Table of Contents

Advertisement

Quick Links

User Manual

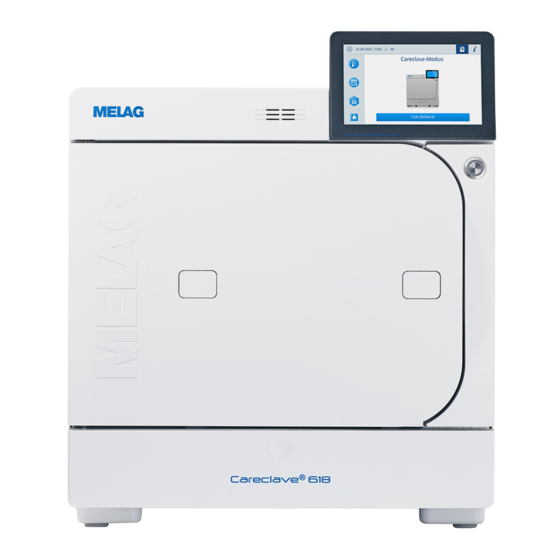

Careclave

Combination steam sterilizer

from software version 21.0.3

EN

Dear customer,

We thank you for your confidence demonstrated by the purchase of this MELAG product. As an owner-run and operated

family concern founded in 1951, we have a long history of successful specialization in hygiene products for practice-

based use. Our focus on innovation, quality and the highest standards of operational reliability has established MELAG

as the world's leading manufacturer in the instrument reprocessing and hygiene field.

You, our customer are justified in your demand for the best products, quality and reliability. Providing

hygiene"

and

"Quality – made in

agement system is subject to close monitoring: one instrument to this end is our annual multi-day audit conducted in ac-

cordance with EN ISO 13485. This guarantees that all MELAG products are manufactured and tested in accordance with

strict quality criteria.

The MELAG management and team.

®

618

Germany", we guarantee that these demands will be met. Our certified quality man-

"competence in

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MELAG Careclave 618

- Page 1 21.0.3 Dear customer, We thank you for your confidence demonstrated by the purchase of this MELAG product. As an owner-run and operated family concern founded in 1951, we have a long history of successful specialization in hygiene products for practice- based use.

-

Page 3: Table Of Contents

Contents Contents 1 General guidelines ................................ 6 Symbols used .................................. 6 Formatting rules................................... 6 Disposal .................................... 6 2 Safety..................................... 7 3 Performance specifications .............................. 9 Intended use .................................. 9 User benefits.................................. 9 Program runs for the Carebox ............................. 9 Program runs for the sterilization chamber........................ 11 Care procedure.................................. 11 Sterilization procedure ............................... 12 Type of the feed water supply............................ 12 Safety equipment................................ 12 Performance characteristics of sterilization programs ....................... 13... - Page 4 Contents Selecting the program................................ 32 Starting the program ................................ 33 Manual program abort ............................... 34 Ending the program prematurely ............................ 35 Program is ended ................................ 35 Removing the Carebox .............................. 36 Removing instruments and hollow objects ........................ 37 Cooling with the Cooling Box............................. 39 Oiling the chucks ................................ 39 9 Vacuclave mode ................................. 41 Preparing the load ................................ 41 Loading the steam sterilizer............................... 42...

- Page 5 Contents 14 Pause times .................................. 79 Duration of the operating pause ............................ 79 Starting after long pauses.............................. 79 Decommissioning ................................ 79 Emptying.................................... 79 Transport ................................... 80 15 Malfunctions .................................. 81 Malfunction logs................................. 81 General events .................................. 81 Warning and malfunction messages.......................... 82 16 Technical data .................................. 94 17 Accessories and spare parts ............................ 96 Glossary .................................... 99...

-

Page 6: General Guidelines

Make sure that you always have access to digital or printed version of the user manual. Should the manual no longer be legible, is damaged or has been lost, you can download a new copy from MELAG down- load centre at www.melag.com. -

Page 7: Safety

Check the device after unpacking for any damage suffered during transport. The device should only be setup, installed and commissioned by MELAG authorised persons. Have the electrical connection, the connections for supply and wastewater and compressed air set up only by a spe- cialist. - Page 8 (MELAG) and the relevant authority of the member state, in which the user and/or patient resides. Personal protective equipment The removal of the Carebox should only be carried out with an aid, e.g.

-

Page 9: Performance Specifications

3 Performance specifications 3 Performance specifications Intended use Careclave is intended for use in the medical field, especially in dentistry. This device is not intended to be used in a pa- tient environment. In accordance with EN 13060 this device is a steam sterilizer (autoclave) with type B cycles. As a ... - Page 10 3 Performance specifications Cleaning and disinfection takes place both in the inner area of the dental instrument (internal cleaning) and on the exter- nal surfaces (external cleaning). Cleaning is done with demineralised water, partly with the support of compressed air pulses and without the use of chemicals.

-

Page 11: Program Runs For The Sterilization Chamber

3 Performance specifications Program runs for the sterilization chamber A reprocessing program runs in three main phases: the air removal and heating up phase, the sterilization phase and the drying phase. After program start, you can follow the program run on the display. It shows the chamber temperature and pressure as well as the time until the end of drying. -

Page 12: Sterilization Procedure

3 Performance specifications Sterilization procedure The steam sterilizer sterilizes on the basis of the fractionated vacuum procedure. This guarantees the complete and ef- fective wetting/penetration of the load with saturated steam. The steam sterilizer uses the double jacket technology to generate the sterilization steam, i.e. the steam sterilizer is fitted with a separate steam generator combined with a double-walled sterilization chamber. -

Page 13: Performance Characteristics Of Sterilization Programs

3 Performance specifications Performance characteristics of sterilization programs The results in this table show which inspections were performed on the steam sterilizer. The marked fields demonstrate compliance with all the applicable sections of the standard 13060. Type tests Universal-B Quick-S Prion-B Gentle-B... -

Page 14: Description Of The Device

▪ MELAG oil for door lock nut ▪ Test gauge TR16 for door lock nut ▪ USB flash drive ▪ 2x can of MELAG Care Oil (1x installed and 1x stock) Optional ▪ Carebox ▪ Short/long mount for trays and sterilization container... -

Page 15: Views Of The Device

4 Description of the device Views of the device View from front Access to the validation fitting Feed water tank cover Accessories compartment cover Power switch Optional: Mounts for Carebox Opening for door opening in an emergency Door Service hatch Front view, with open service hatch Smart touch display LED status bar... -

Page 16: Service Hatch

4 Description of the device Rear view, without cover USB connection Ethernet connection Overflow funnel Spring safety valves Feed water connection of the filling pump Electrical connection of the filling pump Wastewater connection MELAdem (optional) Wastewater connection Feed water connection MELAdem Compressed air connection Cooler Power cable connection... - Page 17 - it must be delivered to the vendor to be disposed of. MELAG devices are synonymous for long-term quality. When you eventually need to decommission your MELAG device, we offer a special disposal service. Simply contact your stockist.

-

Page 18: Power Switch

4 Description of the device Device symbols - front Symbol Description Symbol Description Sterile filter Dust filter/device filter Drain connection Overheat protection reset button USB connection Service connection Device symbols - rear Symbol Description Symbol Description Aqua dem Feed water connection, Osmosis drain Wastewater connection, water treatment unit... -

Page 19: Smart Touch Display

4 Description of the device Smart touch display The user interface consists of a colour 7-inch touch display. The selected menu item is always highlighted in colour. The display of the areas (A, B, C) is dynamic and can change depending on the device status. Due to the dynamic dis- play, the display and position of the buttons on the device may differ from the illustrations shown. -

Page 20: Led Status Bar

4 Description of the device Chuck care buttons Symbol Description Button Chuck care is switched off Switch on chuck care Chuck care is switched on Switch off chuck care Chuck care venting is Switch off chuck care switched on Symbols of the output media Symbol Output media Description... -

Page 21: Device Mode

4 Description of the device Device mode Careclave mode When Careclave mode is activated, the Carebox symbol is displayed in the information area. Symbol Meaning Careclave mode active The device can be operated in Careclave mode (with Carebox) or in Vacuclave mode (as an steam sterilizer). PLEASE NOTE Careclave mode can only be activated by inserting a Carebox. -

Page 22: Program Run

4 Description of the device Program run During a program run, all important information is shown on the display. If no input is made on the display, the program display maximises and overlays the menu. Touch the display to show the menu. -

Page 23: Opening And Closing The Door

5 Opening and closing the door 5 Opening and closing the door The device is fitted with a motor-driven automatic door locking mechanism with a threaded spindle. Opening the door PLEASE NOTE The door is to be left open only whilst loading and unloading the device. Keeping the door closed saves energy. -

Page 24: Manual Door Emergency-Opening

5 Opening and closing the door Manual door emergency-opening In emergency situations e.g. power failure, the door can be opened in the following fashion: Switch off the steam sterilizer and remove the power plug from the socket. Remove the cover cap (pos. a) in order to enable the emergency door opening by pressing the cover cap in on one side. -

Page 25: First Steps

Record of installation and setup The record of installation and setup is to be completed by the responsible stockist and a copy sent to MELAG as proof of the correct setup, installation and initial commissioning. This is a constituent part of any guarantee claim. - Page 26 6 First steps Loosen and remove the screws of the existing adapter. Remove the adapter. Remove the sealing washer and any residue from the seal. Be careful not to scratch the seal face of the Carebox. Insert the new sealing washer by aligning it with the recess and hole pattern.

-

Page 27: Load Mounts

6 First steps PLEASE NOTE Further information on the installation of special adapters, e.g. ME22407, can be found in the user manual “Accessories for Careclave”. See also: ▪ Carebox test [} page 56] Load mounts Detailed information regarding the various mounts, their combinability with various load holders and their application can be found in the user manual “Accessories for Careclave”. -

Page 28: Important Information For Routine Operation

MELAG offers you an example hygiene plan to help you integrate the Careclave into the hygiene process in your daily practice. You can find the example hygiene plan in the download centre of the MELAG website under Manufacturer recommendation. Manufacturer’s recommendation for the routine operation of type B steam sterilizers... -

Page 29: Careclave Mode

8 Careclave mode 8 Careclave mode Preparation and pre-cleaning If instruments are to be subject to manual preparation for cleaning, ensure that no media or tools/resources are deployed which could damage their surface. Never use any aggressive cleaning agents, wire or brass wire brushes or metal scourers. - Page 30 There are no tools (drills) in the chucks. ü The Carebox has no visible contamination. PLEASE NOTE MELAG recommends that the Carebox be fully loaded. If necessary, adapters can remain unfitted. This does not reduce the oil consumption. Bring the Carebox into the dirty area.

-

Page 31: Loading Careclave

8 Careclave mode Carry out a wipe disinfection of the underside of the Carebox with a fully virucidal disinfectant. See also: ▪ Adapter installation [} page 25] ▪ Changing the filter [} page 75] Loading Careclave The following must be fulfilled or present: ü The Carebox has been cleaned and disinfected from the outside before it is moved to the clean side of the reprocessing room. -

Page 32: Selecting The Program

8 Careclave mode Selecting the program WARNING Danger due to subsequent contamination Do not use potentially contaminated gloves to operate the device. If in doubt, clean and disinfect the affected surfaces with a surface disinfectant. WARNING In the Care-S and Care-Therm program, no reprocessing takes place in the sterilization chamber! Program loading Program Packaging... -

Page 33: Starting The Program

8 Careclave mode Starting the program The door locks pressure-tight upon program start. The device performs automatic tests, e.g. a quantity check and con- ductivity measurement of the feed water. Press START PROGRAM. Confirm the subsequent dialogue window with START PROGRAM. With enabled Authentication at Reprocessing program start, authenticate by entering a PIN. -

Page 34: Manual Program Abort

8 Careclave mode Manual program abort You can abort the program at any time. If you abort the program before the end of the sterilization phase, the load is not sterile. Press ABORT to abort a program. Confirm the security query with YES. Ê... -

Page 35: Ending The Program Prematurely

8 Careclave mode Ending the program prematurely You can end the program prematurely. If you abort the program before the end of the drying phase, the load is not com- pletely dried and should be used immediately. The following must be fulfilled or present: ü... -

Page 36: Removing The Carebox

8 Careclave mode Removing the Carebox CAUTION Danger of burns from hot parts and hot condensate. Comply with the following specifications when removing the Carebox: Never touch the Carebox, the inside of the device or the inside of the door with bare hands. The components are hot. -

Page 37: Removing Instruments And Hollow Objects

Place the upper section of the Carebox in the Carebox cover holder or hang it on the side wall of the Careclave. Allow the instruments to cool down. PLEASE NOTE For fast and safe cooling of the instruments, MELAG recommends the Cooling Box. Cooling with the Cooling Box [} page 39]. Approval process According to “Hygiene requirements for the treatment of medical products”, instrument reprocessing ends with the... - Page 38 8 Careclave mode Check that the transmission instrument is firmly seated. Ê Should the connection work loose after reprocessing, the instrument must be reprocessed again. Hold the upper section of the Carebox with one hand. When using an adapter for Sirona T1 Classic: Pull the transmission instrument forcefully and in a straight direction from the adapter with your other hand.

-

Page 39: Cooling With The Cooling Box

PLEASE NOTE To ensure proper functioning of the collets, MELAG recommends oiling them once a week. Chuck care must be performed after reprocessing with the Carebox. Perform the chuck care in addition to the care of the instruments by the Care programs. - Page 40 8 Careclave mode The integrated ADDcare care station can be used to care for the instruments. Proceed as follows: Open the door completely until it snaps into place. Start chuck care by briefly pressing (1 s) on the nozzle or by pressing the chuck care button.

-

Page 41: Vacuclave Mode

9 Vacuclave mode 9 Vacuclave mode Preparing the load Always clean and disinfect properly before sterilization. Only in this way is it possible to guarantee the subsequent sterili- zation of the load. The materials used, cleaning agents and reprocessing procedure are of decisive significance. ... -

Page 42: Loading The Steam Sterilizer

Use aluminium sterilization containers. Aluminium retains and conducts heat and thus accelerates drying. Closed sterilization containers must be either perforated or have a valve on at least one side. MELAG sterilization containers (e.g. MELAstore Boxes) fulfil the requirements for successful sterilization and drying. - Page 43 9 Vacuclave mode Soft sterilization packaging WARNING Risk of contamination due to insufficient drying To improve the drying results for full loads of soft sterilization packages, the setting Drying: Intelligent must be activated. Soft sterilization packaging can be used in both sterilization containers and on trays. Please comply with the following ...

-

Page 44: Selecting The Program

9 Vacuclave mode Selecting the program Now select the sterilization program according to how and whether the load is packed. It is also necessary to take into account the temperature resistance of the load. All sterilization programs are displayed in the Programs menu. The following tables list the correct program for each load. -

Page 45: Starting The Program

9 Vacuclave mode Starting the program With the start of the program, the door closes pressure-tight and the device checks the quantity of feed water and its con- ductivity. Press START PROGRAM. Confirm the subsequent dialogue window with START PROGRAM. With enabled Authentication at Reprocessing program start, authenticate by entering a PIN. -

Page 46: Manual Program Abort

9 Vacuclave mode Manual program abort You can abort the program at any time. If you abort the program before the end of the sterilization phase, the load is not sterile. Press ABORT to abort a program. Confirm the security query with YES. Ê... -

Page 47: Ending The Program Prematurely

9 Vacuclave mode Ending the program prematurely You can end the program prematurely. If you abort the program before the end of the drying phase, the load is not com- pletely dried and should be used immediately. The following must be fulfilled or present: ü... -

Page 48: Removing The Sterile Material

9 Vacuclave mode If automatic log output after the end of the program is activated in the Settings > Log output menu, the log of the run program is output to the activated output media after the door is opened. Approval process According to “Hygiene requirements for the treatment of medical products”, instrument reprocessing ends with the ... -

Page 49: Storing Sterile Material

9 Vacuclave mode Storing sterile material The maximum storage time is dependent on the packaging and the storage conditions. Please observe the regulatory re- quirements for the storage period of sterile materials (in Germany e.g. 58953, Part 8 or the DGSV guidelines) as ... -

Page 50: Logging

As such, the preconditions for correct “Approval” by the person conferred with the task of re- processing are given. All information regarding the correct sterilization procedure can be attributed to the instruments used in patient records. Type MELAG Careclave 618 20216180117 Serial number Universal-B... -

Page 51: Logs Menu

10 Logging Logs menu The Logs menu provides you with the following options: ▪ Display and output of program logs ▪ Display and output of malfunction logs ▪ Display and output of status log ▪ Display and output of system log ▪... - Page 52 10 Logging Press the button with the arrow to view and output a log. Press OUTPUT LOG to enter the Log output options and output the displayed log. Press PRINT LABELS to open the label printing dialogue. Press the button with the arrow to change the Quantity or the Storage duration.

-

Page 53: Finding Logs

When transferring the logs to a USB stick, they will be stored in a separate folder in the main directory. Direct transfer of the logs to a computer via the network and using the MELAG server allows you to work directly in the FTP server ... -

Page 54: Function Tests

11 Function tests 11 Function tests Service programs Service programs in Vacuclave mode Program Program name Operating Use/function time Vacuum test 18 min For measuring the leakage rate, test with a dry and cold device (test without load) Bowie & Dick test 15 min Steam penetration test with special test package (available from specialist stockists) -

Page 55: Vacuum Test

11 Function tests Vacuum test The device can be checked for leakages in the steam system using the vacuum test. This determines the leakage rate at the same time. Perform a vacuum test in the following circumstances: ▪ Once a week in routine operation ▪... -

Page 56: Bowie & Dick Test

11 Function tests Select the desired variant and accept it with OK at the end of the list. Start the vacuum test with START PROGRAM. Bowie & Dick test Bowie & Dick test serves as proof of steam penetration of porous materials such as e.g. - Page 57 Min. Answer the following question according to the result. If a filling level is below the line for the minimum level, repeat the Carebox test. If the minimum level is still not reached, please contact your stockist or MELAG customer service.

-

Page 58: Settings

12 Settings 12 Settings General settings General settings can be changed by any user. Language In the Settings > Language menu, you can switch between the enabled languages. Set the desire language. Press CONFIRM to accept the changes. Ê The dialogues on the display and the log texts are changed to the selected language. Date and time Date and time of the device must be correctly set for proper batch documentation. - Page 59 12 Settings Display brightness In the Settings > Brightness menu, you can individualise the brightness of the display. The display brightness is adjusted immediately. The colour bar (pos. a) gives you an impression of the colour contrast. Move the slider to the left or right or press the plus (pos. b) or minus (pos.

- Page 60 12 Settings Program options In the Settings > Program options menu, you can set default settings for program options. Press the button with the arrow to make changes. Activate or deactivate the desired setting by selecting or deselecting it. Confirm the changes with OK. Press SAVE to accept the changes.

- Page 61 12 Settings If you want to activate intelligent drying, proceed as follows: Press the drying button to select the option Intelligent if you want intelligent drying to take place during the next program run. PLEASE NOTE Intelligent drying is activated in the delivery state. Log output In the Settings > Log output menu, you can set how the log should be output by default for each output medium.

-

Page 62: Administrative Settings

12 Settings Label print In the Settings > Label print menu, you can configure the label printer and set default settings. The label printer can be connected via USB or via integration into a local network (LAN). If several devices access the la- bel printer, it must be integrated via a local network (LAN). - Page 63 12 Settings User administration An individual ID and user PIN can be issued to every user to facilitate reliable traceability via the approval process after the end of a sterilization program. With the user PIN, the user can authenticate himself before the batch is approved. Only created users are authorised to approve and can approve a batch with their user PIN.

- Page 64 12 Settings Authentication In the Settings > Administration menu, you can activate authentication (PIN entry) for the start or end of the pro- gram. The following must be fulfilled or present: ü The logged-in user role is: Administrator or Service technician. Select the Authentication menu. Activate or deactivate the desired setting by selecting or deselecting Press SAVE to accept the changes.

- Page 65 12 Settings Select the Batch approval menu. Activate or deactivate the desired setting by selecting or deselecting Press SAVE to accept the changes. The following settings are possible: Log type Description Batch approval Batch approval after successful program end Indicator assessment Indicator assessment after successful program end Administrator PIN You can change the administrator PIN in the Settings > Change administrator PIN menu.

- Page 66 12 Settings Insert a USB stick with the installation data in any USB connection. Press NEXT to perform the software update. Ê During the software update, the device independently performs one or more restarts. See also: ▪ Log list [} page 51] Network In the Settings > Network menu, you can select an automatic configuration via DHCP or enter the required address details manually.

-

Page 67: Service Settings

12 Settings Logging off a user role In order to log off a user role, proceed as follows: Press the user role button. Press LOGOUT. Ê The symbol of the user role button changes. Service settings To make service settings, such as a Software reinstallation, you must log in as a Service technician. Only authorised technicians have access to the further service documents required for this purpose. -

Page 68: Maintenance

13 Maintenance 13 Maintenance PLEASE NOTE The maintenance work described below can be performed by the user as part of in-house maintenance. All maintenance activities beyond this must only be carried out by an authorized technician. Servicing intervals Interval Measure Device components Daily... -

Page 69: Replacing The Oil Can

NOTICE Danger due to incorrect cleaning and care of the transmission instruments Can result in damage to the transmission instruments. Use MELAG Care Oil only. PLEASE NOTE After changing the oil can, carry out a filter change on all Careboxes. -

Page 70: Venting The Chuck Care System

Checking and oiling the door lock NOTICE Wear of the door lock Only use MELAG oil. Check and oil the door lock every two months as follows: Clean the locking spindle and nut with a non-fuzzing cloth. Insert the test gauge into the door lock nut as far as it will go and turn it 180°. -

Page 71: Changing The Dust Filter

Do not use any hard objects for cleaning such as a metal saucepan cleaner or a steel brush. Sterilization chamber, chamber sealing face, mount, trays To maintain the value of your device and to avoid persistent contamination and deposits, MELAG recommends daily cleaning of the surfaces (e.g. with the MELAG chamber cleaning set). - Page 72 13 Maintenance Spread the cleaning fluid evenly with a non-fuzzing cloth. Allow the cleaning fluid to act and evaporate for a sufficient time. Using a new non-fuzzing cloth, spread ample amounts of demineralised water over the cleaned surfaces. Wipe the surfaces thoroughly to remove cleaning residues. Repeat this process as necessary after wringing out the cloth.

- Page 73 13 Maintenance Open the drain valve by turning the knob 1/4 in an anti-clockwise direction. Drain the water into the collection container. To remove the drain hose, turn the drain valve into the vertical position again. Close the service hatch. Cleaning the feed water tank Open the cover cap on the top of the device.

- Page 74 Clean the sieve under running water with a soft brush or with the MELAjet spray pistol. Check the cleaning result against the light. Reinsert the sieve. Reinsert the fixing clamp. PLEASE NOTE MELAG recommends storing the Carebox on the clean side. Disinfect the Carebox before transferring it to the clean side.

-

Page 75: Carebox

13 Maintenance Carebox Changing the filter PLEASE NOTE After changing the oil can, carry out a filter change on all Careboxes. The filters retain oil in the Carebox. If a filter is missing, clogged or defective, this can lead to malfunctions or severe oiling of the sterilization chamber. - Page 76 13 Maintenance Replace the Carebox housing seal The following must be fulfilled or present: ü A new Carebox housing seal. Pull out the housing seal upwards using the fingers or with the help of tweezers. When inserting the housing seal, note the correct orientation of the above curvature.

- Page 77 13 Maintenance Changing the media seals The following must be fulfilled or present: ü A new set of media seals (five small, two large). Remove the six media seals (1-6) on the rear side of the Carebox 1 2 3 upper section, e.g.

-

Page 78: Maintenance

13 Maintenance Maintenance NOTICE Continuing operation beyond the maintenance interval can result in malfunctions in the device. Maintenance should only be performed by trained and authorised service technicians or stockist technicians. Maintain the specified servicing intervals. Regular maintenance is vital to ensure reliable operation and value retention of the device. All function and safety-rele- vant components and electrical units must be checked during maintenance and replaced where necessary. -

Page 79: Pause Times

14 Pause times 14 Pause times Duration of the operating pause Duration of the operating pause Measure Short pauses between two sterilization ▪ Keep the door closed to save energy processes ▪ Set Energy-saving as required Pauses which last longer than an hour ▪... -

Page 80: Transport

14 Pause times Confirm the dialogue window. Ê The double jacket steam generator is emptied. Confirm the message Draining successful. Ê The device switches to door mode. Switch off the device. Transport CAUTION Danger of injury from incorrect carrying. Lifting and carrying too heavy a load can result in spinal injury. Failure to comply with these provisions can result in crushing. -

Page 81: Malfunctions

The following table contains a summary of the most important events. Should you be unable to find the rele- vant event, or your efforts do not redress the problem, you can contact your stockist or the MELAG customer service. To enable us to give the best possible service, please have the serial number of your device, the malfunction number and a detailed description of the malfunction to hand. -

Page 82: Warning And Malfunction Messages

15 Malfunctions Event Possible cause What you can do Insufficient drying in Unsuitable loading of the Carebox Green Activate Add. drying. the program Care- Use the program Care-S instead of the Therm program Care-Therm. Warning and malfunction messages Event Possible cause What you can do 10026 The oil can is empty. - Page 83 15 Malfunctions Event Possible cause What you can do 10101 The float switch (S13) in the overflow Short-term wastewater blockage - please check funnel detects a short-term impermissible wastewater hose for kinks or, if applicable, a closed shut- water level, which indicates a blockage in off.

- Page 84 15 Malfunctions Event Possible cause What you can do 10145 Monitoring time only runs when Please check the dust filter for contamination and replace it evacuation is started in negative if necessary. pressure. Malfunction is triggered if The intake area of the cooling system under the device evacuation cannot be completed within must be free;...

- Page 85 15 Malfunctions Event Possible cause What you can do 10196 Care. The dosing chamber for the care Please check the compressed air supply (compressor, oil could not be emptied within the blow- main valve). out limit time. Please check the media seals of the Carebox. 10198 Care.

- Page 86 15 Malfunctions Event Possible cause What you can do 10212 Spray channel cleaning. A leakage of the Please make sure that the Carebox is correctly seated. If Carebox was detected during the this occurs repeatedly, replace the small seals on the back cleaning of the spray channels.

- Page 87 15 Malfunctions Event Possible cause What you can do 10234 The continuity check of the Carebox Flow through the Carebox is not possible. Please check delivers impermissible values. the compressed air supply as well as the instruments and adapters for free passage. Run the Carebox test service program.

- Page 88 15 Malfunctions Event Possible cause What you can do 10253 This is triggered when the Carebox is Remove the Carebox or start a reprocessing program. hooked in and the door is closed without starting a program or performing other This is only a warning. The reprocessing result is not activities on the GUI.

- Page 89 15 Malfunctions Event Possible cause What you can do 10264 Monitoring pressure gradient during The Carebox must be dry on the outside before it is pressure release after continuity check. inserted in the Carebox; falling drops can cause an The pressure change at pressure sensor excessively high pressure increase.

- Page 90 10277 Program start. The filling level of the oil Please have a can of MELAG Care Oil ready for can is low, so it can be assumed that an replacement. oil care operation can no longer be performed successfully in the This is only a warning.

- Page 91 15 Malfunctions Event Possible cause What you can do 10279 Carebox pressure release. The pressure Please clean the Carebox daily under running water. change is less than expected; the pressure release speed is decreasing. Please clean the sieve in the lower section of the Carebox. If this occurs repeatedly despite cleaning, please contact the technical service.

- Page 92 15 Malfunctions Event Possible cause What you can do 10283 Pressure-controlled evacuation. This is Please check the dust filter for contamination and replace it triggered when the termination gradient if necessary. is violated in a gradient-monitored The intake area of the cooling system under the device process, which leads to an abort of the must be free;...

- Page 93 15 Malfunctions Event Possible cause What you can do 11004 The writing of the log data to the USB Please insert the USB stick in the media board. storage medium has failed. If necessary, use the USB socket on the rear of the device. This is only a warning.

-

Page 94: Technical Data

16 Technical data 16 Technical data Device type Careclave 618 Device dimensions (H x W x D) 56.2 x 48.0 x 65.3 cm Empty weight 69 kg Operating weight 82.5 kg Sterilization chamber Chamber diameter 250 mm Chamber depth 350 mm Chamber volume/steam generator 17.8 l / 4.4 l... - Page 95 16 Technical data Water quality (water treatment unit) potable water Compressed air Min. pressure 4 bar relative Max. pressure 8 bar relative Min. compressed air supply 55 Nl/min Average compressed air supply 50 Nl/cycle Compressed air quality dried, condensate-free, bacteria-free, oil-free and filtered (filter fineness ≤ 2 μm) Wastewater Max.

-

Page 96: Accessories And Spare Parts

17 Accessories and spare parts 17 Accessories and spare parts You can obtain the specified articles and an overview of further accessories from your stockist. Accessories for the device Category Article Art. no. Mounts Mount C "Plus" ME81370 for 6 trays or 3 MELAstore Boxes 100 Mount D "Plus"... - Page 97 17 Accessories and spare parts General accessories Category Article Art. no. Test body system MELAcontrol Helix consisting of a Helix test body and 250 ME01080 indicator strips MELAcontrol Pro consisting of a Helix test body and 40 ME01075 indicator strips MELAcontrol Pro refill pack ME01076 Water treatment...

- Page 98 Adapter M3.0 x 0.5 mm, internal thread, internal thread ME80790 Carebox Green Adapter M8x1 eccentric ME22407 Spare parts Category Article Art. no. Careclave MELAG oil for door lock nut ME27515 Careclave Test gauge TR16 for door lock nut ME27522 Careclave Care Oil ME84740 Careclave Dust filter...

-

Page 99: Glossary

MELAG to perform maintenance DGUV Regulation 1 and installation work on MELAG devices. Only they may DGUV is the abbreviation for “Deutsche Gesetzliche Un- carry out this work. - Page 100 Glossary EN ISO 11140-1 Porous full load Standard – the sterilization of products for use in medical Serves to prove that the values set on the control satisfy treatment – chemical indicators – part 1: General require- the necessary sterilization conditions in porous loads with ments a maximum mass for which the sterilizer is designed in ac- cordance with EN 13060 [see also EN 13060].

- Page 101 Glossary Sterile barrier system A closed minimum packaging which prevents the entrance of micro-organisms e.g. through sealing bags, sealed and re-usable containers and folded sterilization towels etc. Sterile material Also referred to as a batch: a load which has already been sterilized, i.e.

- Page 102 MELAG Medizintechnik GmbH & Co. KG Geneststraße 6-10 10829 Berlin Germany Email: info@melag.com Web: www.melag.com Original instructions Responsible for content: MELAG Medizintechnik GmbH & Co. KG We reserve the right to technical alterations Your stockist...

Need help?

Do you have a question about the Careclave 618 and is the answer not in the manual?

Questions and answers