DeZurik G Series Manual

Hide thumbs

Also See for G Series:

- Instruction (19 pages) ,

- Manual (17 pages) ,

- Instructions manual (13 pages)

Summary of Contents for DeZurik G Series

- Page 1 DEZURIK MANUAL G-SERIES ACTUATOR USED ON PEC 100% PORT PLUG VALVES D10456 Instruction August 2012 DeZURIK, Inc. Sartell, Minnesota USA | Phone: 320-259-2000 | www.dezurik.com | info@dezurik.com...

- Page 2 Recommended spare parts are listed on the assembly drawing. These parts should be stocked to minimize downtime. Order parts from your local DeZURIK sales representative, or directly from DeZURIK. When ordering parts, please include the 7-digit part number and 4-digit revision number (example: 9999999R000) located on the data plate attached to the valve assembly.

-

Page 3: Table Of Contents

DeZURIK Table of Contents Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -... -

Page 4: Description

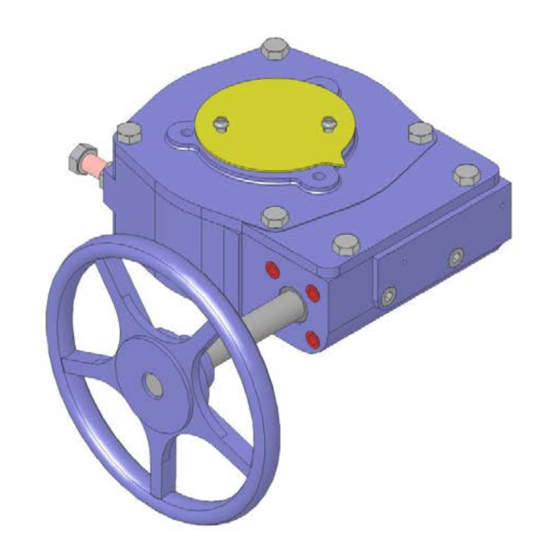

DeZURIK Description The manual operated G-Series actuator is designed to operate a PEF 100% Port Eccentric plug valve. External adjustable stops limit actuator stroke for both the open and closed valve positions. This actuator is available in two sizes: Size 6 and Size 12. See Figure 1 to identify which unit you have. -

Page 5: Parts Identification

DeZURIK Parts Identification Figure 2— Actuator Parts Identification August 2012 Page 5 D10456... -

Page 6: Stop Adjustments

DeZURIK Stop Adjustments The open and closed position stops prevent the valve plug from rotating beyond the optimum open and shutoff positions. If the actuator is factory-mounted on the valve, the stops are preset, and do not require further adjustment. If the actuator is not factory mounted on the valve, or if the actuator has been removed, the stops will require adjustment as described below;... -

Page 7: To Adjust The Open Position Stop

DeZURIK Stop Adjustments (Continued) To Adjust the Open Position Stop See Figure 5 for stop identification. Adjusting stops with flow in the pipeline can allow the valve to close causing personal injury and damaging the flow system. Shut down the flow and relieve pipeline pressure before making stop adjustments. - Page 8 DeZURIK Stop Adjustments (Continued) Figure 5— Open and Closed Position Stop Identification Actuator Input Torque (ft-lbs) Valve Actuator Direct Reverse Pressure Drop (psi) Size Size Pressure Drop(psi) 3 & 4 Note: The “N/A” designation in Table A indicates that the Valve/Actuator combination cannot be used for that particular reverse pressure.

-

Page 9: Removing Actuator From Valve

DeZURIK Removing Actuator from Valve Refer to Figure 6 for connecting parts identification. Figure 6— Connecting Parts Identification Flow in the pipeline with the actuator removed can slam the valve closed causing personal injury and damaging the flow system. Shut down the flow in the pipeline before removing the actuator from the valve. -

Page 10: Replacing Actuator On Value

DeZURIK Replacing Actuator on Valve Refer to Figure 2 and Figure 6 for parts identification. 1. Place the valve in the position it was in when the actuator was removed. Normally this will be so the plug is in the lowest position in the valve body. -

Page 11: Actuator Disassembly And Assembly

DeZURIK Actuator Disassembly and Assembly Under normal operating conditions the G-Series actuator does not require routine maintenance. If the actuator has excessive wear or has been damaged, it is recommended that the actuator be replaced, not repaired. Use the following procedure for replacing leaking seals and o-rings. Refer to Figure 2 for component identification. -

Page 12: Actuator Assembly

DeZURIK Actuator Disassembly and Assembly (Continued) 10. Drive both pins (B1K) thru the worm (B1D) and drive shaft (B1F). 11. Slide the drive shaft (B1F) out of the housing (B1A). 12. Remove the seal (B1J) from the housing (B1A). 13. Remove the o-ring (B1N) thru the bottom of the housing (B1A). -

Page 13: Operator Component Identification

DeZURIK Operator Component Identification Figure 7— Operator Component Identification August 2012 Page 13 D10456... -

Page 14: Replacing Handwheel Or Wrenching Square With Chainwheel

DeZURIK Replacing Handwheel or Wrenching Square with Chainwheel Refer to Figure 7 for component identification. G_-6A and G_-12A (3” - 12” valves) 1. Support the actuator shaft with a solid surface, drive out the pin (B2), and remove the handwheel (B3) or wrenching square (B11) from the actuator shaft. -

Page 15: Replacing Chainwheel With Handwheel Or Wrenching Square

DeZURIK Replacing Handwheel or Wrenching Square with Chainwheel (Continued) 6. Align the second pin hole in the actuator shaft and the pin hole in the chainwheel hub. Support the hub of the chainwheel with a solid surface and drive the connecting pin (B2) into position. -

Page 16: Troubleshooting

DeZURIK Troubleshooting Condition Possible Cause Corrective Action Closed position stop is set Adjust closed position stop. See incorrectly. STOP ADJUSTMENTS section. Actuator closes to wrong position. Rotate pointer to correct Pointer is installed incorrectly. position. Open position stop is set Adjust closed position stop. - Page 17 If you use metric fasteners with ASME Class 150/300 bolt holes and flange bolt patterns, you do so at your sole risk and any liability associated with such use shall not be the responsibility of DeZURIK, Inc. In addition to the foregoing, DeZURIK’s Manufacturer’s Conditions apply.

Need help?

Do you have a question about the G Series and is the answer not in the manual?

Questions and answers