Table of Contents

Advertisement

Quick Links

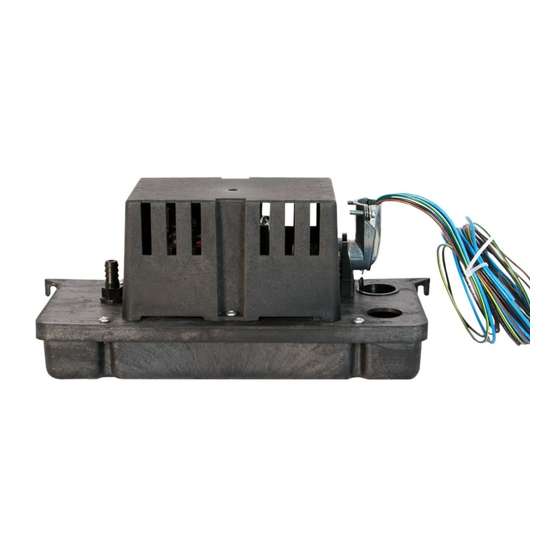

Condensate Removal

Pump for Plenum

Applications

Table of Contents

PRODUCT DESCRIPTION - - - - - - - - - - - -4

Specifications - - - - - - - - - - - - - - - -4

Pump Performance Curves - - - - - - - - - -4

INSTALLATION - - - - - - - - - - - - - - - - -5

Physical Installation - - - - - - - - - - - - - -5

Electrical Connections - - - - - - - - - - - -7

Operation Testing - - - - - - - - - - - - - -9

MAINTENANCE - - - - - - - - - - - - - - - - 10

Periodic Maintenance - - - - - - - - - - - - 10

Troubleshooting - - - - - - - - - - - - - - -11

LIMITED WARRANTY - - - - - - - - - - - - - 12

VCC-20-P

Owner's Manual

Advertisement

Table of Contents

Summary of Contents for Little Giant VCC-20-P

-

Page 1: Table Of Contents

VCC-20-P Condensate Removal Pump for Plenum Applications Owner’s Manual Table of Contents PRODUCT DESCRIPTION - - - - - - - - - - - -4 Specifications - - - - - - - - - - - - - - - -4... - Page 2 SAFETY INSTRUCTIONS Hazard Messages SAFETY INSTRUCTIONS Hazard Messages Before Getting Started This manual includes safety precautions and other import- This equipment should be installed and serviced by techni- ant information in the following formats: cally qualified personnel. Failure to comply with national and local electrical and plumbing codes and within Franklin Electric recommendations may result in electrical shock or fire hazard, unsatisfactory performance, or equipment fail-...

- Page 3 SAFETY INSTRUCTIONS Before Getting Started High voltages capable of causing severe Risk of bodily injury, electric shock, injury or death by electrical shock are or equipment damage. present in this unit. • This equipment must not be used by children or per- •...

-

Page 4: Product Description

UL2043, “Fire Test for Heat and Visible Smoke Release for Discrete Products and Their Accessories Installed in Air-handling Spaces.” The VCC-20-P pump has been evaluated in accordance with UL2043 standard and was found compli- ant with the standard’s requirements. -

Page 5: Installation

INSTALLATION Physical Installation INSTALLATION Physical Installation Risk of damage to pump or other equipment. • Before installing pump, allow air conditioner to cycle several times, collecting condensate in a separate container to help flush any residual oils that may remain in the system. Failure to flush the system can result in damage to the pump and drain line plumbing components. - Page 6 INSTALLATION Physical Installation Piping Connections Connect inlet and outlet tubing to the condensate pump as follows: 1. Cut end of flexible tubing or pipe from evaporator drain at a 20 ° or 60° angle as shown to prevent tubing from sealing closed when sitting against the tank’s floor. 2.

-

Page 7: Electrical Connections

Occupational Safety and Health Act (OSHA). Line Voltage Connections The VCC-20-P pump has individual power conductors for making a hardwire connection to the power supply. It does not have a power cord or electrical plug. The pump should be wired using a junction box or other approved enclosure. - Page 8 INSTALLATION Electrical Connections High Water Level Switch Connection Risk of severe injury or death by electrical shock. • Disconnect power to the air conditioning or refrigeration unit, both main power and the low voltage thermostat circuit. Risk of bodily injury or property damage. •...

-

Page 9: Operation Testing

INSTALLATION Operation Testing Refer to the thermostat or heating/cooling unit’s Operating Manual for expected switch operation and wiring connections. Connect the switch leads (7) in series with the low voltage thermostat cir- cuit as specified in the manual, or as illustrated. Use the following procedure if a Normally Closed (NC) configuration is required: NOTE: This procedure should be performed by a qualified service technician. -

Page 10: Maintenance

MAINTENANCE Periodic Maintenance MAINTENANCE Periodic Maintenance High voltages capable of causing severe injury or death by electrical shock are present in this unit. • To reduce risk of electrical shock, disconnect power before working on or around the sys- tem. More than one disconnect switch may be required to de-energize the equipment before servicing. -

Page 11: Troubleshooting

MAINTENANCE Troubleshooting Troubleshooting Problem Probable Causes Corrective Action Power is not connected to pump Ensure that power is supplied to the pump. Remove the tank and check for blockage of float. Clear any blockage Float movement is blocked around the float and inside the tank. Pump does not start when tank is full of condensate Clear any blockage in the impeller housing. -

Page 12: Limited Warranty

LIMITED WARRANTY THIS WARRANTY SETS FORTH THE COMPANY’S SOLE OBLIGATION AND PURCHASER’S EXCLUSIVE REMEDY FOR DEFECTIVE PRODUCT. Franklin Electric Company, Inc. and its subsidiaries (hereafter “the Company”) warrants that the products accompanied by this warranty are free from defects in materials or workmanship of the Company that exist at the time of sale by the Company and which occur or exist within the applicable warranty period. - Page 13 13. Products in which the sealed motor housing has been opened or the product has been otherwise dismantled by customer. 14. Products in which the cord has been cut to a length of less than three feet. The Company reserves the right at any time, and from time to time, to make changes in the design and/or improvements upon its product with- out thereby imposing any obligation upon itself to make corresponding changes or improvements in or upon its products already manufactured and/or previously sold.

- Page 14 For technical assistance, please contact ....800-701-7894 www.littlegiant.com lgnet@fele.com Franklin Electric Co., Inc. Form 998922 Oklahoma City, OK 73157-2010 Rev. 002 Phone: 1-800-701-7894 03-19 Fax: 1-405-228-1531...

Need help?

Do you have a question about the VCC-20-P and is the answer not in the manual?

Questions and answers