Subscribe to Our Youtube Channel

Summary of Contents for Motorline BRAVO524

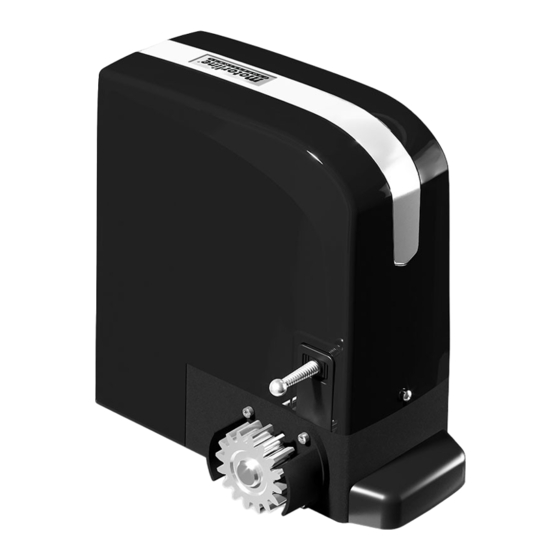

- Page 1 English AUTOMATION SYSTEMS FOR SLIDING GATES Operating and installation instructions BRAVO524 v1.1 Rev. 10/2019...

-

Page 2: Table Of Contents

INDEX 1) General Safety Regulations ................pág. 01 2) Description ......................pág. 02 3) Technical Specifications ..................pág. 03 4) System Description ................... pág. 03 5) Accessories ......................pág. 04 6) Installation Tools ....................pág. 04 7) Installation ......................pág. 05 8) Maintenance ....................... -

Page 3: General Safety Regulations

1) GENERAL SAFETY REGULATIONS 1) ATTENTION! To ensure the safety of people, it is important that you read all the following instructions. Incorrect installation or incorrect use of the product could cause serious harm to people. 2) Carefully read the instructions before beginning to install the product. 3) Do not leave packing materials (plastic, polystyrene, etc.) within reach of children as such materials are potential sources of danger. -

Page 4: Description

2) DESCRIPTION Automated system for residential sliding gates with leaves up to 7m long and 500 kg in weight. It consists of a reversing electro-mechanical gearmotor, powered by a 24V control unit. The automated system houses a programmable electronic control board that enables setting of function logics, work time and pause time, anti-crushing sensitivity as well as partial-opening width. -

Page 5: Technical Specifications

3) TECHNICAL SPECIFICATIONS Technical specifications of the automated operator: Power supply (V) 230V , 50Hz Motor Rated absorbed power (W) 120W Max speed (m/sec) 0.16m/sec Force 700N Working time Noise ≤ 56dB Thermal reset Operating temperature (ºC) > -25ºC to < 65ºC Protection class IP44 Thermal protection (ºC) -

Page 6: Accessories

Note: 1) To lay down electric cables, use rigid and/or flexible adequate tubes. 2) To avoid any kind of interference, always separate low voltage connection cables from AC230V power cables. 3) The description of system is standard system, but we did not provide all parts. If you want system accessories, please contact us. -

Page 7: Installation

7) INSTALATION 7.1. Preliminary checks To ensure safety and an efficiently operating automated system, make sure the following conditions are applied: - The structure of the gate must be suitable for being automated. In particular, check that the structure is sufficiently strong and rigid, and that its dimensions and weight conform to those indicated in the technical specifications;... - Page 8 b) Put the foundation plate to the floor, using adequate expansion plugs and provide one or more tubes for routing the electric cables through the plate (Fig10 and 11). Using a level, check if the plate is perfectly horizontal. Fig. 10 Fig.

- Page 9 7.5. Adjusting the operator Adjust the distance of the operator from the gate by referring to Fig.13. 55 mm Fig. 13 7.6. Fixing operator Fix the operator slightly tightening the screws as shown in Fig. 14. Fig. 14 Fig. 15 After fixing the motor install battery holder (Fig.

- Page 10 After fixing inside components, please screw the upper-cover (Fig. 19 and Fig. 20) Fig. 20 Fig. 19 After the upper-cover fixed, please install the side-cover (Fig. 21). Fig. 21 7.7. Releasing the operator Prepare the operator for manual operating mode as described below: Insert supplied key on the lock, turn it clockwise 90°, pull and open the manual release.

- Page 11 7.8. Installing the rack - Prepare the rack to be applied. Putting these spacers in all holes of the Fig. 24 rack in order to be completely secure. a) Manually put the gate leaf in the closed position. b) Positioning the first rack part to be bolted, supported on the pinion and with help of the level and clamping tool, keep it horizontally leveled.

-

Page 12: Maintenance

NOTES: - Make sure that, during the gate travel, all the rack elements mesh correctly with the pinion. - Do not, on any occasion, weld the rack elements either to the spacers. For fixing these, use screws and washers like in the Fig.20. - Do not use grease or other lubricants between rack and pinion.

Need help?

Do you have a question about the BRAVO524 and is the answer not in the manual?

Questions and answers