Table of Contents

Advertisement

Quick Links

ACE

OM-00740-02

June 16, 1980

Rev. A 09-13-07

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

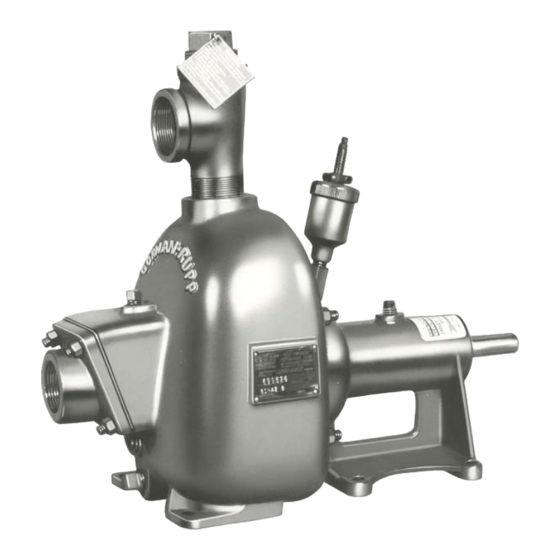

80 SERIES PUMP

MODEL

81 1/2A2-B

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

www.grpumps.com

D

GORMAN-RUPP OF CANADA LIMITED

ST. THOMAS, ONTARIO, CANADA

Printed in U.S.A.

e

Copyright by the Gorman-Rupp Company

Advertisement

Table of Contents

Summary of Contents for GORMAN-RUPP PUMPS 81 1/2A2-B

- Page 1 Rev. A 09-13-07 INSTALLATION, OPERATION, AND MAINTENANCE MANUAL WITH PARTS LIST 80 SERIES PUMP MODEL 81 1/2A2-B THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO www.grpumps.com GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A. Copyright by the Gorman-Rupp Company...

- Page 2 Register your new Gorman-Rupp pump online at www.grpumps.com Valid serial number and e-mail address required. RECORD YOUR PUMP MODEL AND SERIAL NUMBER Please record your pump model and serial number in the spaces provided below. Your Gorman-Rupp distributor needs this information when you require parts or service. Pump Model: Serial Number:...

-

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ..........PAGE I −... - Page 4 TABLE OF CONTENTS (continued) PUMP MAINTENANCE AND REPAIR - SECTION E ....PAGE E − 1 STANDARD PERFORMANCE CURVE ........PAGE E −...

-

Page 5: Introduction

80 SERIES OM−00740 INTRODUCTION Thank You for purchasing a Gorman-Rupp pump. The following are used to alert maintenance per- Read this manual carefully to learn how to safely sonnel to procedures which require special atten- install and operate your pump. Failure to do so tion, to those which could damage equipment, and could result in personal injury or damage to the to those which could be dangerous to personnel:... -

Page 6: Safety - Section A

80 SERIES OM−00740 SAFETY - SECTION A This information applies to 80 Series ba- non-volatile, non-flammable liquids containing specified entrained solids. sic pumps. Gorman-Rupp has no con- Do not attempt to pump liquids for trol over or particular knowledge of the which the pump, driver and/or controls power source which will be used. - Page 7 OM−00740 80 SERIES Overheated pumps can cause severe Never run this pump backwards. Be cer- burns and injuries. If overheating of the tain that rotation is correct before fully pump occurs: engaging the pump. 1. Stop the pump immediately. 2. Ventilate the area. 3.

-

Page 8: Installation − Section Bpage B

80 SERIES OM−00740 INSTALLATION − SECTION B Review all SAFETY information in Section A. configuration, and priming must be tailored to the specific application. This pump is equipped with a Since pump installations are seldom identical, this Gorman-Rupp double grease lubricated seal, section offers only general recommendations and therefore the maximum incoming pressure must practices required to inspect, position, and ar-... -

Page 9: Positioning Pump

OM−00740 80 SERIES The pump assembly can be seriously Only operate this pump in the direction in- damaged if the cables or chains used to lift dicated by the arrow on the pump body and move the unit are improperly wrapped and on the accompanying decal. -

Page 10: Gauges

80 SERIES OM−00740 Lines near the pump must be independently sup- line, and that the openings will not permit passage ported to avoid strain on the pump which could of solids larger than the solids handling capability cause excessive vibration, decreased bearing life, of the pump. -

Page 11: Discharge Lines

OM−00740 80 SERIES reduce the inlet velocity. Calculate the required NOTE submergence using the following formula based The pipe submergence required may be reduced on the increased opening size (area or diameter). by installing a standard pipe increaser fitting at the end of the suction line. -

Page 12: Alignment

80 SERIES OM−00740 of the outer ends of the coupling hub every 90 de- ALIGNMENT grees. The coupling is in alignment when the hub ends are the same distance apart at all points (see The alignment of the pump and its power source is Figure 3A). -

Page 13: V-Belt Tensioning

OM−00740 80 SERIES the belts are a matched set; unmatched sets will en both v-belt and bearing life. Under-tensioning cause accelerated belt wear. will cause belt slippage. Always keep belts free from dirt, grease, oil and other foreign material which may cause slippage. Tension Measurement Correct v-belt tension can be achieved using a v- belt tension tester and Table 1 or 2. - Page 14 80 SERIES OM−00740 er at the measured belt span. Set the small O-ring Read the force applied from the bottom of the small on the deflection force scale to zero. O-ring on the deflection force scale. Compare this force with the value shown in Table 1 or 2 and ad- Place the tension tester squarely on the belt at the just the tension accordingly.

- Page 15 OM−00740 80 SERIES Table 1. Sheave Diameter (Inches) Table 2. Sheave Diameter (Millimeters) Deflection Force (Lbs.) Deflection Force (KG.) Belt Deflection Force Belt Deflection Force Uncogged Cogged Uncogged Cogged Hy-T Belts & Torque-Flex Hy-T Belts & Torque-Flex Uncogged & Machined Uncogged &...

-

Page 16: Operation − Section C

OM−00740 80 SERIES OPERATION − SECTION C Review all SAFETY information in Section A. Add liquid to the pump casing when: 1. The pump is being put into service for the Follow the instructions on all tags, labels and first time. decals attached to the pump. -

Page 17: Operation

OM−00740 80 SERIES sprinkler heads, and any other fixtures connected from the shaft and seriously damage the to the line. When the discharge line is completely pump. filled, adjust the throttling valve to the required flow Consult the operating manual furnished with the rate. -

Page 18: Pump Vacuum Check

OM−00740 80 SERIES equipment. If backflushing is absolutely neces- Cold Weather Preservation sary, liquid pressure must be limited to 50% of the In below freezing conditions, drain the pump to maximum permissible operating pressure shown prevent damage from freezing. Also, clean out any on the pump performance curve (see Section E, solids by flushing with a hose. -

Page 19: Troubleshooting − Section D

80 SERIES OM−00740 TROUBLESHOOTING − SECTION D Review all SAFETY information in Section A. Before attempting to open or service the pump: 1. Familiarize yourself with this man- ual. 2. Lock out or disconnect the power source to ensure that the pump will remain inoperative. - Page 20 OM−00740 80 SERIES TROUBLE POSSIBLE CAUSE PROBABLE REMEDY Impeller or other wearing parts worn Replace worn or damaged parts. PUMP STOPS OR FAILS TO DELIVER or damaged. Check that impeller is properly RATED FLOW OR centered and rotates freely. PRESSURE (cont.) Impeller clogged.

-

Page 21: Preventive Maintenance

80 SERIES OM−00740 equipped) between regularly scheduled inspec- PREVENTIVE MAINTENANCE tions can indicate problems that can be corrected Since pump applications are seldom identical, and before system damage or catastrophic failure oc- pump wear is directly affected by such things as curs. - Page 22 OM−00740 80 SERIES PUMP MAINTENANCE AND REPAIR − SECTION E MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK OPERATING PERFORMANCE. STANDARD PERFORMANCE FOR PUMP MODEL 81 1/2A2−B Based on 70_ F (21_ C) clear water at sea level Contact the Gorman-Rupp Company to verify per- formance or part numbers.

- Page 23 80 SERIES OM−00740 SECTION DRAWING PARTS PAGE Figure 1. Pump Model 81 1/2A2−B MAINTENANCE & REPAIR PAGE E − 2...

- Page 24 OM−00740 80 SERIES PARTS LIST Pump Model 81 1/2A2-B (From S/N 253703 up) If your pump serial number is followed by an N", your pump is NOT a standard production model. Contact the Gorman-Rupp Company to verify part numbers. ITEM PART MAT’L...

- Page 25 80 SERIES OM−00740 PUMP AND SEAL DISASSEMBLY 4. Check the temperature before opening any covers, plates, or AND REASSEMBLY plugs. 5. Close the suction and discharge Review all SAFETY information in Section A. valves. 6. Vent the pump slowly and cau- Follow the instructions on all tags, label and de- tiously.

- Page 26 OM−00740 80 SERIES wise until it rests against the cover (see Figure 4) to Seal Removal and Disassembly prevent the grease in the cup from escaping. Re- move the grease cup and piping (7, 8 and 9). Remove the outer rotating element. Slide the seal plate, shaft sleeve, and remaining seal parts off the Immobilize the impeller by wedging a block wood shaft as a unit.

- Page 27 80 SERIES OM−00740 Remove the slinger ring (12) from the shaft. Re- Clean the bearings thoroughly in fresh cleaning move the pedestal mounting hardware from the solvent. Dry the bearings with filtered compressed base. Tie and tag any shims used under the air and coat with light oil.

- Page 28 OM−00740 80 SERIES oil and the container must be absolutely clean. If the oil has been previously used, it must be thor- oughly filtered. When installing the shaft and bearings into Heat the bearings to a uniform temperature no the bearing bore, push against the outer higher than 250_F (120_C), and slide the bearings race.

- Page 29 80 SERIES OM−00740 shorten seal life. If necessary, clean the faces with a If a replacement seal is being used, remove it from non-oil based solvent and a clean, lint-free tissue. the container and inspect the precision finished Wipe lightly in a concentric pattern to avoid faces to ensure that they are free of any foreign scratching the faces.

- Page 30 OM−00740 80 SERIES Slide the seal plate assembly over the impeller 0.025 inch (0,38 to 0,63 mm). Measure this clear- shaft (17) and temporarily secure the seal plate to ance and add or remove shims from the impeller the pedestal (14) using two capscrews and nuts adjusting shim set (10) until the correct clearance (3/8−16 UNC x 1−1/2 inch long, not supplied).

- Page 31 80 SERIES OM−00740 compound to the fill plug (33). Reinstall and tighten with No. 2 lithium base grease until grease es- the fill plug. capes from the relief hole. Turn the grease cup arm counterclockwise until it is at the top of the stem; Refer to OPERATION, Section C, before putting this will release the spring to apply grease to the the pump back into service.

- Page 32 OM−00740 80 SERIES ously or installed in an environment where variable lubricant supplier for the recommended grade of hot and cold temperatures are common. lubricant. When lubricating a dry (overhauled) pedestal, fill Power Source the cavity with approximately 1.5 ounces (42,5 grams) of grease (approximately one-third full).

- Page 33 For U.S. and International Warranty Information, Please Visit www.grpumps.com/warranty or call: U.S.: 419−755−1280 International: +1−419−755−1352 For Canadian Warranty Information, Please Visit www.grcanada.com/warranty or call: 519−631−2870 THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA...

Need help?

Do you have a question about the 81 1/2A2-B and is the answer not in the manual?

Questions and answers