Table of Contents

Advertisement

Quick Links

Assembly and operating instructions

DULCODOS Pool Professional

EN

A0988

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Part no. 984156

Original Operating Instructions (2006/42/EC)

Version: BA DD 035 06/15 EN

Advertisement

Table of Contents

Summary of Contents for ProMinent DULCODOS Pool Professional

- Page 1 Assembly and operating instructions DULCODOS Pool Professional A0988 Please carefully read these operating instructions before use. · Do not discard. The operator shall be liable for any damage caused by installation or operating errors. The latest version of the operating instructions are available on our homepage.

- Page 2 Supplemental directives General non-discriminatory approach In order to make it easier to read, this document uses the male form in grammatical structures but with an implied neutral sense. It is aimed equally at both men and women. We kindly ask female readers for their understanding in this simplification of the text.

-

Page 3: Table Of Contents

Table of contents Table of contents Identity code..................4 About This Product................7 2.1 Overview of Equipment............7 Safety and Responsibility.............. 10 3.1 Users' qualifications.............. 10 3.2 Explanation of the safety information........10 3.3 General Safety Information........... 12 3.4 Intended Use................. 13 Device overview and operating elements........ -

Page 4: Identity Code

Identity code Identity code DSPa DULCODOS ® Pool Measured variable: pH / ORP pH / free chlorine pH / ORP / free chlorine pH / ORP / free chlorine / total chlorine pH / total chlorine pH / ORP / total chlorine pH / ORP / free chlorine / total chlorine Auxiliary hardware functions: Standard... - Page 5 Identity code DSPa DULCODOS Pool ® Italian Metering pumps for acid/alkali: without metering pumps 0.8 l/h (DULCO ® flex DF2a 0208) 1.6 l/h (DULCO ® flex DF2a 0216) 2.4 l/h (DULCO flex DF2a 0224) ® 1.8 l/h (alpha ALPc 1002 PVT) 3.5 l/h (alpha ALPc 1004 PVT) 1.5 l/h (Beta CANopen BT4a 0401 PVT)

- Page 6 Identity code DSPa DULCODOS Pool ® Assembly supplied loose without mounting plate mounted on a base plate C Base plate with flocculant pump DF4a Certification with CE certification * Calculated for 12% sodium-calcium hypochlorite. HB=indoor pool/ FB=outdoor pool.

-

Page 7: About This Product

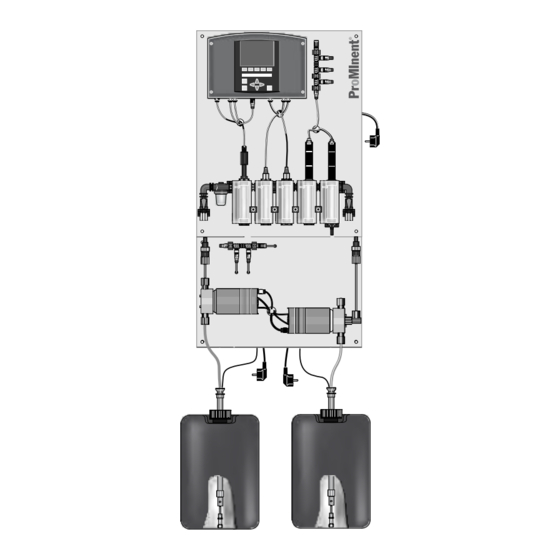

About This Product About This Product DULCODOS ® Pool metering systems are specifically designed for the treatment of swimming pool water. Ready mounted, fully-wired and ready for use, they take on the job of pH value adjustment and disinfection with chlorine. - Page 8 About This Product A0990 Fig. 2: Overview of equipment for the DULCODOS ® Pool Professional, with all options and metering pumps Beta ® Injection valve for acid Metering pump for acid Cable, acid level switch (only with metering pump Beta ®...

- Page 9 About This Product Control Elements A0991 Fig. 3: Control elements for the DULCODOS Pool Professional, with all ® options and metering pumps Beta ® Controller keys and LCD screen Flow meter (by scale) 3a/3b Stroke adjustment dial on the metering pump (concealed on the alpha pump) Ball valve, in-line probe housing, outlet side Multifunctional valve (Not shown in figure)

-

Page 10: Safety And Responsibility

Trained user A trained user is a person who fulfils the requirements made of an instructed person and who has also received additional training specific to the system from ProMinent or another authorised distribution partner. Trained qualified personnel... - Page 11 Safety and Responsibility DANGER! Nature and source of the danger Consequence: Fatal or very serious injuries. Measure to be taken to avoid this danger Danger! – Denotes an immediate threatening danger. If this is disregarded, it will result in fatal or very serious inju‐ ries.

-

Page 12: General Safety Information

Safety and Responsibility 3.3 General Safety Information WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Please ensure when handling hazardous substances that you have read the latest safety data sheets provided by the manufacture of the hazardous substance. The actions required are described in the safety data sheet. -

Page 13: Intended Use

Safety and Responsibility CAUTION! Warning of feed chemical spraying around Spraying feed chemical caused by a leak. Possible consequence: Injuries caused by chemicals. – Regularly check the system for leaks. – Ensure that the system with all components can be de-energised from outside the danger zone by appropriate measures (e.g. -

Page 14: Device Overview And Operating Elements

Device overview and operating elements Device overview and operating elements Keys A0502 Fig. 4: Keys Enter key Start/Stop key ESC key Arrow keys Function keys, variably assigned... - Page 15 Device overview and operating elements Displays A0503 Fig. 5: Displays LCD display CAN 1-LED Device LED...

-

Page 16: Storage And Transport

Storage and transport Storage and transport Ambient conditions for storage and trans‐ port without sensors CAUTION! – Prior to storage or transport, the DULCODOS ® Pool metering systems must be free from feed chemicals and water – Rinse out the media carrying parts, including the tubes using clean, pure water –... -

Page 17: Assembly

Assembly Assembly 6.1 Wall mounting Secure the metering system perpendicular and upright on a wall or a stable mounting system. The metering system should be freely accessible. Select the mounting height you require so that: The controller's display can be easily read There is still space for maintenance work beneath the in-line probe housing (100 mm) There is still room for the chemical storage tank (600 mm) -

Page 18: Fit The Antikink Device For The Bleed Line

Assembly 6.2 Fit the antikink device for the bleed line Only SEK liquid end (metering pump Beta ® for disinfection, right side): A0965 Fig. 7: Fit the antikink device for the bleed line (only SEK liquid end) Bleed valve for the return line in the storage tank, 6/4 mm Red sleeve Discharge valve for discharge line to injection point, 6/4 - 12/9 mm Suction valve for suction line in storage tank, 6/4 - 12/9 mm... -

Page 19: Hydraulic Installation

In-line probe housing cannot become dirty Disadvantage: Measured value with depletion Tab. 2: Interfaces, Hydraulic Description Hose connection Recommended hose from the ProMinent range Sample water inlet / outlet 8 x 5 mm Suction line, soft PVC, 8 x 5 Suction connector for metering pump... -

Page 20: Metering System

Assembly 6.3.1 Metering system WARNING! Possible overdosing Consequence: Sever damage to health caused by the used feed chemical. Measure: The metering pumps with the external control (2) may only be connected to the pulse frequency output of the controller if the multifunctional switch (1) is [EXTERNAL] . - Page 21 Assembly NOTICE! Multifunctional valve: Point of injection with non-return valve If you use a mutifunctional valve, then a non-return valve must be fitted at the point of injection (integrated in the supplied injection valve). Otherwise, when the multifunc‐ tional valve is activated, the swimming pool water may flow back via the bypass line.

- Page 22 Assembly P_BE_0008_SW Fig. 10: Overview of liquid end (PV) beta and alpha Discharge valve Backplate Dosing head Bleed valve Bypass hose sleeve Suction valve A0929 Fig. 11: Connect the hose using the connector kit Valve O-ring Nozzle Clamp ring Union nut Hose Connect the suction hose of the suction assembly to the connector kit on the liquid end of the metering pump...

-

Page 23: Sensors

Assembly Only alpha and Beta pump: Connect a suitable part of the suction hose to the bleed valve of the pump and route the suction hose back into the dosing tank Connect the pressure hose to the injection valve using the con‐ nector kit Testing the hydraulic installation of the metering system:... -

Page 24: Electrical Installation

Assembly Chlorine sensor installation If there is already sample water in the in-line probe housing Slowly lower the sensor into the in-line probe housing. Otherwise the diaphragm of the sensor is overstretched and the sensor delivers incorrect values. Remove the securing bolt (1) using a 35 mm ring spanner Fit the sensor with electrolyte as described in the sensor operating instructions Push the O-ring (4), then the assembly washer (5) onto the sensor... -

Page 25: Connect Power Supply

Assembly 6.4.1 Connect power supply Provide the following sockets for the power supply: Power supply of the controller, 230 V ± 10 % / 50/60 Hz Power supply of the metering pump pH value (only Beta) Power supply of the metering pump chlorine (only Beta) It must be possible for the sockets to be de-energised from outside the danger zone by appropriate measures (e.g. -

Page 26: Start Up

Start Up Start Up Preparation: WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Please ensure when handling hazardous substances that you have read the latest safety data sheets provided by the manufacture of the hazardous substance. The actions required are described in the safety data sheet. -

Page 27: Adjust The Flow Sensor Switching Point

Start Up Maximum permissible operating pressure: In the sample water line: With chlorine sensor, 1 bar at 30 °C (sample water) – Without chlorine sensor, 2 bar at 30 °C (sample – water) Tighten all threaded connectors prior to initial commissioning Open the shut-off valves downstream of the metering pumps, in the sample water line and also the shut-off valves in your system Insert the suction lances into the relevant chemical storage tanks for... -

Page 28: Priming And Bleeding (With An Alpha Or Beta Pump)

Start Up 7.2 Priming and bleeding (with an alpha or Beta pump) WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Measure: The bleed valve must be equipped with a transparent PVC hose (6 x 4 mm). The PVC hose must be connected to the respective chemical storage tank so that the leaking chemicals can flow back into the chem‐... -

Page 29: Chlorine Calibration

Start Up You have to regularly calibrate the pH sensor during operation. That means: 24 hours after initial calibration and then weekly thereafter. Please take into account any deviating national regula‐ tions. Only calibrate the pH sensor with the quality buffer solu‐ tions pH 7 and pH 4. - Page 30 Start Up 7.3.1.1 Calibrate measured variable "chlorine free" Sensor calibration Redox Sensor value = 1,12 mg/l free Slope = 110,43 % Calibration : DPD <photometer> Temp Push CAL key before tapping sampling water HELP HOME A0147 Fig. 14: Calibrate measured variable "chlorine free" Calibrate zero point for measured variable "chlorine free"...

- Page 31 Start Up Sensor calibration Sensor calibration Sensor calibration Redox Redox Redox Sensor value = 0.00 mg/l Sensor value = 0.00 mg/l Sensor value = 1.12 mg/l free free free Zero point = 10.00 pA Slope = 110.43 % Slope = 110.43 % Slope = 110.43 %...

- Page 32 Start Up Conclude calibration with the F5 key (CAL) [zero point calibration completed] ð Display: Press F2 (HOME) ð Zero point calibration is completed. You can now exit the menu with the ESC button Re-install the sensor into the flow gauge Open the shut-off valves for the measured water ð...

- Page 33 If the sensor still cannot not be calibrated, then please phone ProMinent customer service. Please have the following data ready:...

- Page 34 Start Up DPD Calibration ▶DPD value = 1.00 mg/l Cl free Sensor value 1.00 mg/l Temp.value 25.0 °C Calibration started, the calibration is finished with CAL! ESC cancels the calibration! HELP DEFAULT INFO MEAS A0335 Fig. 17: [DEFAULT] . Warning: Calibrate sensor ESC Key - Return to the menu A0336...

- Page 35 Start Up Calibrate zero point for measured variable "total chlorine" CAUTION! – Here you calibrate the CTE sensor for total chlorine – The DXCa calculates the displayed value for bonded chlorine as the difference between the measured values from the free chlorine and total chlorine sen‐ sors.

- Page 36 Start Up The sensor have been run-in – Only carry out a zero point calibration if: – – you are using the sensor in the lower limit of the measuring range you want to measure bonded chlorine (chlorine – differential measurement) ‘Cl comb’...

- Page 37 Start Up Calibrate slope for measured variable "total chlorine" DPD-Calibration Sensor calibration DPD-Calibration Redox DPD value: 1.01 mg/l DPD value: 1.01 mg/l Sensor value = 1.65 mg/l Sensor value = 1.01 mg/l Sensor value = 1.65 mg/l free Slope = 160.43 % Temp.

- Page 38 Start Up You can display the pH value, the sensor current and the temperature at the time of pressing the button with F4 (MESS). In the event that an error message is shown when – calibrating a chlorine sensor, you can call up detailed information with F3 INFO.

-

Page 39: Orp Calibration

Start Up 7.3.2 ORP calibration You need the following materials: Spray bottle with distilled water Clean, soft cloth Buffer solution 465 mV (50 ml) 7.3.2.1 Redox measured variable Check redox sensor You cannot calibrate a redox sensor. A redox sensor can only be tested. -

Page 40: Calibration Ph

Start Up Dip the redox sensor in a buffer solution (e.g. with 465 mV). If you are measuring with an equipotential bonding pin, then also dip this into the buffer solution. If the displayed value is stable, compare it with the specified mV value detailed on the buffer solution bottle - it may not vary more than ±... - Page 41 Start Up 7.3.3.1 1-Point calibration pH Sensor calibration pH Redox Sensor value pH 7.12 free Zero point 0.24 mV Slope 59.23 mV/pH Temp CAL 1Pt: Calibration with reference value or buffer solution CAL2Pt: Calibration with 2 buffer solutions HILFE HOME CAL 1Pt KAL2Pkt Spring 1...

- Page 42 Start Up Re-install the pH sensor into the flow gauge Screw the coaxial cable back onto the pH sensor Re-install the equipotential bonding pin Open the shut-off valves for the measured water ð First open the outlet, then the inlet. 7.3.3.2 2-Point calibration pH Sensor calibration pH...

- Page 43 Start Up Enter the temperature of the buffer solution (arrow keys) and press the ENTER key Press F4 (Buffer) (buffer detection) ‘buffer recognition running’ appears on ð The progress bar and the display The DXCa has detected and stored the value of the buffer solu‐ tion pH 7 (buffer 1) Press the ESC key in order to repeat the calibration process Press the F5 key (CAL) in order to continue with calibration...

-

Page 44: Maintenance

Maintenance Maintenance WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Please ensure when handling hazardous substances that you have read the latest safety data sheets provided by the manufacture of the hazardous substance. The actions required are described in the safety data sheet. Check the safety data sheet regularly and replace, if necessary, as the hazard potential of a substance can be re-evaluated at any time based on new findings. - Page 45 Maintenance Maintenance interval: daily Check the current swimming pool water values daily to guarantee the safe operation of your swimming pool system. Check the chlorine concentration using the DPD test (refer to the operating instructions for the test kit) Check the pH value using the phenol red test (refer to the operating instructions for the test kit) ð...

-

Page 46: Replacing The Chemical Storage Tanks

Maintenance Maintenance interval: 12 months Service Maintenance should be carried out by an authorised service. 8.2 Replacing the chemical storage tanks WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious injuries. Please ensure when handling hazardous substances that you have read the latest safety data sheets provided by the manufacture of the hazardous substance. -

Page 47: Disposal Of Used Parts

Decontaminate the unit before returning it for repair. To do so, remove all traces of hazardous substances. Refer to the Material Safety Data Sheet for your feed chemical. A current Declaration of Decontamination is available to download on the ProMinent website. -

Page 48: Drawings, Drilling And External Dimensions Of The Dul- Codos

Drawings, Drilling and External Dimensions of the DULCODOS ® Drawings, Drilling and External Dimensions of the DUL‐ CODOS ® Versions of the DULCODOS ® The drawings show three possible versions of the DUL‐ CODOS . The drilling and external dimensions of the ®... - Page 49 Drawings, Drilling and External Dimensions of the DULCODOS ® Ø 8,5 A2137 Fig. 28: DULCODOS with metering pumps ®...

- Page 50 Drawings, Drilling and External Dimensions of the DULCODOS ® Dimensional drawing A0994 Fig. 29: Dimensional drawing. All dimensions in mm. Depth 150 mm...

-

Page 51: Technical Data

Technical Data Technical Data Refer to the product-specific operating instructions for technical data on the controller, sensors, in-line probe housing, metering pump and multifunctional valve. Maximum permissible operating pressure In the sample water line: – without a chlorine sensor: 2 bar at 30 °C (sample water) –... -

Page 52: Spare Parts And Accessories

Spare Parts and Accessories Spare Parts and Accessories Tab. 4: Spare parts Spare parts Order no. Chlorine sensor CLE 3.1-CAN-10 ppm (for free chlorine) with electrolyte, 100 ml 1023426 Spare diaphragm cap for CLE 3, CLE 3.1 815073 Electrolyte solution for chlorine sensor for CLE, 50 ml 506270 Chlorine sensor CTE 1-CAN -10 ppm (for total chlorine) with electrolyte, 100 ml 1023427... - Page 53 Spare Parts and Accessories 1 no. 300 µm stainless steel screen for the water filter 1 NBR flat seal for the water filter Tab. 6: The following table shows the assignment of the maintenance kits to the types of DULCODOS Pool.

-

Page 54: Ec Declaration Of Conformity

LIAMENT AND OF THE COUNCIL, Appendix I, BASIC HEALTH AND SAFETY REQUIREMENTS, section 1.7.4.2. C. Without pumps ProMinent Dosiertechnik GmbH Im Schuhmachergewann 5 - 11 DE - 69123 Heidelberg, hereby declare that the product specified in the following, complies with... - Page 55 EC Declaration of Conformity With pumps ProMinent Dosiertechnik GmbH Im Schuhmachergewann 5 - 11 DE - 69123 Heidelberg, hereby declare that the product specified in the following, complies with the relevant basic health and safety requirements of the EC Directive, on the basis of its functional concept and design and in the version distributed by us.

-

Page 56: Index

Index Index Question: What do I need to consider when operating the product for the first time? ....26 Action, step by step ......2 Question: What is the actual purpose of this product? . - Page 60 ProMinent GmbH Im Schuhmachergewann 5 - 11 69123 Heidelberg, Germany Telephone: +49 6221 842-0 Fax: +49 6221 842-419 Email: info@prominent.com Internet: www.prominent.com 984156, 2, en_GB © 2015...

Need help?

Do you have a question about the DULCODOS Pool Professional and is the answer not in the manual?

Questions and answers