Table of Contents

Advertisement

Quick Links

Technical Manual

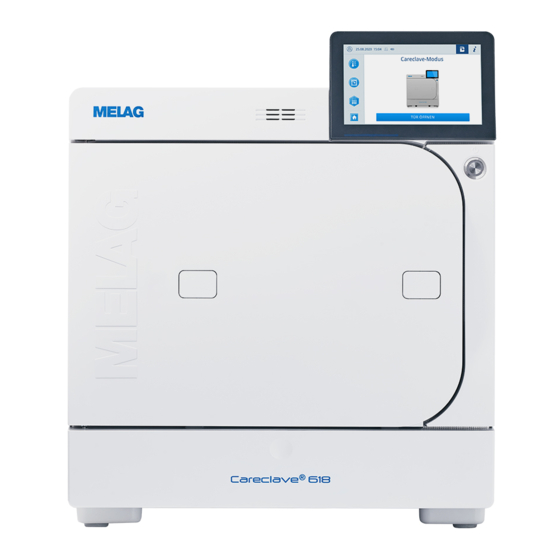

Careclave

Combination steam sterilizer

from software version 21.0.3

EN

Read this manual carefully and in the correct order before setting up and commissioning the device. The instructions in-

clude important safety information. You also receive a user manual with the device. Please store this manual and the

user manual carefully and in close proximity to the device. They represent a component of the product.

®

618

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MELAG Careclave 618

- Page 1 Technical Manual ® Careclave Combination steam sterilizer from software version 21.0.3 Read this manual carefully and in the correct order before setting up and commissioning the device. The instructions in- clude important safety information. You also receive a user manual with the device. Please store this manual and the user manual carefully and in close proximity to the device.

-

Page 3: Table Of Contents

Contents Contents 1 General guidelines ................................ 4 Symbols used.................................. 4 Formatting rules ................................... 4 2 Installation requirements.............................. 5 Installation location................................ 5 Space requirements ................................ 6 Mains supply .................................. 7 Water connection ................................. 8 Compressed air connection .............................. 9 System and network safety .............................. 9 3 Setup and installation ................................ 12 Removing from the packaging ............................ 12 Cover caps or Carebox holders ............................ 12 Connecting the power cable and removing accessories.................... 14 Connecting the feed water supply (installation examples) .................... 15... -

Page 4: General Guidelines

They represent a component of the product. Should the manual no longer be legible, is damaged or has been lost, you can download a new copy from MELAG down- load centre at www.melag.com. -

Page 5: Installation Requirements

Failure to comply with the set-up conditions can result in injuries and/or damage to the steam sterilizer. The steam sterilizer should only be setup, installed and commissioned by persons authorized by MELAG. The steam sterilizer is not suitable for operation in explosive atmospheres. -

Page 6: Space Requirements

2 Installation requirements Space requirements Dimensions Width 48 cm Height 56.2 cm Height without colour touch display 49.7 cm Depth 65.3 cm Clearance between the device feet 27.05 cm Clearance from rear device foot up to the cover 23.1 cm Min. -

Page 7: Mains Supply

2 Installation requirements Additional space requirement for the feed water supply Additional space is required for a storage container or a water treatment unit. It is also necessary to guarantee free ac- cess to the hoses and cables leading from from the device to the water treatment unit. Space require- MELAdem 47 Storage container... -

Page 8: Water Connection

The installation of a leakage water detector with cut-off valve (e.g. the water stop from MELAG) is required. When the device is put into operation for the first time, the double jacket is filled with 4 l of demineralised water according... -

Page 9: Compressed Air Connection

IEEE 802.3 (Practical network) MELAtrace saving log data FTP server saving log data Label printing via MELAprint 60 NOTICE When performing a device software update, use only the update data authorized by MELAG for the corresponding device type. - Page 10 Formatted with a correct file system Perform regular data backup. Restrict access to the device and systems with access authorization to the necessary circle of persons. Only use MELAG USB flash drives. Operating the device in the local network (LAN) NOTICE Do not connect the device to a public network (e.g.

- Page 11 2 Installation requirements Network bandwidth / Quality of Service (QoS) The device does not place any requirements on the LAN bandwidth for data transfer, that exceed the standard time-out times of the respective logs. Process Volume max. Volume normal Program log 1 MB 200 kB Malfunction log...

-

Page 12: Setup And Installation

WARNING Improper installation may lead to a short-circuit, fire, water damage or electrical shock. This could result in serious injury. Only have the device set up, installed and commissioned by people authorized by MELAG. Removing from the packaging CAUTION Danger of injury from incorrect carrying. - Page 13 3 Setup and installation Attaching the cover caps Press the cover caps into the free recess as shown. Attaching the holder for the Carebox PLEASE NOTE The spacers are intended for installation on the side wall of the device. For a room wall installation, the spacers are not used. Insert the fastening hook into the recess at an angle and pointing upwards.

-

Page 14: Connecting The Power Cable And Removing Accessories

3 Setup and installation Place the holder over the corresponding recess on the device (moisten the spacers for easier mounting). Pull the holder and the fastening hook vertically downwards until they click into place. Connecting the power cable and removing accessories NOTICE Before switching on for the first time, the device must have acclimatised to the required ambient temperature (5 –... -

Page 15: Connecting The Feed Water Supply (Installation Examples)

Connecting the feed water supply (installation examples) The following pages provide examples for the recommended installation types for the feed water supply. The connection of a different water treatment unit with the same water quality is possible after consultation with MELAG. PLEASE NOTE For detailed information on the cold water connection of the water treatment unit, see the user manual of the unit. - Page 16 3 Setup and installation 16.3 16.1 17/19 16.4 16.2 Position Description Art. no. contained in Water stop (leak water detector with cut-off valve and sensor) ME01056 Overflow funnel present on the device side Wastewater connection Threaded connection 1/8” on hose 8/6 mm ME89120 present on the device side...

- Page 17 3 Setup and installation Position Description Art. no. contained in MELAdem 53/53C ME01038/ ME01036 16.1 Tap water supply hose EN 1717, 2.5 m ME24930 ME01038/ ME01036 16.2 Pipe elbow with drain valve ME70405 ME01038/ ME01036 16.3 Safety combination HD according to EN 1717 with wall bracket ME70685 ME01038/ ME01036...

- Page 18 3 Setup and installation Example 2: Use of the water treatment unit MELAdem 53/53 C (EA) Cut the PUR 6/4 mm (5 m) hose for the compressed air supply (4) and the feed water connection (5) into two suitable pieces. Connect the water treatment unit MELAdem 53/53 C to the MELAdem feed water connection (5) of the device either via a water branch (17) or by means of a water distributor (20).

- Page 19 3 Setup and installation Position Description Art. no. contained in Wall outlet NW40 present on the building side Compressed air supply present on the building side 13.1 Coupling plug for compressed air on 6 mm hose ME80230 Installation set Water tap present on the building side Mains connection...

- Page 20 3 Setup and installation Example 3: Using the reverse osmosis unit MELAdem 47 (HD) Hook the safety combination HD (16) into the fastening next to the overflow funnel (2) and fix it with the screw supplied. Observe the flow direction indicated on the safety combination. Shorten the PUR 6/4 mm (5 m) hose for the compressed air supply (4) to the required length.

- Page 21 3 Setup and installation Position Description Art. no. contained in Double-chamber siphon ME26635 Installation set 2x double hose nozzle for siphon ME37400 Installation set 10.1 2x Cu seal 13.5x20 ME32050 Installation set 10.2 2x QSS-E straight ME38710 Installation set 10.3 2x wastewater adapter G1/4"...

- Page 22 3 Setup and installation Example 4: Using the reverse osmosis unit MELAdem 47 (EA) Shorten the PUR 6/4 mm (5 m) hose for the compressed air supply (4) to the required length. Cut the PTFE 8/6 mm (5 m) hose for the overflow funnel (2) and the wastewater connection (3) into two suitable pieces. The direct connection of the water treatment unit to the domestic water system requires the installation of the water stop (17).

-

Page 23: Connection To Wastewater System

3 Setup and installation Position Description Art. no. contained in 10.1 2x Cu seal 13.5x20 ME32050 Installation set 10.2 2x QSS-E straight ME38710 Installation set 10.3 2x wastewater adapter G1/4" internal thread ME56930 Installation set Wall outlet NW40 present on the building side Compressed air supply present on the... -

Page 24: Connection To The Compressed Air Supply

3 Setup and installation Drain hose overflow funnel with backflow flap Optional wastewater connection for another device or a water treatment unit Drain hose without backflow flap Connection to the compressed air supply Assemble the compressed air connection, consisting of the banjo bolt (G 1/4"), SVS-E swivel and two copper seals (13.5x18.5). -

Page 25: Settings And Adjustment

Changes to the program sequence can be made to the parameters of the , Care and the Carebox detection functions. Further alterations to the program run are possible in each individual case and will still ensure the effectiveness of the sterilization, but may only be performed by authorized persons. Please consult your stockist or MELAG. System and status log Output a system and status log and document this on the record of installation and setup. -

Page 26: Technical Tables

5 Technical tables 5 Technical tables Feed water quality Minimum requirements placed on the feed water quality based on EN 13060, Appendix C Substance / property Feed water Evaporation residue ≤ 10 mg/l Silicon oxide, SiO ≤ 1 mg/l Iron ≤ 0.2 mg/l Cadmium ≤ 0.005 mg/l Lead ≤ 0.05 mg/l Heavy metal traces apart from iron, cadmium, lead ≤ 0.1 mg/l... -

Page 27: Nominal Value Tolerances

5 Technical tables Drift per year ± 0.004 % corresponds to ± 0.16 mbar corresponds to approx. ± 0.017 K steam Drift in 5 years ± 0.02 % corresponds to ± 0.8 mbar corresponds to approx. ± 0.09 K steam After 1 year Entire measuring chain of the temperature measurement Precision (at 135 °C) at pure addition of individual errors approx. - Page 28 5 Technical tables Step P [mbar ] T [°C] Care-S Care- Univer- Gentle-B Quick-S Program phase and. Therm sal-B Care-B Tolerance P / T SK13 c 1500 +100/-20 Steam intake sterilization chamber c 1500 +100/ Holding conditioning -100 c 500 +30/-30 Fractionation evacuation SK21...

-

Page 29: Empty Chamber Test

5 Technical tables Empty chamber test The coldest point in the sterilization chamber during the empty chamber test lies directly on the temperature sensor (see circular marking in the following figure). The temperature in the rest of the sterilization chamber is almost the same all over (0.6 K range). - Page 30 5 Technical tables Pressure-time diagram for Care-S, 134°C and 2.1 bar Pressure-time diagram for Universal-B, 134°C and 2.1 bar...

- Page 31 5 Technical tables Pressure-time diagram for Quick-S Pressure-time diagram for Prion-B...

-

Page 32: Type Plate Steam Generator

5 Technical tables Pressure-time diagram for Gentle-B Type plate steam generator... - Page 33 Certificate of Suitability According to the recommendations of the Commission for Hospital Hygiene and Infection Prevention at the Robert Koch Institute Manufacturer: MELAG Medizintechnik GmbH & Co. KG Address: Geneststraße 6-10 10829 Berlin Country: Germany Product: Careclave ® Type of device:...

- Page 34 MELAG Medizintechnik GmbH & Co. KG Geneststraße 6-10 10829 Berlin Germany Email: info@melag.com Web: www.melag.com Original instructions Responsible for content: MELAG Medizintechnik GmbH & Co. KG We reserve the right to technical alterations Your stockist...

Need help?

Do you have a question about the Careclave 618 and is the answer not in the manual?

Questions and answers