Table of Contents

Advertisement

Quick Links

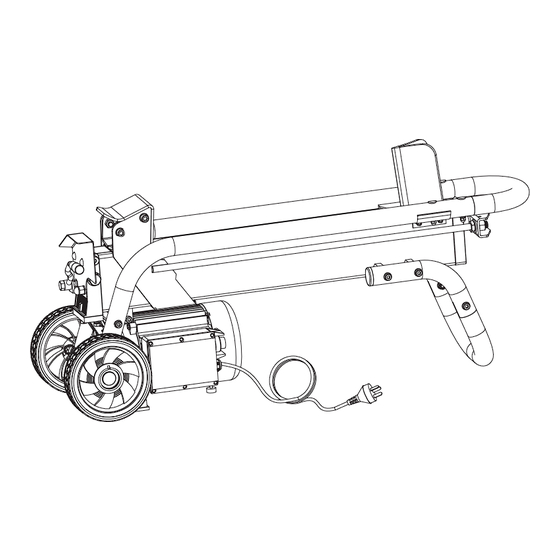

Log Splitter

Instruction Manual

WARNING:

Read carefully and understand all INSTRUCTIONS before operating. Failure to follow the safety rules

and other basic safety precautions may result in serious personal injury.

Save these instructions in a safe place and on hand so that they can be read when required. Keep

these instructions to assist in future servicing.

REV 12/31/20

Advertisement

Table of Contents

Summary of Contents for Super Handy GUT065

- Page 1 Log Splitter Instruction Manual WARNING: Read carefully and understand all INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury. Save these instructions in a safe place and on hand so that they can be read when required. Keep these instructions to assist in future servicing.

-

Page 2: Table Of Contents

Carefully read through this entire operator’s manual before using your new Log Splitter. Take special care to heed the cautions and warnings. SPECIFICATIONS Item No. GUT065 Motor 120V 60H 1 3/4HP S3 40% IP54 Log Capacity Diameter Max. -

Page 3: Symbols

ENVIRONMENTAL Recycle unwanted materials instead of disposing of them as waste. All tools, hoses and packaging should be res or ted, taken to the local recycling center and disposed of in an environmentally safe way. SYMBOLS The rating plate on your machine may show symbols. These represent important information about the product or instructions on its use. - Page 4 DRESS PROPERLY Do not wear loose clothing, gloves, neckties or jewelry (rings, wrist watches). They can be caught in moving parts. Protective electrically non conductive gloves and non-skid footwear are recommended when working. Wear protec- tive hair covering to contain long hair, preventing it from get caught in machinery. PROTECT YOUR EYES AND FACE Any log splitter may throw foreign objects into the eyes.

-

Page 5: Application Conditions

PROTECT YOUR HANDS Keep you hands away from splits and cracks which open in the log; They may close suddenly and crush or ampu- tate your hands. Do not remove jammed logs with you hands. DON'T FORCE TOOL It will do a better and safer job at its design rate. Never try to split logs larger than those indicated in the specifica- tions table. -

Page 6: Assembly

ASSEMBLY Following the assembly directions below, you will assemble the log splitter in a few minutes. Align the holes and assemble the wheels onto the rear frame. Secure the connection with bolts, washers and clips. Attach the caps onto the wheels. KNOW YOUR MACHINE Log Pusher Log Retaining Plates... -

Page 7: Operation

Max Pressure Limiting Screw Do not adjust the max pressure limiting screw ! 1. Max pressure was set before the log splitter ex work and the max pressure limiting screw is sealed with glue to ensure the log splitter works under pressure no more than 132271lbs (6Ton). The setting was done by qualified mechanic with professional instruments. -

Page 8: Freeing A Jammed Log

Break log in the direction of its growing grain. Do not place log across the log splitter for splitting. It may be dangerous and may seriously damage the machine. Do not attempt to split 2 pieces of logs at the same time. One of them may fly up and hit you. -

Page 9: Replacing Hydraulic Oil

REPLACING HYDRAULIC OIL Replace the Hydraulic oil in the log splitter after every 150 hours of use. Take following steps to replace it. 1. Make sure all moving parts stops and the log splitter is unplugged. 2. Unscrew Oil Drain Bolt with Dipstick to remove it. 3. -

Page 10: Trouble Shooting

TROUBLE SHOOTING Problem Cause Remedy Fails to split logs. 1. Log is improperly positioned. 1. Refer to “Log Splitter Operation” section 2. The sizes or hardness of the log. for perfect log loading. Exceeds the capacity of the machine. 2. Reduce the log sizes before splitting it 3. -

Page 11: Parts Schedule

PARTS SCHEDULE... - Page 12 Great Circle USA Support Line: 1-866-493-0524 help@greatcircleus.com www.greatcircleus.com Size: 210x285mm 157克双铜 REV 12/31/20...

Need help?

Do you have a question about the GUT065 and is the answer not in the manual?

Questions and answers

how much hydraulic fluid do you put in a super handy T6 log splitter when draining and installing new fluid

The hydraulic oil capacity for the Super Handy T6 log splitter is 0.85 gallons.

This answer is automatically generated

how much hydraulic fluid to add when changing out fluid

The hydraulic oil capacity for the Super Handy GUT065 log splitter is 0.85 gallons. When changing the fluid, this amount should be added.

This answer is automatically generated