Table of Contents

Advertisement

Quick Links

AppNote_TLI4971_ProgGuide

Current Sensor TLI4971

Programming Guide and User Manual

About this document

This document describes how to program the TLI4971 with the Infineon proprietary one wire interface (SICI).

Timing of the serial inspection interface.

Command structure and commands for write/read and EEPROM access.

A description of the user changeable EEPROM section.

Details on the diagnosis mode.

For productive in circuit programming Infineon recommends to use a verified programmer which has been a

coproduction development between Infineon and CGS. For further documentation please refer to

Sensor –

Programmer – CGS – Computer Gesteuerte Systeme GmbH (cgs-gruppe.de)

Further Infineon provides a programming board for laboratory usage.

Scope and purpose

TLI4971 Coreless Current Sensor Feature set, EEPROM and interface description.

Intended audience

Users who use the high variety of the TLI4971 current sensor by programming the functionality like full scale

or over current detection, operating modes etc. to their need.

Current Sensor Module Developers.

Application Note

Please read the Important Notice and Warnings at the end of this document

Rev. 1.30

www.infineon.com

page 1 of 31

2022-03-01

Advertisement

Table of Contents

Summary of Contents for Infineon XENSIV TLI4971

-

Page 1: Current Sensor Tli4971

Programming Guide and User Manual About this document This document describes how to program the TLI4971 with the Infineon proprietary one wire interface (SICI). Timing of the serial inspection interface. Command structure and commands for write/read and EEPROM access. -

Page 2: Table Of Contents

Current Sensor TLI4971 Programming Guide and User Manual Current Sensor TLI4971 Table of contents Current Sensor TLI4971 ........................1 About this document ........................1 Table of contents ..........................2 Application and Programming circuit ..................3 Circuit / Precondition ..........................3 In-circuit programming ........................... -

Page 3: Application And Programming Circuit

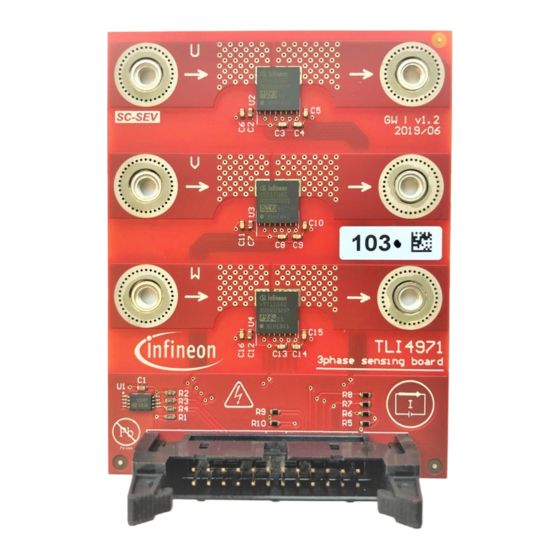

Current Sensor TLI4971 Programming Guide and User Manual Application and Programming circuit The sensor has implemented a serial interface to set the EEPROM content. This chapter describes the hardware environment to program the device. Further, it shows the recommended circuit for a three-phase GPD application. -

Page 4: In-Circuit Programming

Current Sensor TLI4971 Programming Guide and User Manual In-circuit programming To program the EEPROM the digital interface sends a particular programming sequence and applies the programming voltage at pin OCD2. In a multiple sensor system the OCD2 can be connected together as each sensor will receive their individual data set via the separated A pin connection. - Page 5 Current Sensor TLI4971 Programming Guide and User Manual Alternatively, the OCD2 channel can be connected with a pull down resistor to GND while applying the programming voltage on the OCD2 pin as shown in Figure 4. Sens µC Supply GPIO Control TLI4971 CC_IO...

-

Page 6: Serial Inspection And Configuration Interface (Sici)

Current Sensor TLI4971 Programming Guide and User Manual Serial Inspection and Configuration Interface (SICI) The sensor features a digital 16bit bidirectional one wire interface (SICI). Connect the A pin to a GPIO port in order to establish a communication between the sensor and the controller. Hardware Implementation CCIO µC... -

Page 7: Communication Timing

Current Sensor TLI4971 Programming Guide and User Manual Sens High_state(1.6V) 0" 0" 1" 0" IFen (3.3V) sens High_state(1.6V) Low_state(1.3V) 100µs 400µs Figure 5 Enabling SICI interface after device start up Communication timing As communication runs in both direction the GPIO of the external controller shall support tri state. After releasing the A back to V , the 16-bit enter-interface-command with LSB first has to be send from the controller. - Page 8 Current Sensor TLI4971 Programming Guide and User Manual r,max r,min (hi-Z) Figure 7 SICI duty cycle; sending logic '1' to the device; receiving logic '0' from the device Supply sensor force A to V modulate A force A to GND Send password LSB "1"...

-

Page 9: Interface Timing Definition

Current Sensor TLI4971 Programming Guide and User Manual Interface Timing Definition Table 1 Interface timing Parameter Symbol Min. Typ. Max. Unit Notes Interface enable time µs Drive A to GND IFen One communication frame consist of Period time of 1 bit 7500 µs 16 x 2 bits (16bits write / 16bits read) -

Page 10: Interface Description

Current Sensor TLI4971 Programming Guide and User Manual Interface description Command Structure A typical SICI communication consists in multiple input commands sent to the device via A voltage modulation, to which the sensor responds modulating the same A pin. An input command is composed of 16 bits LSB first. One bit consists of a transmission sequence initiated by the master and a receiving sequence driven by the device. -

Page 11: Interface Commands

Current Sensor TLI4971 Programming Guide and User Manual Interface Commands Table 5 Available Commands Command name address command description Activate communication as described in ABCD Enter Interface command chapter Entering Communication Mode reserve if-access to the EEPROM data bus to 8000 Power down ISM avoid that ISM is blocking the data bus... -

Page 12: Write And Programming Sequence

Current Sensor TLI4971 Programming Guide and User Manual Write and programming sequence set data prog. ones EEP command wait set data prog. zeroes EEP command Write command EEP command apply V refresh Write command EEP command apply V refresh PROG PROG Sens 16bit... -

Page 13: Read Example (Temperature Register Read Out)

Current Sensor TLI4971 Programming Guide and User Manual Read Example (temperature register read out) The temperature value can be read out via the SICI interface. The following example describes the required command sequence to enter the interface and to read out the 16 bit temperature value. The temperature sensitivity is set to a sensitivity of 16 LSB /°C. -

Page 14: Eeprom

Current Sensor TLI4971 Programming Guide and User Manual EEPROM The sensor’s non volatile memory (EEPROM) is organized in 16-bit (word) registers which can be addressed individually. When content in the user area is re programmed, a CRC check register has to be updated. Since the EEPROM CRC is calculated covering the entire EEPROM storage space, the user is required to readout the entire EEPROM content, calculate the new CRC values and store it into the respective registers. -

Page 15: Eeprom Content

Current Sensor TLI4971 Programming Guide and User Manual EEPROM Content Table 8 EEPROM (address 40 – 42 address OCD2 OCD1 OCD2 OCD1 MEAS deglitch deglitch mode OCD2 OCD1 thrsh thrsh comp_hyst RATIO RATIO OCD2f QV1V5 Empty VREF Gain only Table 9 Functional description Address 40 Bit field Default Type... - Page 16 Current Sensor TLI4971 Programming Guide and User Manual 6500 7000 7500 The over-current detection enable bit 1 activates the over-current functionality of channel 1. If this bit set to zero the OCD pin 1 will not OCD1 indicate an internal failure or an over-current event. The standard setting is 1 = enabled The over-current detection enable bit 2 activates the over-current functionality of channel 2.

-

Page 17: Programming Example

Current Sensor TLI4971 Programming Guide and User Manual Symbol Setting level x FS 0.50 THR2.1 0.61 THR2.2 0.71 THR2.3 0.82 THR2.4 0.93 THR2.5 1.04 THR2.6 1.14 THR2.7 1.25 THR2.8 Standard setting datecode 2118 and later Table 11 Functional description Address 42 Bit field Default Type... - Page 18 Current Sensor TLI4971 Programming Guide and User Manual Table 12 EEPROM programming example Command name address command description Enter Interface Enter interface DCBA 8250 Write command: get access to the register Power down ISM 8000 Set data 8010 Write command Disable failure indication 0000 Set data...

-

Page 19: Margin Test

EEPROM designed to write under PROG specified condition on the first shot. In case of lower voltage (i.e. 15V) Infineon recommends a margin test to proof quality of EEPROM content and repeat the programming- sequence if needed. EEPROM threshold margin 3.55... - Page 20 Current Sensor TLI4971 Programming Guide and User Manual threshold a '0' is stored in the EEPROM registers. By sweeping the external margin voltage the effective threshold voltages of each EEPROM cell can be identified. The threshold voltages of cells programmed to '1' can be found in this way.

-

Page 21: Cyclic Redundancy Check

Current Sensor TLI4971 Programming Guide and User Manual Cyclic Redundancy Check The CRC calculation is based on the polynomial x8+x4+x3+x2+1. Table 15 describes the CRC calculation. The seed word is defined as 0xAAhex. The CRC calculation of the EEPROM is performed byte by byte, starting from the EEPROM line three (address 43 ). - Page 22 Current Sensor TLI4971 Programming Guide and User Manual Table 15 CRC calculation specification CRC value operation comment CRC_3_1 [0xAA ] XOR The CRC calculation starts with the content [EEPROM_line_03_bit15_downto_bit8] of the upper 8 bits in the EEPROM line 3 CRC_3_2 CRC_3_1 Continue calculating the CRC with the lower [EEPROM_line_03_bit07_downto_bit0]...

-

Page 23: Code Example Crc Calculation

Programming Guide and User Manual Code example CRC calculation //CRC calculation example for Infineon TLI4971 current sensor //CRC 8 (SAE - J1850) CRC polynomial: x^8 + x^4 + x^3 + x^2 + 1 // len = 18 (EEPROM line 0-17) -

Page 24: Operation Mode

Current Sensor TLI4971 Programming Guide and User Manual Operation Mode The default output mode is semi-differential mode V OQbid1 Single-Ended Mode The sensors reference voltage pin is set as input and supplied by an external reference voltage generation circuit. The V input leakage current of up to 20µA has to be considered in the design of the reference voltage generation circuit. -

Page 25: Semi-Differential Mode

Current Sensor TLI4971 Programming Guide and User Manual Figure 18 TLI4971 (fully-differential mode) connected to differential ADC Semi-differential Mode In Semi-Differential Output Mode, the sensor is using a chip-internal reference voltage. This reference voltage is then provided on the VREF. Therefore, the reference voltage can be monitored by the microcontroller and/or used for other devices as a reference voltage (cascade setup). -

Page 26: How To Connect The Sensor In A 5V Domain

Current Sensor TLI4971 Programming Guide and User Manual How to connect the sensor in a 5V domain This chapter gives a proposal how to connect the 3.3V sensor device with a 5V microcontroller. Table 16 Electric parameter for application circuit Name Value Unit... -

Page 27: Diagnosis Mode

Current Sensor TLI4971 Programming Guide and User Manual Diagnosis Mode General Description The TLI4971 current sensor is equipped with an internal self-diagnosis mode. It can be enabled by setting bit 14 at address 0x51 to logical one. In order to verify the full functionality of the device signal path and the external signal conditioning circuit the diagnosis mode can be activated externally. - Page 28 Current Sensor TLI4971 Programming Guide and User Manual CC_IO CC_IO CC_IO 220nF 6.8nF 6.8nF 1nF_50V 220nF 6.8nF 6.8nF 1nF_50V Figure 23 Application Circuit for diagnosis mode, OCD2 are wired separately 250 µs DM external trigger OCD2 OTA and OCD Regular x sensitivity) + V x sensitivity) - V Regular...

-

Page 29: Glossary

General Purpose Input Output Input / Output Pulse Width Modulation No Operation Most Significant Bit Least Significant Bit Alternating Current IGBT Insulated Gate Bipolar Transistor µC Micro Controller General Purpose Drive Infineon Application Note 29 of 31 Rev. 1.30 2022-03-01... - Page 30 Current Sensor TLI4971 Programming Guide and User Manual Revision history Document Date of release Description of changes version Rev. 1.30 2022-03-01 Updated typo in note (table 1) Updated register address (table 5) Added position of Diagnosis_mode_enable_bit in chapter 7 Combine table 12..14 into Table 9..11 and renumber all later tables Delete chapter 8 (OCD-Settings Overview) Added chapter 4.3 (Margin test) Shorten chapter 5 and remove table 16...

- Page 31 Infineon Technologies hereby disclaims dangerous substances. For information on the types © 2022 Infineon Technologies AG. any and all warranties and liabilities of any kind in question please contact your nearest Infineon All Rights Reserved. (including without limitation warranties of non- Technologies office.

Need help?

Do you have a question about the XENSIV TLI4971 and is the answer not in the manual?

Questions and answers