Table of Contents

Advertisement

INSTRUCTION MANUAL

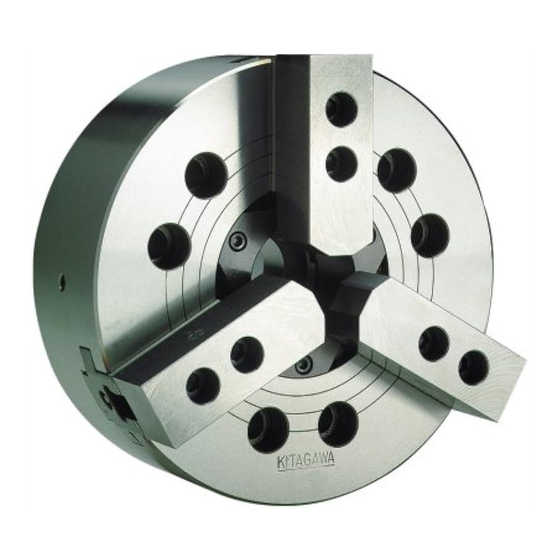

B-200/BT200

Large Thru-Hole Power Chuck

・This instruction manual is for production engineers and

maintenance personnel in charge of operation of this product.

When a beginner uses this product, receive instructions from

experienced personnel, the distributor or our company.

・Before installing, operating or maintaining this equipment,

carefully read this manual and the safety labels attached to

the equipment. Failure to follow these instructions and safety

precautions could result in serious injury, death, or property

damage.

・Store this manual near equipment for future reference.

・If any questions related to safety arise about this manual,

please confirm them with the distributor or our company.

Kitagawa Corporation

77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan

Te l . +81-847-40-0561

Fax. +81-847-45-8911

Version 1.11 (2021.08.03)

Original instructions

type

Advertisement

Table of Contents

Summary of Contents for Kitagawa BT200 Series

- Page 1 ・Before installing, operating or maintaining this equipment, carefully read this manual and the safety labels attached to the equipment. Failure to follow these instructions and safety precautions could result in serious injury, death, or property damage. ・Store this manual near equipment for future reference. ・If any questions related to safety arise about this manual, please confirm them with the distributor or our company. Kitagawa Corporation 77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan Te l . +81-847-40-0561 Fax. +81-847-45-8911...

- Page 2 The chuck and cylinder from Kitagawa Corporation should be used together. If you must use a part not made by Kitagawa, check with us or our distributor to be sure it is safe to do so. We will not be responsible for injury, death, ...

-

Page 3: Table Of Contents

Table of Contents 1. Structural Drawing and Parts List ……………………………………………………………… 3 1-1. Type display 1-2. Structural drawing 1-3. Scope of product 1-4. Parts list Important Safety Precautions ………………………………………………………… 6 3. Specifications …………………………………………………………………………………… 12 3-1. Specifications 3-2. Relationship between gripping force and rotation speed 3-3. Relationship between gripping part center height, static griping force and input force / Relationship between top jaw mass moment and gripping force loss 4. Forming Soft Jaw ……………………………………………………………………………… 21 4-1. Attachment of soft jaw 4-2. Forming soft jaw with outside diameter gripping 4-3. Forming soft jaw with inside diameter gripping 4-4. Forming method when you use forming jig 5. Usage …………………………………………………………………………………………… 24 5-1. Precautions during gripping work with chuck 5-2. Precautions during gripping work in irregular shape 5-3. Precautions related to usage of jaw 5-4. Precautions related to processing 5-5. Attachment of locator and jig 6. Maintenance and Inspection ………………………………………………………………… 26 6-1. Periodic Inspection 6-2. Grease lubrication 6-3. Disassembling 7. Malfunction and Countermeasures …………………………………………………………… 28 7-1. In the case of malfunction 7-2. Where to contact in the case of malfunction For Machine Tool Manufacturers (Chapter 8) 8. Attachment ……………………………………………………………………………………… 29 8-1. Outline drawing of attachment 8-2. In the case that the back plate must be manufactured (B-200 /BT200 series) 8-3. In the case of with back plate (B-200A /BT200A series) -

Page 4: Structural Drawing And Parts List

1 . Structural Drawing and Parts List 1−1 Type display Type display as shown below B - 2 0 6 A 5 9 9 9 Design No. Attachment shape Straight spigot joint:− −5 :A5 −6 :A6 −8 :A8 −11 :A1 −15(Former JIS) :C5 −15(New JIS) :K5 Chuck nominal diameter (inch) B-200 series(3Jaw) BT200 series(2Jaw) Fig.1 1−2 Structural drawing Top jaw Plunger nut Master jaw T nut Body (Soft jaw. hard jaw.special jaw included) Back plate Cover T nut Attaching bolt... -

Page 5: Scope Of Product

1−3 Scope of product This instruction manual is for the chuck part. Cylinder Chuck Drain hose Flexible hose Pressure adjusting Hydraulic Pressure Manual screw pump gauge switching valve SOL. Line Filter Solenoid valve Tank Fig.3 WARNING ・ To prevent the work from flying, safe design, maintenance and erroneous action prevention of the hydraulic system to maintain the gripping force of the chuck is extremely important. Thoroughly read the Important Safety Precautions on and after page 6 in this manual. -

Page 6: Parts List

1−4 Parts list 13 20 18 11 21 14 19 12 Fig.4 Table 1 Part name Quantity Part name Quantity Body Jaw attaching bolt 4 or 6 Wedge plunger Chuck attaching bolt 3or4or6 Master jaw 2 or 3 Set screw Soft jaw 2 or 3 Steel ball T nut 2 or 3 Grease nipple 2 or 3 Plunger nut Hex key Draw nut Hex key Cover Hex key Hex key Coil spring Handle ... -

Page 7: Important Safety Precautions

2 . Important Safety Precautions Important safety precautions are summarized below. Please read this section before first starting to use this product. DANGER Failure to follow the safety precautions below will result in serious injury or death. Turn off main power supply before attaching, inspecting or replacing chuck, and before adding oil. For All Users ・The chuck may start rotation suddenly, and a part of the body or clothing may be Main power supply caught. Lathe Close door before rotating spindle. For All Users ・If the door is not closed, you may touch the rotating chuck or the work may fly out, ... - Page 8 DANGER Failure to follow the safety precautions below will result in serious injury or death. Do not allow the rotation speed of the chuck to exceed the maximum allowable speed limit. (Refer to pages 13-20) For All Users ・If the rotation speed of the chuck exceeds the rotation speed limit, this is very Fly out dangerous as the chuck and work will fly out. Work The input force of the chuck (piston thrust, pulling force of the draw pipe) must not exceed the allowable maximum input force. For All Users (Refer to pages 13-20) ・Input must match the specification of Cylinder the chuck. Draw pipe ・Adjust the hydraulic pressure to the cylinder so that the input force, which ...

- Page 9 Important Safety Precautions DANGER Failure to follow the safety precautions below will result in serious injury or death. Keep the height of the jaw within the range specified in the gripping force limit table (Refer to page 17-19). If you must use a jaw taller than a standard soft jaw, use less than the input (piston For All Users thrust force, draw pipe drawing force) specified in the gripping force limit table. ・Do not use a jaw of a height out of Standard soft Special top jaw height jaw height the range of the gripping force limit table or a jaw with mass moment out Lower the hydraulic of the range of the gripping force pressure when using limit table. The chuck will break and a tall jaw the chuck and work will break and fly ...

- Page 10 DANGER Failure to follow the safety precautions below will result in serious injury or death. Use of a chuck and cylinder that cannot be used together safely may cause the cylinder to break at high pressure resulting in the chuck For All Users and work flying out. ・Check that the chuck and the cylinder are in the safe combination when using at high pressure with our company or the distributor. Especially when the cylinder of our company and a high pressure chuck of other company are combined, confirmation is necessary. ・If one of the abnormal events shown below occurs during Cylinder Chuck operation, ...

- Page 11 Important Safety Precautions DANGER Failure to follow the safety precautions below will result in serious injury or death. Provide sufficient strength for the draw pipe (Refer to pages 30-31). Provide sufficient screw depth for the draw pipe. For Machine Tool Manufactures Firmly tighten the draw pipe. ・If the draw pipe break, the gripping force is instantly lost and this is dangerous as work will Cylinder adapter Draw pipe fly out. Cylinder Chuck ・If the screw depth of the draw pipe is insufficient, the screw will break and the gripping force will be lost instantly, and this is dangerous as work will fly out.

- Page 12 Important Safety Precautions WARNING Failure to follow the safety precautions below could result in serious injury or death. Do not modify the chuck in a way not permitted by the manufacturer. For All Users ・It may not only break the chuck but the chuck and the work may fly out, which is dangerous. ・If you attach a locator or jig on the chuck body surface, only process work in an acceptable range (Refer to page 25). Periodically supply adequate grease (Refer to page 26). Turn off power before adding grease. For All Users ・Insufficient grease supply lowers the gripping force, causes operation failure due ...

-

Page 13: Specifications

3 . Specifications 3−1 Specifications Table 2 ・ B-200 type Type B-204 B-205 B-206 B-208 B-210 B-212 B-215 Plunger stroke Jaw stroke (in diameter) 10.6 10.6 17.5 34.8 Allowable maximum input force (kgf) (1428) (1784) (2243) (3549) (4385) (5608) (9993) 28.5 Maximum static gripping force (kgf) (2906) (3671) (5812) (8769) (11319) (14686) (25391) Allowable maximum rotation 8000 7000 6000... - Page 14 However, the gripping force is different depending on the state of grease lubrication, grease in use, height of the jaw, etc. The maximum static gripping force specified in the specification is the value under the following conditions: ・The Kitagawa standard soft jaw is used as the jaw. ・The attaching bolts of the soft jaw are tightened at the standard soft jaw specified torque. (Refer to page 9) ・The numerical values are obtained with the Kitagawa gripping force meter . The gripping position of the gripping force meter is at a position 1/2 of the height of Allowable the soft jaw top surface (height from the chuck surface maximum to the top surface of the jaw). input force ・CHUCK GREASE PRO is used. (Refer to page 26).

-

Page 15: Relationship Between Gripping Force And Rotation Speed

As the rotation speed becomes higher, the centrifugal force of the jaw increases and the gripping force lowers. The curves displayed in Fig. 6, Fig. 7 shows relationships between the rotation speed and the centrifugal force when using the standard soft jaw. The centrifugal force differs significantly depending on the size and shape of the top jaw and the attaching position, therefore, when the rotation speed is high, actual measurement using a Kitagawa gripping force meter is required. ・B-200 type B-205 B-204 28.5... - Page 16 B-210 B-212 Input force Input force Limit Limit 1000 2000 3000 1000 2000 3000 4000 5000 4200 3300 Rotation Speed(min - Rotation Speed(min - ) ) B-215 Input force Limit Fig.6 1000 2000 3000 2800 Rotation Speed(min - ) ・BT200 type BT205 BT204 Input force Input ...

-

Page 17: Relationship Between Gripping Part Center Height, Static Griping Force And Input Force / Relationship Between Top Jaw Mass Moment And Gripping Force Loss

DANGER ・In the case of processing a considerably unbalanced work, lower the rotation speed. The work will fly out and this is dangerous. ・Vibration is generated if there is unbalance due to the work and the jig, etc. Vibration decreases process precision and shortens the working life of the chuck, even possibly breaking it. Correct the unbalance by using a balance weight, etc., or lower the rotation speed for use. ・In the case of heavy cutting at high rotation speed, vibration is easily generated in the same manner as the unbalance of the chuck, therefore, set the cutting conditions appropriate for the dynamic gripping force and machine rigidity. 3-3 Relationship between gripping part center height, static griping force and input force / Relationship between top jaw mass moment and gripping force loss If the gripping part center height of the used top jaw (dimension H in Fig. 8) is higher than the gripping part center height of the standard soft jaw, a large load is applied to the master jaw, T nut, jaw attaching bolts, etc. To prevent these parts from being broken, it is necessary to use the machine by using a lower input force than the allowable maximum input force. Additionally, if the top jaw is larger and heavier, the centrifugal force generated at the top jaw will increase. It is necessary to examine the dynamic gripping force considering the centrifugal force and to use the machine at a rotation speed that can withstand the cutting force. Work Chuck Chuck G: Center of mass of the top jaw m: Mass of the top jaw r : Distance from the center of mass of the top jaw to the chuck center H : Gripping center height Fig.8... - Page 18 ・ B-200 Type Input force B-204 28.5 Limit 5 12.5 Standard soft top jaw Standard soft top jaw Gripping part center height H (㎜) Mass moment of top jaw m×r×3 ( ㎏ ・㎜) Input force Limit 5 5 1500min 13.5 Standard soft top jaw Standard soft top jaw Gripping part center height H (㎜) Mass moment of top jaw m×r×3 ( ㎏ ・㎜) Input force B-206 Limit Standard soft top jaw Standard soft top jaw Gripping part center height H (㎜) Mass moment of top jaw m×r×3 (...

- Page 19 Input force B-212 Limit 90 80 70 60 50 40 30 20 750min 10 1000 1200 Gripping part center height H (㎜) Standard soft top jaw Standard soft top jaw Mass moment of top jaw m×r×3 ( ㎏ ・㎜) Input force B-215 Limit 80 60 40 50 20 1000 2000 3000 Standard soft top jaw Standard soft top jaw Gripping part center height H (㎜) Mass moment of top jaw m×r×3 (...

- Page 20 Input force BT208 57.3 38.2 Limit Standard soft top jaw Standard soft top jaw Gripping part center height H (㎜) Mass moment of top jaw m×r×2 ( ㎏ ・㎜) Input force BT210 80 49.3 70 Limit 60 50 40 30 20 10 Standard soft top jaw Standard soft top jaw Gripping part center height H (㎜) Mass moment of top jaw m×r×2 ( ㎏ ・㎜) BT212 Input force Limit 90 80 70 60 50...

- Page 21 The required static gripping force and input force required at the rotation speed in use are predicted from Fig.9, Fig 10, however, it contains a number of hypothetical conditions. Therefore, it is necessary to only use these as reference, and the processing conditions must be determined after trial cutting without fail. DANGER ・Reduce the allowable maximum input force of the 2 jaw chuck by 2/3 in comparison with the 3 jaw chuck. (Refer to Table 3) Otherwise the chuck will break, the work will fly out and this is dangerous. ・In the case of inside diameter gripping, keep the input to 1/2 of the allowable maximum input or less. In the case of inside diameter gripping, the length of engagement of the master jaw and the dovetail groove is shorter when compared to the outside diameter gripping, therefore, the chuck will break, the work will fly out and this is dangerous. ・In the case of using only 1 jaw for gripping reduce the input force by 2/3 or more with 3 jaw chuck. If 2 jaws are used for gripping reduce the input force by 1/3 or more with 3 jaw chuck. If 1 jaw is used for gripping reduce the input force by 1/2 or more with 2 jaw chuck. If it is used without lowering the input, the input which is normally applied evenly onto 3 of the jaws is concentrated onto 1 or 2 of the jaws. Otherwise the chuck will break, the work will fly out and this is dangerous.

-

Page 22: Forming Soft Jaw

4 . Forming Soft Jaw 4−1 Attachment of soft jaw The attaching position of the soft jaw can be adjusted by loosening the socket head cap screw, attaching the soft jaw and by changing each serration engagement position. Use the most appropriate soft jaw considering the shape, dimension, material, and surface roughness of the work and the cutting conditions, etc. DANGER ・Use the T nut so that it does not come out from the master jaw. (Refer to Fig.11) ・It if the T nut comes out from the master jaw, the master jaw and T nut will break causing the work to fly out and a possible precision failure. Hard jaw T nut Body Body Body Body (Correct) Fig.11 ・Always tighten the bolts at the specified torque. If the torque is insufficient or excessive, the bolt will break, which is dangerous as the chuck or work will fly out. Table 5 Bolt size Tightening torque Bolt size Tightening torque M 5 7.5 N ・ m 107 N ・ m M 6 13 N ・ m 171 N ・ m M 8 ... -

Page 23: Forming Soft Jaw With Outside Diameter Gripping

4−2 Forming soft jaw with outside diameter gripping 1.Preparation of the plug for forming ・Prepare the plug for forming. The surface roughness of the plug outside diameter is to be approximately 25s, and make a shape with sufficient thickness which does not distort. ・It is convenient to prepare various outside diameter dimensions for dimensions of forming parts. ・It is convenient to process tapping in the center part of the plug and to guide with a bolt, etc. 2.Process of the plug gripping part for forming ・Operate the switch valve and maximize the opening of the jaw. ・Then, process the φD part (part to grip the plug for forming). Set the dimension φD so that gripping near the center of the jaw maximum stroke (diameter) is possible. -

Page 24: Forming Method When You Use Forming Jig

3.Gripping of the ring for forming ・By operating the switch valve, grip the ring for forming in the φD part. At this time, grip by pressing the ring on the jaw in order for the ring not to be tilted. Repeat chucking several times to stabilize the ring. 4.Forming ・Process the gripping part (dimension φD') of the work in the state that the ring is kept gripped. The φD' part is to be approximately the same diameter (H7) as the diameter of the gripping part of the work, and process to be surface roughness at 6s or less. ・Set the hydraulic pressure when forming the same as when processing of the work, or slightly higher. Additionally, in the case of inside diameter gripping, it is necessary to use the input at 1/2 of the allowable maximum input or less. ・When the ring distorts, lower the hydraulic pressure or change the ring into a shape which does not easily distort. 5.Trial cutting ・Remove ... -

Page 25: Usage

・If the protrusion of the work is long, support it with a center or the steady rest. If the protrusion is long the tip of the work turns, and this is dangerous as the work will fly out. 5−3 Precautions related to usage of jaw DANGER ・If a soft jaw other than one made by Kitagawa Corporation is used, the engagement will be inferior, and the master jaw will be deformed, the gripping precision will worsen, and the work will fly out due to gripping failure, which is dangerous. ・Do not use a top jaw with a different serration pitch from the master jaw. The engagement of the crests of the serration will become insufficient, therefore, the serration crests will break when gripping the work, and this is ... - Page 26 5−4 Precautions related to processing DANGER <1> Unbalance ・In the case of processing largely unbalanced work, lower the rotation speed. The work will fly out and this is dangerous. ・Vibrations are generated if there is unbalance owing to the work or the jig, etc. Vibration not only will impart a negative ...

-

Page 27: Maintenance And Inspection

6−2 Grease lubrication 1.Position to lubricate ・Lubricate using a grease gun from the grease nipple on each master jaw periphery part. Supply grease when the jaw is open. After lubrication, repeat opening and closing the jaw several times without gripping work. 2.Grease to use ・Use the designated grease specified in Table 8. If grease other than the designated grease is used, sufficient effect may not be obtained. Table 8 Genuine Kitagawa genuine product CHUCK GREASE PRO product (Kitagawa distributor of each country) Kitagawa chuck grease Conventional product Molykote EP Grease TORAY Dow Corning (only inside Japan) Conventional Chuck EEZ grease Kitagawa-Northtech Inc. (North American region) product MOLYKOTE TP-42... -

Page 28: Disassembling

6−3 Disassembling Disassembling procedures Read the following disassembling procedures with reference to page 5. 1. Turn off the main power of the machine before starting work. 2. Loosen the jaw attaching bolt [13] and remove the soft jaw [4] and the T nut [5]. 3. Remove the cover [8]. 4. Turn the draw nut [7] with the handle [10] while loosening the chuck attaching bolt [14], and remove the chuck from the spindle. 5. Remove the wedge plunger [2] to the chuck rear side. 6. Remove the master jaw [3] to the inner periphery side of the chuck. 7. Assemble again while sufficiently coating the recommended grease in the reverse procedures of disassembling. At this time, pay sufficient attention so as not to make a mistake in the numbers of the body [1], master jaw [3], and the wedge plunger [2]. 8. Refer to page 34 about the installation procedure. (8-4. Attachment of chuck). CAUTION ・Use an eyebolt or a hanging belt when attaching and detaching the chuck to and from the machine, as there is a danger of injury or damage if the chuck drops. Chuck size(inch) Eyebolt 4 , 5 none 6 , 8 , 10 12 , 15 WARNING ・Remove the eyebolt or the belt without fail after using. If the chuck is rotated with the eyebolt, etc., attached, they may fly out and this is dangerous. ・Disassemble and clean the chuck at least once every 6 months or every 100,000 strokes (once every 2 months or more for cutting cast metal). If cutting powder or other substances stagnate inside the chuck, it will lead to insufficient stroke and a drop in the gripping force, and this is dangerous as the work will fly out. Check each part ... -

Page 29: Malfunction And Countermeasures

7 . Malfunction and Countermeasures 7−1 In the case of malfunction Check the points specified in the table below and take the appropriate countermeasure. Table 9 Defective Cause Countermeasure The chuck inside will break. Disassemble and replace the broken part. Disassemble, correct the seized part with oilstone, etc., or replace The chuck The sliding surface is seized. the part. does not Check the piping and the electric system, and if there is no operate. The cylinder is not operating. abnormality, disassemble and clean the cylinder. A large amount of cutting powder is inside. Disassemble and clean. Insufficient The draw pipe loosened. Remove the draw pipe and retighten it again. stroke of the jaw. Adjust so that the jaw is near the center of the stroke when The stroke of the jaw is insufficient. gripping the work. The gripping force is insufficient. Check that the correct hydraulic pressure is obtained. The forming diameter of the top jaw is not Form again based on the correct forming method. consistent with the work diameter. Calculate the cutting force and check that it is suitable for the The Work The cutting force is too large. specification of the chuck. slips. Supply grease from the grease nipple, and open and close the jaw Insufficient grease lubrication several times without gripping a work. The rotation speed is too high. Swinging occurs ... -

Page 30: Attachment

For Machine Tool Manufactures Following pages are described for machine tool manufacturers (personnel who attach a chuck to a machine). Please read following instruction carefully when you attach or detach a chuck to machine, and please sufficiently understand and follow the instructions for safe operation. 8 . Attachment 8−1 Outline drawing of attachment Lathe rear cover Cylinder Cylinder adapter Draw pipe Top jaw Sleeve body NC lathe Chuck Support Back plate Drain hose Flexible hose Use one with large inside diameter as possible Hydraulic pump Pressure Manual Pressure gauge switching valve ajusting screw SOL. Line filter Solenoid valve Tank Return onto the oil surface Fig.15 ・Attach the manual switching valve at a position where it is easy to operate for the attaching equipment. ・Install the hydraulic unit at a position where the drain hose is not kinked and the needle of the pressure gauge is easily read. - Page 31 DANGER ・When other actuators are operated by the same hydraulic pressure source as the cylinder for chuck, be sure that a pressure drop of the cylinder does not occur during use. A hydraulic pressure drop leads to a drop in the gripping force which could allow the work to fly out. ・As to the drain hose ・Use one with inside diameter φ32. ・Use a transparent vinyl hose for visualization. ・Provide a stream slope, without air pocket. This will ensure no back pressure. ・The end of the hose is physically above the oil level. (Refer to Fig.15) ・If the hydraulic oil stagnates inside the cylinder, oil leakage occurs, which may cause a fire. WARNING ・Install after removing the dust inside the pipe completely. ・Add a filter to the pressure supply line. If foreign matters gets inside the cylinder, this is dangerous since the rotation valve of the cylinder will seize, the hose will tear off, and the cylinder will rotate. This is also dangerous ...

- Page 32 The dimension L in Fig.16 is determined from the distance A between the cylinder adapter and the back plate. (Example) In the combination of B-206, SS1246, and when A=800mm, the draw pipe length L is to be L = A + 41 = 800 + 41 = 841mm. At the time of the screw process of the dimension a, the precision is to be JIS 6H and 6h, 6g matching the screw of the piston of the cylinder. Pay attention so that the thread parts on both ends and the inner periphery do not swing or become unbalanced. DANGER ・Provide sufficient strength for the draw pipe. If the draw pipe is broken due to insufficiency of the strength, the gripping force will be lost instantly, which is dangerous as the work will fly out. ・Keep the dimension e and the dimension f in Fig. 16 for the draw pipe and a material with the tensile strength 380MPa (38kgf/mm ) or more must be used. ・The personnel who designed draw pipe must judge whether the strength of the draw pipe is sufficient for the usage conditions. ・The dimensions and materials specified in this manual do not guarantee that the draw pipe will not break under every usage condition. ・If the screw-in depth of the draw pipe to the draw nut is insufficient, the screw will break and the gripping force will be lost instantly, which is dangerous as the work will fly out. ・If the engagement of the screw of the draw pipe is loose, vibration may occur resulting in breakage of the screw. If the screw breaks, the gripping force will be lost instantly, which is dangerous as the work will fly out.

- Page 33 DANGER ・Always tighten the bolts at the specified torque. If the torque is insufficient or excessive, the bolt will break, which is dangerous as the chuck or work will fly out. ・Use the bolts attached to the chuck, and do not use other bolts. However, if you must use other bolts not provided by Kitagawa, use bolts that have at least a strength classification of 12.9 (10.9 for M22 or more) and be sure they are long enough. Table 11 Bolt size Tightening torque Bolt size Tightening torque M 5 7.5 N ・ m 107 N ・ m M 6 ...

- Page 34 DANGER ・Always tighten the bolts at the specified torque. If the torque is insufficient or excessive, the bolt will break, which is dangerous as the chuck or work will fly out. ・Use the bolts attached to the chuck, and do not use other bolts. However, if you must use other bolts not provided by Kitagawa, use bolts that have at least a strength classification of 12.9 (10.9 for M22 or more) and be sure they are long enough. Table 13 Bolt size Tightening torque Bolt size Tightening torque M 5 7.5 N ・ m 107 N ・ m M 6 ...

-

Page 35: Attachment Of Chuck

8−4 Attachment of chuck 1.Attaching the draw pipe to the cylinder ・Apply adhesive onto the screw part of the draw pipe, and screw it into the piston rod of cylinder. At this time, refer to the instruction manual for the cylinder for tightening torque. NOTICE ・When attaching the draw pipe to the cylinder, the stopper pin of the piston may break if tightened at the stroke middle position of the piston. In the case of a S type cylinder, F type cylinder and SR type cylinder, screw it in so that the piston rod is fully out. Follow the explanation of the instruction manual for the cylinder for other items about the cylinder. 2.Attach the cylinder to the spindle (or the cylinder adapter) ・Check the run-out of the cylinder, and if it is normal, attach the hydraulic pipe. ・Move 2 to 3 times at low pressure (0.4 MPa-0.5 MPa, 4 - 5 kgf/cm ) and set the piston at the forward end and turn off the power supply. CAUTION Chuck size(inch) Eyebolt 4 , 5 none ・Use an eyebolt or a hanging belt 6 , 8 , 10 12 , 15 when attaching and detaching the ... - Page 36 ・Turn the handle for connection to make a state that the chuck closely contacts the spindle attaching surface of the lathe. ・In the case of adjusting the centering of the chuck, lightly hit the body side face with a plastic hammer. ・ Tighten the chuck attaching bolts evenly. At this time, tighten the bolts at the specified torque. DANGER ・ Always tighten the bolts at the specified torque. If the torque is insufficient or excessive, the bolt will break, which is dangerous as the chuck or work will fly out. ・Use the bolts attached to the chuck, and do not use other bolts. However, if you must use other bolts not provided by Kitagawa, use bolts that have at least a strength classification of 12.9 (10.9 for M22 or more) and be sure they are long enough. Table 15 Bolt size Tightening torque Bolt size Tightening torque M 5 7.5 N ・ m 107 N ・...

-

Page 37: Other Information

9 . Other information 9−1 About standards and orders This product is based on the following standards or orders. ・ Machinery directive : 2006/42/EC Annex I ・ EN ISO 12100 : 2010 ・ EN1550 : 1997+A1 : 2008 9−2 Information about markings of product Manufacturer's logo F MAX:MAX PERMISSIBLE INPUT FORCE Jaw No. Type of ΣS MAX:MAX STATIC GRIPPING FORCE top jaw N MAX:MAX PERMISSIBLE SPEED Manufacturer's MASS:MASS Specifications address Type MFG No. Jaw No. Stroke mark Fig.23 9−3 About disposal Ultimate disposal of this product should be handled according to all national laws and regulations. - Page 40 Kitagawa Corporation Kitagawa Global hand Company 77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan Tel.+81-847-40-0561 Fax.+81-847-45-8911 ■ JAPAN DOMESTIC 1-405-1,Kita-ku,Yosino-cho,Saitama-shi,Saitama,331-9634,Japan Tokyo office Tel.+81-48-667-3469 Fax.+81-48-663-4678 4-15-13,Yamatomachi,Wakabayashi-ku,Sendai-shi,Miyagi,984-0042,Japan Sendai office Tel.+81-22-232-6732 Fax.+81-22-232-6739 2-62,Kamitakabata,Nakagawa-ku,Nagoya-shi,Aichi,454-0873,Japan Nagoya office Tel.+81-52-363-0371 Fax.+81-52-362-0690 3-2-9,Kitakagaya,Suminoe-ku,Osaka-shi,Osaka,559-0011,Japan Osaka office Tel.+81-6-6685-9065 Fax.+81-6-6684-2025 77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan Hiroshima office Tel.+81-847-40-0541 Fax.+81-847-46-1721 7-6-39,Itazuke,Hakata-ku,Fukuoka-shi,Fukuoka,812-0888,Japan Kyushu office Tel.+81-92-501-2102 Fax.+81-92-501-2103 77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan Overseas office Tel.+81-847-40-0526 Fax.+81-847-45-8911 ■ OVERSEAS KITAGAWA-NORTHTECH INC.

Need help?

Do you have a question about the BT200 Series and is the answer not in the manual?

Questions and answers