Table of Contents

Advertisement

Quick Links

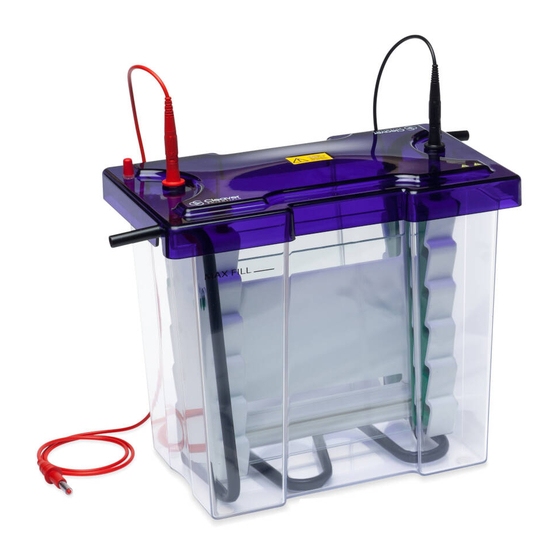

omniPAGE Maxi and

Mini Wide Vertical

Electrophoresis Units

Instruction Manual

Catalogue Numbers

VS20WAVESYS

VS20WAVESYS-CU

VS20WAVED

WAVETETRAD

27/11/2020

VS10WD

VS10WDSYS

VS10WDSYS-CU

Record the following for your records:

Model _____________________

Catalogue No. _____________________

Date of Delivery _____________________

Warranty Period _____________________

Serial No. _____________________

Invoice No. _____________________

Purchase Order No. _____________________

Page 1

Advertisement

Table of Contents

Summary of Contents for Cleaver Scientific omniPAGE Maxi

-

Page 1: Instruction Manual

Maxi and Mini Wide Vertical Electrophoresis Units Instruction Manual Catalogue Numbers VS20WAVESYS VS10WD VS20WAVESYS-CU VS10WDSYS VS20WAVED VS10WDSYS-CU WAVETETRAD Record the following for your records: Model _____________________ Catalogue No. _____________________ Date of Delivery _____________________ Warranty Period _____________________ Serial No. _____________________ Invoice No. -

Page 2: Table Of Contents

Contents Instruction Manual Catalogue Numbers Contents Safety Information Packing List Specifications Operating Instructions Usage Guidance and restrictions Setting up the omniPAGE Gel Tanks Fitting Electrode cables Casting Unit Preparation Cleaning the Glass Plates Gel Cassette Assembly Casting Stand Assembly Casting 4 gels Gel Preparation Gel Volumes Gel Mixture... -

Page 3: Safety Information

Safety Information When used correctly, these units pose no health risk. However, these units can deliver dangerous levels of electricity and are to be operated only by qualified personnel following the guidelines laid out in this instruction manual. Anyone intending to use this equipment should read the complete manual thoroughly. -

Page 4: Packing List

Packing List Each omniPAGE WAVE Maxi unit includes a tank, wired PAGE module, lid, CSL-CAB cables, VS20WAVE-CC Cooling coil and the following items: Glass Plates Combs Caster VS20WAVESYS VS20NG – Notched, Pk/2 2 x VS20-24-1 VS20DCAST -Caster VS20PGS1 – Plain with bonded 1mm thick, 24 1mm spacers, Pk/2 sample... - Page 5 The unit should be checked for damage when received. Cleaver Scientific is liable for all missing or damaged parts / accessories within 7 days after customers have received this instrument package. Please contact Cleaver Scientific immediately regarding this issue.

-

Page 6: Specifications

Specifications Lid and Cables 1500V Rated cables, high impact acrylic lid PAGE Insert Glass filled Nylon and Acetal construction Clamp Screws Injection moulded to avoid thread wear Plate Clamps Injection moulded, provide even pressure across glass plates Glass plates 4mm thick float glass Inner Buffer Chamber Allows use of separate inner running buffer Electrodes... -

Page 7: Operating Instructions

Operating Instructions Further information (including videos) regarding setting up and running the omniPAGE units can be found at www.cleaverscientific.com Usage Guidance and restrictions • Maximum altitude 2,000m. • Temperature range between 4°C and 65°C. • Maximum relative humidity 80% for temperatures up to 31 C decreas- ing linearly to 50% relative humidity at 40 •... -

Page 8: Gel Cassette Assembly

When using a triple glass plate sandwich, two notched glass plates are re- quired, one set of free spacers and a set of plain glass plates with bonded spacers. The plain glass plate is positioned outermost, then a notched glass plate, free spacers and second notched glass plate. -

Page 9: Casting 4 Gels

4. When only one gel is being run, the dummy plate must be used in the second position and fully tightened. 5. Position the Slab Gel Insert in the casting base such that the Cam pins have handles pointing downwards and are located in the insert holes. The top of the module may need to be pushed down very slightly to locate the cam pins. - Page 10 1. To replace the green sliding gel clamps, begin by unscrewing the colour-coded vertical screw pins. There should be no glass plates within the PAGE in- sert, in the side(s) being unscrewed. Once the screw pins are unscrewed sufficiently the green clamp should sit in the resting slot as shown.

- Page 11 5. Insert the yellow sliding gel clamp into the hole clos- est to the core of the PAGE insert. Once inserted gently withdraw the sliding clamp outwards away from the core of the PAGE insert as shown. 6. Withdraw the sliding gel clamps so that they sit sus- pended in the resting slots as shown.

-

Page 12: Gel Preparation

20 - 75 KD 17 – 65 KD 15 % 15 -45 KD 17.5% 12 – 30 KD Gel Volumes For omniPAGE Maxi Number of Gels Volume for 1mm Thick Gel Single 35 ml Double 70 ml 4 Gels (2 x Triple plate) -

Page 13: Gel Mixture

These should be gently mixed avoiding generation of bubbles which will inhibit polymerization by removing free radi- cals. The following values are for a 1mm gel for the omniPAGE Maxi, adjust volumes accordingly for other gel sizes. -

Page 14: Sample Preparation And Loading

Fill the glass plates again avoiding generating any air bubbles. Filling must be performed quickly before the gel becomes too viscous. Overlay the gel carefully with 1 ml of Isobutanol, Isopropanol or distilled water. When using distilled water extra care must be taken to ensure there is no mixing with the gel solution. -

Page 15: Loading The Samples

1. Prepare the protein samples for loading. The volume of sample de- pends on the capacity of the wells (See Comb specifications page 28). 2. Using a 0.5 ml micro-centrifuge tube or other convenient receptacle, combine the protein sample and 4 X sample buffer. It is always advisa- ble to use protein markers in one of the end lanes to indicate sizes of bands. -

Page 16: Buffer Volumes

Buffer Volumes Buffer Volume VS20WAVE VS10W Minimum – Inner tank is filled to above the Total Inner Buffer Total Inner Buffer Cham- wells. Outer Tank is filled to just flood the bot- Chamber: 640ml ber: 300ml tom of the glass plates. Cooling potential is Outer Tank: 1L Outer Tank: 500ml at a minimum which may affect resolution. -

Page 17: Connecting A Recirculating Chiller

Recommended Voltages for 1mm thick, 12% VS20WAVE VS10WD gels. 2-4 gels Constant Voltage Constant Voltage 250V 125V 6 Hours 1 Hour We recommend that for any new sample, a time course experiment is per- formed to obtain the optimal running conditions. Connecting a recirculating chiller Vertical PAGE may sometimes result in high currents. -

Page 18: References

Add 8ml of 10 % SDS Adjust pH to 6.8 with 1N HCl Add Distilled Water to a final volume of 200ml Stock 4 X Tris-glycine tank buffer - SDS 36 g Tris base 172.8 g glycine Distilled Water to 3 L 1 x Tris-glycine tank buffer - SDS 750ml of 4 X Tris-glycine reservoir buffer - SDS 30ml of 10 % SDS... -

Page 19: Troubleshooting

Troubleshooting Problem: Sample Prepara- Cause Solution tion Laemmil sample buffer turns yel- Sample buffer too acidic Add Tris base until buffer turns blue again. Sample very viscous High DNA or carbohydrate con- Fragment DNA with ultrasonic waves during tent cell lysis and protein solubilization. Add endonucleases (for each benzonases). - Page 20 Insufficient buffer in outer buffer Fill inner and outer buffer chambers to ensure chamber wells are completely covered. Electrical disconnection Check electrodes and connections. Gels run faster than expected Running buffer too concentrated Check buffer composition and type. and gel temperature too high; in- correct running buffer concen- tration or type used Running or reservoir buffer too di-...

- Page 21 Power conditions excessive Prepare new buffer, ensuring thoroughly mix- ing, especially when diluting 5x or 10x stock. Do not exceed recommended running con- ditions. Decrease power setting from 200V to Insufficient buffer 150V or fill lower chamber to within 1cm of top of short plate.

-

Page 22: Care And Maintenance

Care and Maintenance Cleaning Vertical Units Units are best cleaned using warm water and a mild detergent. Water at temperatures above 60°C can cause damage to the unit and components. The tank should be thoroughly rinsed with warm water or distilled water to prevent build-up of salts, but care should be taken not to damage the en- closed electrode and vigorous cleaning is not necessary or advised. -

Page 23: Ordering Information

VS20DCAST 20 x 20cm Dual Casting Base VS20DCASTM Replacement Silicone Mat for 20 x 20cm Casting Base VS20WAVEDIRM PAGE insert VS20WAVE-CC Detachable Cooling Coil VS20-x –LG Loading guides for omniPAGE maxi combs, x = comb well number 27/11/2020 Page 23... -

Page 24: Comb Options

VS20NG 20 x 20cm Notched Glass Plates 4mm thick (pk/2) VS20PG 20 x 20cm Plain Glass Plates 4mm thick (pk/2) VS20NGS0.75 20 x 20cm Notched Glass Plates with 0.75mm Bonded Spacers (pk/2) VS20PGS0.75 20 x 20cm Plain Glass Plates with 0.75mm Bonded Spacers (pk/2) VS20NGS1 20 x 20cm Notched Glass Plates with 1mm Bonded Spacers (pk/2) VS20PGS1... -

Page 25: Related Products

VS20-36-1 VS20-48-1 VS20-1-1.5 2200 VS20-5-1.5 VS20-10-1.5 VS20-18MC-1.5 VS20-24-1.5 VS20-30-1.5 VS20-36-1.5 VS20-48-1.5 VS20-1-2 3000 VS20-5-2 VS20-10-2 VS20-18MC-2 VS20-24-2 VS20-30-2 VS20-36-2 VS20-48-2 MC denotes multichannel pipette spacing Related Products Catalogue No. Product description CSL-PPL CSL Pink Plus Prestained Protein Ladder, 10-175kDa, with 10, 40 & 90kDa reference bands, 1x 500μL vial. - Page 26 CSL-GELX4 4mm x 1mm, Gel Cutting Tips, 250/ bag CSL-GELX4RACK 4mm x 1mm, Gel Cutting Tips, 5 racks of 48 CSL-GELX6.5 6.5mm x 1mm, Gel Cutting Tips, 250/ bag CSL-GELX6.5RACK 6.5mm x 1mm, Gel Cutting Tips, 5 racks of 48 POWERPRO300 Power Supply MIDI 300V 700mA 150W - 110/230V POWERPRO500...

-

Page 27: Warranty

Warranty The Cleaver Scientific Ltd. (CSL) omniPAGE Horizontal Electrophoresis units have a warranty against manufacturing and material faults of twelve months from date of customer receipt. If any defects occur during this warranty period, CSL will repair or replace the defective parts free of charge.

Need help?

Do you have a question about the omniPAGE Maxi and is the answer not in the manual?

Questions and answers