Table of Contents

Advertisement

Quick Links

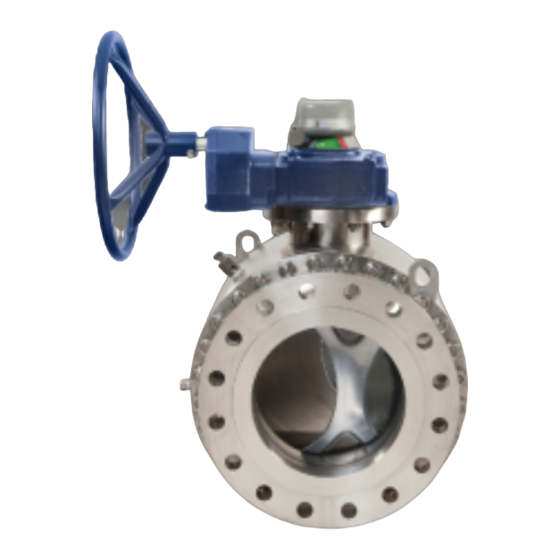

Val-Matic

QuadroSphere

Trunnion Mounted

Ball Valve

Operation, Maintenance and

Installation Manual

INTRODUCTION ....................................... 2

RECEIVING AND STORAGE .................... 2

INSTALLATION ........................................ 2

DESCRIPTION OF OPERATION .............. 2

MAINTENANCE ......................................... 3

TROUBLESHOOTING ............................... 3

VALVE CONSTRUCTION ......................... 5

DISASSEMBLY ....................................... 11

REASSEMBLY ........................................ 12

PARTS & SERVICE ................................. 13

WARRANTY ............................................ 13

®

®

VALVE AND MANUFACTURING CORP.

9 05 R i ver s id e D r .

Phone (630) 941-7600 ●

www.valmatic.com

Manual No.

QS-OM1-1

●

Elmhurs t, IL 60126

Fax (630) 941-8042

Advertisement

Table of Contents

Summary of Contents for Val-Matic QuadroSphere 4700 Series

-

Page 1: Table Of Contents

Manual No. QS-OM1-1 ® Val-Matic ® QuadroSphere Trunnion Mounted Ball Valve Operation, Maintenance and Installation Manual INTRODUCTION ........2 RECEIVING AND STORAGE ....2 INSTALLATION ........2 DESCRIPTION OF OPERATION ....2 MAINTENANCE ......... 3 TROUBLESHOOTING ....... 3 VALVE CONSTRUCTION ......5 DISASSEMBLY ........ -

Page 2: Introduction

VAL-MATIC'S 2"-24" SERIES 4700 QUADROSPHERE BALL VALVE OPERATION, MAINTENANCE AND INSTALLATION installation. Ensure that the actuator has been INTRODUCTION installed properly and is functional. Observe ball bore ® The Series 4700 QuadroSphere Ball Valve has position to ensure valve opens fully. Confirm the... -

Page 3: Maintenance

When performing repair or maintenance operations, Block and Bleed The standard configuration of the QuadroSphere do not attempt to remove the gear/lever, remove or trunnion ball valve is a double block and bleed attempt to replace bolts and nuts when the valve is (DBB) design. - Page 4 Table 1. Common Troubleshooting Causes and Repairs Trouble Probable Causes Remedies Hard to operate/high 1. Remove actuator cover and check screw and 1. Actuator Unit torque linkage for damage 2. Infrequent operation 2. Lubricate seats with sealant and actuator with causes lack of lubrication suitable industrial grease 3.

-

Page 5: Valve Construction

VALVE CONSTRUCTION Valves are designed and tested to API 6D and As shown in Figures 1, 2 and 3 and Tables 2-4, the ASME B16.34 with either carbon steel or stainless QuadroSphere ball valve is a trunnion mounted steel construction. Typical materials of construction design, consisting of a three-piece forged body, are listed in Figures 1, 2 and 3. - Page 6 Table 2. Standard Materials of Construction – NPS 2”-4” Trunnion Mounted Ball Valve Standard Low Temp Stainless Steel Item Part Name (NACE) (NACE) (NACE) Body ASTM A105 A350 LF2 A182 F316 End Adapters ASTM A105 A350 LF2 A182 F316 QS Ball A182 F316+HC Stem A182 F316...

- Page 7 Figure 2. NPS 6"-12" Trunnion Mounted Ball Valve...

- Page 8 Table 3. Standard Materials of Construction – NPS 6”-12” Trunnion Mounted Ball Valve Standard Low Temp Stainless Steel Item Part Name (NACE) (NACE) (NACE) Body ASTM A105 A350 LF2 A182 F316 End Adapters ASTM A105 A350 LF2 A182 F316 QS Ball A182 F316+HC Stem A182 F316...

- Page 9 Figure 3. NPS 14"-24" Trunnion Mounted Ball Valve...

- Page 10 Table 4. Standard Materials of Construction – NPS 14”-24” Trunnion Mounted Ball Valve Standard Low Temp Stainless Steel Item Part Name (NACE) (NACE) (NACE) Body ASTM A105 A350 LF2 A182 F316 End Adapters ASTM A105 A350 LF2 A182 F316 QS Ball A182 F316+HC Stem A182 F316...

-

Page 11: Disassembly

DISASSEMBLY 5. For the other End Adaptor When disassembly of a valve is required, please 1) The procedure removing the other End refer to the materials of construction drawing Adaptor is same as described in Section 4 (Figures 1-3) and disassemble the valve according above. -

Page 12: Reassembly

REASSEMBLY 4. For the Post Trunnion: Prior to reassembly, all parts should be washed, 1) Install O-rings and Gasket on the Post cleaned checked damage. Before Trunnion. reassembling, refer to the structural drawing, and 2) Install the Bleed Valve (or Drain Plug) (2”-4). check that all parts are completely arranged. -

Page 13: Parts & Service

Valve Size and Model Number located on the valve on the Gland Adaptor and tighten the bolts. nameplate and contact: 9. For Lever (If so configured) Val-Matic Valve and Manufacturing Corp. 1) Install the stop plate. 905 Riverside Drive Elmhurst, IL 60126 2) Install retaining ring.

Need help?

Do you have a question about the QuadroSphere 4700 Series and is the answer not in the manual?

Questions and answers