APsystems QT2 Installation Manual

3-phase microinverter

Hide thumbs

Also See for QT2:

- Manual (37 pages) ,

- Installation manual (22 pages) ,

- Quick installation manual (4 pages)

Table of Contents

Advertisement

Quick Links

ALTENERGY POWER SYSTEM Inc.

global.APsystems.com

APsystems Shanghai:

Rm.B305 No.188, Zhangyang Road, Pudong, Shanghai 200120,P.R.C Tel:

021-3392-8205

EMAIL: info.apac@APsystems.com

© All Rights Reserved

APsystems Microinverter

Installation Manual

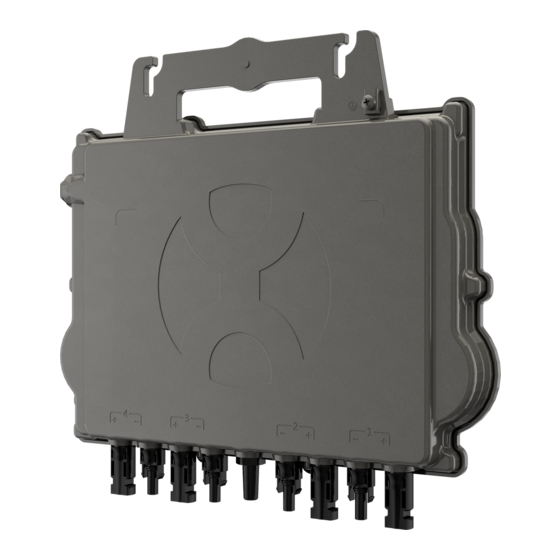

APsystems QT2 3-Phase Microinverter

(For APAC)

Please scan this QR code to

have access to our APPs and

Products information

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for APsystems QT2

- Page 1 APsystems Microinverter Installation Manual APsystems QT2 3-Phase Microinverter (For APAC) ALTENERGY POWER SYSTEM Inc. global.APsystems.com APsystems Shanghai: Rm.B305 No.188, Zhangyang Road, Pudong, Shanghai 200120,P.R.C Tel: Please scan this QR code to have access to our APPs and 021-3392-8205 EMAIL: info.apac@APsystems.com Products information ©...

-

Page 2: Table Of Contents

4.4.4 Step 4 - Ground the system ....................11 4.4.5 Step 5 - Connect the APsystems microinverter to AC bus cable ......12 4.4.6 Step 6 - Install a Bus Cable End Cap at the end of AC bus cable ......13 4.4.7 Step 7 - Connect APsystems Microinverters to the PV Modules ......13... -

Page 3: Important Safety Instructions

APsystems Microinverter system and the solar-array. Be aware that the body of the APsystems Microinverter is the heat sink and can reach a temperature of 80°C. To reduce risk of burns, do not touch the body of the Microinverter. -

Page 4: Radio Interference Statement

20 cm from all persons and must not be co-located or operating in conjunction with any other antenna or transmitter. End-users and installers must be provide with antenna installation instructions and transmitter operating conditions for satisfying RF exposure compliance. APsystems Microinverter QT2 Installation Manual... -

Page 5: Symbols Replace Words On The Equipment, On A Display, Or In Manuals

L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement. APsystems Microinverter QT2 Installation Manual... -

Page 6: Apsystems Microinverter System Introduction

2. APsystems Microinverter System Introduction The APsystems Microinverter is used in utility-interactive grid-tied applications, comprised of three key elements: APsystems Microinverter APsystems Energy Communication Unit (ECU) APsystems Energy Monitor and Analysis (EMA) web-based monitoring and analysis system... - Page 7 Type 6 environmental enclosure rating. Simple to install APsystems Microinvertes are compatible with most of 60 and 72 cell PV modules or 120 and 144 half-cut cells PV modules. (In order to confirm compatibility of PV module with APsystems microinverter, feel free to check our online “E-decider”...

-

Page 8: Apsystems Microinverter Qt2 Introduction

APsystems EMA web-based portal facilitate remote diagnosis and troubleshooting. The new QT2 is grid interactive through its Reactive Power Control (RPC) feature, designed to better manage photovoltaic power spikes in the grid. At 96.5% peak efficiency and improved reliability, the QT2 is a game changer for commercial solar. -

Page 9: Apsystems Microinverter System Installation

4. APsystems Microinverter System Installation A PV system using APsystems Microinverters is simple to install. Each Microinverter easily mounts on the PV racking, directly beneath the PV module(s). Low voltage DC wires connect from the PV module directly to the Microinverter, eliminating the risk of high DC voltage. -

Page 10: Pv Rapid Shut Down Equipment

Additionally, in a prominent location near the initiator device, a placard or label must be provided with a permanent marking including the following wording: ’PHOTOVOLTAIC SYSTEM EQUIPPED WITH RAPID SHUTDOWN’ The term ‘PHOTOVOLTAIC’ may be replaced with ‘PV.’ The label requires reference NEC 690.65 to meet the audit requirements. APsystems Microinverter QT2 Installation Manual... -

Page 11: Installation Procedures

4.4.3 Step 3 - Attach the APsystems Microinverters to the Racking a. Mark the location of the microinverter on the rack, with respect to the PV module junction box or any other obstructions. -

Page 12: Step 4 - Ground The System

The racking must be properly grounded as per local electrical code. 4.4.4 Step 4 - Ground the system There're 2 ways to ground the QT2 series microinverters. 1. By grounding washer attached. After the microinverters and racking are reliably installed, the microinverter's grounding washer can connect to the racking to ensure proper earthing. -

Page 13: Step 5 - Connect The Apsystems Microinverter To Ac Bus Cable

4. APsystems Microinverter System Installation 4.4.5 Step 5 - Connect the APsystems microinverter to AC bus cable Insert the microinverter AC connector into the trunk cable connector. Make sure to hear the “click” as a proof of robust connection Click Figure 4 Best Practice: Use the Bus Cable Unlock Tool of AC Bus to disconnect the connectors. -

Page 14: Step 6 - Install A Bus Cable End Cap At The End Of Ac Bus Cable

Body Seal Figure 8 4.4.7 Step 7 - Connect APsystems Microinverters to the PV Modules Figure 9 No neutral wire output from inverter. Compatible with both Delta and Wye 3-phase grid. When plugging in the DC cables, the microinverter should immediately blink green ten times. - Page 15 Each PV panel must be carefully connected to the same channel. Make sure to not split positive and negative DC cables into two different input channels: microinverter will be damaged and warranty will not apply. APsystems Microinverter QT2 Installation Manual...

-

Page 16: Step 8 - Complete The Apsystems Installation Map

4. APsystems Microinverter System Installation 4.4.8 Step 8 - Complete the APsystems installation map a. Each APsystems Microinverter has 2 removable serial number labels. b. Complete installation map by sticking ID label of each microinverter at the right location. c. The second serial number label, could be stuck on the solar module frame, which... -

Page 17: Apsystems Microinverter System Operating Instructions

Alternatively, LED sequences could be an indicator of microinverters status (see section 6.1) Once the ECU has been commissioned properly, the APsystems Microinverters will start to send performance data to the ECU. The time required for all of the Microinverters in the system to report to the ECU will vary depending on the number of Microinverters in the system. -

Page 18: Troubleshooting

APsystems Technical Support. 6.2 ECU_APP APsystems ECU_APP (available in the EMA Manager APP) is the recommended tool to do on-site troubleshooting. When connecting the ECU_APP to the ECU hotspot (please check ECU User Manual for more detailed information), installer can check every microinverter status (production, communication) but also ZigBee signal strength, grid profile and other insightful data helping the troubleshooting. -

Page 19: Apsystems Technical Support

6.5 APsystems Technical Support APsystems local Technical Support team is available to support professional installers to get familiar with our products and to troubleshoot installations when needed. Do not attempt to repair APsystems Microinverters. Please contact your local APsystems Technical Support. -

Page 20: Replace A Microinverter

7. Replace a microinverter Follow the procedure to replace a failed APsystems Microinverter A. Disconnect the APsystems Microinverter from the PV Module, in the order shown below: 1. Disconnect the AC by turning off the branch circuit breaker. 2. Disconnect the inverter AC connector from the AC Bus. -

Page 21: Technical Data

8. Technical Data ①. Be sure to verify that the voltage and current specifications of your PV module are compatible with the range allowed on APsystems Microinverter. Please check the microinverter datasheet. ②. DC operating voltage range of the PV module must be within allowable input voltage range of the APsystems Microinverter. - Page 22 (3) The inverter may enter to power de-grade mode under poor ventilation and heat dissipation installation environment. (4) Recommend no more than 80 inverters register to one ECU for stable communication. (5) To be eligible for the warranty, APsystems microinverters need to be monitored via the EMA portal. © All Rights Reserved Please refer to our warranty T&Cs available on global.APsystems.com.

-

Page 23: Qt2 - Wiring Diagram

9. QT2 - Wiring Diagram 9.1 Sample Wiring Diagram No neutral wire output from inverter. Figure 12 Compatible with both Delta and Wye 3-phase grid. APsystems Microinverter QT2 Installation Manual... -

Page 24: Apsystems Microinverter Installation Map

10. APsystems Microinverter Installation Map The APsystems Installation Map is a diagram of the physical location of each microinverter in your PV installation. Each APsystems microinverter has two serial number labels. Peel the one label and affix it to the respective location on the APsystems installation map.

Need help?

Do you have a question about the QT2 and is the answer not in the manual?

Questions and answers