Lincoln industrial A Series Installation Manual

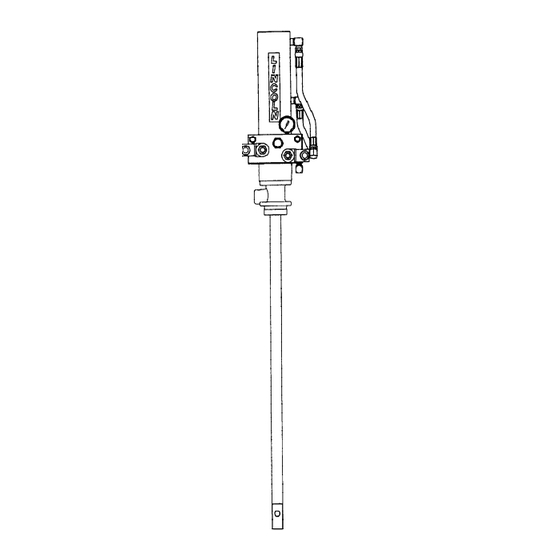

Hydraulically operated grease pump

Hide thumbs

Also See for A Series:

- Manual (12 pages) ,

- Instructions manual (9 pages) ,

- Quick start manual (8 pages)

Advertisement

Table of Contents

MAY - 98

HYDRAULICALLY OPERATED

POWER REQUIREMENTS:

RATIO(See Note in Fig. 2)

INPUT PRESSURE

INPUT FLOW @ 30 CYCLES PER MINUTE

MAXIMUM HYDRAULIC TEMP.

OUTPUT PRESSURE

OUTPUT FLOW @ 30 CYCLES PER MINUTE

AMBIENT TEMP.

SEALS

FILTRATION REQUIRED

DESCRIPTION

Model 84964 is a hydraulically

operated grease pump designed for

centralized lubrication systems on off-

road equipment which utilize 120VAC

power sources.

OWNER/OPERATOR

RESPONSIBILITY

It is the owner/operator responsibility to

properly use and maintain this

equipment.

The instructions and warnings

contained in this manual shall be read

and understood by the owner/operator

prior to operating this equipment.

If an owner/operator does not

understand English, the contents of

this manual shall be explained in the

owner/operator native language to

assure the owner/operator

comprehends.

It is the owner/operator responsibility to

maintain the legibility of all warning

and instruction labels.

The owner/operator shall retain this

manual for future reference to

Important warnings, operating and

maintenance instructions.

One Lincoln Way

St. Louis, Missouri 63120-1578

(314) 679-4200

MODEL NO. 84964

GREASE PUMP-

SPECIFICATIONS

SV1 & SV2= .13 Amps @ 120VAC each

POLYURETHANE AND NITRILE

Failure to heed the following warnings

including misuse, over pressurizing,

modifying parts, using incompatible

chemicals and fluids, or using worn or

damaged parts, may result in

equipment damage and/or serious

injury.

• Do not exceed the stated maximum

working pressure of the pump or of

the lowest rated component in your

system.

• Do not alter or modify any part of this

equipment.

• Do not attempt to repair or

disassemble the equipment while

the system is pressurized.

• Make sure all fluid connections are

securely tightened before using this

equipment.

• Always read and follow the fluid

manufacturer' s recommendations

regarding fluid compatibility, and the

use of protective clothing and

equipment.

• Check all equipment regularly and

repair or replace worn or damaged

parts immediately.

Copyright 1998

Printed in U.S.A.

SERIES "A"

16:1

300-3000 P.S.I.

1.0 G.P.M.

210° F

7500 P.S.I. MAX.

11 CU. IN./MIN.

-40° TO +135° F

10 MICRON

- C8

Section

- 268

Page

FORM 402821

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln industrial A Series

- Page 1 MODEL NO. 84964 HYDRAULICALLY OPERATED GREASE PUMP- SERIES "A" SPECIFICATIONS POWER REQUIREMENTS: SV1 & SV2= .13 Amps @ 120VAC each RATIO(See Note in Fig. 2) 16:1 INPUT PRESSURE 300-3000 P.S.I. INPUT FLOW @ 30 CYCLES PER MINUTE 1.0 G.P.M. MAXIMUM HYDRAULIC TEMP. 210°...

-

Page 2: Safety Instructions

11 3/16" 3" (300 MM) (76 MM) NOTE: 242207 Pressure Reducing Valve is factory set @ 300 PSI. Turn clockwise to increase 15-1/4" pressure. (387 MM) NOTE: For Centro-matic applications, connect port to top of Vent Valve with high pressure 1/4" hose. For 1/4"... -

Page 4: Troubleshooting

TROUBLESHOOTING If the following procedures do not correct the problem, contact a factory authorized service center. When submitting equipment to be repaired, be sure to state the nature of the problem and indicate if a repair cost estimate is required. PROBLEMS CYLINDER PRESSURE GAUGE DOES NOT REGISTER PRESSURE. - Page 5 DISASSEMBLY N. Extend plunger rod (11723) out of Refer to SERVICE PARTS for part bushing extension and unscrew numbers and location. Bleed all priming plunger (11724) to allow pressure from hydraulic and grease removal of priming check parts and lines before disassembling pumps. plunger rod (11723).

- Page 6 TORQUE SPECIFICATIONS 10 - 15 FT. LBS. (14 - 20 NM) 80 FT. LBS. (108 NM) 30 FT. LBS. (41 NM) 90 FT. LBS. (122 NM) 45 IN. LBS. (5 NM) 100 FT. LBS. (135 NM) Page 6 Form 402821...

-

Page 7: Service Parts

SERVICE PARTS PART QTY. DESCRIPTION PART QTY. DESCRIPTION 11329 Piston Bolt 50178 Bolt 11340 Pistion Rod 50771 Bolt 11344 Plunger adapter 57027 Ball stop 11345 Coupling nut 61273 Bushing extension 11346 Coupling stud 61285 Pump tube 11349 Pistion rod connector +66010 Ball +11702... - Page 8 RETAIN THIS INFORMATION FOR FUTURE REFERENCE When ordering replacement parts, list: Part Number, Description, Model Number and Series Letter. LINCOLN provides a Distributor Network that stocks equipment and replacement parts. Page 8 Form 402821...

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers