Technomark M4 inline Installation Manual

Hide thumbs

Also See for M4 inline:

- Software user's manual (47 pages) ,

- Instructions manual (26 pages) ,

- Maintenance manual (22 pages)

Table of Contents

Advertisement

Quick Links

TECHNOMARK

3 Allée Michaël FARADAY

Parc d'activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail : info@technomark-marking.com

Installation Manual

Version

Revision

Revision date

Produced by

Validated by

3 Allée Michaël FARADAY

Parc d'Activités STELYTEC

42400 SAINT-CHAMOND

www.technomark-marking.com

Tel.: +33 (0)4 77 22 25 91

Fax: +33 (0)4 77 22 38 91

Original version from 27/08/2014

1.1

06/11/2015

JLD

FRANCE

Page 1 of 44

Version from 04/11/2015

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Advertisement

Chapters

Table of Contents

Summary of Contents for Technomark M4 inline

- Page 1 Fax: +33 (0)4 77 22 38 91 Page 1 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015...

-

Page 2: Table Of Contents

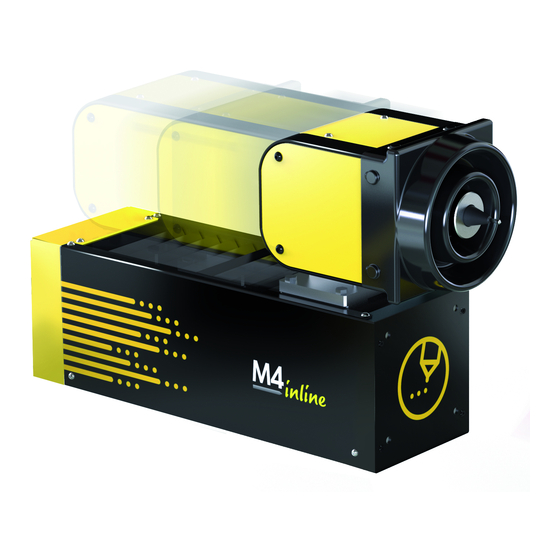

TRAÇABILITÉ CRÉATIVE CREATIVE TRACEABILITY Before we start the TECHNOMARK company would like to warmly thank you for your confidence. You have chosen the M4 Inline, the first intelligent marking tool (IDI track & mark) that is dedicated to marking integration for ensuring your products' identification. - Page 3 List of illustrations _________________________________________________________________________ 43 Page 3 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015...

-

Page 4: Introduction

You should consult the TECHNOMARK company to learn of any changes that may have been made. The TECHNOMARK company can in no case be held responsible for any incidental that is related to damages, direct or indirect, or even exceptional, including but not limited to financial losses related to the use of information contained in this manual. -

Page 5: Illustration 1: Ce Certificate

Illustration 1: CE Certificate Page 5 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 6: Illustration 2: Oc/Cb Certificate

Illustration 2: OC/CB Certificate Page 6 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 7: Precautions Of Use

PLEASE READ THE FOLLOWING BOXED TEXT CAREFULLY BEFORE USING YOUR MARKING MACHINE The Technomark marking machine must be used and installed by personnel who are trained and qualified for Th Th Th Th this purpose. - Page 8 Page 8 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015...

-

Page 9: Unpacking

Head cable Quality test plate Head checklist Maintenance kit (Accessory – not included in the standard machine) 5.1.2. Control unit M4 inline control unit Power cable (depending on country) SubD 25 point male connector Documentation CD Control unit Checklist Control unit bay mounting set (Accessory - not included in the standard machine) -

Page 10: Description Of The Different Elements

The head is composed of different elements: 1. Head connector (depending on the chosen option the connector may be in another position) 2. Protection cover: Flexible for M4 inline 50 (image opposite) Rigid for M4 inline 120 3. Impact unit 4. Stylus The head is also provided with a fixing kit which is not visible in this position. -

Page 11: Illustration 6: Connector Description

Th Th Th Th Th Page 11 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 12: Quality Test Plate

Quality control date Marking head serial number Operator who performed the test product code datamatrix Illustration 7: M4 inline 50 Quality test plate M4 inline 120 format From top to bottom: Quality control date Product code Operator who performed the test... -

Page 13: Head Checklist

Illustration 10: Maintenance kit Page 13 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 14: Control Unit

5.2.8. Sub-D 25 connector In order to connect to the M4 inline control unit 16-way card, a Sub-D 25 point male connector kit is supplied which must be screwed in place. See paragraph 8.2.4 Cabling the for a cabling diagram or refer to the manual Interfacing instruction for M4 inline. -

Page 15: Control Unit Checklist

6000) and QWERTY (Reference: NAI0-6001). The special characters which are available are defined in the control unit's special characters menu. Th Th Th Th Th Th Compatibility with different keyboards that are not provided by Technomark is not guaranteed. Page 15 of 44 TECHNOMARK www.technomark-marking.com... -

Page 16: General Presentation Of The Machine

TRAÇABILITÉ CRÉATIVE CREATIVE TRACEABILITY 6. General presentation of the machine 6.1.Control unit 6.1.1. Dimensions Illustration 15: Dimensions of M4 inline control unit 6.1.2. Connector description Connector description 1. Marking head connector 2. Power plug and ON / OFF switch 3. 12 point accessory connector 4. -

Page 17: Marking Head

6.2.Marking head 6.2.1. Possible configurations The M4 inline machine exists with two different window sizes M4 inline 50 (50 x 55mm) and M4 inline 120 (120 x 55mm). In addition to these dimensions the head connector can be either be located on the top surface of the head (standard) or at the rear (NOI0-0001 option to be specified in the order). -

Page 18: Dimensions

6.2.2.1. M4 inline 50 Illustration 19: Dimensions of M4 inline 50 head In this illustration the machine is shown with a standard stylus and its standard fixing kit. Longer styluses are available as an accessory (See 7.4 Styluses and stylus guides), as are the different compatible fixing kits (See 7.5 Machine fixing kit (compatible with Multi4 ranges)). -

Page 19: Marking Window

However the Y dimensions of the marking window remain the same for all window sizes: 55mm (2.165in). Illustration 20: Marking window in Y Illustration 21: Marking window in X (rear view of machine) M4 inline 50 M4 inline 120 Wx 50mm (1.968in) 120mm (4.724in) 29mm (1.141in) -

Page 20: Normal Operating Conditions

16A maximum protection. The building's electrical system will provide protection from ground faults. Your M4 inline marking machine has unreservedly been approved, and the certified test report is available upon request. When used intensively the active part of the machine (impact unit solenoid) may exceed a temperature of 70°... -

Page 21: List Of Available Accessories And Options

7.3.19 inch rack mounting plates (Optional accessory) Your M4 inline control unit can be installed in a 19 inch rack by using the rack mounting plate kit available as an accessory: reference NAI0-5001. Installation instructions are available in Paragraph 8.2.3 19 inch rack installation. -

Page 22: Styluses And Stylus Guides

100mm length: Stylus guide for 100mm (3.94in) – Reference TKF052A-100 Page 22 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 23: Machine Fixing Kit (Compatible With Multi4 Ranges)

CREATIVE TRACEABILITY 7.5.Machine fixing kit (compatible with Multi4 ranges) The marking head is supplied with a standard M4 inline fixing kit. Specific fixing kits exist if the machine is replaced or the installation updated. They allow an M4 inline machine to be installed in the place of a Multi4 machine while keeping the original machine in the same position (except the Multi 4 V1). -

Page 24: Compatibility Fixing Kit For Reinforced Multi4 V2 Fixing Kit

Multi 4 V1 machines only come with a single window size (110 x 50 mm) this fixing kit allows for the placement of an M4 inline 120. As the window size is slightly smaller than the original M4 inline 120 (120 x 55mm) the Y position shifts 5mm towards the front of the marking head, the X position remains unchanged. -

Page 25: Equipment Installation

CREATIVE TRACEABILITY 8. Equipment installation To obtain the best results from your M4 inline machine in terms of quality and performance, please follow the following recommendations when integrating the control unit and the marking head. If your practical application requires a different installation from these presented in this document please contact Technomark's After Sales Customer Service or your retailer for information. -

Page 26: Illustration 24: Recommended Integration Orientations (1/2)

Illustration 25: Recommended integration orientations (2/2) Page 26 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 27: Illustration 26: Integration Orientations Requiring Validation (1/2)

The integration should take into account all the constraints related to this position. Inspections and regular cleaning with an air blower may be necessary to remove any deposits and accumulations of material on the device and its guides (refer to the M4 inline Maintenance Manual for maintenance frequency) . -

Page 28: Illustration 27: Integration Orientations Requiring Validation (1/2)

Illustration 27: Integration orientations requiring validation (1/2) Page 28 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 29: Positioning Distance Relative To The Parts To Mark

(homogeneity of point depth and their alignment) according to the machine setting. The following illustrations show the nominal case position which is recommended by Technomark. In the following diagram the machine is shown with the standard stylus (length 60mm, sharpened to 90°). In the case... -

Page 30: Illustration 29: Minimum Stylus Part Distance (Rear View)

Illustration 30: Maximum stylus part distance (rear view) Page 30 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 31: Illustration 31: Example Of Impact Depth Based On The Force And Distance For Aluminium

Illustration 32: Example of impact depth based on the force and distance for steel Page 31 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 32: Attaching The Head

By default your equipment comes with a standard M4 inline fixing kit. It is recommended that this is used for fastening your machine (Other types of accessories are available, see 7 List of available accessories and options). -

Page 33: Illustration 34: Head Attachment - Machine Configuration With Noi0-0001 Option

The Ox distance depends on the marking window, refer to Chapter 6.2.3 Marking window. Page 33 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 34: Connecting The Marking Head

Page 34 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 35: Control Unit

250VAC, UL: 115 V - 300 VDC, size 5 x 20mm (e.g.: 0001.2511 Schurter 0001.2511, UL E41599, VDE 40014395). Page 35 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 36: Installation In A Cabinet Or On Workbench

If it is placed in a space that is closed on more that 3 sides, we recommend leaving 5cm (2in) on each side, whatever its orientation. Illustration 37: Installation of M4 inline control unit in a cabinet - laid flat Illustration 38: Installation of M4 inline control unit in a cabinet - vertically placed... -

Page 37: Inch Rack Installation

CREATIVE TRACEABILITY 8.2.3. 19 inch rack installation The M4 inline control unit can be installed in a 19 inch rack using the accessory rack mounting plates: ref. NAI0-5001. The occupied space is equivalent to 3 U. Illustration 39: M4 inline control unit installed in a 19 inch rack... -

Page 38: Illustration 40: Dismantling The Vertical Installation Feet

Illustration 42: Attaching the rack mounting bracket (2/2) Page 38 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 39: Cabling The 16-Way Card

8.2.4. Cabling the 16-way card The M4 inline control unit features a 16-way card, which allows the user to choose whether each way is an input or an output and its associated function (see M4 inline Software User Manual Chapter 16-way configuration) The control unit is supplied with a subD 25 male connector kit to enable the integrator/user to connect it as required. -

Page 40: Illustration 43: 16-Way Connector References (Rear View Of Control Unit)

Illustration 44 : Correspondance repères connecteur 16 voies et fonctions Page 40 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... -

Page 41: Illustration 44: Example Of Input Cabling With Internal Power Supply

Be Be Be Be Be Be Be Page 41 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015... - Page 42 The maximum current permitted by one way of the 16-way card is 1A. Page 42 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015...

-

Page 43: List Of Illustrations

Illustration 36: Unobstructed zone at the rear of the control unit ___________________________________________________ 35 Illustration 37: Installation of M4 inline control unit in a cabinet - laid flat ___________________________________________ 36 Illustration 38: Installation of M4 inline control unit in a cabinet - vertically placed ____________________________________ 36... -

Page 44: Technomark

Illustration 47: Example of output cabling with external power supply ______________________________________________ 42 Page 44 of 44 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail : info@technomark-marking.com Version from 04/11/2015...

Need help?

Do you have a question about the M4 inline and is the answer not in the manual?

Questions and answers