Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Webster Cyclonetic SG Series

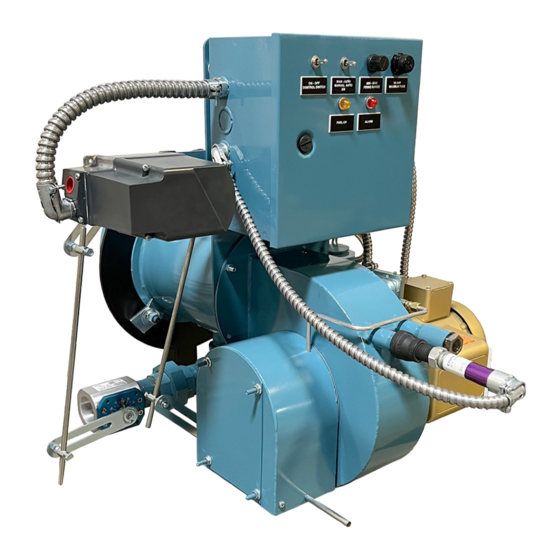

- Page 1 Webster Combustion Technology 619 Industrial Road, Winfield, KS 67156 Installation, Startup, Operation and Maintenance Manual Cyclonetic Series Forced Draft Burners SG Gas Burner Manual Part No. 950212 www.webstercombustion.com February, 2022 2022 All Rights Reserved...

-

Page 2: Safety Precautions

SAFETY PRECAUTIONS Good safety practices must be used when working on burner equipment. The potential energy in the electrical supply, fuel and related equipment must be handled with extreme care to prevent equipment failures, injuries and potential death. Throughout this manual, the following symbols are used to identify potential problems. WARNING This indicates a potential hazardous situation, which if not avoided, could result in personal injury or death. -

Page 3: Table Of Contents

Warranty Validation & Field Start-up Report ..................A. INTRODUCTION This manual covers the SG Model CYCLONETIC burners offered by Webster Combustion. These burners cabe used in a wide variety of Cast Iron, Firebox, Firetube, Flextube and other applications. They fire gas with several different operating systems. -

Page 4: Burner Model Number

Section C. Service, Parts and Other Information 4. Your Complete Manual Service and parts are available from your local Webster In addition to this manual, there are several other docu- Representative. For a list of Webster Representatives, ments that should be considered as part of the complete please visit the Webster web site at: manual for the burner. -

Page 5: Specifications & Sizing

3. Larger motors may be required for single phase or 208 volts. 4. Contact Webster for complete details The above maximum ratings are based on 0 furnace pressure, an altitude of 1000 feet, 90 o F air temperature and 60 HZ electrical supply. -

Page 6: Dimensions

14.3 10.3 * Based off standard burner insertion. For insertion different from 4”, contact Webster for dimensions. All dimensions are for reference only. Webster reserves the right to change dimensions without notice. Model SG burners are listed by Underwriters Laboratories, Inc. (UL / ULC). -

Page 7: Installation

B. INSTALLATION Prior to installing the burner, the site conditions and utili- 7. All manuals should be reviewed, understood and stored ties need to be evalulated. This section provides some in a convenient place. general questions that can help the review process. 8. -

Page 8: Burner Mounting Criteria

10 1/8 - Bolt Circle Use minimum 8 5/8 12 1/8 Minimum of four (4) 1/2” 7 gauge studs with lugs Contact Webster for more 2” detailed refractory drawings. 4” Vessel Specific - Opening Refractory OD is sized to Minimum fit vessel opening with 1/4”... -

Page 9: Fuel Sytems

E. FUEL SYSTEMS Illustrated Gas Trains by Capacity and Code: The following illustrations show the Webster configuration for UL, FM and IRI as grouped by UL capacity ratings. Refer to the legend below for component part identification. These illustrations are not to be used for field erection and/or system design purposes. - Page 10 E. FUEL SYSTEMS (continued) 722197 722197 Vent to Outside Atmosphere VENT TO OUTSIDE ATMOSPHERE Main Solenoid Main Motorized Manual Ball Manual Ball Gas Valve Gas Valve Manual Ball Valve Valve Valve Pressure Regulator GAS BURNER Burner Supply MANIFOLD SUPPLY Manifold Manual Manual Test Valve...

- Page 11 AIR PROVING SWITCH The air proving switch has been adjusted at the factory for an initial setting. If the switch trips during initial start- up, turn the adjustment screw ccw two full turns to reduce the trip pressure setting. TYPICAL AIR AND FUEL ADJUSTMENT LOCATIONS Control cabinet Mod motor Mounting flange...

-

Page 12: Startup & Operating Adjustments

______All wiring is connected. Test pulls on wire show This section covers the startup and operating adjustments them to be tight. of the Webster Model SG burners. ______All fuel lines are connected and tight. ______Burner is mounted to vessel and floor, with all bolts WARNING secured. - Page 13 3. Gas Setup 2. Linkage Adjustments a. Place the burner switch in the “OFF” position Adjusting the air damper on a linkage system requires an b. Place the “Auto-Manual” switch in the manual position, understanding of linkage setups. The rate of change for for modulation or low fire hold, switch in low fire position the fuel valve and air damper must be matched by how for Lo-Hi-Lo operation.

- Page 14 m. Adjust the high fire input to match the maximum input s. Adjust the high gas pressure switch to be 10% above listed on the rating label. At high fire, the gas butterfly the highest expected gas pressure. valve should be at least 75 degrees open (more if avail- •...

- Page 15 4. Operating Control Adjustments 6. Burner Shutdown The operating controls must be adjusted to properly Normal operation of the burner will allow the operating con- cycle the burner “ON and OFF” and provide modulation. trols to shut the burner down when the load demand is sat- The controls should not force the burner into rapid “ON- isfied.

-

Page 16: Troubleshooting

G. TROUBLESHOOTING System Cause Correction No Ignition Electrode is grounded. Porcelain is cracked. Replace (lack of spark) Improperly positioned electrode Recheck dimensions Loose ignition wire connection Reconnect or tighten Defective ignition transformer Check transformer, replace No Ignition Lack of fuel, no gas pressure, closed fuel valve Check fuel supply and valves (spark, no flame) No voltage to gas valve... - Page 17 G. TROUBLESHOOTING (continued) System Cause Correction High CO at low fire (con’t) High stack draft (especially at low fire) Stabilize draft Poor air flow distribution (off center flame) Adjust air straightener blade Diffuser not in optimum position Adjust diffuser position in or out Fluxuating gas pressure (regulator not holding pressure) Check regulator pressure, sensing line and supply pressure: sized properly...

-

Page 18: General Maintenance And Care

H. GENERAL MAINTENANCE AND CARE 1. General There are several different types of controls and the cor- 2. Physical Inspection rective action of each could be different. The following 3. Fuel-Air-Ratio general guidelines can be used for initial steps. 4. Gas Fuel Systems 5. - Page 19 Always give Webster Engineering Serial value, such as flame safety controls, main gas valves and Number and/or UL Serial Number when blower motors should be obtained from your local Webster ordering parts. representative when a need arises. 8 - Inspection and Maintenance Schedule...

-

Page 20: Care Of Burner During Extended Shutdown

Validation and Field Startup Report, Form 113, to: WEBSTER COMBUSTION TECHNOLOGY, LLC 619 Industrial Road, Winfield, KS 67156. WEBSTER Series SG Burners are listed by Underwriters Laboratories, Inc. (U.L.). Also by the State of Massachusetts Fire Marshall, City of New York Board of Standards and Appeals,... - Page 21 START-UP BY _______________________________________________ Date _________________________ Company ___________________________________________ Phone No. ____________________________ Address ___________________________________________________________________________________ NOTE: Warranty Validation - Field Start-up report must be completed, signed, dated and the top copy sent to Webster Combustion Technology, Winfield, KS 67156, to validate equipment warranty. SG Manual...

- Page 22 NOTES Notes SG Manual Page 22...

- Page 23 NOTES Page 23 SG Manual Notes...

- Page 24 Company’s performance and causes its cost of production to increase because of the delay, the Company may pass such increase on to the Buyer. WEBSTER COMBUSTION TECHNOLOGY 619 Industrial Road - Winfield, KS 67156 Phone 620-221-7464 Fax 620-221-9447 sales@webstercombustion.com service@webstercombustion.com...

Need help?

Do you have a question about the Cyclonetic SG Series and is the answer not in the manual?

Questions and answers