Table of Contents

Advertisement

Quick Links

Kit Instructions

™

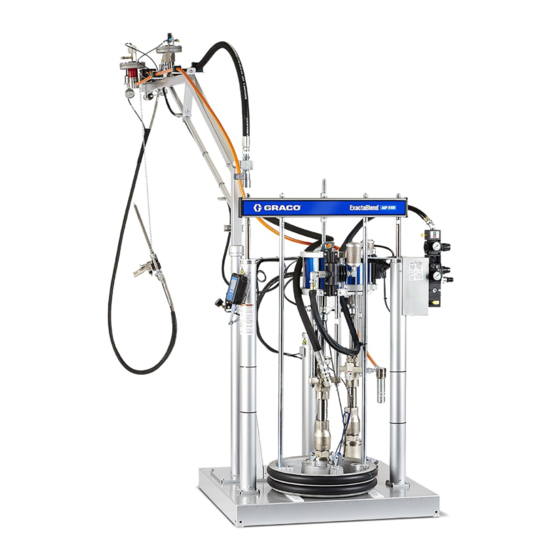

ExactaBlend

AGP Advanced Glazing Proportioner

Accessory Kits

For dispensing two component silicone and polysulfide materials.

For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Refer to ExactaBlend AGP Advanced Glazing Proportioner, Setup-Operation manual for maximum working pressure

and model information.

Important Safety Instructions

Read all warnings and instructions in this

manual and the ExactaBlend AGP Advanced

Glazing Proportioner, Setup-Operation man-

ual. Save all instructions.

332453A

EN

24r809

Advertisement

Table of Contents

Summary of Contents for Graco ExactaBlend AGP

- Page 1 For dispensing two component silicone and polysulfide materials. For professional use only. Not approved for use in explosive atmospheres or hazardous locations. Refer to ExactaBlend AGP Advanced Glazing Proportioner, Setup-Operation manual for maximum working pressure and model information. Important Safety Instructions...

-

Page 2: Table Of Contents

Graco Standard Warranty ....14 Graco Information ......14... -

Page 3: Installation

Installation Installation Light Tower, 24R824 5. Connect the cable from the light tower to port 3 located on the Fluid Control Module (FCM). 1. Perform the Shutdown procedure in the Exact- aBlend AGP Advanced Glazing Proportioner, Setup-Operation manual. 2. Remove the nut that secures the fluid plate. 3. -

Page 4: Low Level Sensors, 24R935

Installation Low Level Sensors, 24R935 6. Mount the sensor to the bracket. 1. Perform the Shutdown procedure in the Exact- aBlend AGP Advanced Glazing Proportioner, Setup-Operation manual. 2. Remove the air shut off valve cable from port 1 located on the Fluid Control Module (FCM). 7. - Page 5 Installation 9. Install a collar on the mast shaft for both chemical 15. Adjust the sensor until it senses the collar. A light rams. will aluminate on the sensor to visually show it is activated. 10. Connect the cable end labeled “J1BA” to the base sensor.

-

Page 6: Usb Kit, 24R936

Setup-Operation manual. 2. Mount the USB Module to the side of the electrical enclosure. Torque the bolts to 2.6 ft-lb (3.5 N•m). 5. Refer to the ExactaBlend AGP Advanced Glazing Proportioner, Setup-Operations manual for screen details. 3. Connect the longest CAN cable to the USB Module. -

Page 7: Calibration Check Assembly, 24R777

Installation Calibration Check Assembly, 5. Install the material tube lines onto the boom assem- bly. Tighten all fittings to prevent leaking. 24R777 1. Perform the Shutdown procedure in the Exact- aBlend AGP Advanced Glazing Proportioner, Setup-Operation manual. 2. Install the hose clamps onto the boom assembly. Hand tighten all hose clamps. -

Page 8: Troubleshooting

Troubleshooting Troubleshooting 1. Follow Pressure Relief Procedure in the Exact- aBlend AGP Advanced Glazing Proportioner, Setup-Operation manual before checking or repair- ing gun. 2. Check all possible problems and causes before dis- assembling gun. Problem Cause Solution Light Tower Light does not blink green, red, and Bad connection or cable Ensure cable is connected or off in sequence when the machine... -

Page 9: Parts

Parts Parts Light Tower, 24R824 . 1: Light Tower Part Description Quantity BRACKET, tower, light, 30mm 127087 LIGHT, tower, 30mm, red/green 127066 HARNESS, m8xm12 --- Not available for individual sale. 332453A... -

Page 10: Low Level Sensors, 24R935

Parts Low Level Sensors, 24R935 103, 103, 103, . 2: Low Level Sensors Part Description Quantity BRACKET, sensor, level, catalyst BRACKET, sensor, low/empty 100016 WASHER, lock 121112 SCREW, cap, socket head 117028 SCREW, socket head, m6x16 122716 SENSOR, inductive, m12 127140 COLLAR, clamp, 1-3/8 id, 2piece 127141... -

Page 11: Calibration Check Assembly, 24R777

Parts Calibration Check Assembly, 24R777 208, 210, 209, 210, . 3: Calibration Check Assembly Part Description Quantity MODULE, ratio check, 127071 FITTING, flareless, 1/2 npt x 1/2 tube 127070 FITTING, flareless, 1/4 npt x 1/4 tube 126691 CLAMP, 1/2 in. od hose 126682 CLAMP, 1/4 in. -

Page 12: Calibration Check Module

Parts Calibration Check Module Apply sealant to pipe threads. . 4: Calibration Check Module Part Description Quantity 215622 VALVE, ball 217562 LEVER, valve 104984 FITTING, tee, pipe 127070 FITTING, flareless, 1/4 npt x 1/4 tube 127051 FITTING, flareless, 1/4 npt x 1/2 tube 112941 GAUGE, pressure, fluid 123253... - Page 13 Parts USB Kit, 24R936 401, . 5: USB Kit Part Description Quantity 24T005 MODULE, GCA, cube 122747 SCREW, socket head, 10x0.75 123273 CABLE 122487 CABLE, CAN, male-female 16V853 SOFTWARE, GCA 332453A...

-

Page 14: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the ExactaBlend AGP and is the answer not in the manual?

Questions and answers