Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for THORLABS EK2000

- Page 1 EK2000 OEM Laser Diode Driver Evaluation Kit User Guide...

-

Page 2: Table Of Contents

Table of Contents Chapter 1 Warning Symbol Definitions ........... 1 Chapter 2 Safety ................. 2 Chapter 3 Description ................ 3 3.1. Using the EK2000 ............4 3.1.1. Minimal Configuration ............... 4 3.1.2. CW Operation ................6 3.1.3. Analog Modulation ..............7 3.1.4. -

Page 3: Chapter 1 Warning Symbol Definitions

OEM Laser Diode Driver Evaluation Kit Chapter 1: Warning Symbol Definitions Chapter 1 Warning Symbol Definitions Below is a list of warning symbols you may encounter in this manual or on your device. Symbol Description Direct Current Alternating Current Both Direct and Alternating Current Earth Ground Terminal Protective Conductor Terminal Frame or Chassis Terminal... -

Page 4: Chapter 2 Safety

OEM Laser Diode Driver Evaluation Kit Chapter 2: Safety Chapter 2 Safety All statements regarding safety of operation and technical data in this instruction manual will only apply when the unit is operated correctly. SHOCK WARNING Warning is given when there is danger of injury to users. CAUTION Caution is given when there is a possibility of damage to the product. -

Page 5: Chapter 3 Description

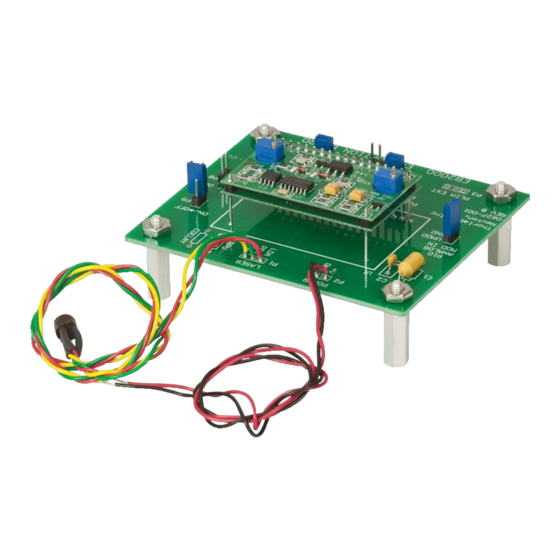

A-style pin configuration and a connection for a power supply. The EK2000 allows users to quickly set up the LD2000R with a laser and DC power supply without having to develop a custom PCB or extensive hand wiring. -

Page 6: Using The Ek2000

Install the appropriate value resistor in RFEXT (see LD2000R Application Notes). The EK2000 is now set up to operate the laser in a CW mode using the LD2000R on-board trim pots to control the laser drive current. NOTE For all modes of operation, we recommend using a linear DC power supply or battery. - Page 7 OEM Laser Diode Driver Evaluation Kit Chapter 3: Description Table 2. EK2000 Component Descriptions Description Connection EK2000 LD2000R Laser Diode Anode Laser Connections Monitor Photodiode Anode Laser Diode Cathode Power Supply Positive +8 to Power Supply +12 VDC Hookup Power Supply Return CW Terminal (Vref 2.5 V)

-

Page 8: Cw Operation

3.1.2. CW Operation To operate the EK2000 in a CW mode, do the following steps: Connect your laser diode to the pre-wired connector assembly. Attach a suitable DC voltage supply across P2 on the Eval Board. A 1’ long prewired cable assembly will be provided. Connect the + voltage to the red wire and the ground to the black wire. -

Page 9: Analog Modulation

Analog Modulation To operate the EK2000 analog modulation feature, follow the setup procedures for CW Operation to establish the laser operating conditions. Once the EK2000 has been setup for your laser, remove the shorting jumper from P10 and apply a positive voltage from P10-VMOD to P10-GND to modulate the laser. -

Page 10: External Modulation Operation

Attach an external modulation source (e.g. function generator, D/A converter, etc.) to the Analog Modulation Input (P10). Apply power to the EK2000 and adjust the modulation input amplitude and frequency for the desired output. The laser output will now be controlled by the external modulation voltage. - Page 11 OEM Laser Diode Driver Evaluation Kit Chapter 3: Description somewhere below 2.5V since the default feedback gain is usually too high for most lasers). If the feedback gain is too low for a laser (i.e. the maximum laser power can be reached at a point somewhere below the maximum setting of PWR Limit, than use care to set the PWR Limit control to the maximum desired operating power before applying the modulating voltage.

-

Page 12: Chapter 4 Ld2000R Overview

OEM Laser Diode Driver Evaluation Kit Chapter 4: LD2000R Overview Chapter 4 LD2000R Overview The LD2000R is composed of three independent circuits: slow start circuit, limit current circuit, and output control circuit. Each is described below. 4.1. Slow Start Circuit The slow start circuit is used to monitor the supply voltage and keep the laser output off until the power supply stabilizes. -

Page 13: Theory Of Operation

OEM Laser Diode Driver Evaluation Kit Chapter 4: LD2000R Overview The photodiode transimpedance amplifier has an internal gain of 20 kΩ which yields a 50 µA/V output. Since the maximum voltage of the feedback loop is 2.5 V, this limits the maximum photodiode current to 125 µA. This upper limit can be easily increased by adding an external resistor (see page 15). - Page 14 OEM Laser Diode Driver Evaluation Kit Chapter 4: LD2000R Overview The laser power is regulated through an integrating feedback loop. The setpoint of the feedback is determined by the PWR LIMIT control trimpot and the OUTPUT ADJUST knob (in external modulation mode, the external voltage is used in place of the OUTPUT ADJUST).

-

Page 15: Setup

The LD2000R can be used with A, D, or F style diodes. The D and F style diodes will need to be configured like an A style diode (see page 17 for diagrams). Please note that the EK2000 is not compatible with the F Pin Style. - Page 16 OEM Laser Diode Driver Evaluation Kit Chapter 4: LD2000R Overview Name Description These pins are provided for connecting an external capacitor to the control loop integrator to extend the integrator time constant. This may be necessary to get maximum bandwidth when using TTL modulation.

-

Page 17: Setting The Feedback Resistor

OEM Laser Diode Driver Evaluation Kit Chapter 4: LD2000R Overview 4.5.1. Setting the Feedback Resistor The LD2000R is configured at the factory for a maximum feedback gain. This gain setting is appropriate for lasers that have low monitor currents in the range of 20 to 120 A. -

Page 18: Chapter 5 Specifications

OEM Laser Diode Driver Evaluation Kit Chapter 5: Specifications Chapter 5 Specifications Specification Value Current Output Limit Current Control Trimpot or External Analog Voltage Limit Current Range 0 to 100 mA Limit Accuracy ±1% �� ) − 5�� Compliance Voltage ����������... -

Page 19: Chapter 6 Mechanical Drawings

OEM Laser Diode Driver Evaluation Kit Chapter 6: Mechanical Drawings Chapter 6 Mechanical Drawings Figure 5 EK2000 Mechanical Drawing Page 17 Rev F, May 21, 2018... - Page 20 OEM Laser Diode Driver Evaluation Kit Chapter 6: Mechanical Drawings Figure 6 LD2000R Mechanical Drawing 2468-D01 Page 18...

-

Page 21: Chapter 7 Regulatory

Waste Treatment is Your Own Responsibility If you do not return an “end of life” unit to Thorlabs, you must hand it to a company specialized in waste recovery. Do not dispose of the unit in a litter bin or at a public waste disposal site. -

Page 22: Thorlabs Worldwide Contacts

UK and Ireland Thorlabs, Inc. Thorlabs Ltd. sales@thorlabs.com sales.uk@thorlabs.com techsupport@thorlabs.com techsupport.uk@thorlabs.com Europe Scandinavia Thorlabs GmbH Thorlabs Sweden AB europe@thorlabs.com scandinavia@thorlabs.com France Brazil Thorlabs SAS Thorlabs Vendas de Fotônicos Ltda. sales.fr@thorlabs.com brasil@thorlabs.com Japan China Thorlabs Japan, Inc. Thorlabs China sales@thorlabs.jp chinasales@thorlabs.com Page... - Page 23 www.thorlabs.com...

Need help?

Do you have a question about the EK2000 and is the answer not in the manual?

Questions and answers