Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for BRUEL & KJAER 2237

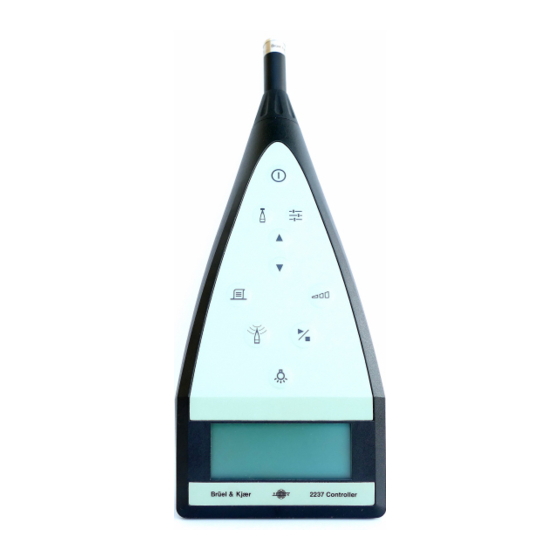

- Page 1 Technical Documentation Sound Level Meter Type 2237 – Version A + B Service Manual Brüel & Kjær 7/6-'89 WORLD HEADQUARTERS: DK-2850 Nærum • Denmark • Telephone: +4545800500 •Telex: 37316 bruka dk • Fax: +4545801405 •e-mail: info@bk.dk BI 5031 –11...

- Page 2 0 − 2 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual...

- Page 3 Sound Level Meter Type 2237 Versions A + B Service Manual Valid from serial number 1 896 028 August 1998 Brüel & Kjær Sound Level Meter Type 2237 A+B BI 5031 –11 Service Manual...

- Page 4 All rights reserved. No part of this publication may be reproduced or distributed in any form or by any means without prior consent in writing from Brüel & Kjær Sound and Vibration Measurement A/S, Nærum, Denmark. 0 − 2 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual...

-

Page 5: Table Of Contents

Noise........................3 – 6 Overall Check ......................3 – 6 4. Calibration and Adjustment ................4 – 1 Introduction ......................... 4 – 2 Power Supply....................... 4 – 2 0 − 3 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... - Page 6 Control...................... 6 – 2 Interfaces ........................ 6 – 3 Power Supply......................6 – 3 Block Diagram......................6 – 4 A. Appendix – Type 2237 B ..................A – 1 Introduction ........................ A – 2 Upgrade ........................A – 2 Special Tools and Equipment ..................

- Page 7 A.11 Noise..........................A – 5 A.12 Calibration ........................A – 6 0 − 5 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual...

- Page 8 0 − 6 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual...

-

Page 9: General Information

Chapter 1 General Information 1− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... -

Page 10: Edition Number

The letter following the Type number indicates whether the instrument is an “A” version or a “B” version. For example, the “A” version is shown as “Type 2237 A”. The “A” version is designed to be used with a microphone input – that is, sound measurement. -

Page 11: Service Policy

1.4.3 Serial Numbers If an part in Type 2237 is found to be faulty, the only way to repair it is to send it to Brüel & Kjær headquarters in Nærum. The faulty part will then be dealt with in one of two ways, depending on how the instrument’s serial number is to be handled. -

Page 12: Repair

Table 1.1 Field replaceable parts in Type 2237 Special Tools and Equipment To perform the complete checking procedure, troubleshooting, adjustment and up- grade of Type 2237, the following special tools and equipment must be available: Type 1049/51 Sine Generator Type 4231... -

Page 13: Service Note

Chapter 2 Service Note 2− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... -

Page 14: General

From time to time some minor changes may be made to improve the performance and serviceability of Type 2237. All information concerning these changes, or any other changes to the Service manual, will be released in the form of a Service Note. -

Page 15: Checking Procedure

Chapter 3 Checking Procedure 3− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... -

Page 16: Introduction

Introduction Introduction The following Checking Procedure for Type 2237 is a subset of the final factory test. The Checking Procedure verifies that the performance of the Type 2237 conforms to the main specifications as given in the Product Data Sheet. To calibrate the Type 2237 to international standards IEC 651 and 804, the Sound Level Meter Calibra- tion System Type 9600 can be used. -

Page 17: Preparation

Serial Output 970028/1e Fig.3.1 The fundamental setup for performing the Checking Procedure 3. When you are asked to ’Preset the Type 2237’ in the following procedures, the setup for the Type 2237 must afterwards be: — Time Weighting: F — Display Parameter: SPL and Peak —... -

Page 18: Checking Procedure

**************** Master Reset **************** The calibration factor is 0.0 dB and the Type 2237 is in a well defined state. 3.3.3 AC Output Adjust the input voltage to give a 120 dB display reading at 1kHz The measured AC Output should be 500 mV ±1 dB (± approx. 55 mV). -

Page 19: Frequency Weighting

‘The reference signal is one that gives a display reading of 110 dB when the range is set to 50–120 and the input signal is 1 kHz Table 3.2 Attenuator linearity 3− 5 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... -

Page 20: Noise

The overall check can also be performed with the Multifunction Acoustic Calibrator Type 4226. By using the Type 4226 the frequency response for the microphone can be checked. 3− 6 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual... -

Page 21: Calibration And Adjustment

Chapter 4 Calibration and Adjustment 4− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... -

Page 22: Introduction

You should only do the procedures given in this chapter if the instrument fails the checking procedure given in Chapter There is no troubleshooting guidance for Type 2237 since the instrument is an FRP. If you cannot adjust it, it must be replaced using the FRP scheme (see Chapter Mechanical spare parts can be ordered from Brüel &... -

Page 23: Battery Voltage And Current

This voltage is approx. 0.1 V lower than the actual battery voltage (J1 pin 1) d. When the Type 2237 is On the voltage is approx. 5.0V, an when Off it is 0.0 V. This line controls the On/Off function. -

Page 24: Input Stage

Type 2237 is “dead” when the supply voltage is below 3.0 V. Adjustment Procedure Set up a dismantled Type 2237 according to Fig.3.1. The input signal to Type 2237 from the generator is supplied through the JJ 2614 ½″ Microphone Adaptor to the ZC 0027 preamplifier. - Page 25 Chapter 4 — Calibration and Adjustment Adjustment Procedure TP 3 DC Ref. AGND DGND 970031e Fig.4.2 Important components on the ZD 0814 Digital Board 4− 5 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual...

- Page 26 Pin 19 R271 Peak Gain RMS Out - Pin 21 X104 R273 Peak Offset Peak Out - Pin 18 970032/1e Fig.4.3 Important components on the ZZ0233 Analogue Board 4− 6 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual...

-

Page 27: Zd 0814 Digital Board Reference Voltage

1. Remove the microphone from the preamplifier and mount the JJ 2614 ½" Micro- phone Adaptor. 2. Remount the preamplifier (and the JJ 2614). 3. Switch On and preset the Type 2237. 4. Apply 116.0 dBµVRMS, 1 kHz, to the adaptor. 5. By means of an oscilloscope check that V... -

Page 28: Peak Detector Gain And Offset

7. Apply 89.4 dBµV at 1 kHz to the input. 8. The display should read 3 dB ± 0.2 dB higher than the SPL reading. If necessary adjust R273 until the reading is correct. 4− 8 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual... -

Page 29: Mechanical Parts

Chapter 5 Mechanical Parts 5− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... -

Page 30: Exploded View

Chapter 5 — Mechanical Parts Exploded View Exploded View 931530/1e Fig.5.1 Exploded view of the Type 2237 5− 2 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual... -

Page 31: Dismantling Kit Wz 0065

“keys” (see Fig.5.2). One key is for removing the LEMO Connec- tors (item 30 in Fig.5.1) and one is for removing the Special Nut (item 18). The third key is not used with Type 2237 (WZ 0065 is also used with Type 2236). 970030e Fig.5.2... -

Page 32: Reassembly

Reassembly When you reassemble the Type 2237 the following hints might be useful: Note the guide for item 19 in the Bottom PC/ABS Shell. The “pre-bending” of the Ribbon Cable (flexible PCB) is made so that the cable is fully hidden between the two boards when the boards are mounted correctly. -

Page 33: Service Parts List

Cable Assembly, ZG0393 to connector on ZZ 0233 AT 2299 Cable Assembly, ZG0393 to connector on ZD 0814 XF 0069 Ribbon Cable (flexible PCB), connector on ZZ 0233 to connector on ZD 0814 5− 5 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual... - Page 34 5− 6 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual...

- Page 35 Chapter 6 Theory of Operation 6− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual...

-

Page 36: Theory Of Operation

PEAK signals are fed to the processor, D1. This processor, 80C517A, includes an AD Converter capable of handling up to eight (internally multiplexed) analog input lines. In the Type 2237 only three lines are used (RMS, PEAK and battery voltage sense). -

Page 37: Interfaces

6.2.4 Power Supply The Power Supply is a switch mode supply giving five different voltages (+15, (+15), +5, −5 and −13 V) for the analog part of the Type 2237, and one voltage (+5 V) for the digital part. The voltage (+15) is only used for the reference voltage, REF, made by V4 on the Digital Board. -

Page 38: Block Diagram

+ 15 V + 5 V Supply – 5 V – 13 V Batteries ZG 0393 6 V (4 pcs. AA size) 970029/1e Fig.6.1 Block diagram of Type 2237 6− 4 Sound Level Meter Type 2237 A+B Brüel & Kjær Service Manual... - Page 39 Appendix A Type 2237 B A− 1 BI 5031 –11 Sound Level Meter Type 2237 A+B Service Manual...

-

Page 40: Appendix - Type 2237 B

Accelerometer cable. Repair If a customer wants to receive exactly the same 2237 B in return from repair, then the whole instrument must be sent to Nærum. A repair time of up to 10 days + transport time must be allowed. -

Page 41: Preparation

Appendix A — Type 2237 B Preparation Part Description FRP Number Type 2237 B Sound Level Meter 2237–B–FRF ZE 0777 Charge amplifier ZE 0777– –FRF Table A.1 FRP numbers Preparation 1. Put new batteries in the Hand Arm Meter 2. Set up the equipment as shown in Fig.A.1. -

Page 42: Checking Procedure

All of the self-tests must be “OK”. Initial setting Caution: If no Calibration Exciter Type 4294 or other calibration equipment are available do not do the checks in sections A.7 and A.8, since Type 2237 will loose its calibration information. 1. Do a Master Reset (see section 3.3) -

Page 43: Frequency Weighting

Appendix A — Type 2237 B Frequency Weighting A.10 Frequency Weighting 1. Preset the Type 2237 2. Set the generator to give a frequency of 159.15 Hz and a level that gives a Hand Arm Weighting display reading of 10.0 m/ss. - Page 44 0.001 – 0.101 +0.02/– Table A.3 Checking noise tolerances A.12 Calibration Do a calibration of Type 2237 and its accelerometer according to the instructions given in the User Manual. A− 6 Sound Level Meter Type 2237 A+B Brüel & Kjær...

Need help?

Do you have a question about the 2237 and is the answer not in the manual?

Questions and answers