Summary of Contents for Hussmann Mobile Produce

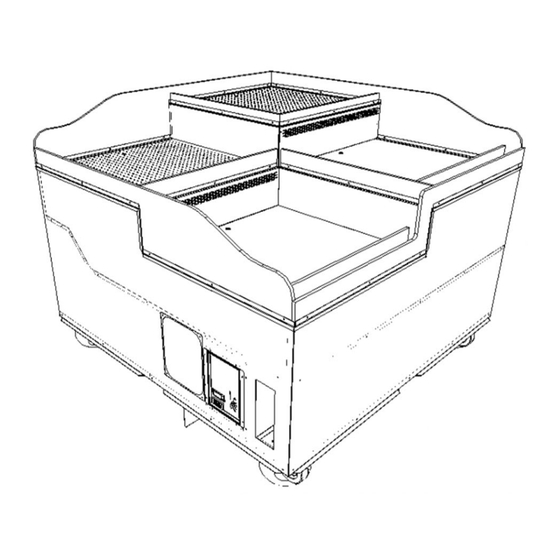

- Page 1 MOBILE PRODUCE CASE REMOTE SELF-CONTAINED I N S T A L L A T I O N & O P E R A T I O N G U I D E...

-

Page 2: Table Of Contents

Table of Contents General Information Installation Case Refrigeration Condensate Pan Setup Controller Programmed Parameters Electrical Wiring Diagram Index Wiring Diagram and Spec Sheets 11-19 Service Maintenance Warranty Controller Manual... -

Page 3: General Information

Shortages: Check your shipment for any possible shortages of material. If a shortage should exist and is found to be the responsibility of Hussmann Chino, notify Hussmann Chino. If such a shortage involves the carrier, notify the carrier immediately, and request an inspection. Hussmann Chino will acknowledge shortages within ten days from receipt of equipment. -

Page 4: Installation

Installation Location Do not Push, Pull, Adjust or Manipulate the Mobile The Mobile Produce Case display has been designed for Produce Case by any glass component. use only in air conditioned stores where temperature and Doing so will result in: humidity are maintained either 75°F ambient and 55% RH. -

Page 5: Case Refrigeration

Case Refrigeration Operation Each self‐contained model is equipped with its own condensing unit located beneath the display area. The unit will be charged per nameplate refrigerant and shipped from the factory with all service valves open, completely ready for opera‐ tion when electrical power has been connected. -

Page 6: Controller Programmed Parameters

Programmed Parameters M P C 3x6 PGM0008A01 S T A N D A R D C A S E R E V A 8/7/17 P a r a m e t e r C o e M ax Default A t u a l ( C ) A t u a l ( F ) T e m p e r a t u r e (set point) -50.0°C... - Page 7 HACCP Actual temperature measurement for the HACCP Last registered peak temperature Selection of function and sensor for the HACCP function. HACCP function. 1 = S4 used (maybe also S3). 2 = S5 Alarm limit for the HACCP function -50.0°C 50.0°C 8.0°C 8.0°C Time delay for the HACCP alarm...

- Page 8 MPC 6x6 PGM0011A01 T A N D A R D CASE REV A 8/7/1 Parameter C o e Default A t u a l ( C) A t u a l ( F) Temperature (set point) -50.0°C 50.0°C 2.0°C -2.2 r o d u c e (Type l) Thermostat Differential...

- Page 9 HACCP Actual temperature measurement for the HACCP Last registered peak temperature Selection of function and sensor for the HACCP HACCP function. 1 = S4 used (maybe also S3). 2 = S5 Alarm limit for the HACCP function -5 0 . 0 C 5 0 .

-

Page 10: Electrical

MPC-3X6-S DAN FOSS 3 X 6 3036674 MPC-3X9-S DAN FOSS 3 X 9 3075528 MPC-6X6-S DAN FOSS 6 X 6 3036675 Specification Sheets Model Description Size Mobile Produce MPC‐3X6‐SC and MPC‐6X6‐SC 2Case and 4Case Mobile Produce MPC‐3X6‐R and MPC‐6X6‐R 2Case and 4Case... -

Page 11: Wiring Diagram And Spec Sheets

Wiring Diagram... - Page 12 Wiring Diagram...

- Page 13 Wiring Diagram...

- Page 14 Wiring Diagram...

- Page 15 Wiring Diagram...

- Page 16 Wiring Diagram...

- Page 17 Wiring Diagram...

- Page 18 Spec Sheet CASE ENERGY USAGE DATA: ACTUAL CDEC MAX ALLOWABLE CASE LENGTH TDA/V (ft /ft) (KWh/day/ft) CDEC (KWh/Day/ft) 1.95 0.27 #DIV/0! #DIV/0!

- Page 19 Spec Sheet CASE ENERGY USAGE DATA: ACTUAL CDEC MAX ALLOWABLE CASE LENGTH TDA/V (ft /ft) CDEC (KWh/Day/ft) (KWh/day/ft) 0.27 1.35 #DIV/0! #DIV/0!

-

Page 20: Service

Service WARNING ! DISCONNECT THE ELECTRICAL POWER WHEN SERVICING OR REPLACING ANY ELEC‐ TRICAL COMPONENT. To access compressor area Remove all four screws in each corner of the access panel behind the case to expose compressor unit and condensate pan through open section of the rear wall. - Page 21 Service Condensor and Controller Access Panel Tips and Troubleshooting Before calling for service: • Check power. Ensure reliable electrical power supply to the equipment • Check shelf loading. Overstocking will adversely af‐ fect case performance. • If frost is collecting on fixture or product, verify that store Humidity Control is working properly, and that ...

- Page 22 Service...

-

Page 23: Maintenance

Maintenance Case Cleaning • DO NOT USE A CLEANING OR SANITIZING SOLUTION THAT HAS AN OIL BASE (these will dissolve the butyl To insure long life, proper sanitation and minimum maintenance sealants) or an AMMONIA BASE (this will corrode the costs, the refrigerator should be thoroughly cleaned frequently. -

Page 24: Warranty

Hussmann Specialty Products Service Department IMPORTANT! FPR PROMPT SERVICE WHEN CONTACTING HUSSMANN CORPORATION BE SURE TO HAVE CASE MODEL AND SERIAL NUMBER IN HAND For any warranty or service issues not covered by this manual, for tech support, or for warranty... - Page 25 August 31, 2018 This warning does not mean that Hussmann products will cause cancer or reproductive harm, or is in violation of any product-safety standards or requirements. As clarified by the California State government, Proposition 65 can be considered more of a ‘right to know’...

-

Page 26: Controller Manual

User Guide Controller for temperature control AK‐CC 210 ADAP‐KOOL® Refrigeration control systems...

Need help?

Do you have a question about the Mobile Produce and is the answer not in the manual?

Questions and answers