Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Microtest 6630

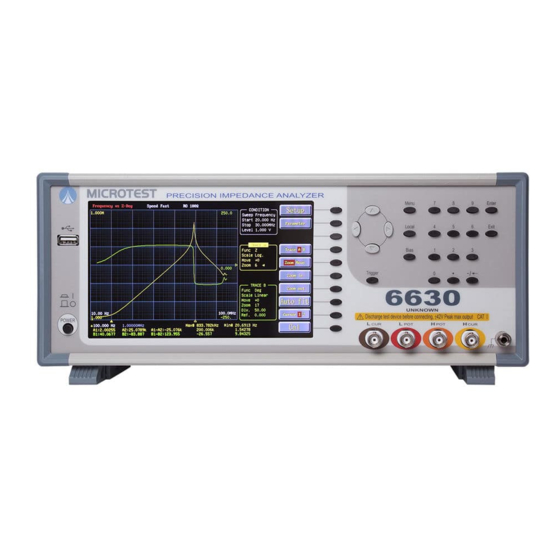

- Page 1 User Manual Precision LCR Meter 6630 S/W Ver Firmware Ver Date 1.21 2021/01...

- Page 2 All brands and trademark are the properties of Microtest Co., Ltd. Microtest Co., Ltd. and its affiliates shall not be liable for the damage, losses or costs incurred due to the accidental use, misuse or abuse by the product buyer or the third party;...

-

Page 3: Table Of Contents

INDEX Safety Specification ....................... 2 Preface ............................4 Introduction ........................4 Key Feature ........................5 Specification ........................6 Description of Installation ....................8 Package & Equipment ....................8 Description of function keys on front panel ............9 Description of function keys on back panel ............10 Hardware Installation .................... - Page 4 4.12 TRIGGER MODE ......................23 4.13 LEVEL/RO/ALC ......................23 4.13.1 RO (Output Impedance) ..................24 4.13.2 ALC (Auto Level Control) ..................24 4.14 SET ε ..........................25 3.14.1. Measurement Method ................... 25 4.15 SET μ ..........................26 4.15.1Magnetic Permeability Coefficient Measurement Method ........26 4.16 COMP (Comparison) ....................

- Page 5 CORR. (LIST CORRECTION) ..................37 CORRECTION ........................38 Open Circuit Correction ....................39 Short Circuit Correction ....................40 HF LOAD .......................... 41 SPOT LOAD ........................41 Cable length ........................41 FIXTURE COMPENSATION..................42 SPOT NO......................... 42 FREQUENCY ........................42 LOAD FUNCTION ......................

- Page 6 Capacitance (C) ...................... 78 Inductance (L) ......................79 Reactance (X) and Susceptance (B) ..............80 Impedance (Z) and Admittance (Y) ..............81 ..........83 Quality factor (Q) and Dissipation factor (D) Phase angle (θ) ....................... 84 Overall Impedance Measurement Theory ............85 Characteristics Example ..................

-

Page 7: Safety Specification

1. Safety Specification This instrument is designed according to EN61010-1 Specification. The main pur- pose of this Specification is to ensure that the instrument will be used in the labor- atory or the factory safely; it is not suitable for outdoor applications, especially the moistened or dusty locations. - Page 8 The instrument will operate normally upon starting the power. To achieve the specified accuracy, it is suggested warming up the instrument for over 15 minutes 1.6 External control unit This unit is able to execute the external control. For this purpose, please ensure that the operator is not touching the signal output end and the Test Piece to avoid causing hazard.

-

Page 9: Preface

6630 LCR Meter. 2.1 Introduction The test frequency of the 6630 LCR Meter is DC 10Hz-30MHz and the test signal is 10mV-2Vrms (min. resolution 1mV), and is suitable for the LCR and DCR testes of AC signals. The measurement in a continuously changing environment can be executed stage-by-stage with the test frequency and grade, and high-speed con- tinuous tests can be performed under different test and mode conditions. -

Page 10: Key Feature

2.2 Key Feature ⚫ Signal source frequency range: DC, 10Hz ~ 3/5/10/20/30MHz ⚫ Signal source grade: 10mV ~ 2V / 100μA ~ 20mA ⚫ Basic accuracy up to ±0.08% ⚫ ALC function ⚫ Output resistance 25Ω/100Ω, switchable ⚫ Wide resistance measurement range from 25 mΩ to 40 MΩ... -

Page 11: Specification

2.3 Specification 6630 LCR Meter 儀 Models Frequency range Meter mode List mode Sweep mode Equivalent circuit analysis √ √ 6630-30 10Hz~ 30MHz √ √ 6630-20 10Hz ~ 20MHz √ √ 6630-10 10Hz~ 10MHz √ √ 6630-5 10Hz~ 5MHz √... - Page 12 10mV~2Vrms Range Resolution Voltage Signal Level Accuracy 4-Terminal test fixture ± [(10 + 0.05 × f )% + 1 mV] Cable length > 0m ± [(15 + 0.1 × f )% + 1 mV] *f : frequency [MHz] 200µA~ 20mArms Range 10µA Resolution...

-

Page 13: Description Of Installation

3. Description of Installation Thank you for using Microtest 6630 LCR Meter as your testing instrument. This Manual contains the detailed installation steps. To ensure personnel safety and to protect your equipment and data, please check if the following accessories are fully supplied before starting the installation. -

Page 14: Description Of Function Keys On Front Panel

3.2 Description of function keys on front panel *Rear view (millimeters) Push Key and Port Function 1. Enter Enter key 2. Exit Exit key 3. Number key Input value 4. Menu For selecting Meter, Multi-step, Trace, Trim and System modes, etc. 5. -

Page 15: Description Of Function Keys On Back Panel

3.3 Description of function keys on back panel *Rear view (millimeters) PORT FUNCTION Pass/Fail signal (see3.4.3 Hander Interface) 1. Handler For connecting to software port(see3.4.2 RS232 Con- 2. RS232 nector) Remote control port: 24-pin block(see3.4.1 GPIB 3. GPIB Connector) For expanding Bias Input/Output port 4. -

Page 16: Hardware Installation

3.4 Hardware Installation 3.4.1 GPIB Connector The computer and the measuring instrument are connected with GPIB (General-Purpose Interface Bus) cable, and the Test Piece will be tested or trimmed on the computer through GPIB. ⚫ Definition of GPIB Pin Definition Definition Dataline1 Dataline5... -

Page 17: Rs232 Connector

3.4.2 RS232 Connector The computer and the measuring instrument are connected through RS232, and the Test Piece will be tested or trimmed on the computer through RS232. ⚫ Definition of RS232Pin Definition Definition Non-connection Non-connection RXD (receiving data) Non-connection TXD (transmitting data) Non-connection Non-connection Non-connection... -

Page 18: Handler Interface

3.4.3 Handler Interface You may control the test function of your machine with an external signal through the Handler Interface and Handler I/O port in its back panel. Please set the Handler Interface ON in SYSTEM menu to enable remote control and set the dip switch to on (both switches are pull down). - Page 19 ⚫ Handler I/O timing diagram: 1. PIN1(trigger) + PIN5(gnd) Start testing after short circuit, NOTE: the shorting time must be greater than 100uS. 2. The other output pins are photo coupler circuit, output sig- nal is low level.The output is as a high resistance floating circuit when it without action.

-

Page 20: Fixture Connecting

3.4.4 Fixture Connecting When connecting the fixture, it is required to discharge the power of Test Piece thoroughly. Turn the latches on both sides of the fixture to left until aligning with the small protruding point on the BNC port. Push the fixture down to the end and then rotate the latch rightward for fixing the fixture. -

Page 21: Lan Port

3.4.5 LAN Port The instrument will be connected to the LAN (Local Area Network) ports. Press the Meun button on the instrument and select the screen SYSTEM to enter and set it as ON, and then click LAN SETUP Select AUTO or MANUAL MANUAL settings are as follows: MAC ADDRESS: Sets the MAC address LAN STATUS: Network connection status (connected or not connected). -

Page 22: Power Cord Connecting

3.4.6 Power Cord Connecting Connect the power cord to the power jack of the instrument. Turn on the Power Switch, and the instrument is ready for use. Confirm that the voltage specification is correct and then insert the power cable Press the Power button Before servicing the instrument, be sure to remove the power cord from the instrument. -

Page 23: Basic Measuring

4. Basic Measuring 4.1 Meter Mode Press “Menu” key and then select “Meter” Mode for accessing the Meter Mode page. Measuring Value Display Vm/Im Statistics Output Impedance100/25Ω Auto Level Control Average Enable/Short Calibration 4.2 FREQ(Frequency) The frequency range is 10Hz~30MHz, and the resolution is set at 6 digits. Press Input Digit key and then<Enter>... -

Page 24: Bias

4.6 BIAS Use the <Up/Down> directional buttons to select <BIAS>. Use ↑↑, ↑, ↓ and ↓↓ to set the Bias value The range is between -12Vdc~+12Vdc. 4.7 RANGE DC Select<Range>with<Direction>key. It is preset as<Auto>. The measuring range belongs to internal parameter, which will be based to search the bay according to the measuring items. -

Page 25: Parameters

4.10 Parameters Press <Menu> key to select <Meter> mode and then move the cursor to the left side for setting the parameters to be measured. Parameters Definition DC Resistance Equivalent Series Inductance Equivalent Parallel Inductance Equivalent Series Capacitance Equivalent Parallel Capacitance Quality Factor, (Q = 1/D) , Loss coefficient (tanδ) Dissipation Factor... -

Page 26: Meter Mode Setup

4.11 METER MODE SETUP Under the Meter Mode page, selected <Setup> function key and you can access the <Meter Mode Setup> page for executing the measuring setup. 4.11.1 TRIGGER DELAY Set the trigger delay time, and such function is normally used by the auto- mated equipment. -

Page 27: Beep When

4.11.5 BEEP WHEN It is preset as <OFF>. The <FAIL> option means that the fail beep will sound if the test result is judged as <FAIL>. The <PASS> option means that the pass beep will sound if the test result is judged as <PASS>. 4.11.6 STATISTICS The default value is <Off>;... -

Page 28: Trigger Mode

4.12 TRIGGER MODE Under the Meter Mode page, select <TRIG> with<Direction> key.It is preset as <REPEAT>, and the instrument will execute the measuring continuously. If se- lecting <SINGLE> option, then it must be activated by pressing <Trigger> key. The measuring will be repeated with each pressing of <Trigger> key. 4.13 LEVEL/RO/ALC Under the Meter Mode page, select <LEVEL>... -

Page 29: Output Impedance)

4.13.1 RO (Output Impedance) The<100Ω>or<25Ω> can be selected according to the user’s demand. The varied signal source output impedance will lead to the varied current or the difference of measuring value. If selecting <25Ω>, then the AC volt- age range change to 10mV~1Vrms, and the current range is 400µA~40mArms. -

Page 30: Set Ε

ε 4.14 SET Under the Meter Mode page, selected <SETUP> function key then selected <SET εr> .function key to access the <DIELECTRIC CONSTANT SETUP> page for set- ting up ε 3.14.1. Measurement Method The <Contact> or <Non-contact> can be selected according to the tested material. -

Page 31: Set Μ

μ 4.15 SET Selected <SETUP> function key then selected <SET μr> function key to access the <PERMEABILITY SETUP> page. 4.15.1Magnetic Permeability Coefficient Measurement Method For setting up the <HEIGHT>, <INNER DIAMETER> and <OUTER DIAMETER> of the tested material and <fixture correction coefficient>. Fixture correction coefficient: This is the compensation parameter used for fixture Fx-0000C8. -

Page 32: Comp (Comparison)

4.16 COMP (Comparison) Under the Meter Mode page, select <COMP> with <Direction> key to access the comparison setup page.It is preset as “No”. When selecting “Yes”, the high/low limit range must be set for using as the measuring setup of the production line or the automated process. -

Page 33: Comp (Comparator) Mode& Disp (Display) Mode

4.16.2 COMP (Comparator) MODE& DISP (Display) Mode ⚫ Set absolute values for the upper limit and lower limit values of the measurement parameters. The measurement values displayed are the same of the measurement parameters. ⚫ △Abs Enter reference values and then set absolute values corre- sponding to the reference values as the upper limit and lower limit values. -

Page 34: Upper

⚫ △% Enter reference values and then set percentages corre- sponding to the reference values as the upper limit and lower limit values. The measurement values displayed are displayed in devia- tions (△%) from the reference value. The following equation is used to calculate and display △% measurement △% = ×... -

Page 35: Parameter And Bin Number

4.17.1 PARAMETER and BIN NUMBER Select the parameter and display up to 9 classifications of judgment re- sults. 4.17.2 BIN METHOD Equal:Set the upper and lower limit values for parameter, the Equal mode averages each the comparison values automatically. The Limit mode can select <ABS>, <△Abs>... - Page 36 The Limit mode can select<△Abs> and <△ %>. Random:Set the upper and lower limit values for each bin. The Limit mode can select <ABS>, <△Abs> and <△%>. 6630 uses three methods for specifying parameter limits as follows...

-

Page 37: File

4.18 FILE The parameter can be saved in the flash Memory of the instrument. The Meter Mode allows the user to access 100 setup groups, and the Multi-Step List Test Mode allows the user to access 50 setup groups (with each group containing 15 measuring steps). -

Page 38: Recal

4.18.6 COPY>USB Insert the USB flash drive into the USB port on the front panel of the instrument, select<COPY>USB> to copy 6630 local file to USB flash drive. 1. The METER mode setting file is saved to USB flash drive NOTE: root IA6630-->METER. -

Page 39: List Test

5. LIST TEST Press <Menu> key and select <LIST SET>for executing the multi-step setup. The measurement frequency or measurement signal level differs for each panel allows you to simply evaluate the characteristics of the DUT. Such function can be used in the production line or the automation test and, at most, 15 testing steps can be set. -

Page 40: List Mode Setup

5.2 LIST MODE SETUP Under the <LIST SET> or <LIST RUN> page, selected <SETUP> function key and you can access the <LIST MODE SETUP> page for executing the measuring setup. 5.2.1 TRIGGER MODE It<REPEAT><SINGLE><AUTO> three different types of trigger can be set. Selecting<REPEAT>... -

Page 41: Alc

5.2.5 ALC It is preset as <ALC OFF>. If selecting <ALC ON>, it ensures that the voltage applied to both ends of Test Piece or the current flowing through the Test Piece will be consistent with the parameter set value. If selecting <ALC ON>, because the instrument needs to calculate the voltage and the current for adjusting the output, it will increase the time required for the measuring. -

Page 42: Preset

5.2.10 PRESET It resets the LIST file as a new List file, all of the steps are deleted. <TRIG- GER MODE: SINGLE>; TRIGGER DELAY:0mS>;<OUTPUT IMPED- < ANCE:100>;<ALC: OFF>;<BEEP WHEN: OFF>;<RANGE HOLD: ON>;<FAIL RETEST: OFF>;<STATISTICS: OFF>. 5.3 CORR. (LIST CORRECTION) Under the LIST SET or LIST RUN page, list correction and meter correction are not the synchronize function. -

Page 43: Correction

6. CORRECTION Press the <Menu> key and select <CORR.>function key for accessing the COR- RECTION page. Before each measuring, the user needs to calibrate (balance) the fixture or the test cable in order to eliminate the stray capacitance and the series impedance that may be produced by the fixture or the test cable. -

Page 44: Open Circuit Correction

6.1 Open Circuit Correction In CORRECTION page, use <OFF><ON> function key to enable the open circuit correction, and use <Open> function key to do the open circuit correction. Before starting the open circuit correction, do not load the Test Piece to avoid correction failure. -

Page 45: Short Circuit Correction

6.2 Short Circuit Correction In CORRECTION page, <OFF><ON> function key to enable the short circuit cor- rection, and use <Short> function key to do the short circuit correction. Before starting the short circuit correction, please insert the shorting plate into the fixture for executing the short circuit correction. -

Page 46: Hf Load

6.3 HF LOAD When the measured frequency exceeded 1MHZ, execution of high frequency load cor- rection is recommended. Connect the FX-000C19 fixture to the instrument, place the STD-LOAD high frequency correction disk and clamp it tightly in place, and then press high frequency correction. 6.4 SPOT LOAD SPOT NO, FREQUENCY, LOAD FUNCTION and REFERENCE can only be set when the fixed frequency load correction is set as <ON>. -

Page 47: Fixture Compensation

6.6 FIXTURE COMPENSATION Choose the fixture model. There are <F42001>,<FX-000C20>, <FX-000C19>, <FX- 000C12>,<FX-000C10>,<FX-000C8>, <FX-000C7>, and <FX-000C6>. 6.7 SPOT NO. Set the fixed frequency point; the range is from 1~16. 6.8 FREQUENCY Click the number key to select the value unit ( Ex:<Hz>、<kHz>、<MHz>) -

Page 48: Load Function

6.9 LOAD FUNCTION Click the <↑><↓> swap the primary and secondary parameters. (EX:<G-B>、<R-X>、<CP-RP>、<CP-D>、<CS-RS>、<CS-D>、<LP-RP>、<LP- Q>、<LS-RS>、<LS-Q>、<Y-Deg>、<Z-Deg>。 6.10 REFERENCE Insert the known values with measurements as reference values 6.11 LOAD It is the value that is measured in the beginning to correct the result value. -

Page 49: System Cnofig

7. SYSTEM CNOFIG Press <Menu> key and then select <SYSTEM> mode for accessing the SYSTEM CONFIG page. The 6630 LCR Meter supports 3 language interfaces, <English>, <Traditional Chinese> and <Simplified Chinese>. The language can be preset with the function key. -

Page 50: Handlerinterface

7.6 HANDLERINTERFACE Under SYSTEM CONFIG page, select <HANDLER INTERFACE>, use <ON><OFF> function key and enable the remote I/O control program for the user to monitor the signal input and PASS/FAIL output result by controlling the instru- ment remotely. 7.7 KEY BEEP Under SYSTEM CONFIG page, select <KEY BEEP>and use <ON><OFF>... -

Page 51: Appendix

Appendix |Z| Accuracy Chart... -

Page 52: Measurement Accuracy

Measurement accuracy Conditions of accuracy All specifications apply at 23 ± 5 °C, and 60 minutes after the instrument has been turned on. Impedance measurement accuracy at 4-terminal test fixture (Typical at > 10 MHz) |Z|, |Y| accuracy ± Ae [%], Where Relative accuracy Ae = ( Ab + Az + Av + Ad + Ac ) ×... - Page 53 Measurement Time / Averaging Measurement Speed 1.Max: 2.5ms (>10kHz) 2.Fast: 50ms (>20Hz) 3.Medium: 100ms 4.Slow: 300ms 5.Slow2: 600ms Display Time 1.6 ~ 5.6ms (depend on the contents) Averaging Range 1 to 64...

-

Page 54: Concept Of Command

Concept of Command ◆ Subsystem Command Tree The top of the subsystem command tree is called the root command, or simply the root. To reach the low-level commands, you must specify a particular path. After Power ON or after *RST, the current path is set to the root. The path settings are change as follows: Colon (:) When a colon is placed between two command mnemonics, the... -

Page 55: Data Format

◆ Data Format ○ ○ ○ ○ :MEASure:PARAmeter<NR1> LF 1. Command 2. Space 3. Parameter 4.Program Message Terminator Parameter: There must be a <space> between the last command and the first parameter in a sub- system command. For example: :MEASure:PARAmeter Z If you send more than one parameter with a single command, each parameter must be separated by a comma. -

Page 56: Common Commands

◆ Commands Common... - Page 57 <Command> :STATus:OPERation:CONDition? Function:It queries the status of Operation Status Register. Description: Return data 0~65535 (Format is in <NR1>) <Command> :STATus:OPERation:EVENt? Function:It queries the status of Operation Event Register. Description: Query syntax : STATus:OPERation:EVENt? Return data 0~65535 (Format is in <NR1>) <Command>...

- Page 58 If 6630 MAX test frequency is 15MHz, it returns F15 If 6630 MAX test frequency is 20MHz, it returns F20 If 6630 MAX test frequency is 30MHz, it returns F30 <Command> *RST Function:It aborts all pending operations, and sets 6630 to its initial setups. Description: Initial Setups Parameters:Ls,Q,Z,θdeg...

- Page 59 Description: Query syntax *STB? Return data<NR1> <Command> *WAI Function:It makes 6630 wait until all previously sent commands are completed. The 6630 then continues executing the commands that follow the *WAI. <Command> *TST? Function:The response to this query is always 0.

-

Page 60: Measure Subsystem

◆ MEASure Subsystem <Command> :MEASure:PARAmeter {OFF|RDC|LS|LP|CS|CP|Q|D|RS|RP|Z|DEG|RAD|R|X|Y|G|B|E|U} :MEASure:PARAmeter? Function:It sets or queries the measurement parameter (max.4 items) at present. Description: Set parameter OFF, RDC(DC Resistance), Ls(Series Inductance), Lp(Parallel Inductance), Cs (Series Capacitance), Cp (Parallel Capacitance), Q (Quality Factor), D (Dissipation Factor), Rs (Series Resistance) Rp(Parallel Resistance), Z(Impedance), θd(Angle), θr(Diameter), R(Resistance), X(Reactance), Y (Admittance), G (Conductivity), B (Susceptance), E(Relative Permittivity), U(Relative permeability) - Page 61 <Command> :MEASure:VOLTage:AC <voltage NR3/disc> :MEASure:VOLTage:AC? Function:It sets or queries the AC measurement voltage (LEVEL). Description: Set parameterWhen RO(output impedance) is setting 100 Ω , the setup value of AC voltage is {0.01~2| MAXimum|MINimum}.When RO(output impedance) is setting 25Ω, the setup value of AC voltage is {0.01~1|MAXimum|MINimum}.

- Page 62 <Command> :MEASure:CURRent:DC <current NR3/disc> :MEASure:CURRent:DC? Function:It sets or queries the DC measurement current (LEVEL). Description: Set parameterThe value of DC currentis {0.0004~0.04| MAXimum|MINimum}. Set syntax :MEASure:CURRent:DC 0.01 :MEASure:CURRent:DC 20m :MEASure:CURRent:DC 1E-2 :MEASure:CURRent:DC MAXimum :MEASure:CURRent:DC MINimum Query syntax :MEASure:CURRent:DC? Return data 2.000000E-04 (Format is in <NR3>) When the Level setup is voltage mode, the data returns 9.9E37.

- Page 63 <Command> :MEASure:FONT {SMALl|LARGe} :MEASure:FONT? Function:It sets or queries the FONT SIZE. Description: Set parameter SMALl (small), LARGe (large) Set syntax :MEASure:FONT LARGe Query syntax :MEASure:FONT? Return dataLARG (Format is in <disc>) <Command> :MEASure:TRIGger:DELay <delay time NR3/disc> :MEASure:TRIGger:DELay? Function:It sets or queries the TRIGGER DELAY. Description:...

- Page 64 <Command> :MEASure:RANGe:DC {1|2|3|4|AUTO|HOLD} :MEASure:RANGe:DC? Function:It sets or queries the DC RANGE. Description: Set parameter{1|2|3|4|AUTO|HOLD} Set syntax :MEASure:RANGe:DC 2 :MEASure:RANGe:DC AUTO Query syntax :MEASure:RANGe:DC Return data 2 (Format is in <NR1>) The range recommends setting as<Auto>in order to obtain better measuring accuracy. The range actually measured will be displayed at the lower-left corner of LCD panel.

- Page 65 <Command> :MEASure:COMParator:MODE <ABSolute|DEViation|PERCent|0|1|2> :MEASure:COMParator:MODE? Function:It sets or queries the COMP MODE. Description: Set parameter ABSolute,0|DEViation,1|PERCent,2 Set syntax :MEASure:COMParator:MODE PERCent Query syntax :MEASure:COMParator:MODE? Return dataPERC (Format is in <disc>) <Command> :MEASure:COMParator:NOMinal <nominal value NR3> :MEASure:COMParator:NOMinal? Function:It sets or queries the NOMINAL. Description:...

- Page 66 <Command> :MEASure:BIN:PARAmeter {OFF|RDC|LS|LP|CS|CP|Q|D|RS|RP|Z|DEG|RAD|R|X|Y|G|B|E|U} :MEASure:BIN:PARAmeter? Function:It sets or queries the BIN Parameter. Description: Set syntax :MEASure:BIN:PARAmeter Z(only allow the parameter which is being used under the meter mode.) Query syntax :MEASure:PARAmeter? Return dataZ(Format is in <disc>) <Command> :MEASure:BIN:NUMBer {2|3|4|5|6|7|8|9|MAXium|MINimum} :MEASure:BIN:NUMBer? Function:It sets or queries the BIN NUMBER. Description:...

- Page 67 Return data +1.000000E-03, +1.000000E-01, +1.000000E+03, +1.000000E+06 (Format is in <NR3>) <Command> :MEASure:FILE:LOAD <filename> Function:It opens the meter mode's file. Description: Set syntax :MEASure:FILE:LOAD MICROTEST.( load the file “MICROTEST”) <Command> :MEASure:FILE:LOAD? Function:It queries the meter mode's filename which is being using. Description: Query syntax: MEASure:FILE:LOAD? Return dataMICROTEST <Command>...

-

Page 68: Fetch Subsystem

<Command> :MEASure:STATistic:COUNt <pass count, fail count> :MEASure:STATistic:COUNt? Function: It sets or queries the statistical data in the meter mode. Description: Set parameter <pass count, fail count> (format is in NR1) The value of pass count and fail count 0~999999999 Set syntax: MEASure:STATistic:COUNt 0,1 Query syntax: MEASure:STATistic:COUNt? Return data n1,n2 where n1= pass count (format is in NR1) -

Page 69: System Subsystem

◆ SYSTEM Subsystem <Command> :SYST:ERR? Function:It queries the error number in error message queue over the interface. The instru- ment has an error queue which is 64 errors deep and operates on a first-in, first-out basis, Repeatedly sending the query ":SYSTem:ERRor?" returns the error numbers in the order that they occurred until the queue is empty. - Page 70 <Command> :CORRection:OPEN :CORRection:OPEN? Function:It sets or queries to do open correction. Description: Set syntax : CORRection:OPEN Query syntax :CORRection:OPEN? Return data When correction fail, it returns 0. When correction passes, it returns 1. <Command> :CORRection:SHORt :CORRection:SHORt? Function:It sets or queries to do short correction. Description:...

- Page 71 <Command> :CORRection:HF :CORRection:HF? Function: It performs the high frequency load correction. Description: CORRection:HF To perform high frequency load correction with no result feedback. CORRection:HF? To perform high frequency load correction with result feedback. Set syntax: CORRection:HF Query syntax: CORRection:HF? Return data 0|1 where 0= The result of high frequenct load correction is failed 1= The result of high frequenct load correction is passed <Command>...

- Page 72 <Command> :CORRection:LOAD:SPOT <spot number 1-16> :CORRection:LOAD:SPOT? Function: It sets or queries the load correction spot number that has been currently edited. Description: Set parameter<spot number 1-16> (format is in NR1) Set syntax: CORRection:LOAD:SPOT 1 Query syntax: :CORRection:LOAD:SPOT? Return data 1 <Command>...

-

Page 73: List Subsystem

◆ LIST Subsystem <Command> :LIST:STEP{1|2|3|4|…|14|15} :LIST:STEP? Function:It sets or queries the step of list mode. Description: Set parameter step number1~15 Set syntax :LIST:STEP 1 Query syntax :LIST:STEP? Return data1(Format is in <NR1>) <Command> :LIST:PARAmeter {OFF|RDC|LS|LP|CS|CP|Q|D|RS|RP|Z|DEG|RAD|R|X|Y|G|B} :LIST:PARAmeter? Function:It sets or queries the measurement parameter of list mode. Description:... - Page 74 <Command> :LIST:CURRent <current NR3/disc > :LIST:CURRent? Function:It sets or queries the measurement current of list mode. Description: Set parameterWhen RO(output impedance) is setting 100Ω, the setup range of AC current is {0.0001~0.02|MAXimum|MINimum}. When RO(output impedance) is setting 25Ω, the setup range of AC current is {0.0004~0.04|MAXimum|MINimum}. The range of DC current is {0.0004~0.04|MAXimum|MINimum}.

- Page 75 <Command> :LIST:COMParator:NOMinal <nominal value NR3 > :LIST:COMParator:NOMinal? Function:It sets or queries the NOMINAL of list mode. Description: Set syntax :LIST:COMParator:NOMinal 1000 :LIST:COMParator:NOMinal 10K :LIST:COMParator:NOMinal 1E+04 Query syntax :LIST:COMParator:NOMinal? Return data 1.000000E+04 (Format is in <NR3>) <Command> :LIST:COMParator:UPPER <upper limit NR3> :LIST:COMParator:UPPER? Function:It sets or queries the UPPER of list mode.

- Page 76 <Command> :LIST:BIN:METHod {EQUal|SEQuential|TOLerance|RANDom|0|1|2|3} :LIST:BIN:METHod? Function:It sets or queries the BIN METHOD of list mode. Description: Set parameterEQUal,0| SEQuential,1|TOLerance,2 |RANDom,3 Set syntax :LIST:BIN:METHod SEQ Query syntax :LIST:BIN:METHod? Return data SEQ (Format is in <disc>) <Command> :LIST:BIN:MODE <ABSolute|DEViation|PERCent|0|1|2> :LIST:BIN:MODE? Function:It sets or queries the BIN MODE of list mode. Description:...

- Page 77 <Command> :LIST:TRIGger:DELay <delay time NR3/disc> :LIST:TRIGger:DELay? Function:It sets or queries the TRIGGER DELAY of list mode. Description: Set parameter The value of delay time is {0.000~5.000|MAXimum|MINimum}. Set syntax :LIST:TRIGger:DELay 0.5 :LIST:TRIGger:DELay 500m :LIST:TRIGger:DELay 5E-3 :LIST:TRIGger:DELay MAXimum :LIST:TRIGger:DELay MINimum Query syntax :LIST:TRIGger:DELay? Return data 0.000 (Format is in <NR2>) <Command>...

- Page 78 Return dataOFF | STEP |ALL (Format is in <disc>) <Command> :LIST:FILE:LOAD <filename> Function:It opens the list mode's file. Description: Set syntax:MEASure:FILE:LOAD MICROTEST.(open the MICROTEST list mode file) <Command> :LIST:FILE:LOAD? Function:It queries the list mode's filename which is being using. Description:...

- Page 79 <Command> : LIST:STATistic:COUNt <pass count, fail count> : LIST:STATistic:COUNt? Function: It sets or queries the statistical data in the list mode. Description: Set parameter <pass count, fail count> (format is in NR1) The value of pass count and fail count 0~999999999 Set syntax: LIST:STATistic:COUNt 0,1 Query syntax: LIST:STATistic:COUNt? Return data n1,n2...

-

Page 80: Read The Measured Value

◆ Read the measured value Read the measured value Read Data format under Meter Mode <para 1 data>,<para 2 data>,<para 3 data>,<para 4 data>,<status>,<bin number>,<para 1 compare status>, <para compare status>,<para 3 compare status>,<para 4 compare status> para 1-4 data During value measuring, not all of four values will be displayed. -

Page 81: Measurement Basics

Measurement Basics To measure capacitance, inductance and resistance user can select series or paral- lel mode. C (Capacitance) : Series mode: Parallel mode: Parallel mode Equations: Series mode Equations: D = dissipation factor D = dissipation factor L (Inductance) : Series mode:... -

Page 82: Resistance (R) And Conductance (G)

◆ Resistance (R) and Conductance (G) The resistance is a measure of the difficulty to pass an electric current through that conductor. The SI unit of resistance is the “ohm” (Ω). The inverse quantity is electrical conductance, and this is the ease with which an electric current passes through a circuit. -

Page 83: Capacitance (C)

◆ Capacitance (C) Capacitance (denoted by the letter C) is the ability of a body to store an elec- trical charge at a given potential difference between its plates. The SI unit of capacitance is the farad (symbol: F). Measure Type:Series mode→Cs / Parallel mode→Cp Relevant Equations:... -

Page 84: Inductance (L)

◆ Inductance (L) Inductance is the property of an electrical conductor by which a change in current through it induces an electromotive force (EMF) in both the conductor itself and in any nearby conductors by mutual inductance. In the SI system, the measurement unit for inductance is the Henry (with the unit symbol H). -

Page 85: Reactance (X) And Susceptance (B)

◆ Reactance (X) and Susceptance (B) In AC circuit analysis, reactance is represented by the capital letter “X” which is the imaginary a part of complex impedance. Reactance is the opposition of a circuit element to a change in the current or voltage, due to that element's inductance or capacitance which is similar to the opposition of resistance to current in a DC circuit. -

Page 86: Impedance (Z) And Admittance (Y)

◆ Impedance (Z) and Admittance (Y) The impedance covers oppositions in AC circuits in- cluding resistance, inductance, and capacitance and is measured in units of Ohm (Ω). In electrical engineering, admittance covers both conductance and suscep- tance and is the reciprocal of impedance. It is measured in units of Siemens (S). - Page 87 −...

-

Page 88: Quality Factor (Q) And Dissipation Factor (D)

◆ Quality factor (Q) and Dissipation factor (D) The quality factor measures energies consumed by relative frequency. In general, the better a circuit's quality factor the better its selectivity. The dissipation factor is the reciprocal of quality factor. It is the signal angle loss by a capacitor (or inductor) and acting frequency at a fixed temperature. -

Page 89: Phase Angle (Θ)

⚫ Dissipation factor (D) Relevant Equations: ◆ Phase angle (θ) This is the shift angle when measuring impedance (Z), admittance (Y), quality factor (Q) and dissipation factor (D). Relevant equations: − ... -

Page 90: Overall Impedance Measurement Theory

◆ Overall Impedance Measurement Theory The simplified model of the 6630 impedance measurement, Vs is the test signal voltage and RO is source resistance. If the current across the DUT is I when a test signal voltage V is applied, the DUT's impedance, Z, is expressed by Z = Impedance, Z, contains real and imaginary parts. - Page 91 Impedance, Z, can also be expressed as admittance, Y. Admittance is expressed in terms of impedance, Z, by Y = − j R+jX = | Y | ∠(−θ) |Z|∠θ For parallel connected circuits, it is better to use admittance, Y. G : Conductance B : Susceptance |Y|: Admittance...

- Page 92 The 6630 measures a DUT's impedance, Z, which is a vector value, and gives the result using the following equivalent circuits. Lp : Parallel Inductance Cp : Parallel Capacitance Ls : Series Inductance Cs : Series Capacitance Q : Quality factor...

-

Page 93: Characteristics Example

◆ Characteristics Example As can be seen in the following figure, a component can have different effective pa- rameter values dependent upon its operating condition. The measured values most useful in actual applications are obtained from precise measurement under the ac- tual operating conditions. -

Page 94: High And Low Impedance Criteria

Measurement Characteristics Example Functions Cp-G Large R Y-∠θ Ls-Rs Small R |Z|-∠θ ◆ High and low impedance criteria The following criteria can be used to roughly discriminate between low, middle, and high impedances by following figure. The medium Z range may be covered with an extension of either the low Z or high Z range.

Need help?

Do you have a question about the 6630 and is the answer not in the manual?

Questions and answers