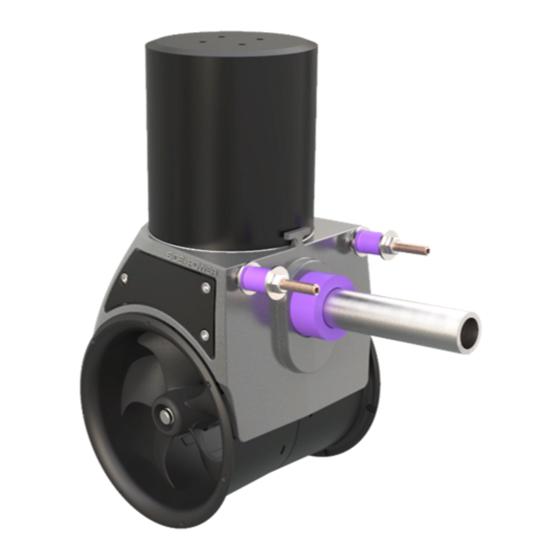

Sleipner SX35 Installation Manual

For dc external electric thruster models

Hide thumbs

Also See for SX35:

- Installation manual (24 pages) ,

- User manual (12 pages) ,

- User manual (12 pages)

Summary of Contents for Sleipner SX35

- Page 1 Installation Guide For DC External Electric Thruster Models SX35, SX50 DOCUMENT ID: SLEIPNER AS 5630 REVISION: P.O. Box 519 DATE: N-1612 Fredrikstad 2021 Norway LANGUAGE: www.sleipnergroup.com...

-

Page 2: Table Of Contents

SM908127 | SX50/140-12V-50MM - SX50/140 - 12V -50mm w/Controller SM908123 | SX35/140-12V-150MM - SX35/140 - 12V -150mmw/Controller Control Box Technical Specifications ............6 SM908125 | SX35/140-12V-OEM02 - SX35/140 - 12V -OEM02 w/Controller Positioning the Stern Thruster ..............7 Stern Thruster Cowls/ Grids ..............8 Thruster Installation Instructions Thruster Installation Considerations and Precautions ...... -

Page 3: Bow Installation Considerations And Precautions

• If able ensure that stern-drives/ trim-tabs do not interfere with the water flow from the thruster as this can reduce the thrust effectiveness considerably. We recommend the use of our Sleipner cowls to enhance the performance and allow installation in shallow draft boats. Sleipner cowls will also minimise the effect if stern-drives/ trim-tabs obstruct the thruster. -

Page 4: Thruster Measurements

Extended tube length for thicker hulls 10.9 10.9 Height of support bolts from tube 35.8 35.8 Main tube diameter Support bolts diameter Distance of support bolts from tube Distance of support bolts *Valid for SX & SXP SX35 & SX50 5630 2021... -

Page 5: Thruster Specifications

- Electronic time-lapse device protects against sudden change of drive direction. - The electric thermal cut-off switch in electro motor protects against overheating (auto-reset when electro motor cools down). - Original Sleipner panels shut off automatically 6 minutes after last use. - Original SLeipner panels use child-safe double ON buttons. -

Page 6: Control Box Technical Specifications

Max Current: 250A 380A Duty Cycle: Max ambient temp: 50ºc 50ºc Min ambient temp: -25ºc -25ºc Power supply cable: 35 - 70mm²/ AWG 2 - 00 35 - 70mm²/ AWG 2 - 00 Mount direction : SX35 & SX50 5630 2021... -

Page 7: Positioning The Stern Thruster

The average force the thruster propels water is 5-7 meters per sec, therefore angled installations must be as deep as possible under the water to minimise spray breaking beyond the water surface. (NB: install the thruster at an angle only if no other suitable location can be found.) Max hull thickness 50mm include spacer SX35 & SX50 5630 2021... -

Page 8: Stern Thruster Cowls/ Grids

Designed to aid in water redirection and reduce air entering the tunnel in shallow installations. Grid’s: Designed to protect the thruster from objects while in use. IMPORTANT Install the cowls/ grids before mounting the tunnel to the SX thruster. SX35 & SX50 5630 2021... -

Page 9: Thruster Installation Considerations And Precautions

• If able ensure that stern-drives/ trim-tabs do not interfere with the water flow from the thruster as this can reduce the thrust effectiveness considerably. We recommend the use of our Sleipner cowls to enhance the performance and allow installation in shallow draft boats. Sleipner cowls will also minimise the effect if stern-drives/ trim-tabs obstruct the thruster. -

Page 10: Grids Or Cowls Assembly

1. Remove propeller and the old tunnel. (NB: the tunnel is not designed to be removed non-destructively. Break off the snap locks between the tunnel half ends by pushing a small screwdriver through the holes from the outside.) 2. Follow the above installation process. IMPORTANT Remember the tunnel can not be removed without being destroyed. SX35 & SX50 5630 2021... -

Page 11: Tunnel Installation

Connect both ends of the tunnel to the thruster motor. All hooks must be completely interlocked making the inside of the tunnel smooth. (NB: Ensure tunnel moulding around the gear leg and tunnel top align.) IMPORTANT Ensure all snap-lock positions are correctly connected into place. SX35 & SX50 5630 2021... -

Page 12: Sx Spacer

Apply MS Polymer sealant or equal to the back surface face of the spacer. Place the spacer to the hull. Motor Installation. Continue the installation of the SX thruster from step 4 in the IMPORTANT If using the 50mm spacer ensure you have the extended tube SX model. SX35 & SX50 5630 2021... -

Page 13: Motor Installation

Insert the thruster with compression rings into the hole. Fasten the thruster For installations in high corrosive environments (saltwater) the exposed aluminium parts of the thruster must be coated with an epoxy primer before antifouling or/and use. SX35 & SX50 5630 2021... -

Page 14: Propeller Installation

Insert the washer to the end of the shaft spline. Tighten with the propeller lock-nut. Apply anti fouling to the gear leg and propeller. Do not apply anti fouling to any rubber elements of the gear leg or anodes. SX35 & SX50 5630... -

Page 15: Control Box Installation

BAT. + # SX35 CONTROL BOX 5.6 Nm Hose claps BAT. - 5.6 Nm MOTOR CABLE - 6 1232i MOTOR CABLE + TORQUE 8Nm BAT. + 5.6 Nm # SX50 CONTROL BOX BAT. - 5.6 Nm MOTOR CABLE - Control Box... -

Page 16: Thruster Electrical Installation

After all electrical connections have been completed check with an ohm meter that there is no electrical connection between 1. electro-motor flange and the positive terminal on the motor 2. electro-motor flange and the battery negative terminal on the motor If unsure contact skilled personnel. SX35 & SX50 5630 2021... - Page 17 Thruster Electrical Installation Control Cables Blue Hose Tighten to 4 NM # SX35 CONTROL BOX Thruster Thruster Thruster Thruster Tighten to Tighten to 5.6 NM 5.6 NM Temp switch NC Blue Hose (BLUE HOSE) Temp switch NC Tighten to *Only used for PRO systems...

-

Page 18: Electrical Specifications

Electrical Specifi cations MC_0077 SX35 & SX50 5630 2021... -

Page 19: Control Panel Cable Installation

(NB: If two or more control panels are operated at the same time in opposite directions, the electronic control box will stop the thruster until it receives a single signal or thrust in one direction.) • Sleipner on/off equipment it is entirely “plug & play” and require no additional confi guration setup. See the Control panel manual for more information. SX35 & SX50... -

Page 20: Control Panel Installation

Place the gasket to the back face of the panel Plug cables into the connectors at the rear of the control panel. Insert the control panel in place and fasten screws. Insert the control panels covering caps. SX35 & SX50 5630 2021... -

Page 21: Pre-Delivery Checklist

Correct drive direction as per control panel: ..............................The compartment for the thruster has been isolated from general bilge water and has no obvious or suspected risks for flooding: .................................................................................................................................. Other comments by installer: .................................................................................................................................................................... SX35 & SX50 5630 2021... -

Page 22: Service And Support

10. This warranty gives you specific legal rights, and you may also have other rights which vary from country to country. Patents MC_0024 At Sleipner we continually reinvest to develop and offer the latest technology in marine advancements. To see the many unique designs we have patented visit our website www.sleipnergroup.com/patents SX35 & SX50... - Page 23 Notes MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................SX35 & SX50 5630 2021...

- Page 24 © Copyright Sleipner Motor AS, 2021 The information given in the document was correct at the time it was published. However, Sleipner Motor AS can not accept liability for any inaccuracies or omissions it may contain. Continuous product improvement may change the product specifi cations without notice.

Need help?

Do you have a question about the SX35 and is the answer not in the manual?

Questions and answers