Summary of Contents for Schmalz Ecosystem MATCH

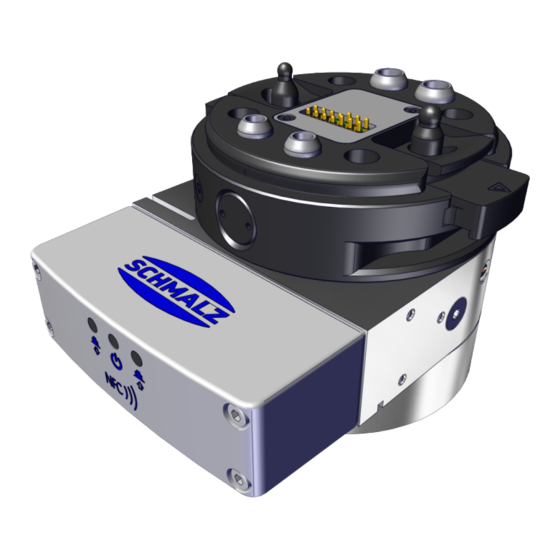

- Page 1 Operating instructions Ejector Module RECBi | End-of-Arm Ecosystem MATCH WWW.SCHMALZ.COM EN-US · 30.30.01.03118 · 02 · 03/23...

- Page 2 Published by © J. Schmalz GmbH, 03/23 This document is protected by copyright. J. Schmalz GmbH retains the rights established thereby. Repro- duction of the contents, in full or in part, is only permitted within the limits of the legal provisions of copyright law. Any modifications to or abridgments of the document are prohibited without explicit writ- ten agreement from J. Schmalz GmbH.

-

Page 3: Table Of Contents

Contents Contents 1 Important Information ........................... 6 Note on Using this Document...................... 6 The technical documentation is part of the product ................ 6 Other Applicable Documents...................... 6 Type Plate............................. 7 Symbols.............................. 7 2 Fundamental Safety Instructions........................ 8 Intended Use ............................ 8 Non-Intended Use.......................... - Page 4 Contents 5.19 Device Status ............................ 31 5.20 Energy and Process Control (EPC) ..................... 32 5.21 IO-Link Events ............................ 36 5.22 Active Profile (Active Profile Ejector x)..................... 36 5.23 Condition Monitoring Autoset ...................... 36 6 Technical Data............................... 37 General Parameters ........................... 37 Tool-Changer-Specific Data.......................

- Page 5 Contents 15.4 UKCA Conformity .......................... 74 16 Attachment .............................. 75 16.1 Data_Dictionary_RECBi_MATCH_1C.PDF.................. 76 16.2 Data_Dictionary_RECBi_MATCH_2C.PDF.................. 79 EN-US · 30.30.01.03118 · 02 · 03/23 5 / 84...

-

Page 6: Important Information

ð Failure to follow the instructions in these Operating instructions may result in injuries! ð Schmalz is not liable for damage or malfunctions that result from failure to heed these instructions. If you still have questions after reading the technical documentation, contact Schmalz Service at: www.schmalz.com/services... -

Page 7: Type Plate

1 Important Information 1.4 Type Plate The type plate is permanently attached to the product and must always be clearly legible. It contains product identification data and important technical information. 4 For spare parts orders, warranty claims or other inquiries, have the information on the type plate to hand. -

Page 8: Fundamental Safety Instructions

2.2 Non-Intended Use Schmalz does not accept any liability for any direct or indirect losses or damages that result from using the product. This applies, in particular, to any use of the product that is not in accordance with the in- tended purpose and to any use that is not described or mentioned in this documentation. -

Page 9: Warnings In This Document

2 Fundamental Safety Instructions Applicable for Germany: A qualified employee is defined as an employee who has received technical training and has the knowl- edge and experience – including knowledge of applicable regulations – necessary to enable him or her to recognize possible dangers and implement the appropriate safety measures while performing tasks. -

Page 10: Modifications To The Product

4 Do not walk, stand or work under suspended loads. 2.6 Modifications to the Product Schmalz assumes no liability for consequences of modifications over which it has no control: 1. The product must be operated only in its original condition as delivered. -

Page 11: Criteria For Use In Collaborative Applications

2 Fundamental Safety Instructions 2.7 Criteria for Use in Collaborative Applications 1) Automation cell 2) Coexistence The following criteria justify the suit- ability of the gripper for use in collabo- rative applications: See the adjacent image, Figure 3) and The gripper has an inherently safe de- sign and rounded edges and shapes that prevent hazards. -

Page 12: Product Description

3 Product description 3 Product description 3.1 Product Variants Versions of the RECBi MATCH: The products differ in the following features: • Control interface • The basic position of the ejectors in the de-energized state NO (normally open) and NC (normally closed) •... - Page 13 3 Product description 3.1.4 Gripper design and preparation Universal flange plate for: - Central suction cup connection - Mounting threads for customer-specific grippers PXT1 For connecting a gripper from the modular system PXT to one beam - Central vacuum supply or - Vacuum supply via the connections on the ejector module PXT2 For connecting a gripper from the modular system PXT to...

- Page 14 3 Product description 3.1.5 Part Table Schmalz part no. Version 10.02.03.00394 Digital I/O + IO-Link RECBi 24V-DC NC MATCH-PXT1 1C 10.02.03.00395 Digital I/O + IO-Link RECBi 24V-DC NC MATCH-PXT2 1C 10.02.03.00397 Digital I/O + IO-Link RECBi 24V-DC NO MATCH-PXT1 1C 10.02.03.00398...

-

Page 15: Product Design

3 Product description Schmalz offers a wide range of quick-change modules (RMQC) especially for connecting the product to the standard robot systems available on the market: 1. https://www.schmalz.com 2. Alternatively, search for “quick-change module RMQC” on the Schmalz home- page. -

Page 16: Led Display

3 Product description The venturi nozzle on the ejector is activated and deactivated using the suction command: • In the NO (normally open) version, vacuum generation is deactivated when the suction signal is received. (This means that if the power fails or if no control signal is present, vacuum is constantly generated (continuous suction).) •... -

Page 17: Nfc Interface

All the parameters of the upper and lower modules are parameterized via this NFC interface. Important: If an SCM module from Schmalz is used to operate the RECBi MATCH, writing via NFC is blocked. EN-US · 30.30.01.03118 · 02 · 03/23 17 / 84... -

Page 18: Storage Station (Accessories)

3 Product description For the best data connection, set the reading de- vice on the middle of the control and display ele- ment. The values from “production setup profile P0 are the decisive values in digital I/O mode and SIO mode. - Page 19 3 Product description 3.7.1 Function of the Sensors The figure below shows an example of a combination consisting of a fixed member, loose member with gripper and storage station. When the sensor system is used, it checks whether the loose member is present in the storage station. The fixed member is then moved onto the loose member from above.

- Page 20 3 Product description Circuit symbol for sensor in storage position Series connection of two sensors in test position Power Supply Power Supply Safety Safety Input Input Safety Input 3.7.3 Configuration of “Test Position” Sensor 1. With the loose member connected to the fixed member, bring the markings on the locking elements into line with the front markings on the storage station.

-

Page 21: Io-Link Operating Mode

4 IO-Link Operating Mode 4 IO-Link Operating Mode By default (after the supply voltage has been applied), the product always runs in digital I/O mode or SIO mode, but can be switched to IO-Link mode at any time by an IO-Link master. When operating the product in IO-Link mode (digital communication), the supply voltage, the ground and the communication line are connected to a controller, either directly or using intelligent terminal boxes. -

Page 22: Process Data

4 IO-Link Operating Mode Controller manufacturers usually provide a specialized function module – e.g. the “IOL_CALL” module for Siemens controllers – to enable these ISDU parameters to be accessed from a control program. These con- trol unit-specific modules must be obtained directly from the control unit manufacturer. The acyclical data channel can be used to retrieve ISDU parameters with further information about the system status. -

Page 23: Description Of Functions

5 Description of Functions 5 Description of Functions 5.1 Monitoring the System Vacuum and Defining Switching Points (P-0: 0x0064 to 0x0067) The product has integrated sensors for measuring the vacuum. The current vacuum value and current pressure values can be retrieved via IO-Link. Two independent switching points (SP1 and SP2) can be set for each ejector module. -

Page 24: Production Setup Profiles

5 Description of Functions Overview of the switching points P-0; the specified parameters apply to production setup profile P0 for ejector module 1 (for other profiles or ejector module 2, the data can be taken from the data dictionary): ISDU [hex] Limit value parame- Description Factory... -

Page 25: Picking Up The Workpiece (Vacuum Generation)

5 Description of Functions The RECBi allows you to conserve compressed air or prevent an excessive vacuum from being generated. Vacuum generation is interrupted once the configured switching point SP1 is reached. If leakage causes the vacuum to fall below the hysteresis switching point rP1, vacuum generation resumes. The following control function operating modes can be chosen: ISDU Parameter... -

Page 26: Depositing The Workpiece/Part (Blow-Off Mode)

5 Description of Functions The diagram below shows the vacuum curve when the control function is activated: Vacuum [mbar] OUT=on OUT=off Time [s] Vacuum on The ejector has an integrated control function and automatically regulates the vacuum in suction mode: •... -

Page 27: Automatic Operation

5 Description of Functions 5.6.1 Externally Controlled Blow-Off The ejector switches to blow-off mode for as long as the signal for “Blow-off” mode is present. 5.6.2 Internally Time-Controlled Blow-Off After the suction signal is switched off, the ejector switches to blow-off mode automatically for the set time. -

Page 28: Access Control

5 Description of Functions 5.9.2 Resetting the Application Only the technology-specific application parameters are reset by this function. System command “Reset application” 0x81 is used to reset all the parameters except the device localiza- tion parameters (see “Data Dictionary”) to their factory settings. Any IO-Link communication is not stopped in doing so. -

Page 29: Device Data

5 Description of Functions When a PIN code between 001 and 999 is set, the valid PIN must be entered for every subsequent write process using a mobile NFC device to ensure that the RECBi accepts the changes. 5.11 Device Data The device provides a range of identification data that can be used to uniquely identify a specific device. -

Page 30: Shutdown Delay (0X004B) (Output Filter Ejector)

5 Description of Functions 5.14 Shutdown Delay (0x004B) (Output Filter Ejector) You can use this function to set a switch-off delay for signals SP1 and SP2 for each individual ejector mod- ule. This can be used to mask short-term fluctuations in the vacuum level of the vacuum system. The dura- tion of the switch-off delay is set in IO-Link via the “Output filter”... -

Page 31: Counters

5 Description of Functions 5.18 Counters Each Ejector module has three internal, non-erasable counters and three erasable counters. Parameter address Description 0x008C Counter for suction cycles (suction signal) (Vacuum on counter Ejector x) 0x008D Counter for suction valve switching frequency (Valve operating counter Ejector x) 0x008E Counter for condition monitoring (Condition monitoring counter Ejector x) 0x008F... -

Page 32: Energy And Process Control (Epc)

5 Description of Functions When using an RECBi with two ejector modules (version C2), the status of the respective ejector modules can be read out via the “Device Status Ejector x” input process data, while “Device Status Overall” reflects the status of the entire product. A warning or fault within an RECBi with two ejector modules (version C2) thus leads to a warning or fail- ure for the overall device. - Page 33 5 Description of Functions 5.20.1 Condition Monitoring [CM] The active warnings are displayed via individual bits in the parameter “Condition monitoring” 0x0092. You can find a detailed description in the Data Dictionary. In addition, the warnings are transmitted in the process data: •...

- Page 34 5 Description of Functions Vacuum [mbar] Start suction cycle Time [s] Measure the evacuation time t0 (parameter “Evacuation time t0 of last suction cycle” 0x0094): The evacuation time t0 is defined as the time (in ms) from the start of a suction cycle, which is started by the “Suction ON”...

- Page 35 5 Description of Functions For determining the electrical energy consumption, the neutral phase of the suction cycle must also be considered. Therefore the measured values can be updated only when the next suction cycle begins. Dur- ing the entire cycle, they represent the results from the previous cycle. 5.20.4 Predictive Maintenance (PM) Overview of Predictive Maintenance (PM) To allow early detection of wear and other impairments to the vacuum gripping system, the product pro-...

-

Page 36: Io-Link Events

5 Description of Functions Maximum Vacuum Reached (Max Reached Vacuum of Last Cycle) In each suction cycle, the maximum system vacuum level reached is determined and made available as the parameter “Max reached vacuum of last cycle” 0x00A4. Minimum Input Pressure Reached from the Last Cycle (Min Reached Input Pressure of Last Cycle) In each suction cycle, the minimum compressed supply air level reached is determined and made available as the parameter “Min reached input pressure of last cycle”... -

Page 37: Technical Data

6 Technical Data 6 Technical Data 6.1 General Parameters Parameter Symbol Limit value Unit Comment min. typ. max. Working temperature ° C Storage temperature ° C Humidity % r.h. Free from condensation Degree of protection IP40 Operating pressure (flow pressure) Max. vacuum -850 mbar Operating medium Air or neutral gas, 5 µm filtered, with or without oil, class 3-3-3 com- pressed air quality in acc. - Page 38 6 Technical Data Version PXT 10.02.03.00 10.02.03.00 10.02.03.00 10.02.03.00 10.02.03.00 10.02.03.00 Control unit NC, nor- NC, nor- NO, nor- NO, nor- NC, nor- NO, nor- mally closed mally closed mally open mally open mally closed mally open Max. suction 52.5 l/min rate per vac- uum duct Suction air...

-

Page 39: Electrical Specifications

6 Technical Data 10.02.03.00375 10.02.03.00379 10.02.03.00377 10.02.03.00408 Status display Mass 715 g 1055 g 715 g 1055 g Version PXRx 10.02.03.00376 10.02.03.00407 10.02.03.00378 10.02.03.00409 Control unit NO, normally NO, normally NC, normally NC, normally open open closed closed Max. suction rate per 52.5 l/min vacuum duct Suction air consump- 89 l/min 178 l/min... -

Page 40: Maximum Forces

6 Technical Data 6.5 Maximum Forces The holding force of the different grippers is limited; that is, the absorption of load forces and torques is limited. To prevent the load from shifting or even coming loose during the handling process, the operator of the respective gripper is therefore obliged to determine the optimum settings for the permitted process parameters for the handling process (load, acceleration, vacuum level, and so on) by performing testing and carefully increasing the load. - Page 41 6 Technical Data Part no. 10.02.03.00395 69.5 10.02.03.00398 75.5 86.2 112.5 10.02.03.00400 94.5 10.02.03.00405 EN-US · 30.30.01.03118 · 02 · 03/23 41 / 84...

- Page 42 6 Technical Data Part no. 10.02.03.00401 74.5 10.02.03.00402 75.5 86.2 107.5 inter- 10.02.03.00403 99.5 10.02.03.00404 threa Part no. 10.02.03.00375 67.5 10.02.03.00379 92.5 75.5 86.2 107.5 10.02.03.00377 67.5 10.02.03.00408 92.5 42 / 84 EN-US · 30.30.01.03118 · 02 · 03/23...

-

Page 43: Factory Settings

6 Technical Data Part no. 10.02.03.00376 67.5 10.02.03.00407 92.5 75.5 86.2 10.02.03.00378 67.5 10.02.03.00409 92.5 All dimensions given in millimeters [mm]. 6.7 Factory Settings Parameter Value of the factory setting Limit value SP1 750 mbar Reset value RP1 600 mbar Limit value SP2 550 mbar Reset value RP2 540 mbar... -

Page 44: Pneumatic Circuit Plans

6 Technical Data 6.8 Pneumatic Circuit Plans Key: Normally closed Normally open Compressed air connection Vacuum connection Exhaust outlet RECBi MATCH with one ejector module 44 / 84 EN-US · 30.30.01.03118 · 02 · 03/23... - Page 45 6 Technical Data RECBi MATCH with two ejector modules EN-US · 30.30.01.03118 · 02 · 03/23 45 / 84...

- Page 46 6 Technical Data 46 / 84 EN-US · 30.30.01.03118 · 02 · 03/23...

-

Page 47: Transportation And Storage

1. Compare the entire delivery with the supplied delivery notes to make sure nothing is missing. 2. Damage caused by defective packaging or occurring in transit must be reported immediately to the carrier and J. Schmalz GmbH. 7.2 Unpacking the Device Remove product packaging only to the extent required for further internal transport. -

Page 48: Installation

8 Installation 8 Installation 8.1 General Mounting Information CAUTION During assembly/disassembly, the loose member is accelerated by the applied com- pressed air and flies around uncontrolled. Risk of injury 4 During installation or replacement, deactivate the compressed air supply via the robot 4 Wear protective glasses or face protection. -

Page 49: Electrical Connection

8 Installation Manual gripper change: 4 Manually actuate (press) the locking mecha- nism on both sides of the loose member RECBi MATCH. Connect the loose member RECBi MATCH with the fixed member RMQC. The two markings (triangles) must point to each other. -

Page 50: Static Electricity

8 Installation The electrical contacts must always be dry, clean and undamaged. Damage to the contacts can cause the product to malfunction. The electrical connection for the fixed member must not be established and the fixed member must not be put into operation until the entire gripper has been completely installed. 8.4 Static Electricity NOTE Static Electricity... - Page 51 8 Installation 8.5.1 Assembling the Vacuum Gripping System This interface offers two options for connecting vacuum suction cups. Central vacuum connection 1. Remove the screw (1). Ensure that the O-ring is fitted. Install the vacuum suction cup (a bellows suction cup is shown as an example here) via the central vac- uum connection (1) with a ¼-inch female thread with a max.

- Page 52 8 Installation 2. Connect the vacuum gripping system to the vacuum supply. Remove the selected screw for the vacuum supply and install a suitable hose connection. In the version with one ejector module, a total of five vacuum connections are available for the vac- uum supply.

- Page 53 8 Installation 8.5.2 Interface PXT The interface PXT is used to receive a vacuum gripper based on the modular gripping system PXT from Schmalz. The modular system PXT includes the following versions that differ with respect to the gripper features: •...

- Page 54 Detailed information about the modular system PXT and a description of the assembly can be found in the assembly instructions part no. 30.30.01.02710). Request the instructions from the Schmalz Service department at: www.schmalz.com/services. 54 / 84 EN-US · 30.30.01.03118 · 02 · 03/23...

- Page 55 8 Installation 8.5.3 Interface PXR The interface PXR has a sheet metal structure for positioning and attaching suction cups. The vacuum line can be established only via hose connections. The sheet metal structure is available in two versions: • With 2 in-line mounting options (PXRi) •...

- Page 56 8 Installation 2. Fasten by hand with the nut (3). 3. Insert the plug connector (4) into the hose connection of the hollow bolt (2) until it stops. 4. Ensure that the O-ring is mounted on the vac- uum suction cup (5). Screw the vacuum suction cup (5) onto the hollow screw (2) and fasten with a tightening torque of 2.5 Nm.

- Page 57 8 Installation 5. Position the suction cup assembly in the RECBi MATCH holder and secure with a tightening torque of 9 Nm using the nut (3). 6. Remove the required number of plugs (6) from the ejector module. 7. Screw the plug-in screw unions (7) into the free vacuum connections and fasten them with a tightening torque of 2.5 Nm.

- Page 58 8 Installation 8. Cut the vacuum hose (8) to length and insert it into the hose connections. ð Example of a fitted RECBi MATCH PXR-i with vacuum gripping system 58 / 84 EN-US · 30.30.01.03118 · 02 · 03/23...

-

Page 59: Operation

9 Operation 9 Operation 9.1 Safety Instructions for Operation WARNING Change of output signals when product is switched on or plug is connected Risk of injury to persons and damage to property due to uncontrolled movements of the higher-level machine/system! 4 The electrical connection must be performed only by specialists who can evaluate the effects of signal changes on the overall system. -

Page 60: Setting Process Parameters

(load, acceleration, vacuum level, and so on) by performing testing and carefully increasing the load. Schmalz assumes no liability for damages resulting from slippage or the release of the load due to the in- correct adjustment of process parameters. -

Page 61: Help With Malfunctions

10 Help with Malfunctions 10 Help with Malfunctions Error Cause Measure 4 Connection to IO-Link class A port Master or peripheral Connection to IO-Link master with power supply disturbed IO-Link class-B port 4 Check electrical connection and pin No output signal Incorrect electrical connection or device does not re- assignment... -

Page 62: Maintenance And Cleaning

Unauthorized disassembly and assembly of the product can lead to complications, as special assembly de- vices are sometimes required. Schmalz stipulates the following checks and check intervals. The operator must comply with the legal regulations and safety regulations applicable at the location of use. These intervals apply to single-shift operation. -

Page 63: Cleaning

11 Maintenance and Cleaning Maintenance task When start- Weekly As required Every six ing work months Clean the product Maintain the locking device for and po- sitioning of the loose member The operating instructions are avail- able, legible and can be accessed by personnel The visual inspection covers only the components and their function. - Page 64 11 Maintenance and Cleaning ü Deactivate the device and depressurize the pneumatic systems. ü A new silencer spare part set with part no. 10.02.03.00422 or 10.02.03.00441 is available as a replace- ment. 1. Release the two fastening screws on the si- lencer housing.

-

Page 65: Replacing The Nozzle

11 Maintenance and Cleaning 5. Push the silencer housing (2) into the ejector module and secure with two screws (tighten- ing torque 0.7 Nm). 11.5 Replacing the Nozzle ü Deactivate the device and depressurize the pneumatic systems. ü The new nozzle is ready for mounting. See accessories. 1. - Page 66 11 Maintenance and Cleaning ð Remove the nozzle from the ejector mod- ule. 4. Check that all O-rings and flaps are present, correctly mounted and lightly greased. Push the new nozzle into the ejector module in the correct position. 5. Push the silencer housing (2) into the ejector module and secure with two screws (tighten- ing torque 0.7 Nm).

- Page 67 11 Maintenance and Cleaning 6. Ensure that the O-ring is fitted on the screw (1) and is lightly greased. Mount the screw (1) and tighten with a torque of 1.5 Nm. EN-US · 30.30.01.03118 · 02 · 03/23 67 / 84...

-

Page 68: Spare And Wearing Parts

12 Spare and Wearing Parts 12 Spare and Wearing Parts The following list contains the most important spare and wearing parts. Part no. Designation Part type 10.02.03.00422 Silencer spare parts set Spare part ERS RECBi SD 10.02.01.01449 Spare parts set, size: 13 contains: 6x non-return Spare part valve ERS SEP-13 6xRUE-KLAP... -

Page 69: Accessories

The function of the product cannot be guaranteed if you use accessories that are not sold or authorized by Schmalz or the Zimmer Group. Schmalz accessories are tailored especially to the individual products. You can find optional accessories and the accessories included in delivery in the table below and at www.schmalz.com. -

Page 70: Taking The Product Out Of Operation And Disposal

14 Taking the Product Out of Operation and Disposal 14 Taking the Product Out of Operation and Disposal If the product reaches the end of the utilization phase, it may be fully disassembled and disposed of. Only qualified specialist staff may prepare the product for disposal. 1. -

Page 71: Declarations Of Conformity

15 Declarations of Conformity 15.1 EC Conformity EU Declaration of Conformity The manufacturer Schmalz confirms that the product with the name “ejector module RECBi MATCH” that is described in these operating instructions complies with the following applicable EC directives: 2011/65/EU RoHS Directive... -

Page 72: Ukca Conformity

15 Declarations of Conformity 15.2 UKCA Conformity Declaration of Conformity (UKCA) The manufacturer Schmalz confirms that the product described in these operating instructions fulfills the following applicable UK regulations: 2012 The Restriction of the Use of Certain Hazardous Substances in Electrical and... -

Page 73: Eu Declaration Of Incorporation

15.3 EU Declaration of Incorporation Declaration of Incorporation The manufacturer Schmalz confirms that the product with the name “ejector module RECBi MATCH” that is described in these operating instructions complies with the following applicable EC directives: The product specified is solely intended for installation indoors in a complete system. Startup is prohibited until the end product has been declared to comply with the Directive 2006/42/EC. - Page 74 15 Declarations of Conformity 15.4 UKCA Conformity The manufacturer Schmalz confirms that the product described in these operating instructions fulfills the following applicable UK regulations: The product specified is solely intended for installation indoors in a complete system. The start of opera- tions shall be prohibited until the conformity of the final product with the “Supply of Machinery (Safety)

- Page 75 16 Attachment 16 Attachment See also 2 Data_Dictionary_RECBi_MATCH_1C.PDF [} 76] 2 Data_Dictionary_RECBi_MATCH_2C.PDF [} 79] EN-US · 30.30.01.03118 · 02 · 03/23 75 / 84...

- Page 76 IO-Link Data Dictionary RECBi MATCH 1-C 10.02.03.00394 22.03.2023 J. Schmalz GmbH Johannes-Schmalz-Str. 1, D 72293 Glatten Tel.: +49(0)7443/2403-0 Fax: +49(0)7443/2403-259 IO-Link Implementation Vendor ID 234 (0xEA) Device ID 100280 (0x0187B8) SIO-Mode IO-Link Revision 1.1 (compatible with 1.0) IO-Link Bitrate 38.4 kBit/sec (COM2)

- Page 77 0x00F8 NFC web link 1…64 bytes https://myproduct.schmalz.com/#/ Web link to NFC app (base URL for NFC tag) https://… 0x00F9 Storage location 1…32 bytes User string to store storage location 0x00FD Installation date 1…16 bytes User string to store date of installation ...

- Page 78 Primary supply voltage live bytes Unit: 0.1V 0x0042 Primary supply voltage min bytes Unit: 0.1V Primary supply voltage max bytes Unit: 0.1V 0x0113 Active profile byte Number of active profile Communication Mode 0x00 = SIO mode 0x0234 Communication mode byte 0x11 = IO-Link revision 1.1 ...

- Page 79 IO-Link Data Dictionary RECBi MATCH 2-C 10.02.03.00394 22.03.2023 J. Schmalz GmbH Johannes-Schmalz-Str. 1, D 72293 Glatten Tel.: +49(0)7443/2403-0 Fax: +49(0)7443/2403-259 IO-Link Implementation Vendor ID 234 (0xEA) Device ID 100281 (0x0187B9) SIO-Mode IO-Link Revision 1.1 (compatible with 1.0) IO-Link Bitrate 38.4 kBit/sec (COM2)

- Page 80 Size Access Default Value Remark Range Identification Device Management 0x0010 Vendor name 0…32 bytes J. Schmalz GmbH Manufacturer designation 0x0011 Vendor text 0…32 bytes Innovative Vacuum Solutions Internet address 0x0012 Product name 0…32 bytes RECBi_MATCH_2C Product name 0x0013 Product ID 0…32 bytes...

- Page 81 Unit: 1ms, Permissable leakage rate 0x00BC bytes 0-999 no leakage rate warning if set to 0 0x00C7 Profile name 0…16 bytes Name of profile Production Setup - Profile P2 Ejector 1 0 = not active (off) 0x00C8 Air-Saving function byte 1 = active (on) 2 = active with supervision (onS)

- Page 82 SP2 > rP2 Resetpoint 2 (rP2) 0x016D bytes Unit: 1mbar >= 10 0x016E Duration automatic blow bytes 10-9999 Unit: 1ms Unit: 1ms, 0x016F Permissable evacuation time bytes 0-9999 2000 no evacuation time warning if set to 0 Unit: 1ms, Permissable leakage rate 0x0170 bytes 0-999...

- Page 83 Energy Monitoring [EM] 0x009B Air-Consumption of last suction-cycle Ejector 1 byte Unit: 1% 0x009B Air-Consumption of last suction-cycle Ejector 2 byte Unit: 1% 0x009C Air-Consumption of last suction-cycle Ejector 1 bytes Unit: 0.1 L std. 0x009C Air-Consumption of last suction-cycle Ejector 2 bytes Unit: 0.1 L std.

- Page 84 At Your Service Worldwide Vacuum automation Handling systems WWW.SCHMALZ.COM/AUTOMATION WWW.SCHMALZ.COM/EN-US/VACUUM-LIFTERS- AND-CRANE-SYSTEMS J. Schmalz GmbH Johannes-Schmalz-Str. 1 72293 Glatten, Germany T: +49 (0) 7443 2403-0 schmalz@schmalz.de WWW.SCHMALZ.COM...

Need help?

Do you have a question about the Ecosystem MATCH and is the answer not in the manual?

Questions and answers