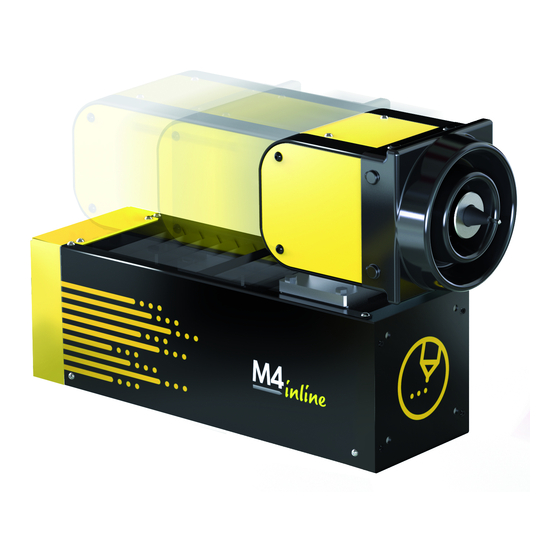

Technomark M4 inline Maintenance Manual

Hide thumbs

Also See for M4 inline:

- Installation manual (44 pages) ,

- Software user's manual (47 pages) ,

- Instructions manual (26 pages)

Table of Contents

Advertisement

Quick Links

TECHNOMARK

3 Allée Michaël FARADAY

Parc d'activités STELYTEC

42400 SAINT-CHAMOND (France)

Tel: +33 (0) 4 77 22 25 91

Fax: + 33 (0) 4 77 22 38 93

E-mail: info@technomark-marking.com

Maintenance manual

Type

Revision

Revision date

Drafted by

Validated by

3 Allée Michaël FARADAY

Parc d'Activités STELYTEC

42400 SAINT-CHAMOND

www.technomark-marking.com

Tel.: +33 (0)4 77 22 25 91

Fax: +33 (0)4 77 22 38 91

Original version from 22/08/2014

1.3

27/04/2016

FT

SJ

FRANCE

Page 1 of 22

Model from 14/04/2016

TRAÇABILITÉ CRÉATIVE

CREATIVE TRACEABILITY

www.technomark-marking.com

Advertisement

Table of Contents

Summary of Contents for Technomark M4 inline

- Page 1 Fax: +33 (0)4 77 22 38 91 Page 1 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

-

Page 2: Table Of Contents

TRAÇABILITÉ CRÉATIVE CREATIVE TRACEABILITY Before we start the TECHNOMARK company would like to warmly thank you for your confidence. You have chosen the M4 inline, the first intelligent marking tool (IDI track & mark) that is dedicated to marking integration for ensuring your products' identification. -

Page 3: Introduction

You should consult TECHNOMARK to learn of any changes that may have been made. Under no circumstances may TECHNOMARK be held responsible for any direct or indirect incident related to damages, even if exceptional, including, but not limited to, financial losses related to the use of information contained in this manual. -

Page 4: Customer Service Team

Tailored solutions If required, TECHNOMARK can provide you with a machine free of charge while we deal with your equipment. You can get in touch with our customer service team via: ... -

Page 5: Identity Of Your Marking Equipment

Illustration 3: 120x55 marking head nameplate. Page 5 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... -

Page 6: Components And Wear Parts

Illustration 4: Exploded view – 50x55 marking head. Page 6 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... -

Page 7: Illustration 5: Exploded View - Impact Unit Parts

Illustration 5: Exploded view – Impact unit parts Page 7 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... -

Page 8: Illustration 6: Exploded View - Valve Sub-Assembly/Moving Part - 50X55 Window

Detection magnets Page 8 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... -

Page 9: Preventive Maintenance: Maintenance Timetable

Page 9 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... - Page 10 -Check (always with the control unit disconnected) that the axes of the X/Y have no hard points. To do this, move the internal part of the machine, using the guides for grip. DO NOT MOVE BY PUSHING THE IMPACT UNIT -Ask the TECHNOMARK team, or an authorised dealer, to service the machine. This service will include: ...

-

Page 11: Machine Information

Illustration 8 : Information window Page 11 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... -

Page 12: Sharpening The Stylus

In addition, a lateral impact on a hard material may leave the tip chipped and result in poor quality marking. All styluses provided with your TECHNOMARK machine (whether the standard model or with optional extras) are solid carbide. As a result, it is possible to sharpen them using a suitable wheel. -

Page 13: The Spring

- the replacement of a M4 inline marking head by a Multi4 V3 marking head (with the M4 inline control unit) - or the replacement of a Multi4 V3 marking head by a M4 inline marking head (with the Multi4 V3 control unit) Important: this has been made possible for the sole purpose of avoiding production stops. -

Page 14: Remedial Maintenance: Error Detection

Page 14 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016... - Page 15 The depth of the marking depends on the impact force, but also the distance between the stylus and the part. For the M4 inline machine, the recommended distance is 3mm. With this setting, a gradual 1 to 6 force depth is obtained.

-

Page 16: Error Codes

TRAÇABILITÉ CRÉATIVE CREATIVE TRACEABILITY 8.2.Error codes The TECHNOMARK machine can help you detect potential malfunctions. If a problem is detected, error codes will appear on the screen. The window disappears when you click Refer to the following table to identify the issue. - Page 17 Customer Service Team. Page 17 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

- Page 18 Customer Service Team. Page 18 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

- Page 19 Service Team. Page 19 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

- Page 20 Customer Service Team. Page 20 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

- Page 21 (contact details on page 4). Page 21 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

-

Page 22: List Of Illustrations

Illustration 9 : Maintenance window _________________________________________________________________________ 12 Page 22 of 22 TECHNOMARK www.technomark-marking.com 3 Allée Michaël FARADAY Parc d’activités STELYTEC 42400 SAINT-CHAMOND (France) Tel: +33 (0) 4 77 22 25 91 Fax: + 33 (0) 4 77 22 38 93 E-mail: info@technomark-marking.com Model from 14/04/2016...

Need help?

Do you have a question about the M4 inline and is the answer not in the manual?

Questions and answers