Summary of Contents for Scantool 40BK

- Page 1 Industrivej 3-9 DK-9460 Brovst Denmark Tlf. +45 98 23 60 88 Fax +45 98 23 61 44 MANUAL Geared Head Milling & Drilling Machine 40BK - 40BKS...

- Page 2 +45 98 23 60 88 Fax.: +45 98 23 61 44 hereby declares that SCANTOOL Geared Head Milling & Drilling machine 40BK/BKS are manufactured in accordance with the provisions of the European Parliament and Council Directive 2006/42 / EC of 17 May 2006 And also in accordance with: •...

-

Page 3: Table Of Contents

..............................12 ROUBLE HOOTING WIRING DIAGRAMS ............................15 POWER DOWN FEED OPERATION ..........FEJL! BOGMÆRKE ER IKKE DEFINERET. SPARE PARTS ..............................17 40BK .......................... 17 RAWINGS FOR MODEL 40 BK ..........................22 ARTS IST FOR MODEL 40BKS ........................26 ART DRAWINGS FOR MODEL 40 BKS ............................. -

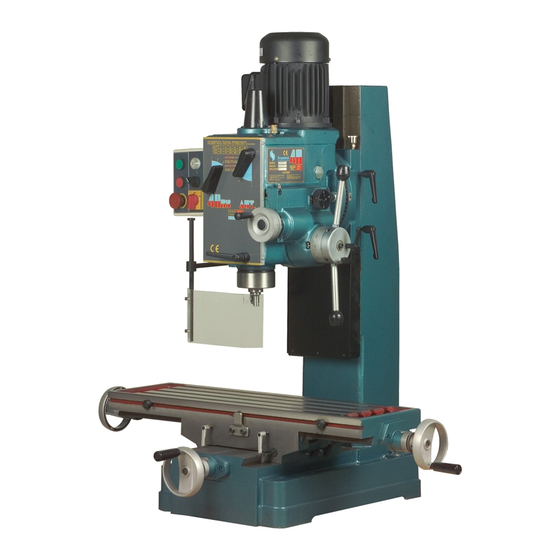

Page 4: Overall Aspect

1. Overall Aspect... -

Page 5: Safety Rules

2. SAFETY RULES Warning: Failure to follow these rules may result in serious personal injury. As with all machinery there are certain hazards involved with operation and use of the machine. Using the machine with respect and caution will considerably lessen the possibility of personal injury. -

Page 6: Specifications

Don’t use in dangerous environment. Don’t use power tools in damp or wet locations, or expose them to rain. Keep work area well-lighted. Keep children and visitors away. All children and visitors should be kept a safe distance from work area. E. -

Page 7: Tools Selection & Proper Material Range

Tools selection & proper material range Tool type Tool materiale Work piece material End mill Non-iron material iron TUNGSTEN CARBIDE Cast iron non-iron material Face mill TUNGSTEN CARBIDE Non-iron material iron Light material Drilling Non-iron material iron Light material Tapping Non-iron material iron Light material Speed Levels... -

Page 8: Delivery And Installation

4. Delivery and Installation Be sure all locks of headstock and column are tightened before operation. Always keep proper footing and balance while moving this 300 kgs. machine and only use heavy duty fibre belt to lift the machine. Keep machine always out from sun, dust, wet, and raining area. Properly position and tighten 4 bolts into base holes after machine is in balance. -

Page 9: Quill Return Spring Adjustment

Clean the machine and coat it with lubricant. Cover the machine with cloth to keep out the dust. 3. Adjustment of Head To raise and lower the head, loosen the two heavy duty head lock nuts shown in Fig. 1. Use the left side head handle to raise and lower the head on its rack and pinion mechanism. -

Page 10: Adjusting Table Slack And Compensate For Wear

Adjusting Table Slack and Compensate for Wear 1. Your machine is equipped with hub strip adjustment to compensate for wear and excess slack on cross and longitudinal travel. 2. Clockwise rotate the job strip bolt with a big screw for excess slack otherwise a little counter clockwise if too tight. -

Page 11: Change Tools

When changing the running direction of the spindle, forward to reverse or reverse to forward, STOP THE MOTOR POWER first. Absolutely do not change the spindle running direction when machine is running. Improper operation of the switch may cause to the damage of switch, machine or the danger to operator. -

Page 12: Specification Of T-Solt

SPECIFICATION OF T-SOLT The size of T-Slot on table as Fig 6: Fig. 6 6. Maintenance That's easier to keep machine in good condition or best performance by means of maintaining it at any time then remedy it after it is out of order. •... -

Page 13: Lubrication

Remove the oil filler plug filler the oil to the gear box until the oil lever reach the middle of oil fluid lever indicator. Then look the plug. Lubrication: All ball bearings in your mill/drill are sealed for life, requiring no lubrication. Points requiring lubrication are: •... - Page 14 3. Feed too deep -Decrease depth of feed. • Shake of spindle and roughness of working surface has taken place during performance: 1. The gap of spindle bearing too wide - Adjust the gap in proper or replace bearing with new one. 2.

- Page 15 Failure to clamp work-piece or work holding device to table. - Clamp work-piece or work holding device to table surface.

-

Page 16: Wiring Diagrams

7. WIRING DIAGRAMS Item Designation and Technical Suppiler Suppilerg Remark Function Data Reference IE 13,5A K700 VDE 0620 Klinger Klinger UE= 230V 082917 IEC 204-1 UC=230V/50Hz VDE 0113 Teil 1 Overload 11,5A EN 60204-1/6,93 Motor 1,11Kw Jiuh Dah Jef-H 230V 1420 rpm... - Page 17 Item Designation Technical Supplier Supplier Remark and Function Data Reference Klinger IE 13,5A Klinger K700 VDE 0620 UE=400 082917 IEC 204-1 VUC=400V/50Hz VDE 0113 Teil 1 Overload 2,1A EN 60204-1/6,93 Motor 0,75Kw Jiuh Dah Jef-H 400V 1420 rpm...

-

Page 18: Spare Parts

8. Spare Parts Part Drawings for model 40BK... -

Page 23: Parts List For Model 40 Bk

Parts List for model 40 BK CODE PART NO DESCRIPTION SPECIFICATION NOTE 2401011S Head Body Set 2401001-2 Main Shaft Cover 6101 Chuck Arbor Bolt MT3 M10xP1.5 6101-1 Chuck Arbor Bolt MT3 M12xP1.75 MT3 W3/8”-16 6101-2 Chuck Arbor Bolt MT3 W1/2”-12 6101-3 Chuck Arbor Bolt R8 W7/16”-20... - Page 24 6126A Fixed Tight Collar 5/8”-11UNC N008 Hex. Nut 5/8”x25xt1 W019 Washer 2402056 Fixed Bolt 2401072 Name Plate S708 Cross Round Head Screw 3/16”-24UNCx3/8”L 2401075S Speed Lever Set 61102 Limit Plate 1/8” W032 Washer 1/8”x1/4”L S705 Cross Round Head Screw 2401085 Dust Plate 2401085A Dust Plate...

- Page 25 2401096A Chuck Arbor MT4 M12xP1.75 B16 6168 Punch Key 6187-1 Chuck ½-B16 6187 Chuck Switch 260616S Chuck Guard Asbly For CE Only 260616AS Chuck Guard Asbly Optional For CE Only 6628-1 Table 6229 Fixed Block 6230 Movable Fixed Ring ¼”x1/2”L S402 Hex.

- Page 26 HN004 Hex. Nut HW109 Spring Washer HS149 Hex. Head Screw M20x60L 2422018 Steel Plate HS519 Cross Round Head Screw M5x10L 2422019 Steel plate 2422027 Bracket CA6003ZZ Bearing 6003ZZ HCS06 C-Retainer Ring 2422028 Gear Shaft HK010 5x5x28L 2422023 Rack 2422035 Bushing 2422036 Bushing HS291...

-

Page 27: Part Drawings For Model 40Bks

Part drawings for model 40BKS... -

Page 34: Parts List Model 40 Bks

Parts List Model 40 BKS CODE PART NO DESCRIPTION SPECIFICATION QTY NOTE 2450002S Head Body Set 2401001-2 Main Shaft Cover 6101 Chuck Arbor Bolt MT3 M10xP1.5 6101-1 Chuck Arbor Bolt MT3 M12xP1.75 MT3 W3/8”-16 6101-2 Chuck Arbor Bolt MT3 W1/2”-12 6101-3 Chuck Arbor Bolt R8 W7/16”-20... - Page 35 3/16”-24UNCx3/8”L S708 Cross Round Head Screw 2401075S Speed Lever Set 2450069 Dust Plate 3/16”-24UNCx3/8”L S708 Cross Round Head Screw HP309S Miter Pin Set 6121 Chuck Arbor MT3 M10xP1.5 6121-1 Chuck Arbor MT3 M12xP1.75 MT3 W3/8”-16 6121-2 Chuck Arbor MT3 W1/2”-12 6121-3 Chuck Arbor R8 W7/16”-20...

- Page 36 5/16”X1/2”L S018 Hex. Socket Head Screw 6212 Gib Strip Bolt 6630 Bushing 6213-1 Grip 6213-2 Grip 6151-1 T Screw 6213 Thumb Screw 5/16”X1”L S414 Hex. Socket Head Screw 5/16” W205 Spring Washer 5/16”x2-1/4”L S418 Hex. Socket Head Screw 6215S Acme Nut Assembly Metric 6215-1S Acme Nut Assembly...

- Page 37 2450100 Washer 2450087AS Clutch Bushing Set 416-1 2450087A Clutch Bushing 416-2 2450031 Bushing Stop 416-3 2450030 Bushing Pin 416-4 2450032A Scale Base Inch 416-4 2450032B Scale Base Metric 416-5 HP017 § 5 416-6 2450037 Handle Body 416-7 2450039 Handle Rod Pin 416-8 2450033 Scale Base Set Screw...

- Page 38 HS291 Hex. Socket Head Screw M12x85L HCR04 C-Retainer Ring 2422024 Worm Shaft 2422026 Worm Gear 2422030 Bearing 2422025 Support Flange HS243 Hex. Socket Head Screw M8x25L HS250 Hex. Socket Head Screw M8x60L 6158S Head Handle Set 6027-1S Clamp Handle HG005 Oil Seal §...

- Page 39 Fig. 2: Drawing for 40 BK Aut Power Feed System...

-

Page 40: Drawing For 40-45Aut/40-45Kaut Power Feed System

Drawing for 40-45Aut/40-45KAut Power Feed System CODE NO. PART. NO DESCRIPTION SPECIFICATION 2450068 Gear Box 2450086A Pinion Shaft 2450023 Transmission Gear 2450024 Clutch Key Base 2450022 C110 C Ring 2450095 Cluth Screw 2450095 Cluth Nut 2450097 Cluth Key Pin 2450027 Spring Pin 2450028 Spring... - Page 41 CODE NO. PART. NO DESCRIPTION SPECIFICATION 2450089A Bushing Bracket S620 Hex. Socket Headless Screw M6x6L 2450072A Gear 2450074A Washer 2450071A Gear 2450070A Gear 2450073A Shaft K007 5x5x28L 2450008 Transmission Gear S303 Flat Cross Head Screw 3/16"x3/8"L C003 C Ring 2450014 Cover 2450078A Transmission Worm...

-

Page 42: Warranty

9. Warranty Guarantee If within 2 year of purchase this machine supplied by Scantool A/S becomes defective due to faulty materials or workmanship we guarantee to repair or replace the machine or defective part or parts free of charge provided that: •...

Need help?

Do you have a question about the 40BK and is the answer not in the manual?

Questions and answers