Advertisement

Quick Links

Advertisement

Summary of Contents for SMC Networks IRV10

- Page 1 No.DIK-45700-OM002-A PRODUCT NAME Vacuum regulator MODEL/ Series IRV10 IRV10A IRV20 IRV20A...

- Page 2 Table of Contents Safety Instructions 2~3 Introduction 1.Specifications 2.Construction and Operating Principle 3.How to Order 6~7 4.Specific Product Precautions 8~13 5.Warranty - 1 -...

- Page 3 Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC)*1) , and other safety regulations.

- Page 4 Safety Instructions Caution The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

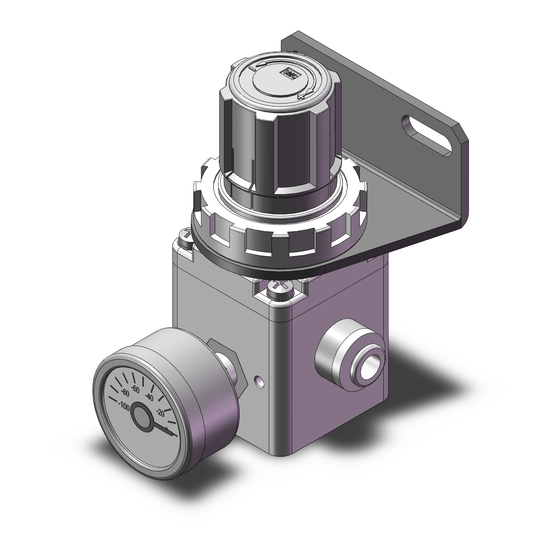

- Page 5 Introduction IRV10,10A,20,20A vacuum regulator is an apparatus to adjust vacuum pressure (negative pressure) Arbitrarily by connecting vacuum pump to the port on the VAC. side. 1.Specifications Model IRV10 ※ IRV20 ※ Fluid Set pressure range Note1) -100 to -1.3kPa Note2)

- Page 6 2.Construction and Operating Principle By turning handle ① clockwise, force of set spring ② pushes down diaphragm ③ and main valve ④ that VAC. Pressure side and SET. Pressure side are connected, which increases vacuum on SET. Pressure side (become closer to absolute vacuum). Vacuum pressure on SET.

- Page 7 (Note2) One plug nut assembly, one gauge nut assembly (Rc1/8) and two clips are included in the same Connection port size container. symbol Port size IRV10 IRV20 (Note3)Pressure gauge assembly or digital pressure switch φ6 ● ● assembly, one plug nut assembly and two clips are φ8...

- Page 8 【Single sided connections】 I R V 20 A - ※ C08 ※ ※ Body size Accessories2 The maximum flowing quantity 140l/min(ANR) 【Accessory is included in the same container】 The maximum flowing No accessory (Note1) quantity 240l/min(ANR) With gauge nut assembly (Note2) With pressure gauge (Note3)

- Page 9 Excessive torque can damage the mounting screws and product body. And insufficient torque can cause the threaded parts to loosen. Cross recessed round head screw for mounting the bottom bracket Square nut Bottom bracket Applicable torque IRV10(A):M3 0.32±0.03N・m IRV20(A):M4 0.76±0.05N・m - 8 -...

- Page 10 Caution Handling (1) Reduce the set pressure to zero(atmospheric pressure) for removing the plug when additionally mount the pressure gauge and pressure switch. 1.For customers purchasing regulator with a pressure gauge or pressure switch Accessories ・Pressure gauge (GZ43,GZ33)or pressure switch (ZSE30A)------------1 piece ・Gauge nut (with O-ring)-----------------------------------------------------------1 piece Note) The gauge nut is mounted on the pressure gauge or pressure switch.

- Page 11 3) Insert the plug nut into the opposite gauge port completely. 4) Insert the clip into the left side of the product completely as with 2). Clip Plug nut 3) 4) Note) When the pressure gauge or pressure switch is removed, be sure to remove the clip straight.

- Page 12 How to pull out the clip Set the driver tip to the slope of the place where the clip inserted, lift the clip by moving the driver slowly. Mounting of fitting assembly Fitting assembly Clip Clip - 11 -...

- Page 13 Caution Environment (1)Do not use the product in an environment where the product is directly exposed to corrosive gases, chemicals, salt water or steam. (2)Do not mount the product in a location where it is subject to strong vibrations and/or shocks. (3)Use this vacuum regulator in a location free from dirt since this product sucks atmosphere all the time.

- Page 14 diameter. If the vacuum pump may not be replaced, add a tank (capacity of the tank depends on the operating conditions) on VAC side. (7)Note that pressure response time after valve (solenoid valve) opening/ closing is affected by internal volume of the setting side (including piping volume).

- Page 15 .Warranty 1. Period: 1.5 year after delivery to the customer’s specified location or one year after starting operation, whichever comes sooner. 2. Scope: If a failure occurs within the warranty period which is deemed to be SMC’s responsibility, we will provide a replacement product as limited warranty. Any loss or damage incurred by the failure is not covered by the warranty.”...

- Page 16 Revision A How to Order display content correction, etc. URL http://www.smcworld.com 4-14-1 Sotokanda, Chiyoda-ku, Tokyo 101-0021, Japan Tel: 03-5207-8271 Fax: 03-5298-5361 2021 SMC Corporation All Rights Reserved - 15 -...

Need help?

Do you have a question about the IRV10 and is the answer not in the manual?

Questions and answers