Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Loepfe YARNMASTER 1N1

- Page 1 YARNMASTER 1N1 / 3N1 ® Instruction Manual LZE-V Version 2.X / 08. 2014...

- Page 3 Instruction Manual to third parties – even in form of extracts – as well as the use and / or disclosure of the contents are not allowed without the written approval of Loepfe Brothers Ltd., except for internal purposes. YarnMaster® is a registered trademark of Loepfe Brothers Ltd.

-

Page 5: Table Of Contents

Table of Contents Table of Contents General Information on this Instruction Manual 1.1.1 General 1.1.2 Duty to Read this Manual 1.1.3 Availability of Instruction Manual 1.1.4 Loss of Instruction Manual Explanation of Symbols 1.2.1 Symbols 1.2.2 Signal Words 1.2.3 Information Liability 1.3.1 Information in this Manual... - Page 6 Table of Contents Product Description General Equipment Configuration 3.2.1 Central Unit LZE-V 3.2.2 Section Electronic (SE) 3.2.3 Sensing Head YM 1N1 / 3N1 TK Status LED Clearer Functions / Clearer Variants Identification of Components / Article Description Technical Data Operation of LZE-V General Safety 5.2.1...

- Page 7 Table of Contents 5.12 Machine Data 5.12.1 Rotor Status Color Codes 5.13 Monitoring Data 5.13.1 Quality 5.13.2 Foreign Matter 5.13.3 Polyprop 5.13.4 Stops & Locks 5.13.5 Piecings 5.13.6 Q-Pack 5.13.7 Hitlist 5.14 Reports USB (Export / Import) Upgrades Data Export / Import System Snapshot Customer Logo Inspection and Maintenance...

- Page 8 Abbreviations Production data collection Foreign matter Imperfections LZE-V Loepfe central unit (version V) N / S / L / T Neps / shorts / longs / thin places Original Equipment Manufacturer Synthetic foreign matter (Polypropylene) Quality Section electronics Sensing head...

-

Page 9: General

Instruction Manual and, in particular, the safety information. Availability of Instruction 1.1.3 The Instruction Manual is part of yarn clearer system YarnMaster 1N1 / 3N1 and must be kept in direct vicinity of the equipment and accessible for person- Manual nel at all times. -

Page 10: Explanation Of Symbols

General 1.2 Explanation of In this Instruction Manual, safety information is marked with symbols and signal words which express the extent of the hazard. Symbols The safety information must be strictly observed to prevent accidents, personal injuries and damage to property. Symbols 1.2.1 General danger... -

Page 11: Liability

In addition to the contractually agreed obligations, the manufacturer’s General Terms and Delivery Conditions are applicable. Technical Modifications 1.3.3 Loepfe Brothers Ltd. will not be liable for damage and accidents resulting from the following: ƒ Unauthorized conversion and modification of the yarn clearer system ƒ... -

Page 13: Safety

Safety 2.1 Responsibility of Operating Company Basic Information 2.1.1 The operating company of yarn clearer system YarnMaster 1N1 / 3N1 is subject to the legal requirements for industrial safety. It is responsible for ƒ safe and proper operation of the yarn clearer system ƒ... -

Page 14: Use

2.3 Use Intended Use 2.3.1 Yarn clearer system YarnMaster 1N1 / 3N1 has been designed and built for online yarn monitoring and clearing of undesired yarn faults on openend spin- ning machines from various manufacturers. The yarn clearer system must be installed and operated with observation of the Instruction Manual and the included instructions. -

Page 15: Electrostatic Charging

X Do NOT touch soldered connectors, pin contacts, printed circuits or electronic components. 2.5 Safety Devices (Emergency-stop Button) Yarn clearer system YarnMaster 1N1 / 3N1 is integrated in a openend spinning machine and has no additional safety devices. For detailed information on the safety devices, e.g. -

Page 17: Product Description

Product Description 3.1 General Yarn clearer system YarnMaster 1N1 / 3N1 serves to clear yarn faults and foreign matter (only 3N1) as well as quality monitoring in the spinning shop. It is installed in openend spinning machines from various manufacturers. -

Page 18: Central Unit Lze-V

Product Description Central Unit LZE-V 3.2.1 Central unit LZE-V consists of the following components: ƒ Computer ƒ User interface (touchscreen 15.6 inches) ƒ USB port for data transfer ƒ Central unit software Functions: ƒ Control and monitoring of yarn clearing ƒ... - Page 19 Product Description Rear (left) 24 V DC Marking Type Description Power Sub D PSC Power supply 24 V DC Contact 1 (+) 24 V DC Contact 2 not connected Contact 3 (–) 0 V DC Only 24 V DC may be supplied to this connection! ATTENTION Threaded connection Protective ground...

-

Page 20: Section Electronic (Se)

Product Description Rear (right) 1 Q-bus 4 Input status LEDs 2 4k status LEDs 5 Input signals 3 4k connector 6 Output signals Section Electronic (SE) 3.2.2 The SE-board is the interface between the control unit and a section of sensing heads. -

Page 21: Tk Status Led

Product Description 3.3 TK Status LED During normal operation, the red LED is off and the green LED blinks shortly. If there is a quality or other problem, the way the LEDs light up or flash indicates the kind of lock, stop or problem. Check the Machine overview page for details. Unlock Method Sensing Head LEDs Status and Color... -

Page 22: Clearer Functions / Clearer Variants

Product Description 3.4 Clearer Functions / Clearer Variants P Clearing ƒ Clearing of synthetic foreign matter PP PE etc. ƒ Matrix setting and classification ƒ P cluster clearing F Clearing ƒ Clearing of foreign matter ƒ Matrix setting and classification ƒ... -

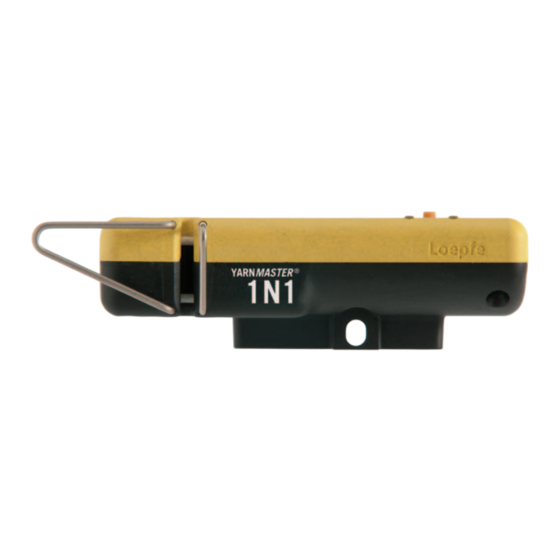

Page 23: Identification Of Components / Article Description

Article description ZE YM 1N1 LZE-V XXX 46872000 Article number FFFFFFSSSSKWJJ Order number Serial number Calendar week / year Sensing head Loepfe article number Order number YM 1N1 46760000 1004153 4213 0001 Barcode Consecutive serial number Calendar week / year... -

Page 25: Technical Data

Technical Data Technical Data (Changes reserved) System Concept Modular, integrated in spinning system / components individually replaceable / Power supply depends on machine type LZE-V One control station per machine / Date and time indication / Data memory in case of power failure / Bus connection to section electronic / Data connection to machine control station LAN connection to local network Operating Setting of the conventional clearing parameters via touch screen... - Page 26 Technical Data Parameter Settings Settings for thick and thin places Default values Valid values To disable, set to Matrix lengths in mm 4, 10, 20, 40, 80, 160, 320 2 to 8, 6 to 18, 12 to 38, 22 to 78, 42 to 158, —...

- Page 27 Technical Data Settings for foreign matter detection Default values Valid values To disable, set to Matrix lengths in mm 10, 14, 20, 24, 30, 34, 40 2 to 12, 12 to 18, 16 to 22, 22 to 28, 26 to 32, —...

-

Page 29: Operation Of Lze-V

Operation of LZE-V Operation of LZE-V 5.1 General The 1N1 / 3N1 yarn clearer system is controlled for all openend spinning machine types via central unit LZE-V. Machine-specific differences in operation or in the settings are possible and have been stated accordingly in the instructions. All clearer functions are described in this Instruction Manual. -

Page 30: Central Unit Lze-V

Operation of LZE-V 5.3 Central Unit LZE-V User interface USB interface Monitor 5.3.1 Operation / entry is performed by applying light pressure on the touch-sensi- tive screen (touch-screen) of the monitor. ATTENTION! Risk of damage by incorrect handling of surface! Z Operation by tapping with the finger or a blunt, non-metal object (e.g. -

Page 31: User Interface / Navigation

Operation of LZE-V 5.4 User Interface / Navigation level menu navigation level menu navigation level tab navigation level tab navigation Detail page Lock / unlock Language selection Help USB device Page name Date and time Shift start date and time / Number of stopped rotors Machine number Machine type 1N1 / 3N1... -

Page 32: Menu Overview

Operation of LZE-V Menu Overview 5.4.1 Monitoring > > > Overview Details Quality Foreign matter Polyprop Stops and Locks Piecings Q-Pack Hitlist Quality Foreign matter Polyprop Reports Setup > > > Machine Configuration Shifts System Articles Quality Foreign matter Polyprop Production groups Service >... -

Page 33: Function Buttons (Additional Buttons Explained Per Page)

Operation of LZE-V Function Buttons 5.4.2 (additional buttons explained per page) Language selection Filter events Unlock / lock Rename article Online help Archive manipulation Next / previous page / list. Open USB possibilities Select next / previous option / value. Enter rotor number Go to the operating system Previous / next rotor. -

Page 34: Language Selection

Operation of LZE-V 5.5 Language Selection The required operator language can be selected. 5.6 User Password Default: 123 ƒ Enter the password and confirm. ƒ The password can be changed individually: Setup > Machine > Configuration ƒ Qualified personnel can touch the lock button and enter the service pass- word. -

Page 35: Base Settings

– Select your GUI theme ƒ Light trees – Optional if a light tree is connected to the LZE-V Set an individual password. Advanced settings should only be entered and changed by an authorized Loepfe service technician. 1N1 / 3N1... -

Page 36: Shifts

Operation of LZE-V Shifts Setup > Machine > Shifts 5.8.2 ƒ Shift system – Enable external shift cycles if the machine central unit provides this information. – It is therefore possible to set up to 7 different shift cycles manually. Therefore determine the shift cycle per day (2 column). -

Page 37: Group Administration

Operation of LZE-V 5.9 Group Administration Setup > Production Groups With LZE-V it is possible to run up to two different production groups on one machine (only for double sided machines). The range of the production groups can be either one machine side or the entire machine. The rotor range of a group can be selected by enlarging or reducing the size of the transparent window on the rotor overview. - Page 38 Operation of LZE-V 5. An article with assigned clearer settings must be selected from the 10 active articles of the LZE-V. More details for article selection can be found in the chapter “Article Administration”. 6. For a lot change tick the box of the production group that you want to change and confirm.

-

Page 39: Article Administration

The three buttons are used for article archive organization / loading the default values / loading the original values. Advanced menu should only be entered by Loepfe service technicians. Activate the different yarn clearer functions by ticking the box next to the specific clearer channels. -

Page 40: Article Settings

Operation of LZE-V 5.11 Article Settings Setup > Articles The major clearer channels can be set by the selection of classes within the clearer matrix through the touch screen. Each class is limited by a length and deviation limit which both can be set individually within certain limits. A red class is activated for clearing, a yellow one can be selected in addition. -

Page 41: Foreign Matter (F) (Only 3N1)

Operation of LZE-V Locks are used to block particular rotors that have repetitive quality stops or longer defects which cannot be removed by the piecer. ƒ Quality, Thick / Thin Sliver and Moiré Locks: Blocks particular rotors to repeated Q stops within the set length. ƒ... -

Page 42: Polypropylene (P) (Only 3N1)

Operation of LZE-V Polypropylene (P) 5.11.3 (only 3N1) Polypropylene clearing is activated by setting classes within the clearer matrix. The length and deviation limits of the classes can be set individually within certain limits. ƒ Sensitivity SC / SdC: sensitivity for short cluster (possible to remove during piecing) ƒ... -

Page 43: Machine Data

Operation of LZE-V 5.12 Machine Data Monitoring > Overview Overview shows all important production related data. ƒ Machine Block – Shows the state and the efficiency of each particular rotor. – The state of a rotor is indicated by the color of the efficiency bar. ƒ... -

Page 44: Monitoring Data

Operation of LZE-V 5.13 Monitoring Data Monitoring > Details It is possible to view the following production data for the production group and for each rotor (for more information refer to the chapter Index Data Explanation). Chart (for all Clearer Data): Value description Values of selected rotor Mean value: Machine... -

Page 45: Foreign Matter

Operation of LZE-V Foreign Matter 5.13.2 Displays foreign matter cleaning data for the production group as well as a particular rotor of the same group. Specific information of the production group – Stopped rotor: total stops – Produced length (since shift start) Specific information of the rotor –... -

Page 46: Stops & Locks

Operation of LZE-V Stops & Locks 5.13.4 Information about the stops and locks for the production group as well as a particular rotor of the same group. – Amount of the particular state since shift start – Quality generally: amount of the particular state since shift start –... -

Page 47: Q-Pack

Operation of LZE-V Q-Pack 5.13.6 Real time online laboratory for advanced analysis of the production group as well as specific rotors. Histogram X-axis: + / -x / 100 mm Y-axis: relative % to maximum value Spectrogram Helps to analyze the yarn diameter profile for the presence of periodically occurring deviations. -

Page 48: Hitlist

Operation of LZE-V Hitlist 5.13.7 Quality Displays the rotors with the highest or lowest measured or calculated Q values. Choose + for the highest values Choose - for the lowest values Foreign Matter Displays the rotors with the highest or lowest measured or calculated F values. -

Page 49: Reports

Operation of LZE-V 5.14 Reports Monitoring > Reports The LZE-V continuous collects all production data of each rotor that is assigned to an active production group. After each lot or shift change, data collection is finished and the collected data of each production group is sum- marized and saved as a separate report, along with the used clearer setting. -

Page 51: Usb (Export / Import)

The LZE-V contains a USB port on the front panel of the central unit. ATTENTION: Make sure that the USB stick is free from viruses! LOEPFE assumes no liability for possible damage on the system (loss of data etc.,) which could be caused by viruses! When a USB stick is inserted into the USB port, the USB device icon is displayed in the header. -

Page 52: Data Export / Import

USB (Export / Import) 6.2 Data Export / Import Export 6.2.1 The LZE-V offers the possibility to export the machine setup, the archived articles as well as the reports to an inserted USB stick. – Copy setup to USB device –... - Page 53 USB (Export / Import) Import 6.2.2 The LZE-V offers the possibility to import a machine setup or articles to the LZE. – Install setup from USB device – Install articles from USB device Once one of the possibilities is chosen and confirmed, a window displaying the directory of the USB stick is opened.

-

Page 54: System Snapshot

GUI and save it as a folder named “snap-shot_YYMMDD_hhmm”. For further analysis the whole folder should be compressed and sent to the official Loepfe service representative! 6.4 Customer Logo The LZE-V offers the possibility to create and upload a customized logo to the GUI. -

Page 55: Inspection And Maintenance

Safety risk with non-original spare parts or non- approved accessories! Non-original spare parts or non-approved accessories could affect safety and cause damage, malfunctions or total fail- ATTENTION ure of the yarn clearer system. Z Only use original spare parts or accessories approved by Loepfe. 1N1 / 3N1... -

Page 56: Cleaning The Measuring Slot

This will reduce dust locks. Always clean when a rotor is stopped for dust lock (both sensor LEDs on). Only use the cleaning swabs With? 7.4.2 from LOEPFE (part no. 16964900). Use it either dry or dampened with optical lens cleaner. How? 7.4.3 Drag the soft tip of the cleaning stick a few times through the measuring slot. -

Page 57: Diagnostics

Inspection and Maintenance 7.5 Diagnostics Service > Diagnostics Versions 7.5.1 Versions The submenu displays a summary of the installed software package, as well as the included LZE-V, SE and SH software versions. In addition it also shows a summary of the software actually installed on the SE boards and the sensing head. -

Page 58: Tests

Inspection and Maintenance Tests 7.5.3 Tests are used to check the communication between the LZE-V, the SE and the sensing heads as well as the communication of the interface connections between the SE and the machine section electronics. When starting the test, each rotor of the chosen rotor range will go into a forced lock one by one starting with the smallest rotor number. -

Page 59: Troubleshooting

Troubleshooting 8.1 Hardware Locks / Recommended Action LOEPFE YM 1N1 / 3N1 has a built-in diagnostic function. Technical problems are indicated by means of hardware locks. Hardware locks can only be cancelled on the LZE-V GUI. Hardware failures can have a severe influence on yarn quality! -

Page 60: Analysis Of Rotors With Unusual Behavior

Troubleshooting 8.2 Analysis of rotors with Rotors with unusual behavior, such as too many cuts, increased Q, F or P data etc., are an indication that something at this rotor position is different unusual behavior from the rest of the machine. This unusual behavior can have various causes, such as differences in the applied sliver, the spinning components or malfunc- tions of the clearer. -

Page 61: Index Data Explanation

Index Data Explanation Index Data Explanation Ref.Mean (mm): Reference mean value from adjustment at the lot start or from a forced mean by the user Measurement absolute in mm Act. Mean (mm): Current mean in real time Dust (mm): Contamination of the sensor (according to the empty and clean optic) CV%: Statistic calculation IPI Neps / km:... - Page 62 Loepfe Brothers Ltd. 8623 Wetzikon / Switzerland Phone +41 43 488 11 11 Fax +41 43 488 11 00 info@loepfe.com www.loepfe.com Subject to technical modifications...

Need help?

Do you have a question about the YARNMASTER 1N1 and is the answer not in the manual?

Questions and answers