Sleipner ERV130 Installation Manual

Hide thumbs

Also See for ERV130:

- Installation manual (28 pages) ,

- User manual (12 pages) ,

- Installation manual (36 pages)

Table of Contents

Summary of Contents for Sleipner ERV130

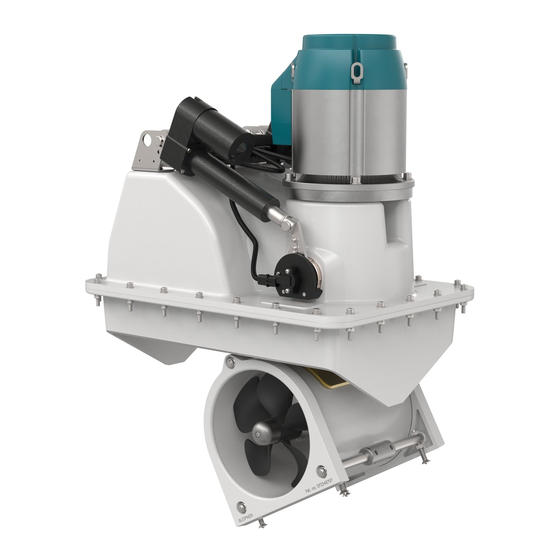

- Page 1 Installation Guide For E-vision Electric Retractable Thruster Models ERV130, ERV170, ERV210 DOCUMENT ID: SLEIPNER MOTOR AS 7241 REVISION: P.O. Box 519 DATE: N-1612 Fredrikstad 2022 Norway LANGUAGE: www.sleipnergroup.com...

-

Page 2: Table Of Contents

CE Declaration of Conformity ..............................24 UK Declaration of Conformity ..............................25 Products ERV130/250T-24V - ERV130 eVision retract bow/stern thruster 24V ERV130/250T-48V - ERV130 eVision retract bow/stern thruster 48V ERV170/250TC-24V - ERV170 eVision retract bow/stern thruster 24V ERV170/250TC-48V - ERV170 eVision retract bow/stern thruster 48V... -

Page 3: Responsibility Of The Installer

Sleipner products. If you are interfacing the S-Link™ bus by agreement with Sleipner through a designated Sleipner supplied interface, you are still required to install at least one original Sleipner control panel to enable efficient troubleshooting if necessary. -

Page 4: Product Measurements

SRF flange & motor housing width 18,9 18,93 18,93 18,93 18,93 18,93 Retracted hatch width 13,7 13,7 13,7 13,7 13,7 13,7 SRF flange inner frame width 16,29 16,29 16,29 16,29 16,29 16,29 MG_0572 ERV130 & ERV170 & ERV210 7241 2022... -

Page 5: Product Specifications

ERV210 24V 210 kg / 462 lbs (21V) 10 kW / 13,15 hp ERV210 48V 210 kg / 462 lbs (42V) 10 kW / 13,15 hp ERV130 & ERV170 & ERV210 7241 2022... -

Page 6: Positioning Of The Retract Thruster

Always ensure enough space for the complete SR unit including motor, actuators, retract frame, future service and for installation moulding to the hull. Retract thruster Thruster moved to avoid conflict Thruster moved to Hatch opens towards the avoid conflict direction of travel Transom MG_0121 ERV130 & ERV170 & ERV210 7241 2022... -

Page 7: Preparing A Sandwich Hull For Retract Systems

Hull construction typical in many vessels is a composite layering method called a sandwich. To ensure the retract thruster is installed securely to these hull types, additional hull structure reinforcement is required to strengthen the area around the Sleipner retract housing mould. -

Page 8: Marking And Trimming Of Srf Flange

45º Stern 45º 30º Important When cutting use a suitable guide tool to ensure correct cutting angles. Side View Front View 45º 45º Stern Starboard Port 30º 45º Hull Hatch Hull Hatch MG_0117 ERV130 & ERV170 & ERV210 7241 2022... -

Page 9: Installation Pre-Check

Remove wooden installation part Conflict with hatch hatch opens and hull without conflict Hatch does not close Hatch closed with with pressure pressure MG_0118 ERV130 & ERV170 & ERV210 7241 2022... -

Page 10: Required Modifications After Pre-Check

Conflict with hatch hatch opens and hull without conflict Use wedge to prop the SRF flange to required height hatch opens without conflict Hatch closed with pressure MG_0133 ERV130 & ERV170 & ERV210 7241 2022... -

Page 11: Srf Flange Installation

SRF flange surfaces after cutting. After curing time - Smoothen all moulded surfaces. Grind in this area, deepest where the hull and lower unit meets. Layers of fiberglass cloth MG_0119 ERV130 & ERV170 & ERV210 7241 2022... -

Page 12: Motor House Installation

Insert and fasten bolts. Start with the 4 corner bolts followed by the remaining to required torque. Retract thruster Apply MS polymer or equivalent on flange surface Retract thruster Tighten bolts to 4Nn/ 2.9lb/ft MG_0122 ERV130 & ERV170 & ERV210 7241 2022... -

Page 13: Hatch Installation

filler on hatch edges Smooth out filler and add Apply coating more if needed. After curing time grind and smoothen Tighten bolts Glue tunnel rings the surface and nuts to hatch before tightening bolts MG_0129 ERV130 & ERV170 & ERV210 7241 2022... -

Page 14: Motor To House Installation

Install the relevant motor and other electronics according to electrical instructions in the manual Bolt tightening force (4x) 33 Nm (24 lb/ft) MG_0587 ERV130 & ERV170 & ERV210 7241 2022... -

Page 15: Electrical Installation

Do NOT use washers between lugs, End nut this causes overheating and fire. Spring washers must be placed in the outer position before tightening the nut. Multi-lug Lugs configuration Ensure lug faces are back to back. MG_0523 ERV130 & ERV170 & ERV210 7241 2022... -

Page 16: Electrical Reference Guide

Cable lengths and dimensions • Performed tunnel installation • Ventilation • Obstructing marine growth For each installation an experienced electrician should be consulted for cable cross section calculations and selection of fuses, main circuit and batteries. ERV130 & ERV170 & ERV210 7241 2022... -

Page 17: Wiring Diagram 24V Retract Thruster

Automatic Main Switch * S-Link Backbone cable Fuse 10A S-Link Spur cable ANL Fuse BATTERY Fuse 5A Fuse 30A BATTERY *Automatic Main Switch can be replaced by a fuse holder and manual main switch. MG_0585 ERV130 & ERV170 & ERV210 7241 2022... -

Page 18: Wiring Diagram 48V Retract Thruster

Automatic Main Switch * S-Link Spur cable ANL Fuse Fuse 5A Fuse 30A THRUSTER THRUSTER THRUSTER THRUSTER BATTERY BATTERY BATTERY BATTERY *Automatic Main Switch can be replaced by a fuse holder and manual main switch. MG_0586 ERV130 & ERV170 & ERV210 7241 2022... -

Page 19: S-Link System Description

MC_0120 S-Link is a CAN-based control system used for communication between Sleipner products installed on a vessel. The system uses BACKBONE Cables as a common power and communication bus with separate SPUR Cables to each connected unit. Units with low power consumption are powered directly from the S-Link bus therefore one power cable must be connected to the BACKBONE Cable through a T-Connector. -

Page 20: Check Drive Shaft Alignment

Re-calibrated “down”-position. Flashing green light: No S-Link communication. Actuator arm and bearing Controller (FUSE) SETTINGS 1 2 3 4 DOWN FAULT STATUS Align pointer on lever arm with red mark on bearing MG_0108 ERV130 & ERV170 & ERV210 7241 2022... -

Page 21: Control Panel Installation

For Control Panel installation please refer to the Installation Guide accompanying the control panel to be installed. Installation Guide Control Panel SLEIPNER MOTOR AS DOCUMENT ID: REVISION: P.O. Box 519 N-1612 Fredrikstad DATE: Norway www.sleipnergroup.com LANGUAGE: ERV130 & ERV170 & ERV210 7241 2022... -

Page 22: Pre-Delivery Checklist

Correct drive direction as per control panel: ..............................The compartment for the thruster has been isolated from general bilge water and has no obvious or suspected risks for flooding: .................................................................................................................................. Other comments by installer: ........................................................................................................................ERV130 & ERV170 & ERV210 7241 2022... -

Page 23: Service And Support

11. This warranty gives you specific legal rights, and you may also have other rights which vary from country to country. Patents MC_0024 At Sleipner we continually reinvest to develop and offer the latest technology in marine advancements. To see the many unique designs we have patented visit our website www.sleipnergroup.com/patents ERV130 & ERV170 & ERV210... -

Page 24: Ce Declaration Of Conformity

RoHS EN 63000:2018 criteria outlined in: This declaration of conformity is issued under the exclusive responsibility of the manufacturer. Fredrikstad, 12 of October 2022 Ronny Skauen, President and CEO ERV130 & ERV170 & ERV210 7241 2022... -

Page 25: Declaration Of Conformity

RoHS EN 63000:2018 criteria outlined in: This declaration of conformity is issued under the exclusive responsibility of the manufacturer. Fredrikstad, 12 of October 2022 Ronny Skauen, President and CEO ERV130 & ERV170 & ERV210 7241 2022... - Page 26 MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................ERV130 & ERV170 & ERV210 7241 2022...

- Page 27 MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................ERV130 & ERV170 & ERV210 7241 2022...

- Page 28 © Sleipner Group, All rights reserved The information given in the document was right at the time it was published. However, Sleipner Group cannot accept liability for any inaccuracies or omissions it may contain. Continuous product improvement may change the product specifi cations without notice.

Need help?

Do you have a question about the ERV130 and is the answer not in the manual?

Questions and answers