Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks LECSA Series

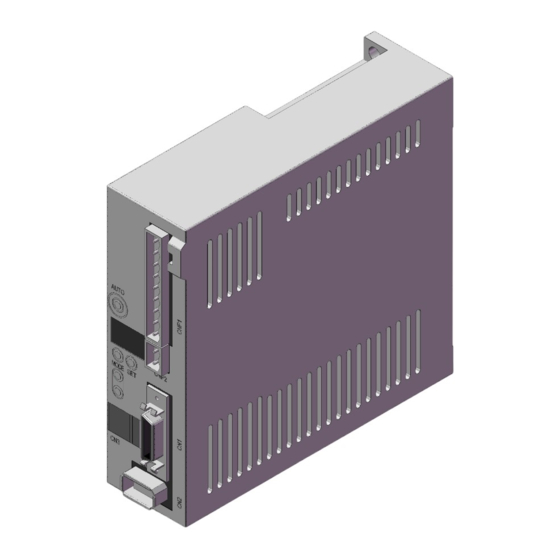

- Page 1 LEC-OM05611 (Doc No. JXC※-OMT0052-A) (Simplified Edition) PRODUCT NAME AC Servo Motor Driver (Pulse input type/Positioning type) MODEL / Series / Product Number LECSA Series...

- Page 2 文書管理 No. - 旧文書体系 No. 対応表 文書管理 No. 旧文書体系 No. JXC※-OMT0052 LEC-OM05610 JXC※-OMT0052-A LEC-OM05611 本書は、対応文書の原紙と一緒に保管する。...

-

Page 3: Table Of Contents

Contents Contents ..................... 1 Introduction ....................6 Terms ......................6 1. Configuration ..................6 2. Pre-Operation Procedure ..............7 2.1 Flow chart ......................7 3. Wiring ..................... 8 3.1 Power Supply Wiring..................8 3.2 I/O signal connection example ................9 3.2.1 Position control mode (Sink I/O interfaces) .............. - Page 4 5.5.3 Signal Allocation using Setup Software ..............42 5.5.4 Allocation Examples for Position Control Mode (Pulse Input) ......43 5.5.5 Setting a Maximum of 7 Points using the Point Table in Positioning mode (Point Table) 5.5.6 I/O Signal Allocation Check ..................49 5.6 Positioning Mode in Setup Software ..............

- Page 5 8. Troubleshooting ..................91 8.1 Alarms and Warning List ................. 91 8.2 Alarm Display....................93 - 3 -...

- Page 6 LECSA Series / Driver Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger”. They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC), Japan Industrial Standards (JIS) *1.) and...

- Page 7 LECSA Series / Driver Safety Instructions Caution The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries; consult SMC beforehand and exchange specifications or a contract if necessary.

-

Page 8: Introduction

Introduction It is recommended that the operator read the operation manual for LECSA prior to use. For the handling and details of other equipment, please refer to the operation manual for said equipment. Check that the main circuit power supply (AC100V/AC200V) and controller circuit power supply (24V) are wired correctly. -

Page 9: Pre-Operation Procedure

2. Pre-Operation Procedure 2.1 Flow chart Wiring See “3. Wiring” Parameter setting See “4. List of Parameters for each Mode” Parameter Settings using the Setup Software (MR Configurator2 See “5. Parameter Settings using the Setup Software (MR )” Configurator2 Signal Assignment Configuration See “5.5 Changing I/O Signal Allocation”... -

Page 10: Wiring

3. Wiring 3.1 Power Supply Wiring Connect the actuator and driver power supply. This wiring diagram is common for each mode. (1) LECSA (Incremental encoder) EX.) Power supply voltage is 200VAC single phase Trouble Forced stop (Note 5) Servo amplifier Driver Servo motor CNP1... -

Page 11: I/O Signal Connection Example

3.2 I/O signal connection example Detail of connection examples for the I/O signals of the driver. 3.2.1 Position control mode (Sink I/O interfaces) (1) Connection example An example of a connection for the position control mode is shown below. Connect wires as necessary. This is a wiring example using the Mitsubishi Electric (FX3U-□□MT/ES) PLC for position control. - Page 12 (2) Input signal Position control mode: P, Speed control mode: S, Torque control mode: T, Point table method: CP, Program method: CL ●: Automatic ON can be set, ○: Initial setting, □: Assignment is available with parameter,-: Assignment is not available Automatic Symbol Device name...

- Page 13 (3) Output signal Position control mode: P, Speed control mode: S, Torque control mode: T, Point table method: CP, Program method: CL : Initial setting, : Assignment is available with parameter,-: Assignment is not available ○ □ Symbol Device name Function This signal turns off while alarm is generated.

-

Page 14: Speed Control Mode (Sink I/O Interfaces)

3.2.2 Speed control mode (Sink I/O interfaces) (1) Connection example An example of a connection for the speed control mode is shown below. Connect wires as necessary. Driver Servo amplifier (Note 7) (Note 7) (Note 4, 9) (Note 2) 24VDC DICOM T rouble (Note 6) DOCOM... -

Page 15: Torque Control Mode (Sink I/O Interfaces)

3.2.3 Torque control mode (Sink I/O interfaces) (1) Wiring example An example of a connection for the torque control mode is shown below. Connect wires as necessary. Driver Servo amplifier (Note 6) (Note 6) 24VDC (Note 4, 8) (Note 2) DICOM T rouble (Note 5) RA 1... -

Page 16: Positioning Mode (Sink I/O Interfaces)

3.2.4 Positioning mode (Sink I/O interfaces) (1) Connection example An example of a connection for the position control mode is shown below. Connect wires as necessary. Servo amplifier Driver (Note 7) (Note 7) (Note 2) 24VDC (Note 4, 9) RA 1 T rouble (Note 6) DICOM T ravel completion... -

Page 17: Source I/O Interfaces

3.2.5 Source I/O interfaces Source type I/O interfaces can be used with this driver. If used, all DI-1 input signals and DO-1 output signals are source type signals. Complete wiring according to the following interfaces. (1) Digital input interface DI-1 Driver Servo amplifier SON,... -

Page 18: List Of Parameters For Each Mode

4. List of Parameters for each Mode These parameters require configuration in each control mode. Please configure parameters as required. Refer to “LECSA Operation Manual (Simplified Edition)”, section 5.3 and “LECSA Operation Manual”, chapter 4 for details. Refer to “LECSA Operation Manual”, chapter 4 for parameters which are not disclosed in this document. (MR Configurator2 : LEC-MRC2E) is necessary for the setting of parameter. -

Page 19: Speed Control Mode

4.3 Speed control mode (1) [Basic settings parameters (No.PA□□)] Symbol Name Initial value Unit PA08 Auto tuning mode 001h PA09 Auto tuning response (2) [Extension setting parameters (No. PC□□)] Symbol Name Initial value Unit Acceleration time constant PC01 PC02 Deceleration time constant PC05 Internal speed command 0 r/min... -

Page 20: Positioning Mode

4.5 Positioning mode (1) [Basic settings parameters (No.PA□□)] Symbol Name Initial value Unit ×100 PA05 *FBP Number of command input pulses per revolution pulse/rev Electronic gear numerator PA06 (Command input pulse multiplying factor numerator) Electronic gear denominator PA07 (Command input pulse multiplying factor denominator) PA08 Auto tuning mode 001h... -

Page 21: Parameter Configuration Using Setup Software (Mr Configurator2 )

5. Parameter Configuration using Setup software (MR Configurator2 This section describes the configuration procedure for main parameters using the setup software (MR Configurator2 LEC-MRC2E). See chapter 4 of the “LECSA Operation Manual” for parameter details. 5.1 PC Setup software (MR Configurator2 *1 Setup software version 1.52E or above is required. -

Page 22: Start Up The Setup Software

5.2.1 Start up the Setup software (MR Configurator2 ① Connect the PC and LECSA using the USB cable. ② Turn on the power of the LECSA. ③ Start application “MR Configurator2”. Once the application starts, the screen below will be displayed. - 20 -... -

Page 23: System Settings

5.2.2 “System Settings” ① From “Project” menu select “New”, the “New project” window will be displayed. 5.2.3 Model Selection ① The Mitsubishi Electric Corporation series will be displayed in the model selection list. Please select MR-JN-A when using the LECSA. The station should be set to 00. -

Page 24: Driver On Line Check

5.2.4 Driver ON LINE Check Check that the driver is enabled (ONLINE). Check that the “ONLINE/OFFLINE” icon is displayed “ ”. When It is OFFLINE it is displayed as “ ”. * For OFFLine, PC and amplifier aren’t communicating. Confirm the following points. - Is amplifier's power supply turned on? - Is the PC and LECSA amplifier connected with the USB cable? - Is the USB driver installed? -

Page 25: Parameter Setting (Driver Side)

5.3 Parameter setting (Driver side) is necessary for setting the parameter. The setup software (MR Configurator2 : LEC-MRC2E) *1 Setup software version 1.52E or above is required. *2 The setup software (MR Configurator2 : LEC-MRC2E) must be purchased as an additional item. *3 The USB cable (LEC-MR-J3USB) must be purchased as an additional item. -

Page 26: Change Of Parameter Block

5.3.1 Change of parameter block To enable settings for all parameters. ① Select “Basic” tab and change “PA19” value to “00E”. ② Click the “PA19” row then click “Selected Items Write”. ③ Cycle the power for parameters for this driver to be enabled. ②... -

Page 27: Parameter Configuration Method (Ex. "Control Mode" Selection)

5.3.3 Parameter Configuration Method (Ex. “Control mode” selection) Please set the parameters for each actuator. Please change the parameter values according to usage. Refer to "LECSA Operation Manual”, chapter 4 for details of each parameter. Refer to “LECSA Operation Manual (Simplified Edition)”, section 5.4.3 for recommended parameter values for SMC supplied actuators. -

Page 28: Recommended Parameter Values By Actuator Model

5.3.4 Recommended Parameter Values by Actuator Model Please change the parameter values according to the customer application. See section 4 of the “LECSA Operation Manual” for details. Recommended Parameter Values [LEF] LEFS25 LEFS32 LEFS40 Series Lead symbol Lead Initial Para Parameter *1,*2 Recommended Value value... - Page 29 LEFB25 LEFB25U LEFB32 LEFB32U LEFB40 LEFB40U Series Lead symbol Lead Initial Para Parameter *1,*2 Recommended value value Number of command input pulses per PA05 revolution *3. Electronic gear PA06 100 (Positioning mode: 10) numerator *3. Electronic gear PA07 denominator *3. Feel length multiplication PE02 0000...

- Page 30 Recommended Parameter Values [LEJ] LEJS40 LEJS63 LEJB40 LEJB63 Series Lead symbol Lead Para. Initial Parameter *1,*2 Recommended value value Number of command input pulses per PA05 revolution *3. Electronic gear numerator 100 (Positioning mode: 10) PA06 Electronic gear PA07 denominator *3. Feel length multiplication PE02 0000...

- Page 31 Recommended Parameter Values [LEY] LEY25/LEYG25 LEY25D/LEYG25D LEY32/LEYG32 LEY32D/LEYG32D Series Lead symbol Lead Initial Parameter Para. No Recommended value *1,*2 value Number of command input pulses per PA05 revolution *3. Electronic gear PA06 100 (Positioning mode: 10) numerator *3. Electronic gear PA07 denominator *3.

- Page 32 LEY63 LEY63D Lead symbol Series Lead 5(2.86) (Including pulley (Pulley ratio) ratio 4/7) Initial Parameter Para. No Recommended value *1,*2 value Number of command input pulses per PA05 revolution *3. Electronic gear PA06 numerator *3. (10) (10) Electronic gear PA07 denominator *3.

-

Page 33: Electronic Gears

5.3.5 Electronic Gears It is necessary to adjust the electric gear to convert from the command pulses sent from position unit to the travel amount of electrical actuator. See “LECSA Operation Manual (Simplified Edition)”, section 5.3.4 for the recommended values for electronic gears for each actuator model. -

Page 34: Control Mode Selection

5.3.6 Control mode selection ① To use position control mode (pulse input), navigate to the "Basic" tab of the "Parameter Setting" screen - "Control mode selection" - Please select "Position control mode". (“PA01” parameter in the "Basic" tab of the List display also changes to "000".) To use positioning mode (point table), navigate to the "Basic"... -

Page 35: Set The Parameter Of Command Pulse Input Form

5.3.7 Set the parameter of command pulse input form It is required to set the command input pulse form dependent on the upper unit pulse train when using the Position control mode (pulse input). ・Input form (3 types) ① Forward rotation pulse train/Reverse rotation pulse train ②... - Page 36 ① Set the "PA13" to "201" in the "Basic" tab. ② Click on the "Single Axis Write" button. ③ Turn the power OFF and ON again. Parameter is enabled. ② ① - 34 -...

-

Page 37: Verify Of Parameters

5.3.8 Verify of parameters If you want to compare the "parameter" set in the setup software with the " Parameters set in the driver" / "Initial value parameter" / "Saved parameter", perform " Verify ". ① Click the “Verify” button on the [Parameter Setting] window. "Verfication Setting" screen will display. ②... -

Page 38: Parameter Initialization

5.3.9 Parameter initialization If you want to initialize parameters in the driver, please perform "Set to Default". When you initialize the parameters, parameters can not be undone. Please be sure to save the parameters in use. (Refer to “LECSA Operation Manual (Simplified Edition)”, section 5.8.1 for the parameter storage method.) ①... -

Page 39: Jog Mode In The Setup Software

5.4 JOG Mode in the Setup Software ① T The “JOG Mode” window can be displayed by selecting “Jog Mode” from the “Test Mode” menu in the setup software. ② Click “OK”. (When using this function, all external input signal operation will be diabled. If controlling using a PLC or other upper device, please turn off the power and reset the device before use.) ①... -

Page 40: Jog Mode

5.4.1 JOG Mode ① In order to prevent accidental impact at the end of the stroke, test actuator operation at low speed. “LECSA Operation Manual (Simplified Edition)”, section 5.6.2 for motor speed configuration. See “LECSA Operation Manual (Simplified Edition)”, section 5.6.3 for Acceleration/deceleration time. ②... -

Page 41: Changing I/O Signal Allocation

5.5 Changing I/O Signal Allocation Input/output signal assignment can be changed as appropriate from initial settings. There may be cases when changes to the Input/output signal assignment are required for actuator operation. Please be aware that any changes will alter signals entered as initial settings. Please allocate it according to your system specification. - Page 42 During Actuator Operation: <Signals which must be ON during actuator operation> Set PD01 as 0C24. The following signals will automatically turn on when power supply turns on. Servo-on OFF:Servo-off ON :Servo-on (operational) Forward rotaion Stroke end OFF: Forward rotaion Stroke end (normally closed contact) ON :Forward rotaion Stroke end off (operational) Reverse rotaion Stroke end...

-

Page 43: Initial I/O Signal Allocation

5.5.2 Initial I/O Signal Allocation (1) Position control mode (pulse input): The initial (Default) allocation of I/O signals is shown below. PD03 to PD14 Input signal assignment (CN1-3 to CN1-8) PD15 to PD18 Output signal assignment (CN1-9 to CN1-12) Input signal points (6): (position control mode) and initial assignment Output signal points (4) (position control mode) and initial assignment See “LECSA Operation Manual”, section 3.5 and “LECSA Operation Manual”,section 3.6 for details regarding signals. -

Page 44: Signal Allocation Using Setup Software

5.5.3 Signal Allocation using Setup Software ① The “Parameter Setting” window will be displayed when “parameter list” is selected from the “parameters” menu in the setup software. ② Click the I/O tab. ③ When changing the allocation of signals, parameters for “PD02” - “PD18” can be altered. ③... -

Page 45: Allocation Examples For Position Control Mode (Pulse Input)

5.5.4 Allocation Examples for Position Control Mode (Pulse Input) (1) Example of Gain switch (CDP) Settings When changing pin CN1-4 from Servo-on (SON) to Gain switch (CDP). ① ① Changing PD05 from 0202 to 0211 - 43 -... - Page 46 (2) Symbol allocation using the setup software: Changing pins CN1 – 4 from servo-on (SON) to gain switch (CDP): ① Change PD05 from 0202 to 0211 in the I/O tab. ② Click on the "Single Axis Write" button. ③ Cycle the power off, then on for the parametersto be enabled.. ②...

-

Page 47: Setting A Maximum Of 7 Points Using The Point Table In Positioning Mode (Point Table)

5.5.5 Setting a Maximum of 7 Points using the Point Table in Positioning mode (Point Table) The point table can reach a maximum of 7 points using input signals DI0, DI1 and DI2. The default allocation, allocates signals DI0 to (CN1-5) and DI1 to (CN1-23). Note –... - Page 48 (1) Example of Allocation of a Maximum of 7 Points in current SINK (NPN) Interface Changing pin CN1-7 from Reverse rotation start (ST2) to point table no./program no. selection 3 (DI2): ① ① Change PD12 from 0808 to 2E08. Note – CN1-23 can only be used if the input is configured as current sink NPN - 46 -...

- Page 49 (2) Example of Allocation of a Maximum of 7 Points in current Source (PNP) Interface ① Changing pins CN1-3 from Automatic/manual selection (MD0) to point table no./program no. selection 3 (DI2): ② Changing pins CN1-7 from Reverse rotation start (ST2) to point table no./program no. selection 2 (DI1): ①...

- Page 50 (3) Example of Signal Allocation using the setup software When changing pins CN1-7 from Reverse rotation start (ST2) to point table no./program no. selection 3 (DI2): ① Change PD12 from 0808 to 2E08 in the I/O tab. ② Click on the "Single Axis Write" button. ③...

-

Page 51: I/O Signal Allocation Check

5.5.6 I/O Signal Allocation Check The ON/OFF state (including layout check) and signal names allocated to CN1 can be checked. When parameters for PD02 - PD18 have been changed, It is necessary to confirm these are correctly assigned. ① From the Monitor menu of the Setup Software select I/O Monitor. The I/O Monitor window opens and displays the inputs and outputs that are applicable. -

Page 52: Positioning Mode In Setup Software

5.6 Positioning Mode in Setup Software ① From the Test Mode menu of the Setup Software select Positioning Mode. The Move Distance Unit Selection window opens. ② Check Command pulse unit (Electronic gear valid) and click OK. Electronic gear ratio that is set in the PA05 / PA06 / PA07 is enabled. ③... -

Page 53: Positioning Mode

5.6.1 Positioning Mode ① In order to prevent accidental impact at the end of the stroke, operate the actuator at a low speed initially. When changing speed or movement, increase the values whilst checking operation (Change motorspeed, acceleration/deceleration time, movement distance values if required). See “LECSA Operation Manual (Simplified Edition)”,section 5.6.2 for motorspeed configuration. -

Page 54: Motorspeed Configuration

5.6.2 Motorspeed Configuration <Rotation Speed Configuration> ① Motorspeed (r/min) configuration. *r/min (rpm): Indicated motor rotation speed (motor rotations/min) Rotation speed must be between 0 and the allowable speed limit for each actuator. Please be aware that the actuator will not operate if this is set to 0. If the rotation speed is too low, this may cause vibration;... -

Page 55: Acceleration/Deceleration Time Configuation

5.6.3 Acceleration/deceleration Time Configuation < Acceleration/deceleration Time Configuration> ① Acceleration/deceleration time (ms) configuration: The acceleration/deceleration time sets the amount of time (ms) in which a prescribed number of rotations (3000[r/min]) is reached. The acceleration/deceleration time must be set to a value between 0 and the allowable acceleration/deceleration speed for each actuator. -

Page 56: Move Distance Configuration And Operation< Move Distance Configuration

5.6.4 Move distance Configuration and Operation < Move distance Configuration> < Move distance Configuration> ① Set the move distance [pulse]. Select a value within the stroke range. ② Actuator position will operate using [Forward (CCW)], [Reverse (CW)]. The position at which power is turned ON will be set as the home position, and the actuator will travel the amount set as move distance (check wiring and parameters If operation is not performed correctly). -

Page 57: Positioning (Point Table) Operation Using The Setup Software

5.7 Positioning (Point Table) Operation using the Setup Software This feature is only available in positioning (point table) mode. When positioning using the positioning (point table) mode, the point table (target position, speed data, acceleration time, deceleration time etc.) must be configured. 5.7.1 Point table List ①... -

Page 58: Point Table Data

5.7.2 Point Table Data By parameters "PE01:Command mode selection” settings, registration method of data of the point table is different. (1) If the parameter " PE01:Command mode selection " setting is "0000:Absolute value command system " . Item Setting range Unit Description (1) When using this point table as absolute value command system,... -

Page 59: Point Table (Target Position) Configuration

5.7.3 Point table (Target position) Configuration < Target position Configuration> ① Please set the parameters as "PE02 (Feed function selection)" and "Feel length multiplication (STM) (Multiplier)". Please change the "PE02 (Feed function selection)". " Feel length multiplication (STM) (Multiplier)" will be automatically scaled. For actuators with a stroke less than 1000mm, set parameter “PE02 (Feed function selection)”... - Page 60 1) Please click on the [Detailed Setting] button in the [Point Table] tab. 2) Please confirmation or change of [Feel length multiplication (STM) (Multiplier)]. 3) Click on the "OK" button. 4) Target position input range varies depending on the set value of [Feel length multiplication (STM) (Multiplier)].

- Page 61 ② Configure target position (mm). Set to a value within the stroke range. ② * If electronic gear parameters (PA05/PA06/PA07) are set according to “LECSA Operation Manual (Simplified Edition)”,section 5.3.4 in positioning mode: The smallest unit for actuator movement is 1[μm] (0.001[mm]). - 59 -...

-

Page 62: Point Table (Rotation Speed) Configuration

5.7.4 Point table (Rotation Speed) Configuration <Rotation Speed Configuration> ① Rotation speed configuration: *r/min (rpm): motor command rotation speed (motor rotations/min) Travel speed (mm/s) must be converted into rotation speed (r/min). See below for the conversion formula. Example using a 20[mm] Lead Actuator with target travel speed of 500[mm/sec] Rotations per second ÷... -

Page 63: Point Table (Acceleration Time Constant/Deceleration Time Constant) Configuration

5.7.5 Point Table (Acceleration time constant/Deceleration time constant) Configuration < Acceleration time constant/Deceleration time constant Configuration> ① Acceleration time constant (ms)/Deceleration time constant (ms) configuration: Acceleration/deceleration (mm/s ) must be converted to the acceleration time constant/deceleration time constant (ms). See below for the conversion formula. Conversion example for a 8[mm] lead actuator driven at an acceleration of 3000 [mm/sec Rated Motor Rotation Speed (mm/s) *Note) -

Page 64: Single-Step Feed

5.7.7 Single-Step Feed In Test mode a single step within point table can be executed. ① From the “Test” menu in the setup software select “Single-step Feed” which opens a window for “Single-step feed”. (When using this function, external input signal operation will be disabled. If controlling using a PLC or other upper device, ensure the power is turned off and then on before operation.) ②... -

Page 65: Saving/Loading Parameters

5.8 Saving/Loading Parameters 5.8.1 Saving Parameters ① From the “Parameter Setting” window in the setup software, select “Save As”. ② Please specify location to be saved. ③ Please enter any file name. ④ Click “Save”. Files Saved .prm2 Settings files for parameters PA, PB, PC, PD and PE * Note Always upload current parameters from the driver to the software before saving. -

Page 66: To Load Saved Parameters

5.8.2 To Load saved Parameters ① From the “Parameter Setting” window in the setup software, select “Open”. ② Please specify location of the file. ③ Please select the file you wish to import parameters [.prm2]. ④ Click “Open”. Parameters will be loaded. ①... -

Page 67: Saving/Loading Project

5.9 Saving/Loading Project 5.9.1 Saving Project ① From the “Project” menu in the setup software, select “Save As”. ② Please specify location to be saved. ③ Please enter any file name. ④ Click “Save”. Project will be saved in the specified folder. If you change the drive / path name, it will be saved in the "drive ¥path name ¥... -

Page 68: To Load Saved Project

5.9.2 To Load saved Project ① From the “Project” menu in the setup software, select “Open”. ② Please select the "drive ¥ path name ¥ project name" that you want to read parameters are stored. ③ Please select the file you wish to import project [.mrc2]. ④... -

Page 69: Saving/Loading Point Table

5.10 Saving/Loading Point table 5.10.1 Saving Point table ① From the “Point Table” window in the setup software, select “Save As”. ② Please specify location to be saved. ③ Please enter any file name. ④ Click “Save”. ① ② ④ ③... -

Page 70: To Load Saved Point Table

5.10.2 To Load saved Point table ① From the “Point table” window in the setup software, select “Open”. ② Please specify location of the file. ③ Please select the file you wish to import point table [.ptb2]. ④ Click “Open”. Point table will be loaded. -

Page 71: Acquisition Of Motion Waveform With Graph Monitor

5.11 Acquisition of motion waveform with graph monitor With the setup software (MR Configurator2 : LEC-MRC2E) monitor graph function, the motion waveform during electric actuator operation can be obtained as described below. ① Click “Monitor” - “Graph” of Setup software to display “Graph” window. ①... -

Page 72: Under The Setting Tab: Setting Of The Items To Display The Graph

5.11.1 Under the setting Tab: Setting of the items to display the graph Set the items to display analogue and digital waveform, trigger conditions and time for the Horizontal axis of the graph. Click the “Setting” tab of the “Setting” window to set the items to display the waveform, trigger conditions and horizontal axis of the graph. - Page 73 (2) Trigger “Trigger” is a condition which decides the display timing of the graph. If trigger conditions are not satisfied, waveform will not be displayed. ① Click “ “ of [Data] to set the condition. (In general, set the Motor speed.) ①...

- Page 74 (4) Waveform Set the waveform data which will be displayed in the graph. ① Click “ “ of each “Analog” or “Digital” and set the type of waveform to be displayed. ① The analogue and digital waveforms that can be set with LECSA are shown below. ■Analogue waveform Name Function...

- Page 75 Name Function Unit Note Multi-revolution The move distance from the home position in the 1rev counter absolute position detection system is displayed in the multiple-revolution counter value of the absolute position encoder. Load inertia The estimated ratio of the servo motor axis converted 0.1times moment ratio load inertia moment to the servo motor inertia...

-

Page 76: Trigger Wait

5.11.2 Trigger wait When the “Start” button is clicked, the screen will be on stand-by. When trigger conditions are satisfied during the trigger wait, waveforms can be captured and displayed. Click the “Start” button every time measurement fresh capture is required. (The advantage of this method of capturing the waveform is a waveform will not be updated in the case of an incorrect operation.) ①... -

Page 77: Operation Instruction

5.11.3 Operation Instruction When the PLC on the master side sends the operation command, the actuator will operate. When the trigger conditions in 5.11.1 (2) are satisfied, the operation waveforms can be captured. When the time set in 5.11.1 (1) has passed after the acquisition start, the acquisition of the waveforms will complete and waveforms are displayed on the screen. -

Page 78: Saving Of Waveform

5.11.4 Saving of waveform After the waveform is displayed, it is possible to save the data in 3 ways. ① Click the “Save As” button. Select the folder in which the step data is to be saved and save the data. Waveform data file (extension: gpf2) will be prepared. -

Page 79: Display All Monitor List

5.12 Display All Monitor List The method how to obtain the electric actuator condition is described with the display all function of the setup software. ① Click “Monitor” - “Display All” of the setup software to display “Display All” window. ②... - Page 80 Indication Name Function Unit range Command pulse The frequency of the position command input pulses is frequency displayed. Reverse rotation is indicated by a minus (-) sign. -999999999 to (Note) -1500 to 1500 kpulse/s is showed when pulse 999999999 inputting command pulse. Pulse unit of encoder is displayed during test operation.

-

Page 81: Home Position Return Method

6. Home Position Return Method 6.1 Position Control Mode (Pulse Input) When using the home position return in position control mode (pulse input), use the home position return function in the positioning module of the upper PLC. Please see product operation manuals for positioning module layouts, parameter configuration, home position return method etc. -

Page 82: Stopper Type Home Position Return

6.2.1 Stopper type home position return In stopper type home position return, a machine part is pressed against a stopper using to make a home position return and that position is defined as the home position. After completion of stopper type home position return, please move to any position (Not pressed position) from the pressing position. - Page 83 (2) Timing chart Automatic/manual selection (MD0) (Note 4) DI0, DI1, and DI2 (Note 1) Forward rotation start 6ms or more 6ms or more (ST1) Reverse rotation start (ST2) Parameter No. PC14 (Note 3) Parameter No. PE 11 Parameter No. PC14 Torque limit value Acceleration time Home position...

-

Page 84: Diriving Methods For Each Mode

7. Diriving Methods for Each Mode 7.1 Position Control Mode (Pulse Input) The motor rotation speed and direction is controlled using the pulse train and executes positioning operation. 7.1.1 Position Control Mode Instructions The command pulse sent as input to the driver from the positioning unit and the driver operates the actuator in accordance with the command pulse. -

Page 85: Speed Control Mode

7.2 Speed control mode This mode allows for accurate, smooth control of the rotation speed and direction of the servo motor. * To set [PC**], set parameter write restriction [PA19] to "00E". 7.2.1 Speed Control Mode Operation Instruction The servo motor will rotate when signal ST1 and ST2 turn on. An operation example of the speed control mode is shown below. -

Page 86: Torque Control Mode

7.3 Torque control mode Servo motor output torque is controlled. Speed control function is also available. * To set [PC**], set parameter write restriction [PA19] to "00E". 7.3.1 Torque Control Mode Operation Instruction The servo motor will rotate when signal RS1 and RS2 turn on. An operation example of the torque control mode is shown below. -

Page 87: Positioning Mode (Point Table Method)

7.4 Positioning Mode (Point table method) Positioning operation can be executed by setting the target position, rotation speed, acceleration time constant, deceleration time constant to the point table data. (The maximum points that can be set in point table is 7.) See “LECSA Operation Manual”,section 13.3 for details regarding the positioning mode (point table). - Page 88 Automatic/manual selection (MD0) Servo-on (SON) (Note 1) 6ms or more 6ms or more Forward rotation start (ST1) Point table No. Point table 3ms or less No.3 Forward Point table rotation No.1 Servo motor 0r/min speed Point table Reverse No.2 rotation In-position (INP) Rough match (CPO) (Note 2)

-

Page 89: Setting Method

7.4.2 Setting method (1) Setting with the button on the front of the driver Driver operation Ex.) When the servo motor rotation speed of point table No.3 is changed from 2500 (r/min) to 1000 (r/min) . display a. When the "MODE" button on the driver operation is pressed, the display will be shifted as shown below. Select "P-1". -

Page 90: Positioning Mode (Programimg Method)

7.5 Positioning Mode (Programimg Method) To perform the positioning operation, create a program using target position, rotation speed, acceleration constant and deceleration constant (The maximum number of programs is 8 for which a total of 120 steps can be created per program). -

Page 91: Command In The Program System

7.5.2 Command in the program system An example of the program commands is shown below. See “LECSA Operation Manual”,section 13.4.2 for details regarding programming command. The maximum number of program steps is 120. Though up to 8 programs can be created, the total number of each program steps is up to 120. -

Page 92: Operation Instruction Method Of Program System

7.5.3 Operation Instruction Method of Program System Select the program No. represented by the values of DI0, DI1 and DI2 and start the operation by selecting ST1. Positioning Connector mode Device Symbol Functions/Applications pin No. division Point table No. CN1-5 <In point table method>... - Page 93 8. Troubleshooting 8.1 Alarms and Warning List POINT As soon as an alarm occurs, turn off servo-on (SON) and the main circuit power supply. When a fault occurs during operation, the corresponding alarm or warning is displayed. If an alarm or warning occurrs, refer to“LECSA Operation Manual”,section 8.2 or “...

- Page 94 3-digit, 7-segment The servo motor stops Name /does not stop. display Stops A.90 Home positioning incomplete warning Does not stop A.91 Driver overheat warning Stops A.96 Home position setting error Does not stop A.97 Program operation disabled Stops (Note 2) A.98 Software limit warning Stops (Note 2)

- Page 95 8.2 Alarm Display The contents of the alarm / warning that is currently occurring in the driver are displayed in the alarm display function of the setup software. In addition, history is listed for alarms that occurred in the past. ①...

- Page 96 Revision history No.LEC-OM05601 Dec./2012 1st printing No.LEC-OM05602 Dec./2013 2nd printing No.LEC-OM05603 Jun./2014 3rd printing No.LEC-OM05604 Aug./2014 4th printing No.LEC-OM05605 Oct./2014 5th printing No.LEC-OM05606 Oct./2014 6th printing No.LEC-OM05607 Dec./2014 7th printing No.LEC-OM05608 Apr./2015 8th printing No.LEC-OM05609 Sep./2015 9th printing No.LEC-OM05610 (No.JXC※-OMT0051) Sep./2016 10th printing No.LEC-OM05611 (No.JXC※-OMT0051-A) Jun./2017 11th printing...

Need help?

Do you have a question about the LECSA Series and is the answer not in the manual?

Questions and answers