO_Output Data Type) o Ready: This flag is set if motor is in operation enabled status.

-

Page 67: Example Project: Moving The Axis In Velocity Profile Mode

Profinet Reference Manual - Pag. 66 Example project: Moving the Axis in Velocity Profile Mode Download the example project from www.motorpowerco.it in DUET AD area. After the example project has been successfully loaded into the TIA portal, the program blocks shown in are listed in the Project tree area. - Page 68 Profinet Reference Manual - Pag. 67 26-U FB V IGURE SING THE DEVICE WITH ELOCITY MODE...

- Page 69 Profinet Reference Manual - Pag. 68...

- Page 70 Profinet Reference Manual - Pag. 69...

Need help?

Do you have a question about the DUET AD Series and is the answer not in the manual?

Questions and answers