Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tempsens CALsys -35/200

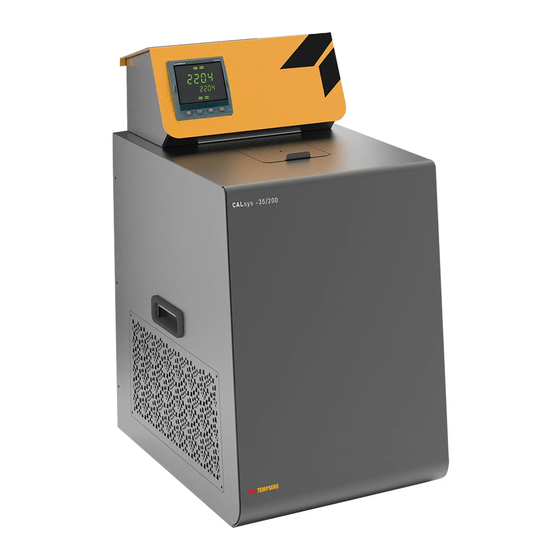

- Page 1 Liquid bath Temperature Calibrator (CALsys -35/200) User's Guide TEMPSENS INSTRUMENTS (l) PVT. LTD. UNIT ll A-190, Road No.5, M.I.A., Udaipur-313003 INDIA Ph. : +91-294-3500600, Fax : +91-294-3500631 Email : tech@tempsens.com Web : www.tempsens.com...

- Page 2 Legal Disclaimer The information contained in this document is the property of TEMPSENS. TEMSPENS reserves the right to make changes to this document and to the product described herein without notice. Before installing and using the product, review the latest version of the applicable documentation, which are available from the Tempsens website at: http://www.tempsens.com/...

-

Page 3: Table Of Contents

Cautions and Preventions....................... 7 Document Conventions......................8 Chapter 1 Introduction...........................9 1.1 About CALsys -35/200.......................9 1.2 Basic Working Model of CALsys -35/200................. 10 1.3 Physical Measurements......................11 1.4 Technical Specifications......................12 Chapter 2 Setting Up CALsys -35/200......................13 2.1 Installation..........................13 2.2 Optimal Environmental Conditions.................. - Page 4 7.3 Replace Solid State Relay......................26 Chapter 8 Troubleshooting CALsys -35/200....................27 8.1 CALsys -35/200 unit does not turn on..................27 8.2 CALsys -35/200 unit is not stable................... 27 8.3 The temperature of the calibrator does not rise..............27 Page | 3...

- Page 5 Temperature Calibrator (CALsys -35/200) User's Guide Appendix A : Calibration Services ....................28 In House Calibration Facility....................28 On-site Calibration Facility...................... 29 Fixed-Point Calibration Facility....................29 Appendix B : Warranty ......................... 31 Limit of Liability........................31 Caution in Using the Product....................31...

-

Page 6: Preface

Preface Welcome to the Liquid bath Temperature Calibrator (CALsys -35/200) user guide. This guide provides detailed information about all the product options and features, and explains how to use the product and configure basic settings to suit your requirements. This user manual contains information about the product and its proper use and should be kept in a place where it will be easy to access. -

Page 7: Electrical Safety

Temperature Calibrator (CALsys -35/200) User's Guide Electrical Safety WARNING: This equipment must be correctly grounded before use. Make sure the ground conductor wire (colored green/yellow) in the main power cable is connected to a protective earth/ground. If the equipment is not properly grounded, the high voltage may flow through the equipment body (chassis). -

Page 8: Health And Safety Instructions

After use, do not return the apparatus to its carrying case until the unit has cooled down. There are no user serviceable parts inside. When required, contact Tempsens agent for repair. Ensure all materials, especially flammable materials are kept away from the hot parts of the apparatus, to prevent fire risk. -

Page 9: Cautions And Preventions

Temperature Calibrator (CALsys -35/200) User's Guide Cautions and Preventions To avoid possible damage to the instrument, follow these guidelines: Before working inside the equipment, turn the power off and disconnect the power cord. DO NOT turn the unit upside down with the inserts in place; the inserts will fall out of the unit. -

Page 10: Introduction

Introduction 1.1 About CALsys -35/200 The 'CALsys -35/200' has been designed to provide stable and accurate temperature to enable professionals to calibrate Temperature Sensing Devices by comparison method. The 'CALsys -35/200' model has been designed to be rugged and easily maintained. This model provides an isothermal enclosure in which the thermocouple/RTD can be calibrated against the temperature of the calibrator. -

Page 11: Basic Working Model Of Calsys -35/200

To obtain and maintain a required temperature the controller varies the power to the heater via solid-state relay. 'In CALsys -35/200, SS chamber with cooling media is cooled with compressed refrigerant gas system. Temperature is controlled by heater in the chamber & PID controller. Cooling media is agitated to keep homogeneous temperature. -

Page 12: Physical Measurements

Introduction 1.3 Physical Measurements CALsys -35/200 has the following physical measurements Height: 702mm Ÿ Width: 410mm Ÿ Depth: 605mm Ÿ Page | 11... -

Page 13: Technical Specifications

Introduction 1.4 Technical Specification CALsys -35/200 has the following technical specifications: PARAMETER SPECIFICATION Temperature Range -35°C to 200°C Accuracy ±0.5°C Stability ±0.05°C uniformity ±0.07°C Immersion depth 150mm Volume 6 Ltr. Access opening 105X105 mm Cooling time 60 minutes(Room Temperature to -35°C) -

Page 14: Setting Up Calsys -35/200

Chapter 2 Setting up CALsys -35/200 2.1 Installation Place the liquid bath on a flat surface with at least 10 inches of free space around the instrument. Overhead clearance is required. DO NOT Place this unit under a cabinet or structure. Plug the power cord into a grounded mains outlet located on the controlling unit rear panel. -

Page 15: Unpacking And Initial Inspection

CALsys -35/200 is packed in custom-designed packaging to send out your unit. Unpack the furnace carefully. Inspect the unit after unpacking for any signs of damage, and confirm that your delivery is in accordance with the packing note. If you find any damage to the unit or an item is missing, notify Tempsens immediately. -

Page 16: Operating Instructions

Temperature Calibrator (CALsys -35/200) User's Guide 2.4 Operating Instructions 1. Open the box carefully and takeout the operating manual from the box and read carefully. 2. Take out the Temperature Calibrator unit carefully and keep it at suitable place. 3. Connect the power cable to the rear power entry and the power plug to the main power outlet. -

Page 17: Operating Of Calsys -35/200

Chapter 3 Operating CALsys -35/200 3.1 Turning On the unit 1. Before plugging the unit to main power outlet, ensure that the voltage, frequency and current from the main power outlet are within the recommended rages(typically:230 VAC±10, 50/60 Hz). 2. Turn the controller on using the switch located on the back side and set the temperature value in the controller. -

Page 18: Operating Instructions

Correct Liquid level Cooling coil 2. Connect the 'CALsys -35/200' to a suitable power supply & ON the Heater & Cooling Switch temperature source and set the desire temperature value in PID by using raise & lower key. 3. Insert the reference (Master) temperature sensor and UUC (Unit under calibration) into the chamber. -

Page 19: Cooling Down The Source

This method will save the time. Take the reading of sensors (master andtest) at stable temperature with the help of digital multi-meter, or by using Tempsens' TEMPMET 08 or TEMPMET 09 for reading RTD or TC sensor. 3.4 Cooling Down the Source Before transporting the bath, ensure that the temperature of bath has cooled sufficiently. -

Page 20: Drain System

Operating CALsys -35/200 3.5 Drain System Pull the drain valve lever counterclockwise to open Drain valve the drain valve, and push it clockwise to close the drain valve. Example: 1. Now let say if furnace is operating at temperature -35°C and medium is methanol. Now you want to check at 200°C. -

Page 21: Operating Unit Control

Chapter 4 Operating Unit Controller 4.1 Front Panel Layout The following image shows the front panel of CALsys -35/200. 4.2 The Temperature Controller The controller has a dual display, the upper display indicates the measured temperature, and the lower display indicates the desired temperature or set point. -

Page 22: Monitoring The Controller Status

Operating Unit Controller 4.4 Monitoring the Controller Status A row of beacons indicates the controller's status as follows: · OP1: Heat Output · OP2: Cool Output (only for models which operate below 0°C) · REM: This beacon indicates activity on computer interface 4.5 Temperature Units Press the Scroll key to show the controller units in °C or °F. -

Page 23: Digital Communication

Chapter 5 Digital Communication Digital Communication allows the controller to communicate with a PC or a networked computer system through RS-232 (or EIA232) protocol. RS-232 (or EIA232) is a standard communication protocol for linking computer and its peripheral devices to allow serial data exchange. RS-232 communication is not available if Remote Set point is fitted. -

Page 24: Digital Communications Parameters

Digital Communication 5.2 Digital Communications Parameters The following table shows the available parameters. IGITAL OMMUNICATION COMMS CCESS CROLLING ISPLAY ARAMETER ESCRIPTION ALUE EFAULT EVEL O MODULE FITTED R232 R 232 M ODBUS INTERFACE R485 EIA485 M ODBUS INTERFACE S ORDER MODULE IDENTITY C OMMUNICATION DENTITY... -

Page 25: Software Installation

Chapter 6 Software Installation The provided Tempsens software offers possibilities to connect furnace temperature bath and change set point, maximum time span, view real time graph and evaluate measuring data. 6.1 Installation Install the calibration software using the installation guide file on PEN Drive. After installing the software, start the application. - Page 26 Software Installation PVI Value displays the current present value of furnace temperature. The Scale Trend section enables you to configure Y-Axis Min (minimum value: 0), Y-Axis Max (maximum value: 1500), Maximum Time Span of data logging up to 120 minutes, and then click the Start Graph button.

-

Page 27: Service & Maintenance

Turn the electricity supply off before attempting any cleaning operation. The only moving part in this unit is fan, which is sealed for life. Depending on the environment in which CALsys -35/200 is used, periodic cleaning is recommended. Cleaning may be accomplished by the use of a small dry paint brush. The instrument should be periodically checked to ensure it is in good order both mechanically and electrically. -

Page 28: Troubleshooting Calsys -35/200

If the fuse breaks repeatedly, contact Tempsens for technical support. 8.2 The CALsys -35/200 unit is not stable If the CALsys -35/200 is not stable or the temperature varies too often, the control parameters might have been modified. If this happens, contact Tempsens for technical support. -

Page 29: Appendix A: Calibration Services

Appendix A: Calibration Services Tempsens Calibration Center is an independent unit of Tempsens instruments (I) Pvt. Ltd, having laboratories at Udaipur, Vadodara & Bangalore. It is accredited for wide range of temperature calibration services. It is the only private sector Laboratory in the country with accredited Fixed Point Temperature Calibration Facilities. -

Page 30: On-Site Calibration Facility

Appendix A: Calibration Services On-site Calibration Facility & M ALIBRATION EASUREMENT UALITY EASURED NSTRUMENTS EMPERATURE ANGE APABILITY Contact Type RTD, Thermocouples -25°C to 0°C 0.07°C Thermometers >0°C to 140°C 0.04°C >140°C to 250°C 0.09°C >250°C to 650°C 0.12°C >650°C to 1200°C 1.30°C Non-Contact Type Pyrometer 0°C to 250°C... -

Page 31: Appendix B: Warranty

INTERFERENCE WITH OR FAILURE TO PROPERLY MAINTAIN THISINSTRUMENT MAYINVALIDATE THIS GUARANTEE Limit of Liability TEMPSENS is not liable for any damages that arise from the use of any examples or processes mentioned in these Specifications are subject to change without notice. Caution in Using the Product Tempsens products are intended for use by technically trained and competent personnel familiar with good measurement practices. - Page 32 TEMPSENS INSTRUMENTS (l) PVT. LTD. Tempsens Instruments (l) Pvt. Ltd. U# Il, A-190, Road No.5, M.I.A., Udaipur india tech@tempsens.com +91-294-3500631, 3500600, Fax : +91-294-2500650...

Need help?

Do you have a question about the CALsys -35/200 and is the answer not in the manual?

Questions and answers