Table of Contents

Advertisement

Quick Links

DIGITROLL

DIGITROLL Ltd.

SEED MASTER

(version 8.6x and 8.7x)

IN T EL L IGEN T S EN S O R T E CH N OL O GY

STOP

8 6 0 0 0

DISPLAY

150%

Ã

100%

ÿ

ÿ

ÿ

50%

TEST

ÿ

ÿ

ÿ

0%

1

2

3

4

5

1

2

3

A

B

DIGITROLL

SEED MASTER

seeding control system for

Tel: +36 52/ 557-480

Fax: +36 52/ 557-482

* / h a

Å

ÿ

ÿ

ÿ

ÿ

ÿ

6

7

8

9 10 1112 1314 15 16

4

5

6

7

8

SENSORS

C

D

O U T

+1

INFO

STOP

PLANTERS

USER'S MANUAL

Web: www.digitroll.hu

Email: info@digitroll.hu

Plus

D

L

C

max.

B

R

A

ALL-IN-ONE

Plus

Advertisement

Table of Contents

Summary of Contents for Digitroll SEED MASTER Plus 8.6 Series

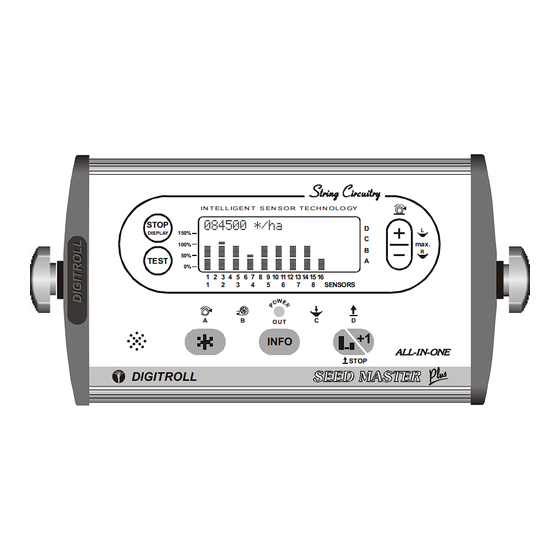

- Page 1 ÿ ÿ 9 10 1112 1314 15 16 SENSORS O U T INFO ALL-IN-ONE STOP DIGITROLL SEED MASTER Plus seeding control system for PLANTERS USER’S MANUAL DIGITROLL Ltd. Tel: +36 52/ 557-480 Web: www.digitroll.hu Fax: +36 52/ 557-482 Email: info@digitroll.hu...

-

Page 2: System Draft

ÿ ÿ ÿ ÿ ÿ 9 10 11 1213 14 15 16 SENSORS RADAR-II O U T INFO ALL-IN-ONE STOP DIGITROLL RAD/HIR/4 BLUE DA 02 PIROS KÉK SPEED MODUL DSI-18J AKKU SPEED MODUL 12VDC MAX. DS 1000 -custom designed for seeder type, placed in seed tube... -

Page 3: Table Of Contents

CONTENT SYSTEM DRAFT ......................2 GENERAL DESCRIPTION ................... 4 MOUNTING ........................6 MONITOR FRONT ......................7 SWITCH ON ........................7 SYSTEM TEST ......................8 MENU ..........................9 SETTING BASIC DATA ..................... 10 MONITOR SETTINGS ....................13 CONTROL OF SEEDER SETTINGS ................14 SEEDING CONTROL .................... -

Page 4: General Description

GENERAL DESCRIPTION GENERAL DESCRIPTION SEED MASTER Plus MONITOR · illuminated LCD display · massive aluminium housing · audible and visual alarms · adjustable horn volume · 8 selectable languages · nonvolatile memory for safe storage of measured and adjusted data SYSTEM CONSTRUCTION ·... - Page 5 Horn volume Tractor The seeding control system and its technical characteristics described in this manual are under patent process. Any means of recording or public use of principles, images, system drafts are subject to prior written contribution of DIGITROLL Kft.

-

Page 6: Mounting

MOUNTING MOUNTING MONITOR Place the monitor on a clearly visible place in the tractor cabine and fix it with the U-bracket and bolts, up or bottom position to avoid direct sunlight on LCD. The display is illuminated which enables nighttime use with superb visibility •... -

Page 7: Monitor Front

Every push of a button is accompanied by a short beep in case the button is operative in that function. SWITCH ON Following switch on the console presents Seed Counting Pro v8.71 running software version, DIGITROLL Ltd. > RS... selected horn volume, > <Normal >... -

Page 8: System Test

SYSTEM TEST SYSTEM TEST The system test is executed: • every switch on, • by pressed button on screen of any seed control mode TEST SENSOR • automatically by change settings of photosensors. TEST TEST function may be used when there is no seeding in progress! .. -

Page 9: Menu

MENU MENU INFO POPULATION RATIO CONTROL OF SEEDING TOTAL SEEDS AND TOTAL DISPLAY, ACTUAL BLOCKAGE ADJUSTABLE AREA SEED/HA SENSITIVITY AVERAGE SEED/HA TEST PARTIAL SEEDS AND PARTIAL AREA TEST 2 sec. AVERAGE SEED/HA 2 sec. STATISTICS OF 100 DISTANCE MEASUREMENT SEEDED GRAINS STATISTICS OF 100 SEEDED GRAINS SETTING OPTIMAL SEED... -

Page 10: Setting Basic Data

SETTING BASIC DATA SETTING BASIC DATA SETTING OPTIMAL SEED SPACING Two options are available: Normal One spacing value can be entered. Adjustment between 3,0 - 45,0 cm <Normal > STOP DISPLAY f?e~ 20.0 cm Spinner up & down Shift to Hybrid TU<J * * * >... - Page 11 SETTING BASIC DATA SELECTION OF SEED SIZE AND SHAPE Selection of seed size DS2000 *: 6-9mm> DS2000/HR (3-5 / 6-9 mm) DS2000/HR *: o > Selection of seed shape (round or long) In order to reach more precise seed detection when using DS 2000 optomodules, main seed characteristics like size and shape must be entered.

- Page 12 SETTING BASIC DATA ENTRY OF WORKING WIDTH Seeding machine working width is adjustable between 0.75-30 metres > TU<J |? 4.50 m Spinner up & down > This constant is needed for area count. Working width can be calculated: row number multiplied by row spacing. 100 SPEED SIGNAL COUNT This is a side function to get information about distance traveled in 100 speed signals.

-

Page 13: Monitor Settings

MONITOR SETTINGS • In case of individual installation find a possibly non-driven wheel for speed sensor, where slip rarely occurs. • In order to reach maximum accuracy in calibration take soil conditions, tyre pressure, hopper weight (ideally half filled),...etc. into consideration to create similar conditions to real circumstances. -

Page 14: Control Of Seeder Settings

CONTROL OF SEEDER SETTINGS CONTROL OF SEEDER SETTINGS STATISTICS OF 100 EXPECTED/SEEDED GRAINS TEST 2 sec. To reach this function push button for at least 2 seconds. TEST The appliance calculates the seeding time of 100 seeds on the basis of the given distance, the optimal seed spacing and current speed. - Page 15 CONTROL OF SEEDER SETTINGS If time interval between seed drops is smaller than expected: • Use of unsuitable seed disk results homogenous, but too dense seed drops. This case the program does not interpret it as double drop, but the number of measured seeds will be higher than 100. •...

-

Page 16: Seeding Control

SEEDING CONTROL SEEDING CONTROL CONTROL OF SEEDING BLOCKAGE The monitor simultaneously detects seeding continuity in all rows. Where seed drop is missing for longer time than preset limit value, seed symbol of that row (*) will disappear from display and alarm sounds in according length. 2.00 sec STOP DISPLAY... - Page 17 SEEDING CONTROL CONTROL OF POPULATION RATIO You can read the ratio of the desired and the actually measured population in each row, displayed with bar graphs. Use this function for seeds that can be detected precisely by the photoelectric cells (seeds larger than 5 mm, such as maize, sunflower, sugar beet, etc) Necessary basic data •...

- Page 18 SEEDING CONTROL Display hold To ease analysis, display can be freezed (fixed) any time, even when seeder is stopped.. In this case the monitor scans row diagrams and their values are shown numerically. Push button again to STOP 084500 */ha DISPLAY STOP Á...

-

Page 19: Stored Seeding Data

STORED SEEDING DATA STORED SEEDING DATA SEEDED GRAINS AND AREA COUNTS INFO The SEED MASTER Plus monitor continuously measures here (and in both seeding control mode) the seeded area and the number of total seeded grains. The area count controlled (start/stop) by signals of photosensors. If photosensors are not applied, the counting is continuously. -

Page 20: Distance Measurement

DISTANCE MEASUREMENT DISTANCE MEASUREMENT STOP <0 DISPLAY |Ü------------Û| up to 65.500 meters Deletion START> The date of distance traveled in 100 speed signal is used here. Measurement begins when START button pushed, appears new display on screen, and it ends by the next push of the button. <0 |Ü------------Û| 600 m... -

Page 21: Troubleshooting

TROUBLESHOOTING TROUBLESHOOTING THE MONITOR DOES NOT FUNCTIONING, NO LIGHTS ON DISPLAY • The monitor does not receive 12 VCD power supply (min. 8,5V) • Wrong polaritiy battery lead connection • Missed to switch ON button on the back side of monitor Defected main switch or electronic part •... - Page 22 TROUBLESHOOTING THE MONITOR FUNCTIONS ‘POWER OUT’ LIGHTS, BUT FOLLOWING THE TEST SENSOR SIGNALS ARE PARTIALLY OR TOTALLY MISSING • Caused by mistaken switch off of row detection, some rows are missing from screen. Check again and reset row detection where necessary. (See SETTING ROW SKIP) •...

- Page 23 TROUBLESHOOTING THE MONITOR INDICATES BLOCKAGE AT A SEED MODULE FOLLOWING TEST AND EVEN AFTER CLEANING Defected seed module. Troubleshooting: insert a long stick inside the seed sensor. If LED gets dark for a second: it works. If not: sensor is defected. THE MONITOR INDICATES IRREGULAR SEED DROPS WHEN SEEDER STOPPED Seeds or seed fragments picked up accidentally by the air-flow are detected by...

-

Page 24: Maintenance, Storage

MAINTENANCE, STORAGE MAINTENANCE, STORAGE • The most important is keep cables and connectors unhurt and check then regularly. • Always clean sensors at the end of seeding season, close the end of extension cable with the waterproof seal. • Do not expose the monitor to direct water, do not store it under –20 C and above + 40 C temperature, protect it from excessive heat and dust.

Need help?

Do you have a question about the SEED MASTER Plus 8.6 Series and is the answer not in the manual?

Questions and answers