Summary of Contents for HESHBON HL-26K

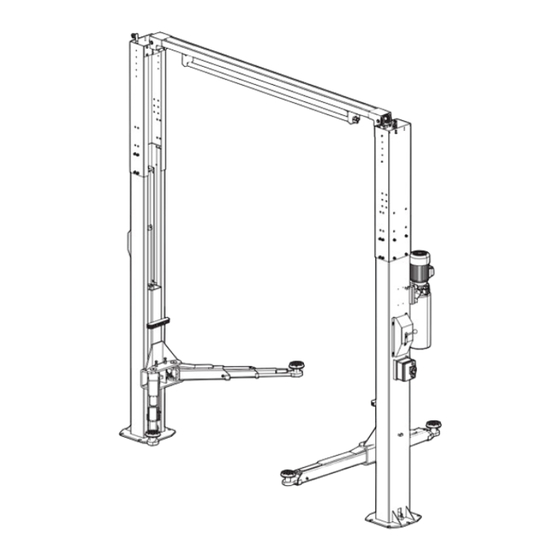

- Page 1 HESHBON 2 POST LIFT Installation/Operation & Maintenance Manual HL-26K Please read this manual before you get started. You must read and understand the precautions for safety purposes and any damages that may occur to your property.

- Page 2 Don’t use the car lift in a potentially explosive atmosphere. ANY PART OF THIS PRINT MUST NOT BE REPRODUCED IN ANY FORM WITHOUT PERMISSION. THIS PRINT IS SUBJECT TO CHANGE WITHOUT NOTICE. NO. 26K101101A ⓒ Copyright Heshbon Co.,Ltd. HBS Project 2010 All rights reserved.

-

Page 3: Table Of Contents

TABLE OF CONTENTS Introduction Features and Characteristics Part Descriptions Description Specification Safety Danger/Warning/Caution Installation Procedures Checklist Before Installing Place of Installation-Layout Operation Check Points Before Operation Operation Operation Procedures of Each Part Maintenance Maintenance Troubleshooting Check List and Periodic Maintenance Part List ■This manual was prepared in November. -

Page 4: Introduction

Features and Characteristics Upper limit protection bar Introduction Industrial ram type cylinder Door protection rubber Arm lock gear ■ Upper limit protection bar ▶A limit bar prevents the vehicle from being lifted too high. This feature effectively protects taller vehicles from being damaged. ■... - Page 5 ■ Cable adjustment ▶Correct adjustment ensures synchronization of both carriages. Cable adjustment Introduction ■ Operation of ram type cylinder ▶Two industrial ram type cylinders ensure reliability and longevity. Unlocked Locked ■ Powerful arm lock gear ▶At the bottom position the gears are unlocked to allow arm adjustment.

-

Page 6: Part Descriptions

Part Descriptions Introduction Cross beam Slave post Post extension Industrial ram type cylinder Main post Carriage Powerpack Door protection rubber pad Locker cover & Locker(inside) Long arm Control panel Pick-up pad Short arm... -

Page 7: Description

Introduction 1. Main power lamp 2. Main switch - To connect or disconnect power to the lift. 3. Ascent button - To raise the lift. Specification MODEL HL-26K CAPACITY 4,000 Kg MAX. PRESSURE 220 Kgf/㎠ MAX.HEIGHT 1,890~1,930 mm MIN. HEIGHT... -

Page 8: Safety

The rules are The terms are described to enhance applied only to the equipment. the understanding of the manuals of Heshbon Co., Ltd. Information to use the equipment Safety efficiently. Precautions or check points for the use of the equipment. - Page 9 Warning when operating Allow no unauthorized Before lowering the lift, When the vehicle is Do not lift a vehicle persons in the work lifted, do not rock it as using one pair of arms check that there are area. this may dislodge it. only.

-

Page 10: Installation Procedures

The lift should be installed by skilled engineers either from Heshbon or from Heshbon's appointed representatives. Failure to observe this makes the lift warranty invalid. If the lift is to be moved to another site at a later date, it must be reinstalled by skilled engineers... -

Page 11: Place Of Installation-Layout

Place of Installation-Layout Check points before selecting the place of installation. ① Distance from wall or any fixed object ② Drive-on direction ③ Positions of power post and slave post ④ Ceiling height and height of cross member Installation 2490 3205 3440... - Page 12 ■Setting up a post ▶Before securing with anchor bolts, ensure Vertical balance that the post is vertical in both directions. Adjusting verticality Check that the post is vertical in both directions and adjust by means of the shim plates provided. Fixing the post Fix by anchor bolts.

- Page 13 ■Cable synchronization ▶The cables ensure synchronization between the carriage on the power post and the carriage on the slave post. ① Top roller for cable. ② Synchronization cable from the opposite carriage. ③ Synchronization cable mounting bracket. ④ Bottom roller for cable. Installation Adjusting the cables Check which carriage first touches the base...

- Page 14 ■Hydraulic line drawing ▶Please refer to this for hydraulic line installation. Installation...

- Page 15 ■Electric line drawing ▶Please refer to this for electric line installation. Installation...

-

Page 16: Operation

Check Points Before Operation Before loading the lift check the following points. ■ Test Operation ▶Operate the lift up and down 2-3 times to check the full travel of the carriages. ■ Switch Operation ▶Check that the ascent and descent lever operate correctly. -

Page 17: Operation

Operation Prior to use Check that the carriages and arms are at lowest position by operating the descent push button. Prior to vehicle entry At the bottom position the arm locks are released. Swing the arms to the straightahead position as shown. Vehicle entry Position the vehicle centrally between posts with the vehicle's center of gravity in... -

Page 18: Operation Procedures Of Each Part

Ascent After checking that the 4 pads are correctly adjusted under the pick-up points recommended by the vehicle manufacturer and that the arm locks are engaged as previously described, press the ascent push button and raise the lift to the required working height. - Page 19 ▶ 26K Arm 2-section telescopic arm ⓐ 971 mm ⓑ 1560 mm 3-section telescopic arm ⓐ 567 mm ⓑ 852 mm ⓒ 1077 mm 3-stage telescopic pad adjustment The height of the pad can be adjusted 3 stages as shown below. ⓐ...

-

Page 20: Maintenance

Maintenance ■ Lubrication ▶At 2-or 3-month intervals, depending on service usage. Molybdenum disulphide grease ▶Apply molybdenum disulphide grease liberally to the carriage guides and the guide runners inside the posts. Lubricating oil ▶Lubricate with oil the upper and lower cable rollers and axles. - Page 21 ■ Arms ▶Once a year check the condition of each arm by sliding each section to its fully extended position and ensure that the arm stop is working correctly. ■ Emergency lowering in the event of power failure In the event of a power failure the lift must be lowered manually.

- Page 22 Excessive adjustment can result in serious damage. If the lift fails to raise the maximum rated load, contact your Heshbon approved maintenance engineer. Standard pressure settings model HL-26K 200kgf/㎠...

-

Page 23: Troubleshooting

Troubleshooting Maintenance... -

Page 24: Check List And Periodic Maintenance

Check list and periodic maintenance Maintenance... -

Page 25: Part List

PART LIST HL-26K Version 2 - 11.2010 This installation manual is prepared as of November 2010. This manual is subject to change without prior notice if the lift specificaion is changed. - Page 26 HL-26K Full Ass'y 1. Drive post 6. Long arm 2. Driven post 7. Short arm 3. Carry 8. Power units 4. Upper support beam 9. Control panel 5. Cylinder...

- Page 27 HL-26K Main post PARTS LIST PARTS LIST PARTS LIST POST LEVER CONNECTOR KEY SWITCH EXTENDED POST WRENCH BOLT PUSH BUTTON SWITCH LOCK COVER LOCK SPACER WIRE ROLLER LOCK SHAFT LOCK BLOCK POWER UNIT LOCK SPRING 1 SPRING PIN ANTI-VIBRATED RUBBER...

- Page 28 HL-26K Carriage & Cylinder PARTS LIST PARTS LIST PARTS LIST CARRY PISTON BACK UP RING CARRY GUIDE LOCKING BOLT(M6) U-PACKING ARM SHAFT HOSE ADAPTER BACK UP RING DOOR PROTECT RUBBER CYLINDER O-RING FLAT WASHER(M8) HEAD COVER D.U BEARING WRENCH BOLT(M8)

- Page 29 HL-26K Slave post PARTS LIST PARTS LIST PARTS LIST CARRY ARM SHAFT HEXA BOLT CARRY GUIDE LARGE ARM LOCK GEAR FLAT WASHER LONG ARM SMALL ARM LOCK GEAR ARM SUPPORT RUBBER LONG SLIDE ARM ARM LOCK SPRING ARM SUPPORTER SLIDE ARM (3 rd)

- Page 30 HL-26K Cross beam PARTS LIST PARTS LIST UPPER SUPPORT BEAM E-RING WIRE ROLLER SHAFT LIMIT SWITCH FIXTURE SNAP RING UPPER LIMIT TOUCH BAR WIRE ROLLER HEXA BOLT WIRE ROLLER SPACER HEXA NUT LIMIT SWITCH FLAT WASHER...

- Page 31 26MA00 HL-26K Hydraulic circuit...

- Page 32 HL-26K Electric circuit...

- Page 34 HESHBON CO.,LTD. 673-52, GYEONGSEO-DONG, SEO-GU, INCHEON, 404-170 KOREA TEL:+82-32-585-3570(Int’l trading) / FAX: +82-32-585-3535 http://www.heshbon.com / e-mail:export@heshbon.com...

Need help?

Do you have a question about the HL-26K and is the answer not in the manual?

Questions and answers