Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for THORLABS ELL18

- Page 1 ELL18 and ELL18K Rotation Stage Kit Operating Manual Original Instructions...

-

Page 2: Table Of Contents

5.2. Notes on Making a Picoflex Cable for Use when Daisy Chaining Devices ..15 Chapter 6 Specifications ......................17 Chapter 7 Regulatory ........................18 7.1. Declarations of Conformity ................... 18 7.1.1. For Customers in Europe ....................18 7.1.2. For Customers In The USA ................... 19 Chapter 8 Thorlabs Worldwide Contacts .................. 20... -

Page 3: Chapter 1 Introduction

Chapter 1 Introduction The ELL18 Rotation Stage is part of the Thorlabs series of resonant piezo motor circuits and bare modules for OEM applications. The resonant piezo design of these motors offers fast response times and precise positioning, and are therefore particularly useful in scanning applications. -

Page 4: Chapter 2 Safety

ELL18K Rotation Stage Evaluation Kit Chapter 2: Safety Chapter 2 Safety For the continuing safety of the operators of this equipment, and the protection of the equipment itself, the operator should take note of the Warnings, Cautions and Notes throughout this handbook and, where visible, on the product itself. -

Page 5: Chapter 3 Description

ELL18K Rotation Stage Evaluation Kit Chapter 3: Description Chapter 3 Description 3.1. Environmental Conditions Warning Operation outside the following environmental limits may adversely affect operator safety. Location Indoor use only Maximum altitude 2000 m Temperature range 15°C to 40°C Maximum Humidity Less than 80% RH (non-condensing) at 31°C To ensure reliable operation the unit should not be exposed to corrosive agents or excessive moisture, heat or dust. -

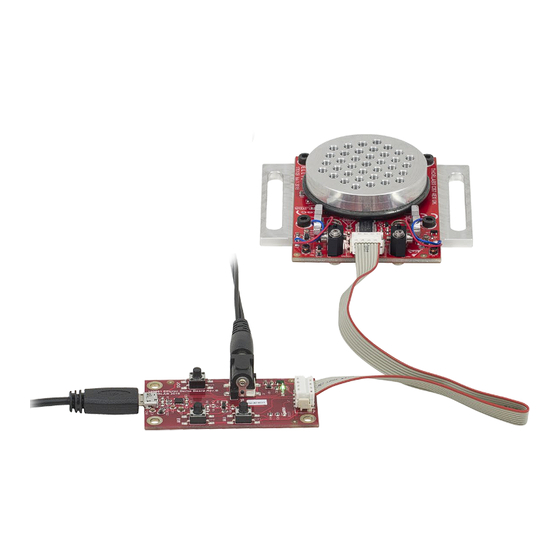

Page 6: Mounting

Do not allow the wires to contact other moving parts. The recommended mounting orientation is horizontal. Two mounting brackets are shipped with the ELL18K/M kit to allow mounting to a standard 1” or 25 mm pitch optical table or breadboard. Figure 1 ELL18 rotation stage Page 4 DTN000524-D02... - Page 7 The image below shows a diffraction grating mounted on the stage, with the diffracted light being incident on the slit located to the right. Figure 2 ELL18 with components fitted Figure 3 Fixing the ELL18K to the work surface 1. Using the M3 x 6 mm (6-32 x ¼”) bolts supplied, fix the mounting brackets to the circuit board as shown above.

-

Page 8: Chapter 4 Operation

ELL18K Rotation Stage Evaluation Kit Chapter 4: Operation Chapter 4 Operation 4.1. Getting Started Caution Although the module can tolerate up to 8kV of air discharge, it must be treated as ESD sensitive device. When handling the device, anti-static precautions must be taken and suitable anti-discharge appliances must be worn. Do not expose the stage to magnetic fields as this could affect the positioning and homing sensor operation. -

Page 9: Controlling The Stage

ELL18K Rotation Stage Evaluation Kit Chapter 4: Operation 4.2. Controlling the Stage The stage can be controlled in three ways; via the handset, by the Elliptec software running on a PC, or by writing a custom application using the messages described in the communications protocol document. Homing and Jogging functionality can also be accessed by applying voltages to the digital lines on Connector J1. -

Page 10: Hand-Held Controller

ELL18K Rotation Stage Evaluation Kit Chapter 4: Operation 4.2.1. Hand-held Controller Caution On power up the stage will move while the unit checks the sensors and then searches for the home position. The hand-held controller supplied with the ELL18K Evaluation Kit features two buttons (marked FW and BW) that allow control of the stage position. -

Page 11: Software Control

4.2.2. Software Control When connected to the host PC, the stage can be controlled remotely, via the Elliptec software. 1. Download the Elliptic software from the downloads section at www.thorlabs.com. Double click the saved .exe file and follow the on-screen instructions. -

Page 12: Communications Protocol

ELL18K Rotation Stage Evaluation Kit Chapter 4: Operation 4.2.3. Communications Protocol Custom move applications can be written in languages such as C# and C++. The communication bus allows multi-drop communication with speeds at 9600 baud, 8 bit data length, 1 stop bit, no parity. - Page 13 ELL18K Rotation Stage Evaluation Kit Chapter 4: Operation Connector J1 Pin Out TYPE FUNCTION Ground ODTX - open drain transmit 3.3V TTL RS232 RX receive - 3.3V TTL RS232 In Motion, open drain active low max 5mA JOG/Mode, active low max 5V BW Backward , active low max 5V FW Forward, active low max 5V VCC +5V +/-10% 800mA...

-

Page 14: Frequency Search

ELL18K Rotation Stage Evaluation Kit Chapter 4: Operation 4.3. Frequency Search Due to load, build tolerances and other mechanical variances, the default resonating frequency of a particular motor may not be that which delivers best performance. A frequency search can be performed using the Main GUI Settings panel in the ELLO software, or by using the serial communication line (SEARCHFREQ_MOTORX message), which offers a way to optimize the operating frequencies for backward and forward movement. -

Page 15: Chapter 5 Troubleshooting And Faq

ELL18K Rotation Stage Evaluation Kit Chapter 5: Troubleshooting and FAQ Chapter 5 Troubleshooting and FAQ 5.1. Frequently Asked Questions Stage is moving back and forth after power up If the digital line “bw” is driven low before powering up the stage, the module will go into calibration mode. Remove power to exit calibration mode. - Page 16 What is the typical product life time? ELL18 product life time is restricted by the wearing of moving surfaces and the motor contact as motion is started (due to resonance build up) and performed (due to friction), and is expressed in km travelled. Lifetime will depend on several factors (e.g.

-

Page 17: Notes On Making A Picoflex Cable For Use When Daisy Chaining Devices

ELL18K Rotation Stage Evaluation Kit Chapter 5: Troubleshooting and FAQ 5.2. Notes on Making a Picoflex Cable for Use when Daisy Chaining Devices The multi-drop communications bus offers the option of connecting the stage to a hybrid network of up to 16 Elliptec resonant motor products and controlling the connected units with a device such as a microprocessor. - Page 18 ELL18K Rotation Stage Evaluation Kit Chapter 5: Troubleshooting and FAQ 3. Using a screwdriver or other suitable tool, push down the crimp of each pin to make connection with the ribbon cable. 4. If other connectors are required they should be fitted at this point. Slide each connector onto the cable, paying attention to the orientation as shown below, then crimp as detailed in step (3).

-

Page 19: Chapter 6 Specifications

ELL18K Rotation Stage Evaluation Kit Chapter 6: Specifications Chapter 6 Specifications General Specifications Travel 360° Continuous Minimum Life Time 100 km (600,600 revolutions). Max Speed 430 °/s Bidirectional Repeatability 0.05 ° Homing Repeatability 0.25 ° Bidirectional Accuracy 0.4 ° Backlash 0.013 °... -

Page 20: Chapter 7 Regulatory

ELL18K Rotation Stage Evaluation Kit Chapter 7: Regulatory Chapter 7 Regulatory 7.1. Declarations of Conformity 7.1.1. For Customers in Europe Page 18 DTN000524-D02... -

Page 21: For Customers In The Usa

ELL18K Rotation Stage Evaluation Kit Chapter 7: Regulatory 7.1.2. For Customers In The USA This equipment has been tested and found to comply with the limits for a Class A digital device, persuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. -

Page 22: Chapter 8 Thorlabs Worldwide Contacts

EC, and are not dissembled or contaminated. Contact Thorlabs for more information. Waste treatment is your own responsibility. “End of life” units must be returned to Thorlabs or handed to a company specializing in waste recovery. Do not Annex I dispose of the unit in a litter bin or at a public waste disposal site. - Page 23 www.thorlabs.com...

Need help?

Do you have a question about the ELL18 and is the answer not in the manual?

Questions and answers